OM-HY-3E

5

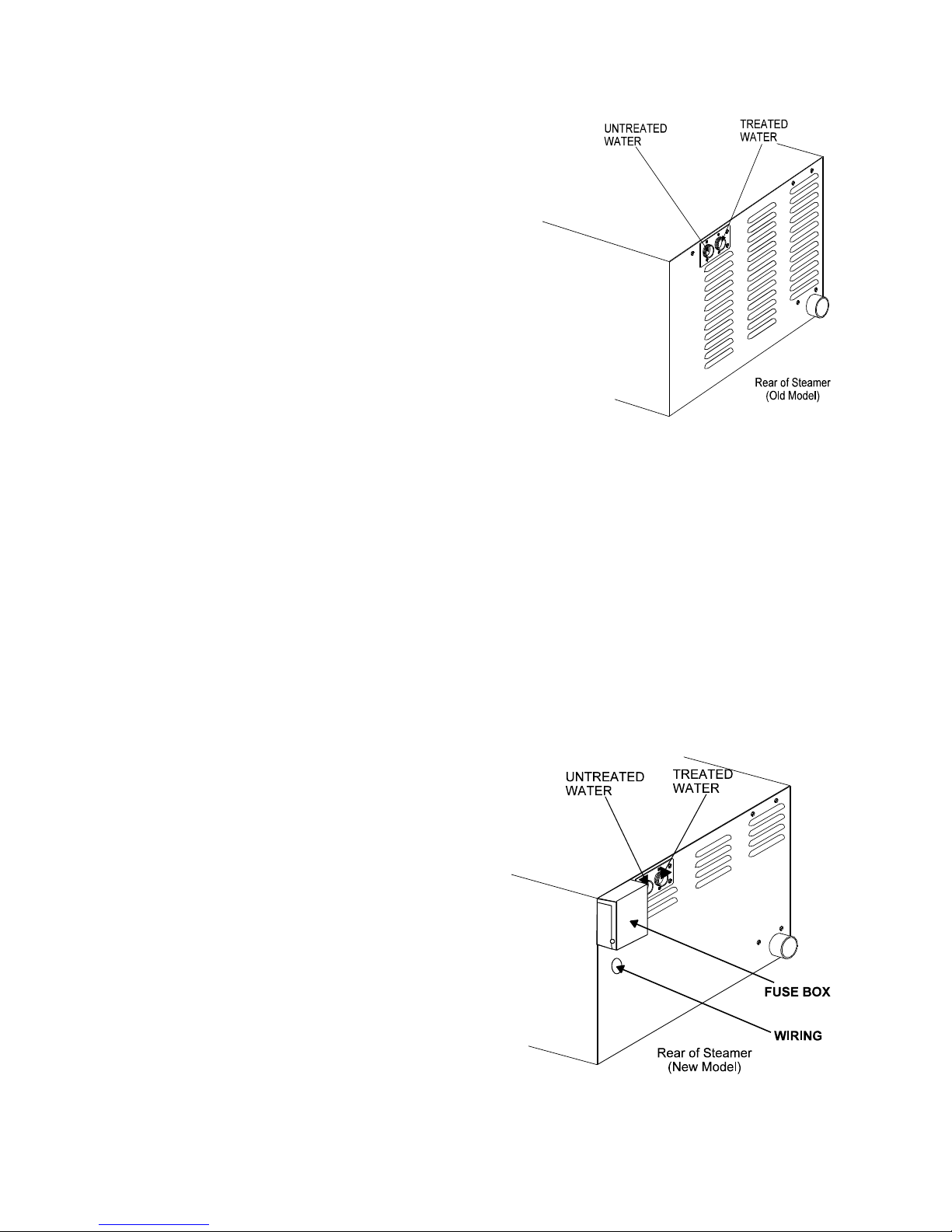

The optional second water connection can reduce

treated water requirements.

New models have a fuse box mounted on

the rear.

Water Conditioning

It is essential to supply the steam generator with water

that will not form scale. Even though the steam

generator is engineered to minimize scale formation,

scale development depends on water hardness and

the number of hours per day you operate the

equipment. In some areas, water is low enough in

mineral content to avoid scale formation. But most

water supplies are full of minerals which form scale. It

is this scale which could lead to an early component

failure.

Your water utility can tell you about the minerals in your

water. For the steam generator's water level sensing

system to function properly, the water must conduct

electrical current. This typically requires it to have a

minimum of 40 parts per million (ppm) total dissolved

solids (TDS) as measured with a Groen Test Kit (P/N

110889). At high TDS concentrations, however,

serious scaling problems may occur. Consult your local

water utility for information and referral regarding

effective water treatment in your area. Please follow

these simple precautions:

1. Do not rely on unproven water treatments

which are sold for scale prevention or scale

removal. The best way to prevent scale is to

supply water with minimum levels of dissolved

solids (but at least 40 ppm TDS).

2. If your water contains scale-forming minerals, as

most water does, use a well-maintained water

softener. Whether an exchangeable softener

cartridge or a regenerating system is chosen, a

regular replacement or regeneration program is

essential.

IMPORTANT: ENSURE ANY WATER TREATMENT

SYSTEM DELIVERS SUFFICIENT WATER VOLUME

AND FLOW RATE.

3. Installing a water meter between the softener and

the steamer will provide an accurate gauge of

water use, and will help determine when to

exchange cartridges or regenerate the softener.

Using a water softener will provide longer

generator life, higher steam capacity, and reduce

maintenance requirements.

4. If you notice a slowdown in steam production, have

the unit checked for scale build-up. Heavy scale

reduces the unit’s ability to boil water, and can

even cause heating elements in the steam

generator to overheat and burn out.

Groen Steamers are also available with an option for

two separate water intakes — one for the steam

generator (soft water), the other for the spray

condenser (untreated water). The steam generator

only uses 14 to 31% of a steamer’s water.

Since softener systems are typically sized by total

GPH (gallons per hour), the second intake could

reduce treatment requirements by up to 80%,

resulting in significant savings.

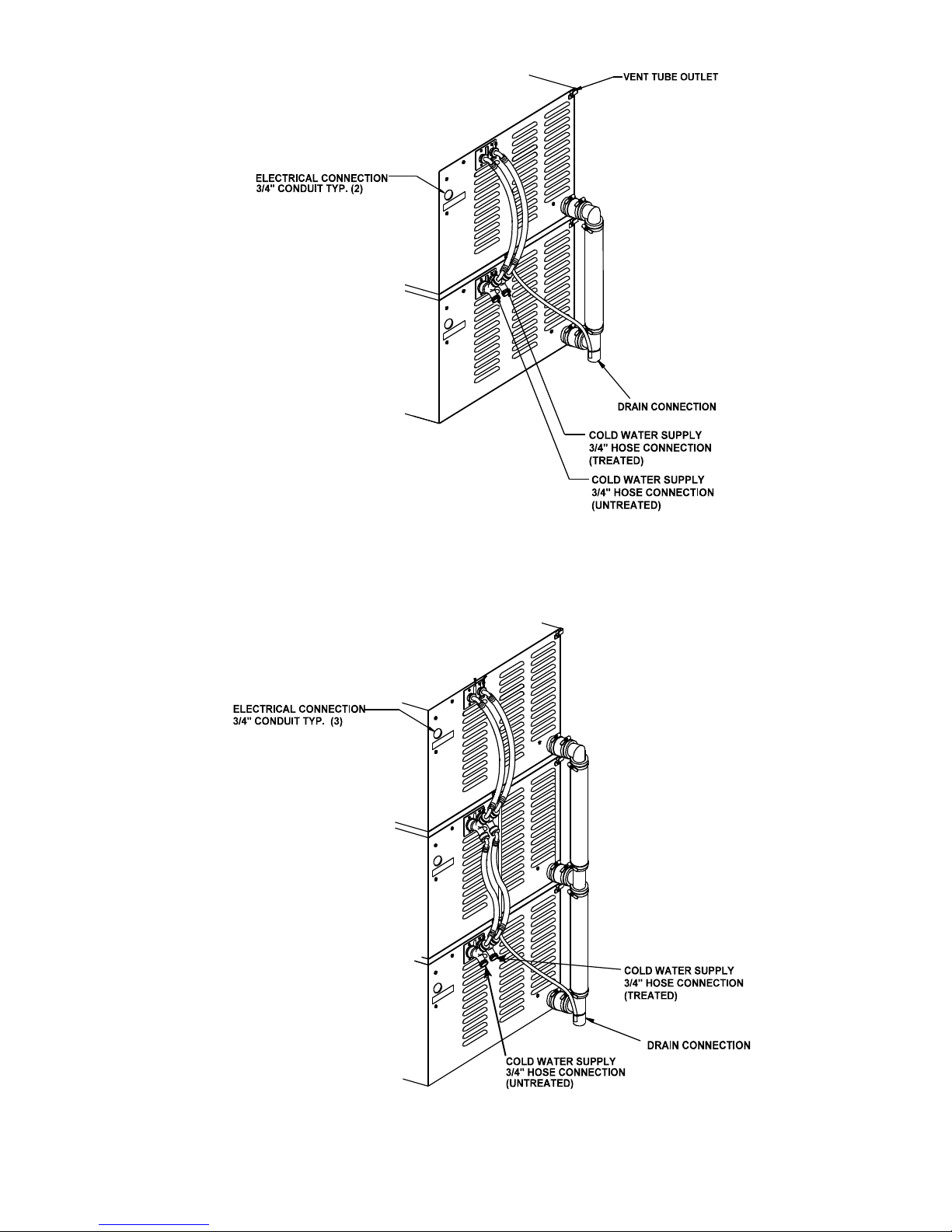

On the HY-3E, the twin water connections are side

by side on the rear of the unit. When facing the back

of the unit, the treated (softened) water intake is on

the right.