Page 2 www.greyline.com

Table of Contents

1: General Description ...................................................................................................................6

1.1 Introduction.......................................................................................................................6

1.2 Principles of Operation.....................................................................................................7

1.3 Supplied Hardware...........................................................................................................8

1.4 Portaflow PT400 Instrument.............................................................................................9

1.4.1 Connectors.............................................................................................................9

1.4.2 Keypad ..................................................................................................................10

1.4.3 Power supply and battery charging.......................................................................11

1.5 Transducers.....................................................................................................................11

2: Installation……………………………………………………………………………………………..12

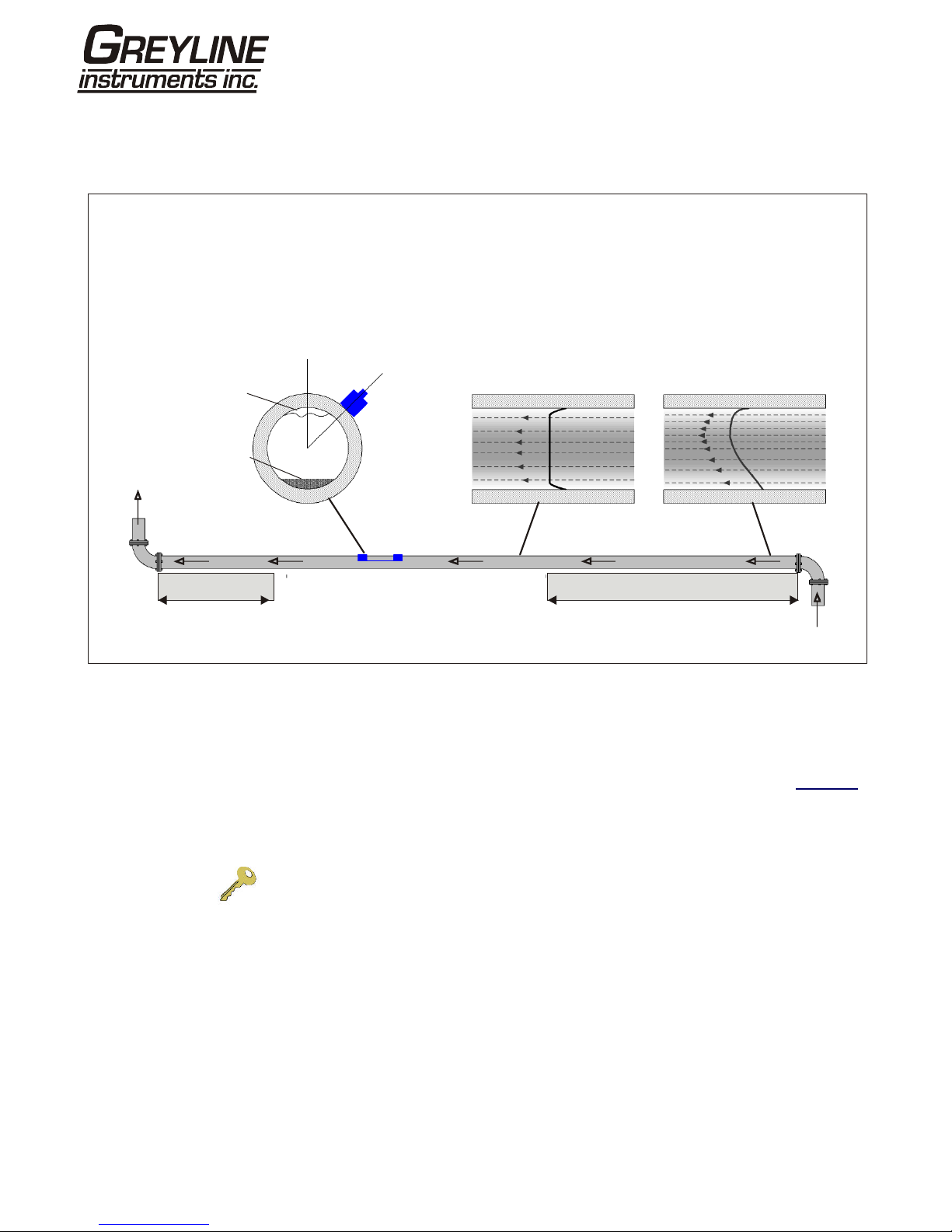

2.1 Transducer Positioning....................................................................................................12

2.2 Transducer Attachment (Type ‘A’ & ‘B’)..........................................................................13

2.2.1 Preparation...........................................................................................................13

2.2.2 Attaching the guide rails.......................................................................................13

2.2.3 Fitting the transducers..........................................................................................14

3: Operating Procedures..............................................................................................................15

3.1 Setting-up the Instrument...............................................................................................16

3.1.1 Using the instrument for the first time ..................................................................16

3.1.2 Enabling/disabling the backlight...........................................................................17

3.2 Using the Quick Start Menu ............................................................................................17

3.3 Using the System at a Regularly Monitored Location.....................................................20

3.4 Managing Named Sites...................................................................................................22

3.4.1 Setting up a new site............................................................................................22

3.4.2 Changing a site name ..........................................................................................23

3.5 Instrument Calibration .....................................................................................................24

3.5.1 Adjusting the zero cut-off .....................................................................................24

3.5.2 Adjusting the set zero flow offset .........................................................................24

3.5.3 Adjusting the calibration factor.............................................................................25

3.5.4 Adjusting the roughness factor.............................................................................25

3.5.5 Adjusting the damping factor................................................................................27

3.6 Performing Monitoring Functions ....................................................................................28

3.6.1 How to measure totalised flows (manually) .........................................................28

3.7 Configuring the Portaflow PT400 Interfaces ...................................................................30

3.7.3 How to turn the 4-20mA output OFF/ON .............................................................30

3.7.4 4-20mA signal calibration and ranging.................................................................30