Contents

1 Safety............................................................................................................................... 4

1.1 Hazard Assessment................................................................................................ 4

1.2 Working on energized conductors and equipment................................................. 4

1.3 Equipment safety.................................................................................................... 5

2 Introduction to the LineIQ devicefamily....................................................................... 6

2.1 Glossary.................................................................................................................. 8

2.2 Implementation Scenarios .................................................................................... 10

2.3 System Functionality............................................................................................. 10

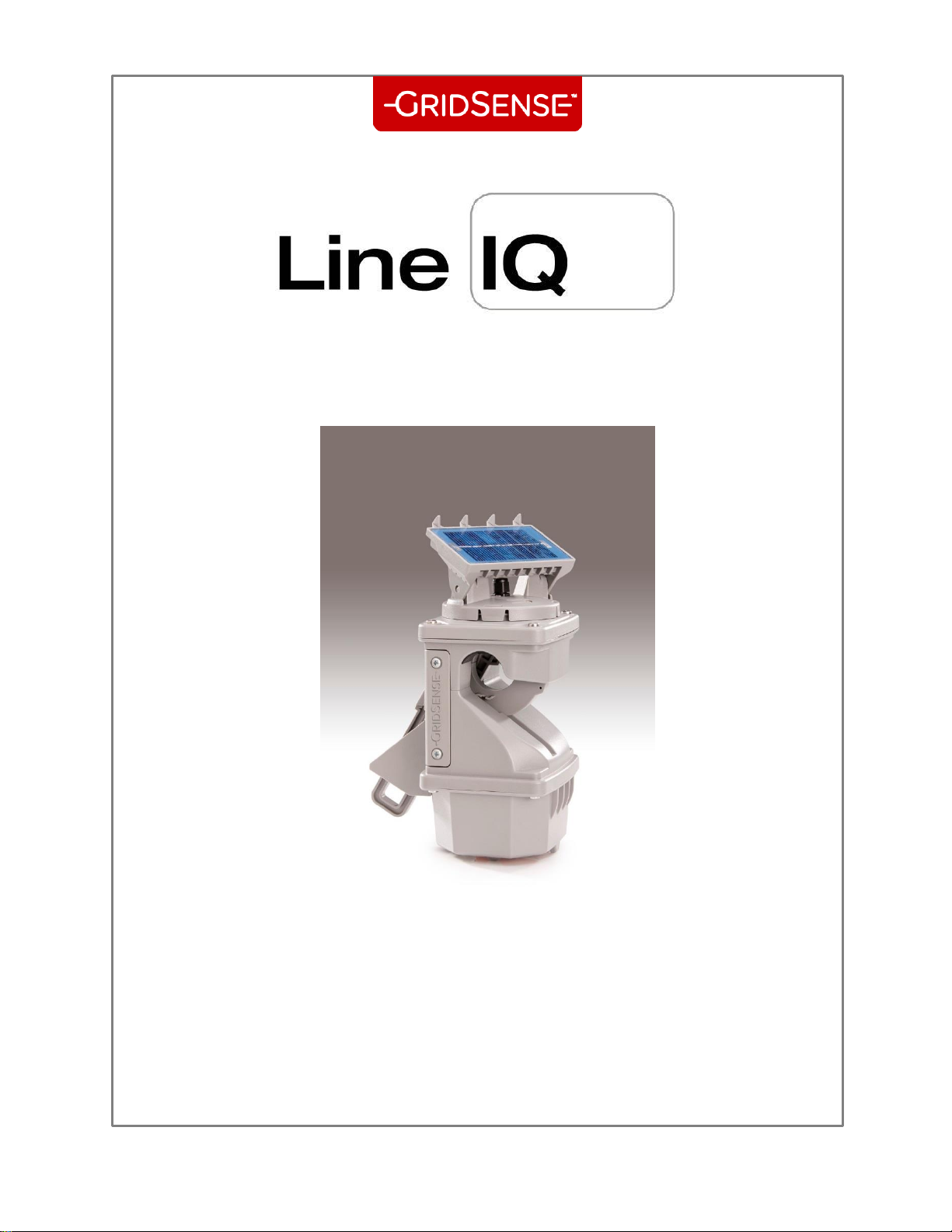

2.4 LIQ-60 Conductor Mounted Sensor overview ...................................................... 10

2.4.1 LIQ-60 Design………………………………………………………………………11

2.4.2 LIQ-60 Sensing………………………………………………………………………..12

2.4.3 Operation Modes……………………………………………………………………...13

2.4.4 Visual Indicators……………………………………………………………………….15

2.4.5 Power Factor Calculation…………………………………………………………….18

2.5 LIQ-Gateway Overview......................................................................................... 19

2.6 LIQ-LocalLink Overview........................................................................................ 19

3 Initial setup.................................................................................................................... 21

3.1 LIQ-LocalLink installation...................................................................................... 21

3.1.1 For Microsoft Windows 7……………………………………………………………..21

3.1.2 For Microsoft Windows XP…………………………………………………………. 21

3.2 LIQ-60 setup......................................................................................................... 21

3.2.1 Switching on the LIQ-60……………………………………………………………...22

4

Configuration...........................................................................................................................

22

4.1 LIQ-60 configuration............................................................................................. 22

5

Commissioning.......................................................................................................................

22

5.1 Commissioning the LIQ-60................................................................................... 22

5.1.1 Pre-commissioning check of the LIQ-60s………………………………………….22

6 Installation and removal............................................................................................... 23

6.1 LIQ-60 installation................................................................................................. 23

6.1.1 Pre-installation………………………………………………………………………… 23

6.1.2 Mounting………………………………………………………………………………..23

6.1.3 Post-installation checks………………………………………………………………23

6.1.4

Removal……………………………………………………………………………………...

24

7 Power Systems............................................................................................................. 24

7.1 LIQ-60 Battery ...................................................................................................... 24