Table of Contents

INTRODUCTION............................................... 2

Machine Description ...................................... 2

Contact Info.................................................... 2

Manual Accuracy ........................................... 2

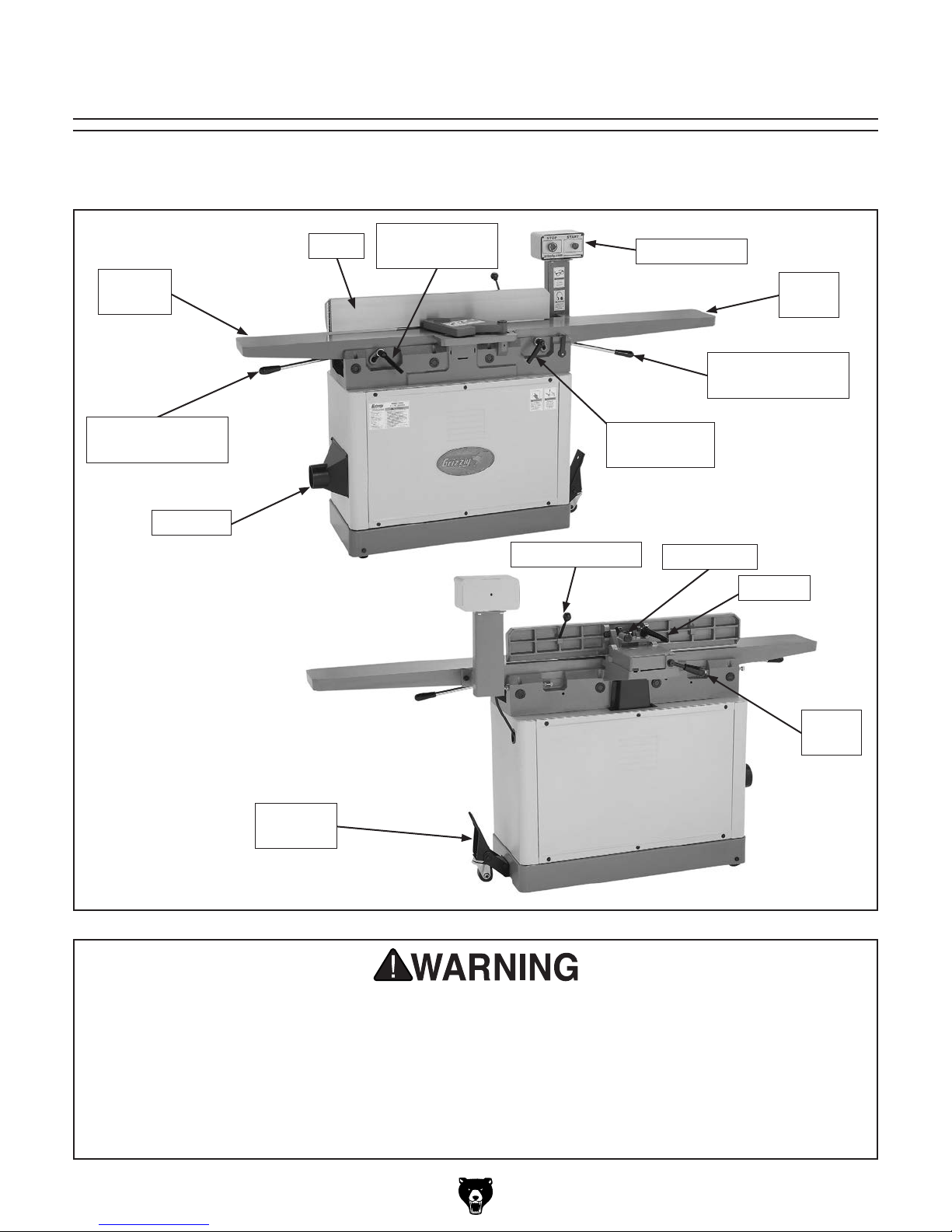

Identification ................................................... 3

Controls & Components ................................. 4

G0490 Machine Data Sheet .......................... 5

G0490X Machine Data Sheet ........................ 7

SECTION 1: SAFETY....................................... 9

Safety Instructions for Machinery .................. 9

Additional Safety for Jointers ....................... 11

SECTION 2: POWER SUPPLY ...................... 12

Availability .................................................................12

Full-Load Current Rating ...........................................12

Circuit Information .....................................................12

Circuit Requirements .................................................12

Grounding Requirements ..........................................13

Extension Cords ........................................................13

SECTION 3: SETUP ....................................... 14

Needed for Setup ......................................... 14

Unpacking .................................................... 14

Inventory ...................................................... 15

Cleanup ........................................................ 16

Site Considerations ...................................... 17

Assembly ..................................................... 18

Dust Collection ............................................. 23

Test Run ...................................................... 24

Recommended Adjustments ........................ 24

SECTION 4: OPERATIONS ........................... 25

Operation Overview ..................................... 25

Stock Inspection & Requirements................ 26

Squaring Stock............................................. 27

Surface Planing............................................ 28

Edge Jointing ............................................... 29

Bevel Cutting................................................ 30

Rabbet Cutting ............................................. 31

SECTION 5: ACCESSORIES ......................... 32

SECTION 6: MAINTENANCE......................... 33

Schedule ...................................................... 33

Cleaning & Protecting .................................. 33

Lubrication ................................................... 33

SECTION 7: SERVICE ................................... 34

Troubleshooting ........................................... 34

Servicing Poly V-Belt ................................... 36

Aligning Pulleys .........................................................36

Replacing/Tensioning V-Belt .....................................36

Inspecting Knives (G0490) .......................... 37

Inspecting Knife Height .............................................37

Setting Knives (G0490) ................................ 37

Cutterhead Inserts (G0490X) ....................... 38

Checking/Adjusting Table Parallelism ......... 39

Checking Outfeed Table ...........................................39

Checking Infeed Table ..............................................40

Adjusting Table Parallelism .......................................41

Setting Outfeed Table Height ...................... 43

Adjusting Infeed Table Stop Bolts ............... 44

Calibrating Depth Scale ............................... 44

Setting Fence Stops .................................... 45

Setting 45° Inward Fence Stop .................................45

Setting 90° Fence Stop .............................................45

Setting 45° Outward Fence Stop ..............................45

SECTION 8: WIRING...................................... 46

Wiring Safety Instructions ............................ 46

G0490/G0490X Wiring ................................. 47

SECTION 9: PARTS....................................... 49

Jointer Breakdown ....................................... 49

Stand Breakdown......................................... 52

Labels .......................................................... 54

WARRANTY & RETURNS ............................. 57