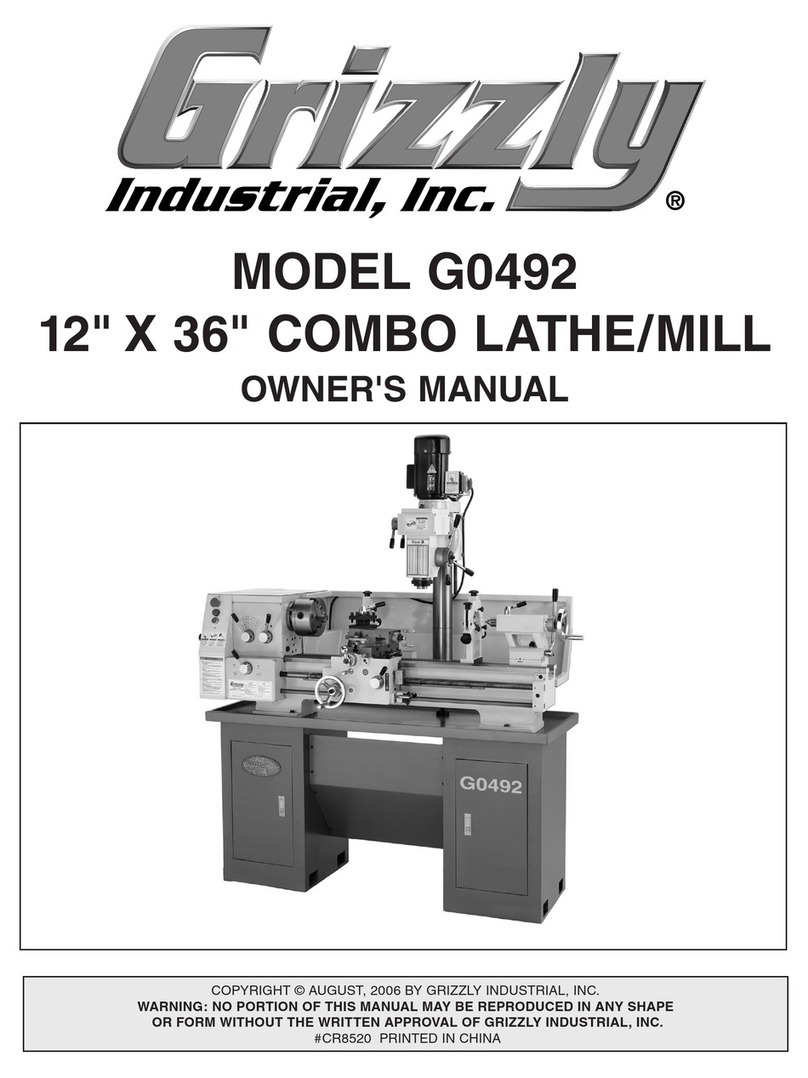

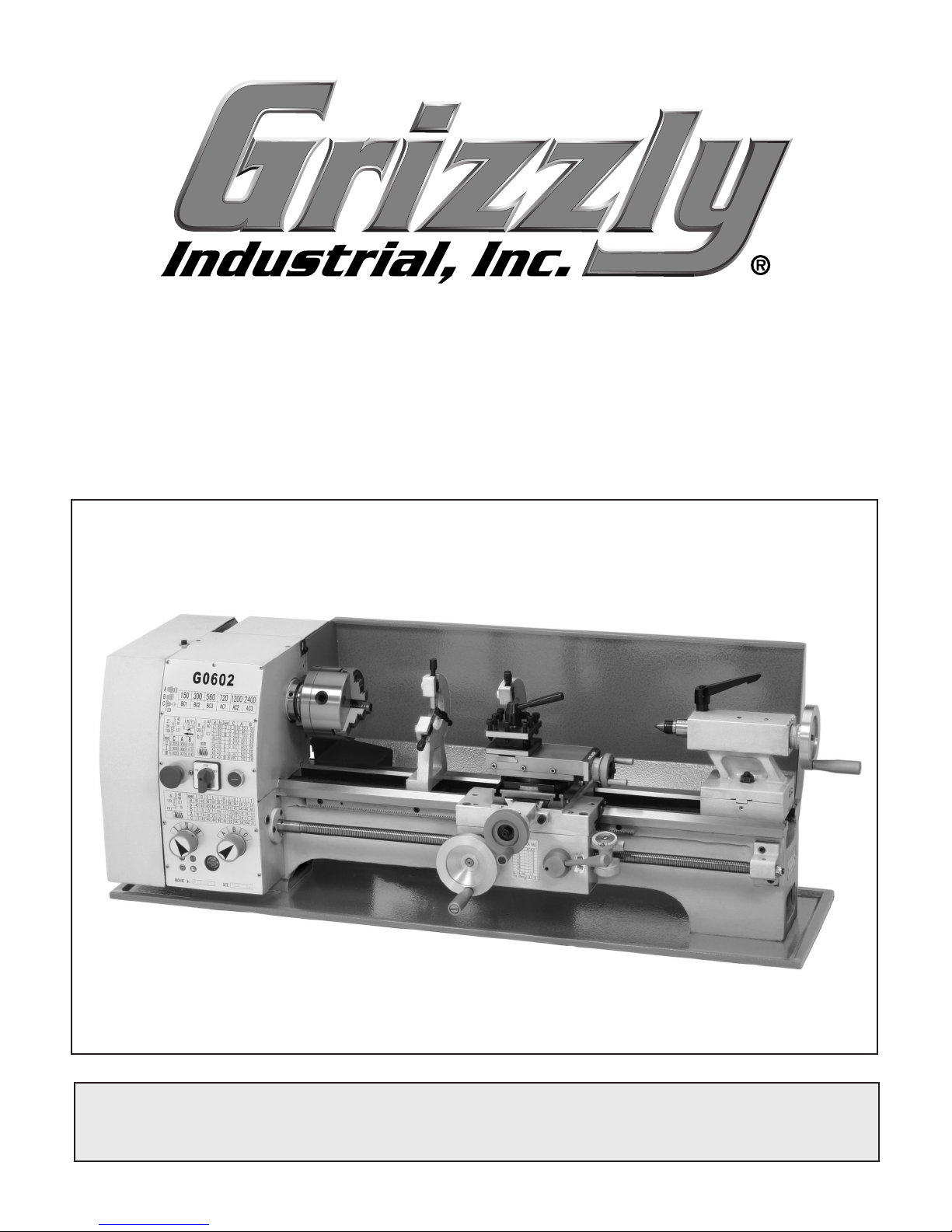

G0602 10" X 22" Benchtop Lathe -1-

INTRODUCTION ............................................... 2

Foreword ........................................................ 2

Contact Info ................................................... 2

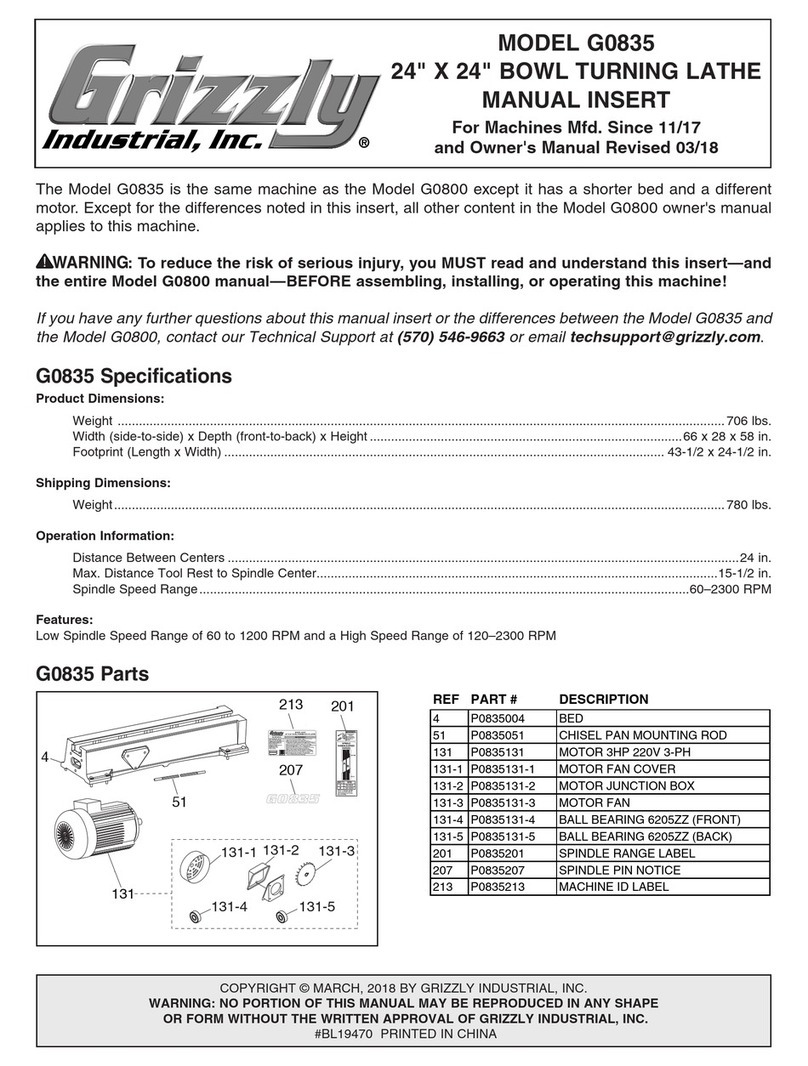

Machine Data Sheet ...................................... 3

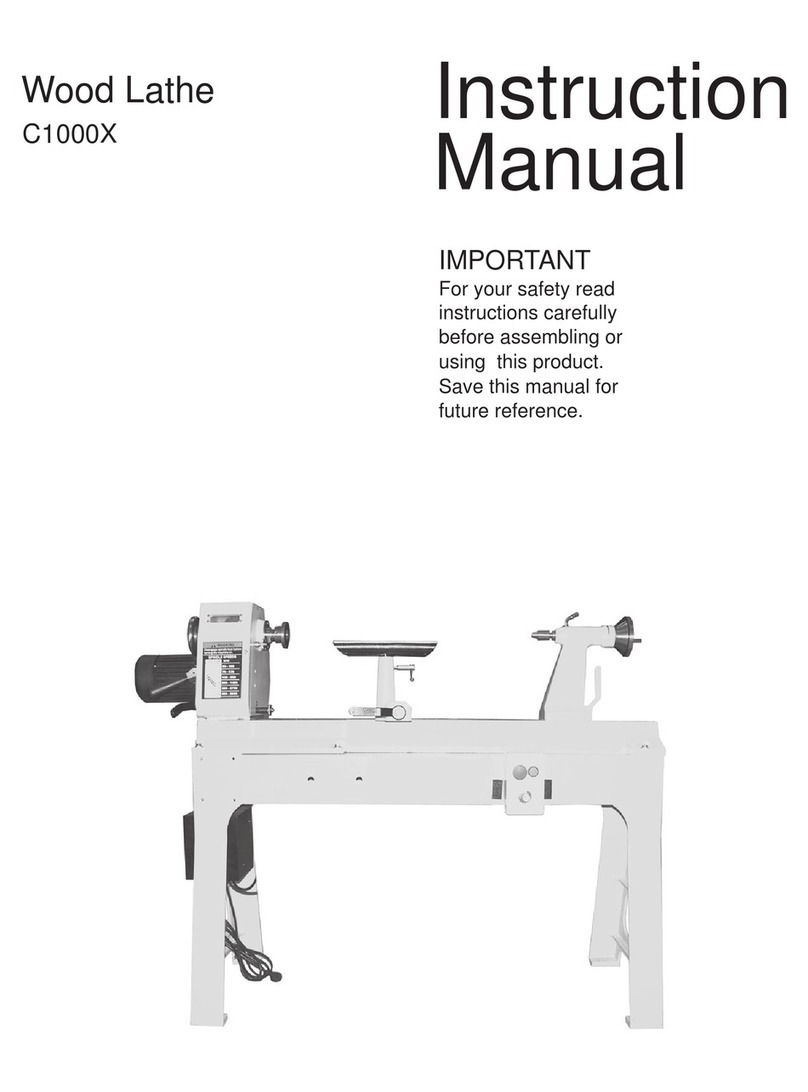

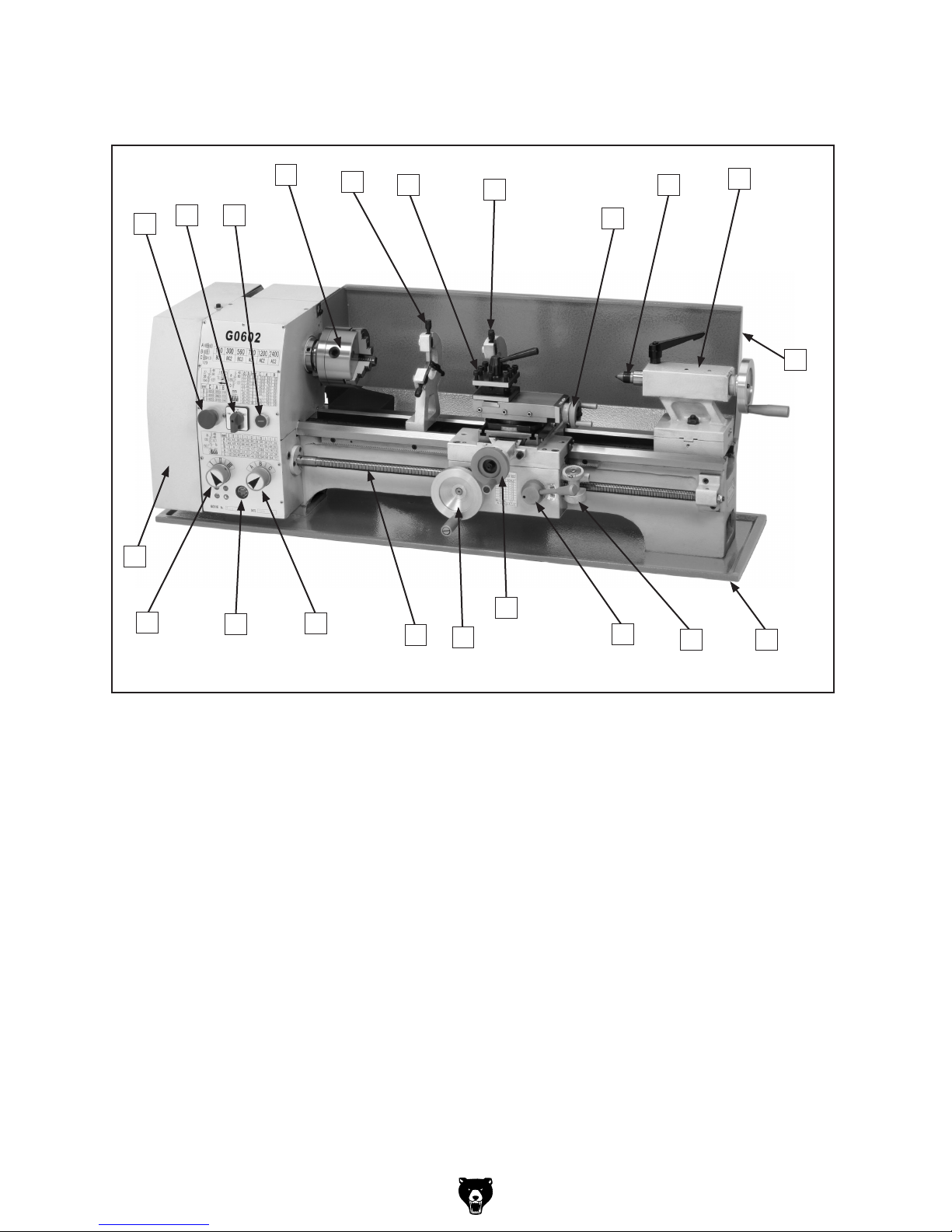

Identification ................................................... 5

SECTION 1: SAFETY ....................................... 6

Additional Safety Instructions for Lathes ....... 8

Glossary of Terms ......................................... 9

SECTION 2: CIRCUIT REQUIREMENTS ...... 10

110V Operation ............................................ 10

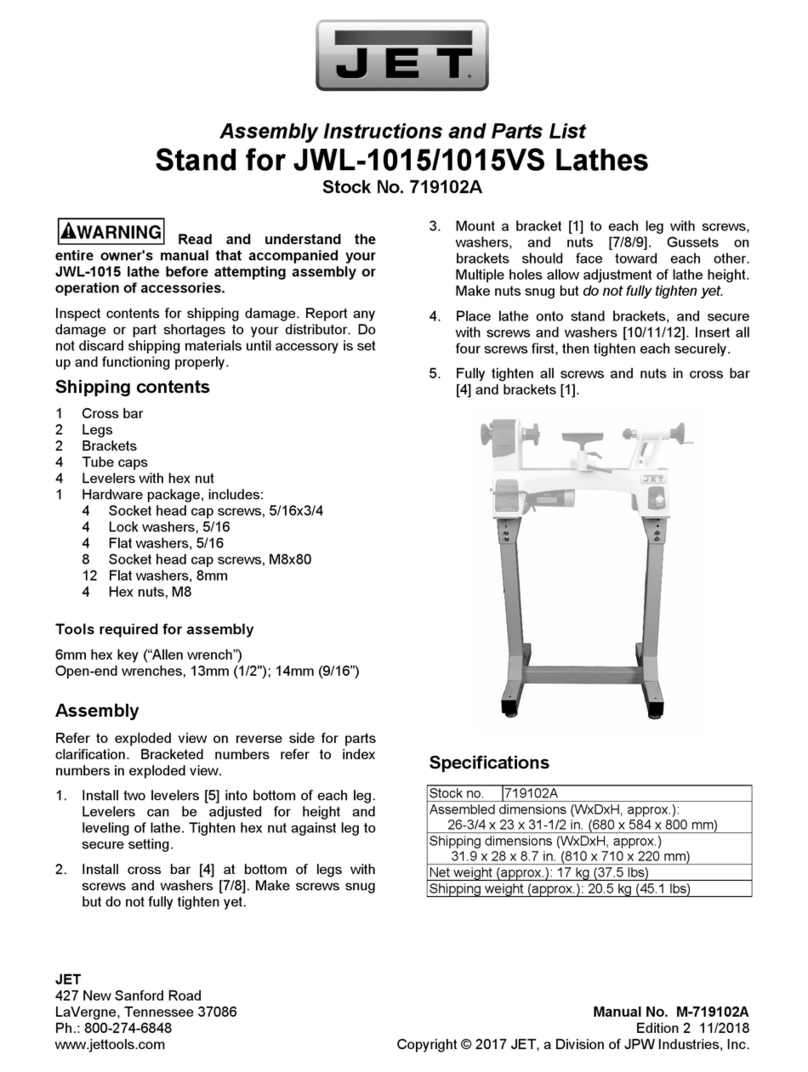

SECTION 3: SET UP ...................................... 11

Unpacking .................................................... 11

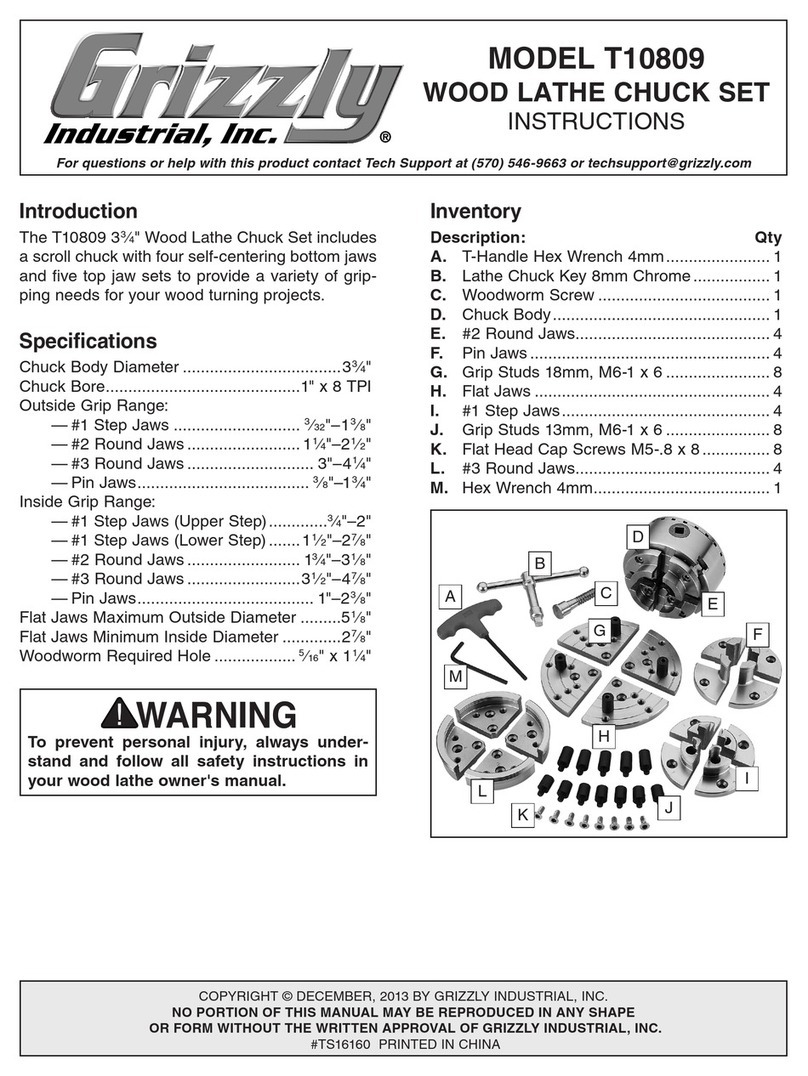

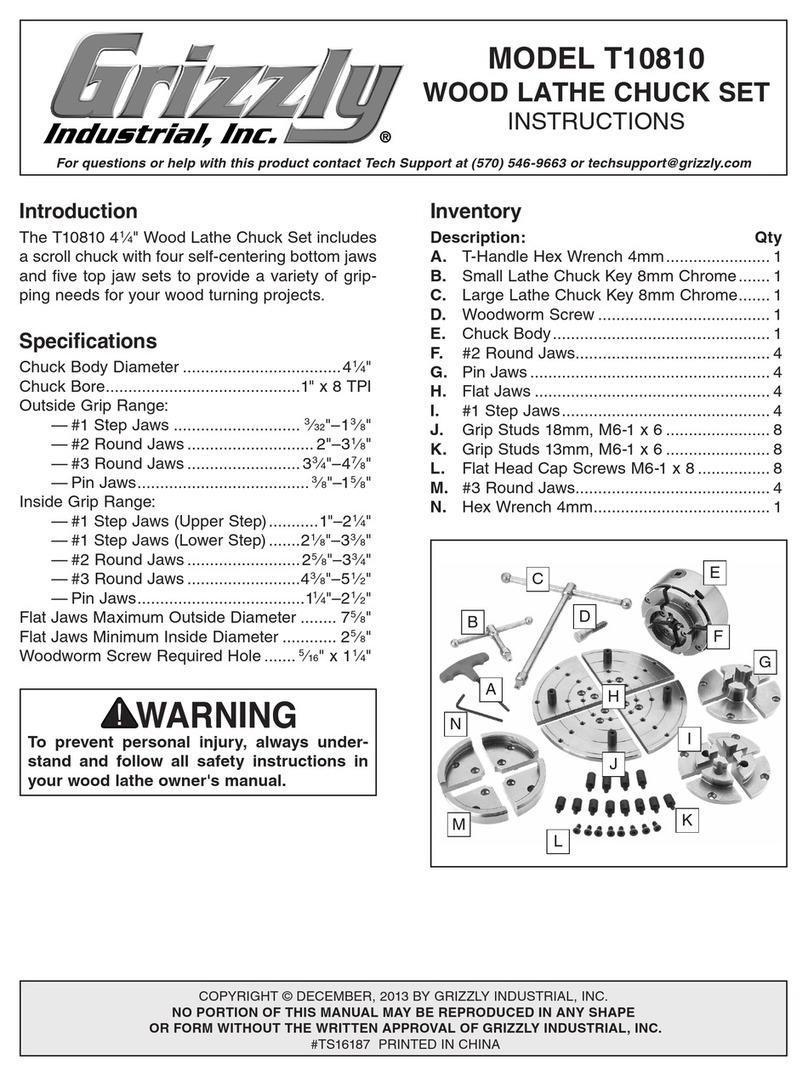

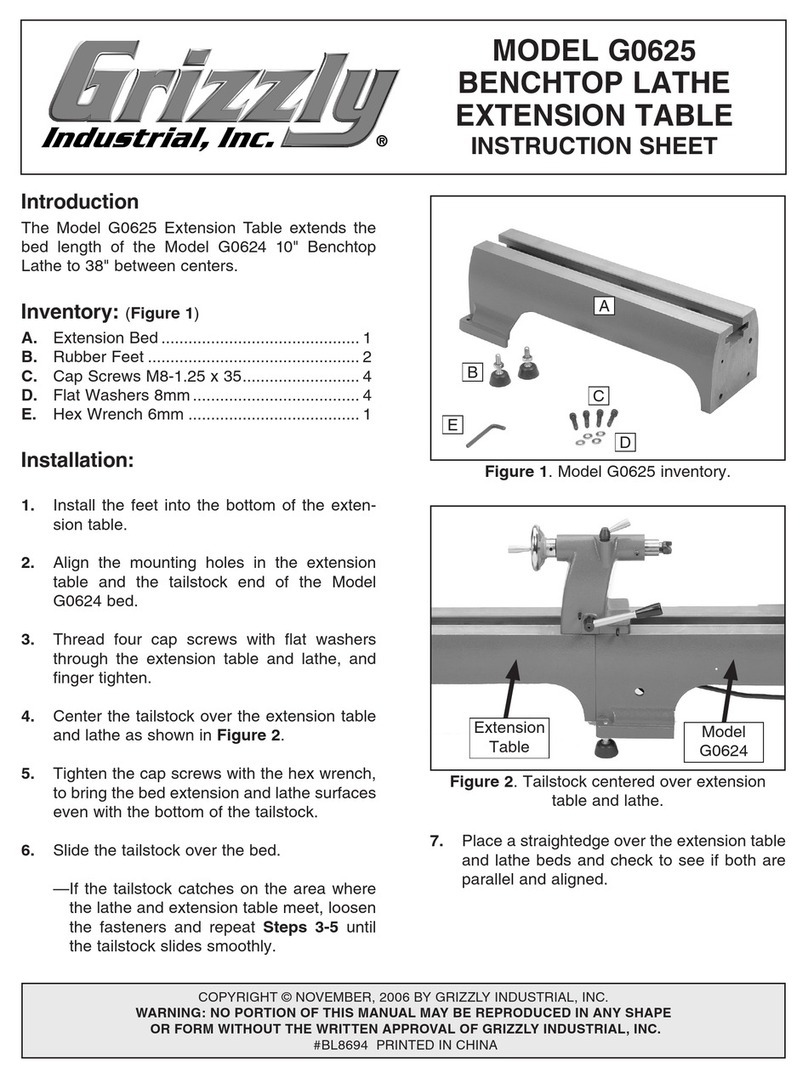

Inventory ...................................................... 12

Site Considerations ...................................... 13

Clean Up ...................................................... 13

Test Run & Break-In ................................... 14

SECTION 4: OPERATIONS ........................... 15

Operation Safety .......................................... 15

Power Supply ............................................... 15

Mounting Chuck or Faceplate ................... 16

Replacing Jaws ............................................ 17

Four-Jaw Chuck ........................................... 18

Faceplate ..................................................... 19

Tailstock ....................................................... 20

Drilling with the Tailstock ............................. 20

Cutting Shallow Tapers with Tailstock ......... 21

Aligning Tailstock ........................................ 21

Centers ........................................................ 23

Steady Rest ................................................. 24

Follow Rest .................................................. 24

Compound Rest ........................................... 25

Tool Post ...................................................... 25

Manual Feed Handwheels ........................... 26

Determining Correct Spindle RPM .............. 27

Setting Spindle ............................................ 28

RPM ............................................................. 28

Setting the Power Feed Rate ...................... 29

Inch Threads ................................................ 30

Metric Threads ............................................. 31

SECTION 5: ACCESSORIES ......................... 32

SECTION 6: MAINTENANCE ......................... 34

Basic Maintenance ...................................... 34

General Lubrication ..................................... 34

Belt Adjustment or Replacement ................. 35

SECTION 7: SERVICE ................................... 36

Troubleshooting ........................................... 36

Cross Slide Backlash Adjustment ................ 38

Gib Adjustments .......................................... 38

Electrical Component Connections .............. 39

Wiring Diagram ............................................ 40

SECTION 8: PARTS ....................................... 41

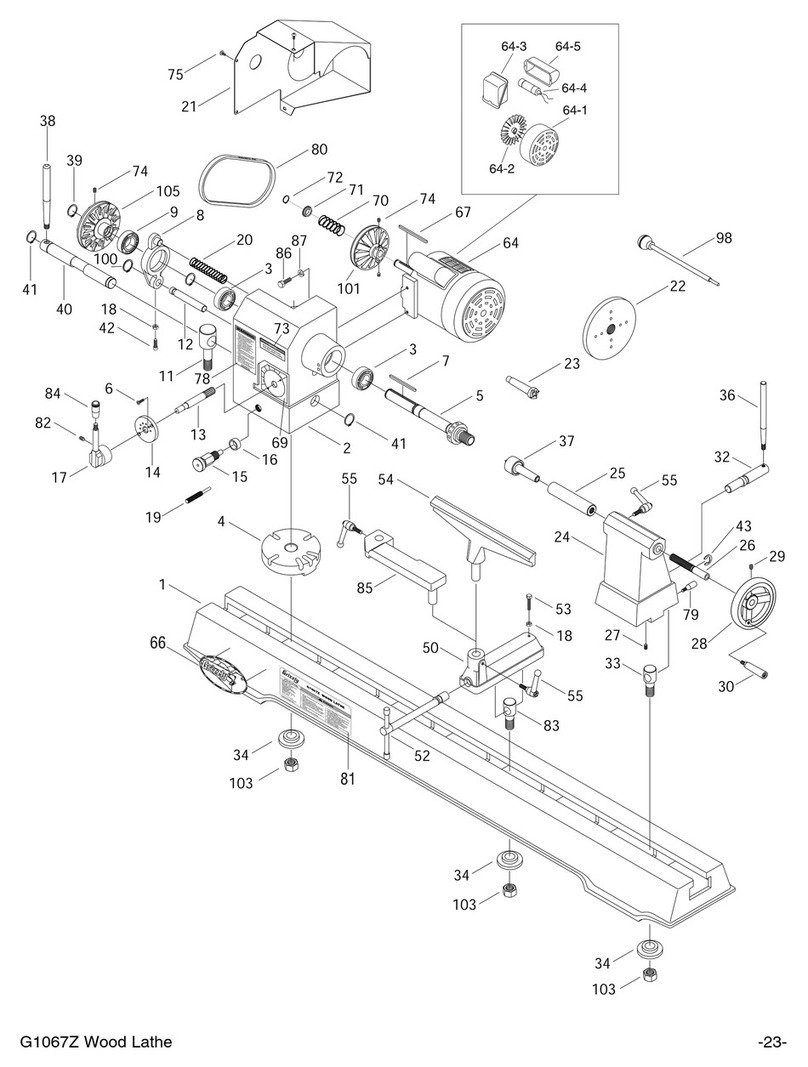

Spindle and Drive Belt ................................. 41

Apron ........................................................... 43

Tool Holder and Compound Rest ................ 44

Tailstock ....................................................... 45

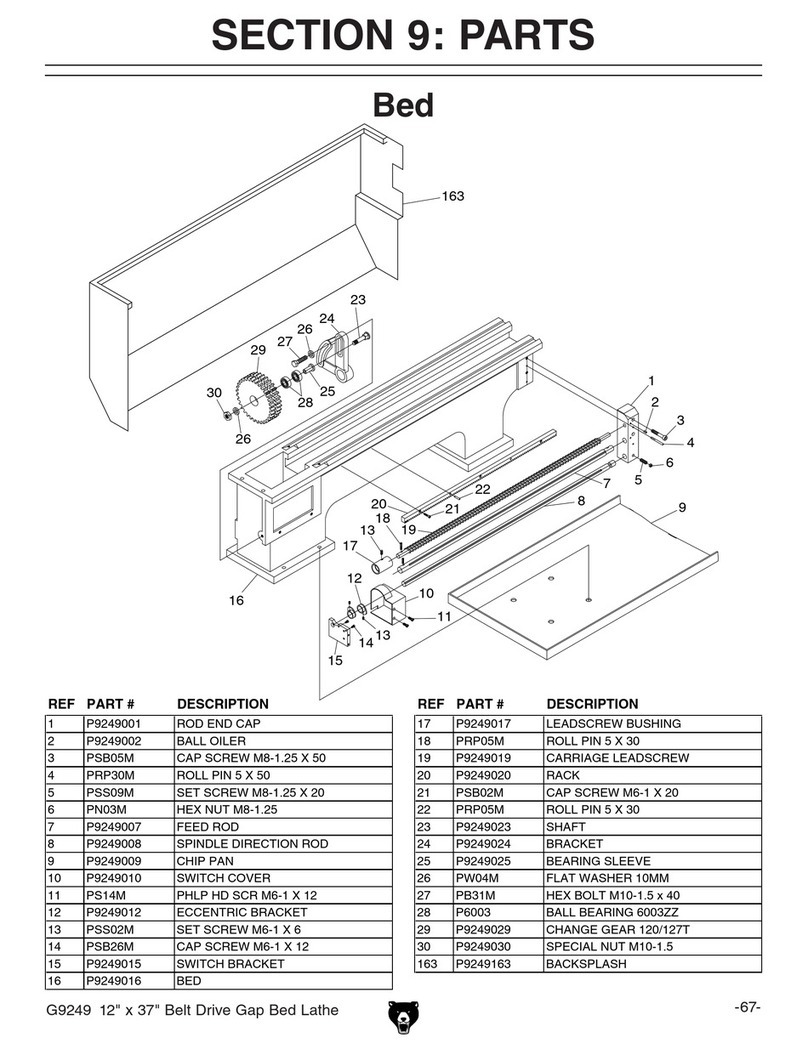

Bed and Leadscew ...................................... 46

Steady Rest and Follow Rest ...................... 47

Motor and Electrical ..................................... 48

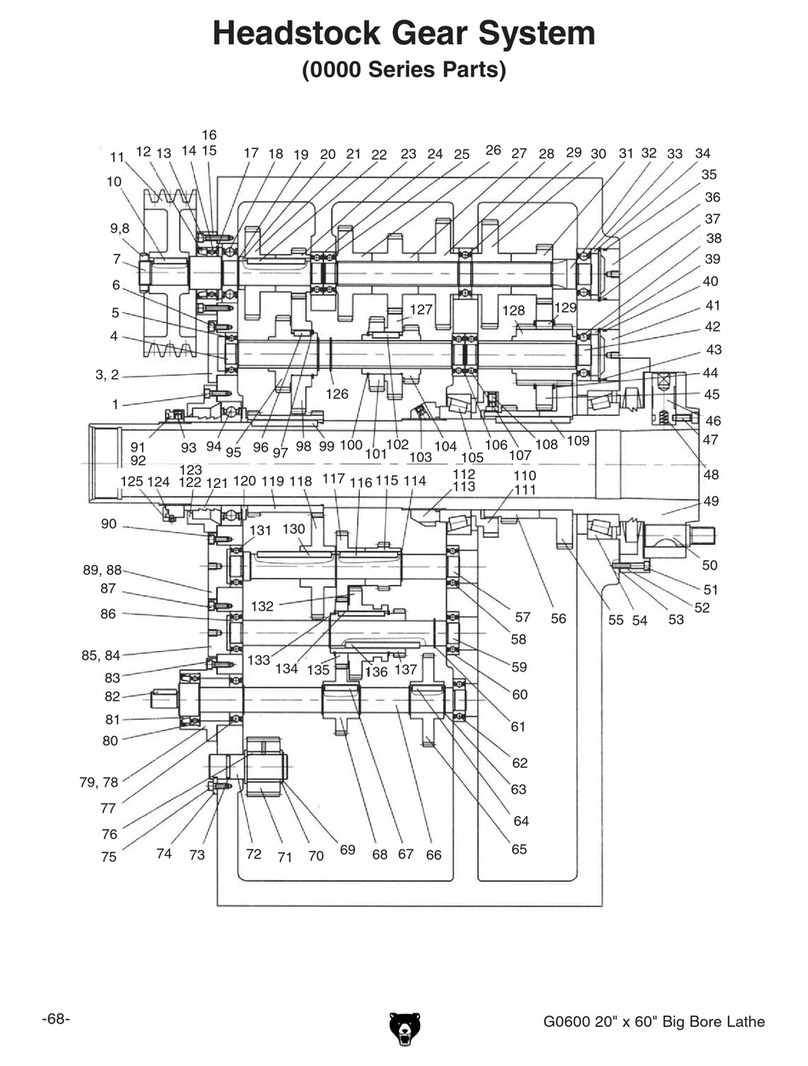

Gearbox Diagram A ..................................... 49

Gearbox Diagram B ..................................... 50

Cross Feed and Carriage ............................ 52

WARRANTY AND RETURNS ........................ 54

Table of Contents