Grizzly T32793 User manual

Other Grizzly Tools manuals

Grizzly

Grizzly G4181 User manual

Grizzly

Grizzly H6087 User manual

Grizzly

Grizzly T23124 User manual

Grizzly

Grizzly 7 1/2" Mini Shear Brake T21322 User manual

Grizzly

Grizzly C1367 User manual

Grizzly

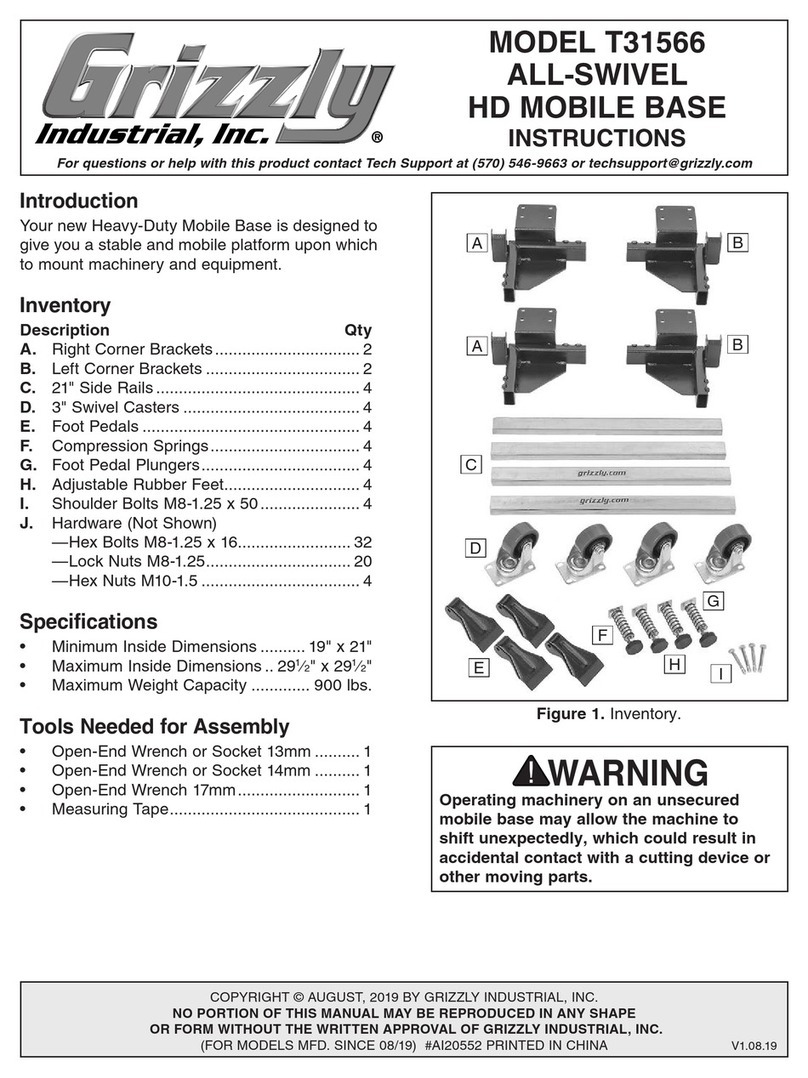

Grizzly T31566 User manual

Grizzly

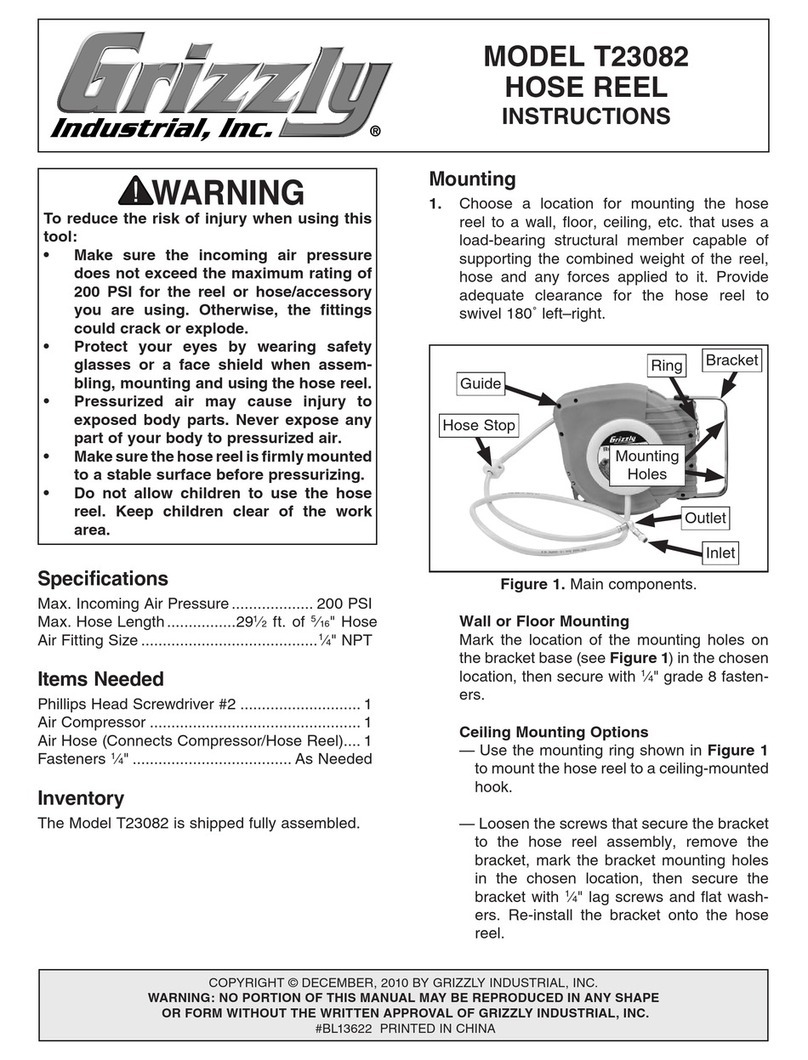

Grizzly T23082 User manual

Grizzly

Grizzly T10264 User manual

Grizzly

Grizzly H7583 User manual

Grizzly

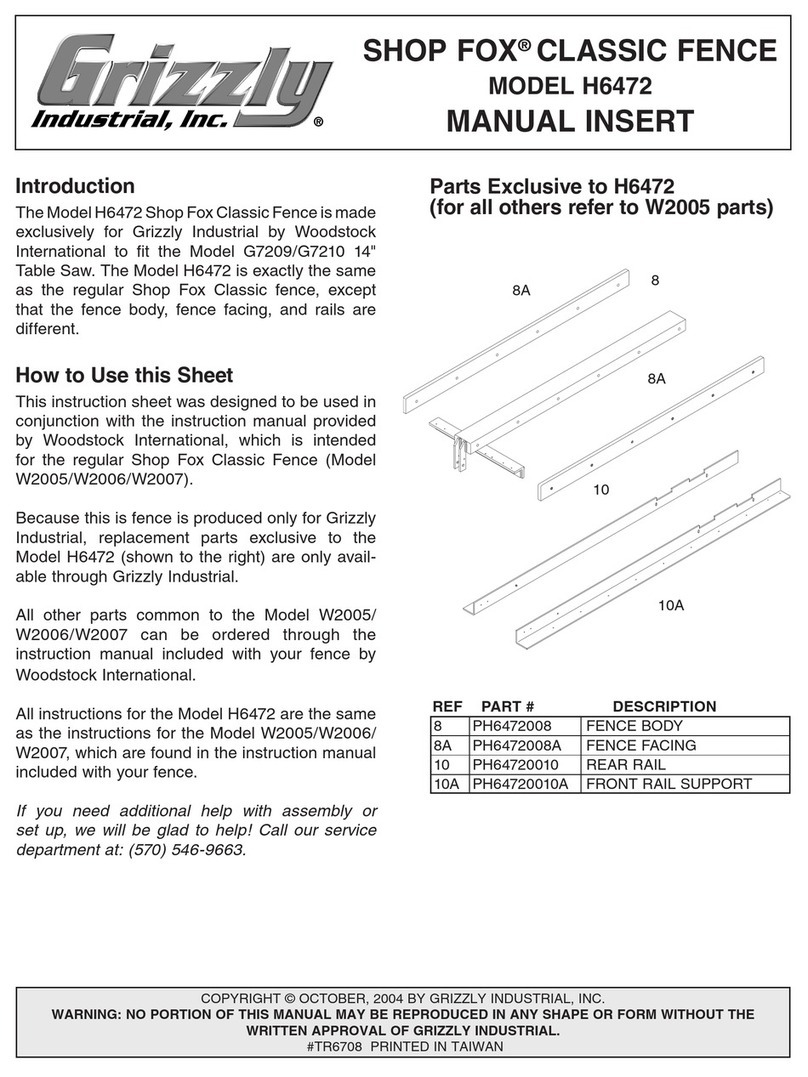

Grizzly H6472 User manual

Grizzly

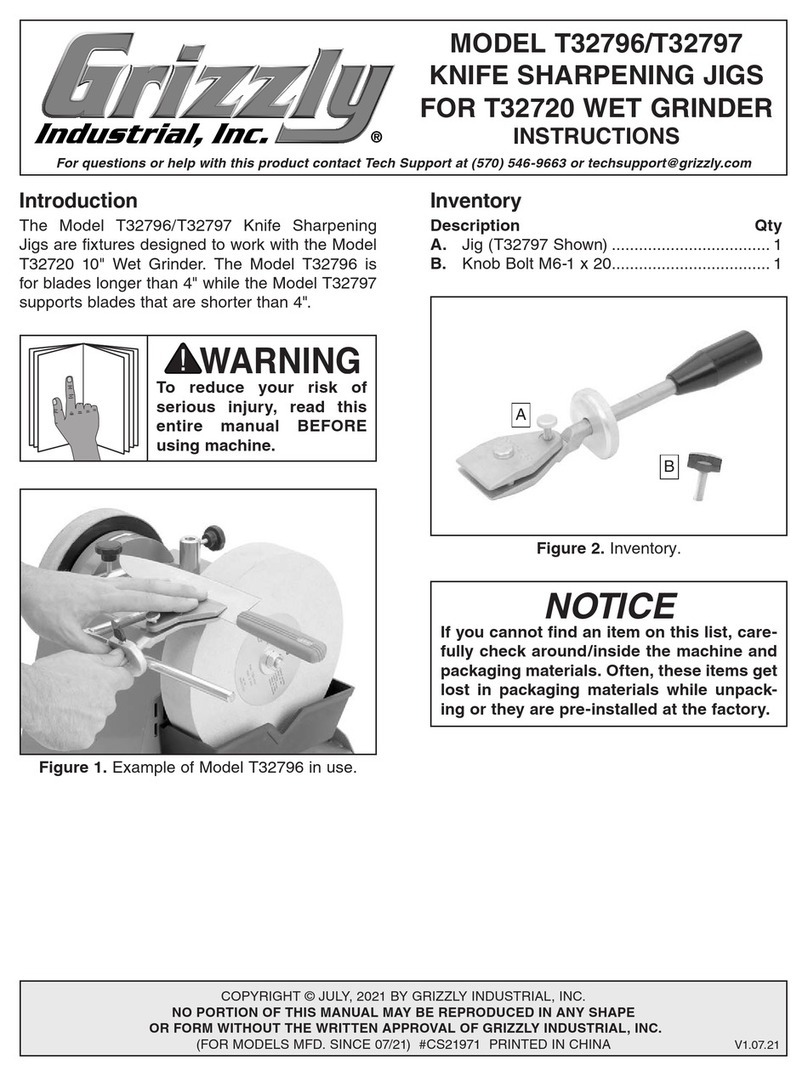

Grizzly T32796 User manual

Grizzly

Grizzly H0613 User manual

Grizzly

Grizzly T23103 User manual

Grizzly

Grizzly T32719 User manual

Grizzly

Grizzly T23034 User manual

Grizzly

Grizzly T1213 User manual

Grizzly

Grizzly T1227 User manual

Grizzly

Grizzly H7507 User manual

Grizzly

Grizzly H7583 User manual

Grizzly

Grizzly G0497 User manual