Table of contents

1. INTENDED USE .................................................................................................................................................5

2. GUARANTEE TERMS........................................................................................................................................5

3. CLEANING .........................................................................................................................................................6

3.1. Cleaning ABS Elements..............................................................................................................................6

3.2. Cleaning Stainless Steel Elements .............................................................................................................6

3.3. Cleaning Powder-coated Elements.............................................................................................................6

3.4. Cleaning Aluminum Elements .....................................................................................................................7

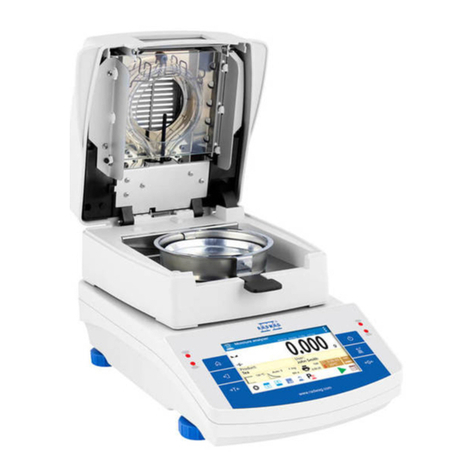

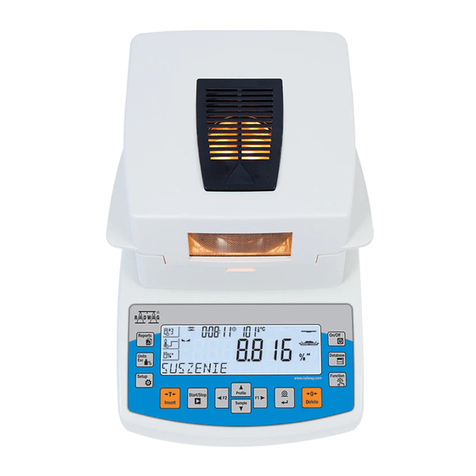

4. STRUCTURE......................................................................................................................................................7

4.1. Dimensions..................................................................................................................................................7

4.2. Description of connectors............................................................................................................................8

4.3. Technical parameters..................................................................................................................................9

5. INSTALLATION..................................................................................................................................................9

5.1. Unpacking and Assembly............................................................................................................................9

5.2. Switching on ................................................................................................................................................9

6. HOME PAGE....................................................................................................................................................10

7. NAVIGATION IN THE MENU...........................................................................................................................11

7.1. Scale Keyboard .........................................................................................................................................12

7.2. Return to Weighing Function.....................................................................................................................12

8. INSTALLER......................................................................................................................................................12

8.1. Connection of the 6-wire Load Cell...........................................................................................................13

8.2. Connection of the 4-wire Load Cell...........................................................................................................14

8.3. Connection of Load Cell Screen................................................................................................................15

9. OPTIONAL EXTENSION MODULES ..............................................................................................................15

9.1. Additional Weighing Platform ....................................................................................................................15

9.1.1. Technical Specification...................................................................................................................16

9.1.2. Colors of Signal Wires from Weighing Platform.............................................................................16

10. FACTORY PARAMETERS............................................................................................................................17

10.1. Access to Factory Parameters................................................................................................................17

10.2. List of Global Parameters........................................................................................................................18

10.3. List of Factory Parameters......................................................................................................................20

10.4. Factory Adjustment .................................................................................................................................22

10.4.1. External Factory Adjustment........................................................................................................22

10.4.2. Determination of Factory Start Mass ...........................................................................................23

10.5. Interval Correction...................................................................................................................................23

10.5.1. Corrections...................................................................................................................................23

10.5.2. Linearity Deletion..........................................................................................................................24

10.6. Gravitational Correction ..........................................................................................................................24