10 OM-HY/6E OM-HY/6E 11

Cleaning

WARNING

DISCONNECT THE POWER SUPPLY BEFORE

CLEANING THE OUTSIDE OF THE STEAMER.

KEEP WATER AND CLEANING SOLUTIONS

OUT OF CONTROLS AND ELECTRICAL

COMPONENTS. NEVER HOSE OR STEAM

CLEAN ANY PART OF THE UNIT.

DON’T MIX DE-LIMING AGENTS (ACID) WITH DE-

GREASERS (ALKALI) ANYWHERE IN THE UNIT.

AVOID CONTACT WITH ANY CLEANERS,

DE-LIMING AGENT OR DE-GREASER AS

RECOMMENDED BY THE SUPPLIER. MANY

ARE HARMFUL. READ THE WARNINGS AND

FOLLOW THE DIRECTIONS!

EVEN WHEN THE UNIT HAS BEEN SHUT OFF,

DON’T PUT HANDS OR TOOLS INTO THE

COOKING CHAMBER UNTIL THE FAN HAS

STOPPED TURNING.

DON’T OPERATE THE UNIT UNLESS THE TWO

REMOVABLE INTERIOR PARTITIONS HAVE BEEN

PUT BACK IN THEIR PROPER LOCATIONS.

DON’T USE ANY CLEANING OR DELIMING

AGENT THAT CONTAINS ANY SULFAMIC

AGENT OR ANY CHLORIDE, INCLUDING

HYDROCHLORIC ACID (HCl). TO CHECK FOR

CHLORIDE CONTENT SEE ANY MATERIAL

SAFETY DATA SHEETS PROVIDED BY THE

CLEANING AGENT MANUFACTURER.

To keep your HY-6E Steamer in proper working condition, use the following procedure

to clean the unit. This regular cleaning will reduce the effort required to clean the

steam generator and cavity.

SUGGESTED TOOLS

1. Mild detergent

2. Stainless steel exterior cleaner such as Zepper®

3. Steam generator de-liming agent, such as Groen Delimer Descaler. A liquid

de-liming agent will be easier to use than crystals or powders. See the warning

about chlorides.

4. De-greaser

5. Cloth or sponge

6. Plastic wool or a brush with soft bristles

7. Spray bottle

8. Measuring cup

9. Nylon pad

10. Towels

11. Plastic disposable gloves

12. Funnel

PROCEDURE

1. Outside

a. Prepare a warm solution of the mild detergent as instructed by the sup-

plier. Wet a cloth with this solution and wring it out. Use the moist cloth to

clean the outside of the unit. Do not allow freely running liquid to touch the

controls, the control panel, any electrical part, or any open louver.

b. To remove material which may be stuck to the unit, use plastic wool, a ber

brush, or a plastic or rubber scraper with a detergent solution.

c. Stainless steel surfaces may be polished with a recognized stainless steel

cleaner such as Zepper®.

2. Steam Generator and Cooking Chamber

The steamer cavity and steam generator may be cleaned separately. Regular de-

liming, depending on your steamer usage and local water quality, must be done

to enhance performance and prolong the life of your HyPerSteam™ convec-

tion steamer. Steamer must be turned off after every use to prevent lime scale

buildup - do not run steamer continuously. When cleaning is scheduled, or the

SERVICE light is on, follow the simple deliming instructions on the next page.

NOTE: ALWAYS USE HOT PADS OR MITTS WHEN HANDLING HOT STEAMER PAN-

ELS OR RACKS. DON’T ALLOW DE-LIMING AGENTS TO MIX WITH DEGREASERS.

RECOMMENDED TOOLS & CLEANERS:

• Groen Delimer/Descaler (Part Number 114800). Do NOT use any product

containing chlorides or sulfamic acid, including hydrochloric acid.

• Nylon scrub pad, cloth and/or sponge.

IMPORTANT

DO NOT USE ANY METAL MATERIAL (SUCH

AS METAL SPONGES) OR METAL IMPLEMENT

(SUCH AS A SPOON, SCRAPER OR WIRE

BRUSH) THAT MIGHT SCRATCH THE SURFACE.

SCRATCHES MAKE THE SURFACE HARD TO

CLEAN AND PROVIDE PLACES FOR BACTERIA

TO GROW. DO NOT USE STEEL WOOL, WHICH

MAY LEAVE PARTICLES IMBEDDED IN THE

SURFACE WHICH COULD EVENTUALLY CAUSE

CORROSION AND PITTING.

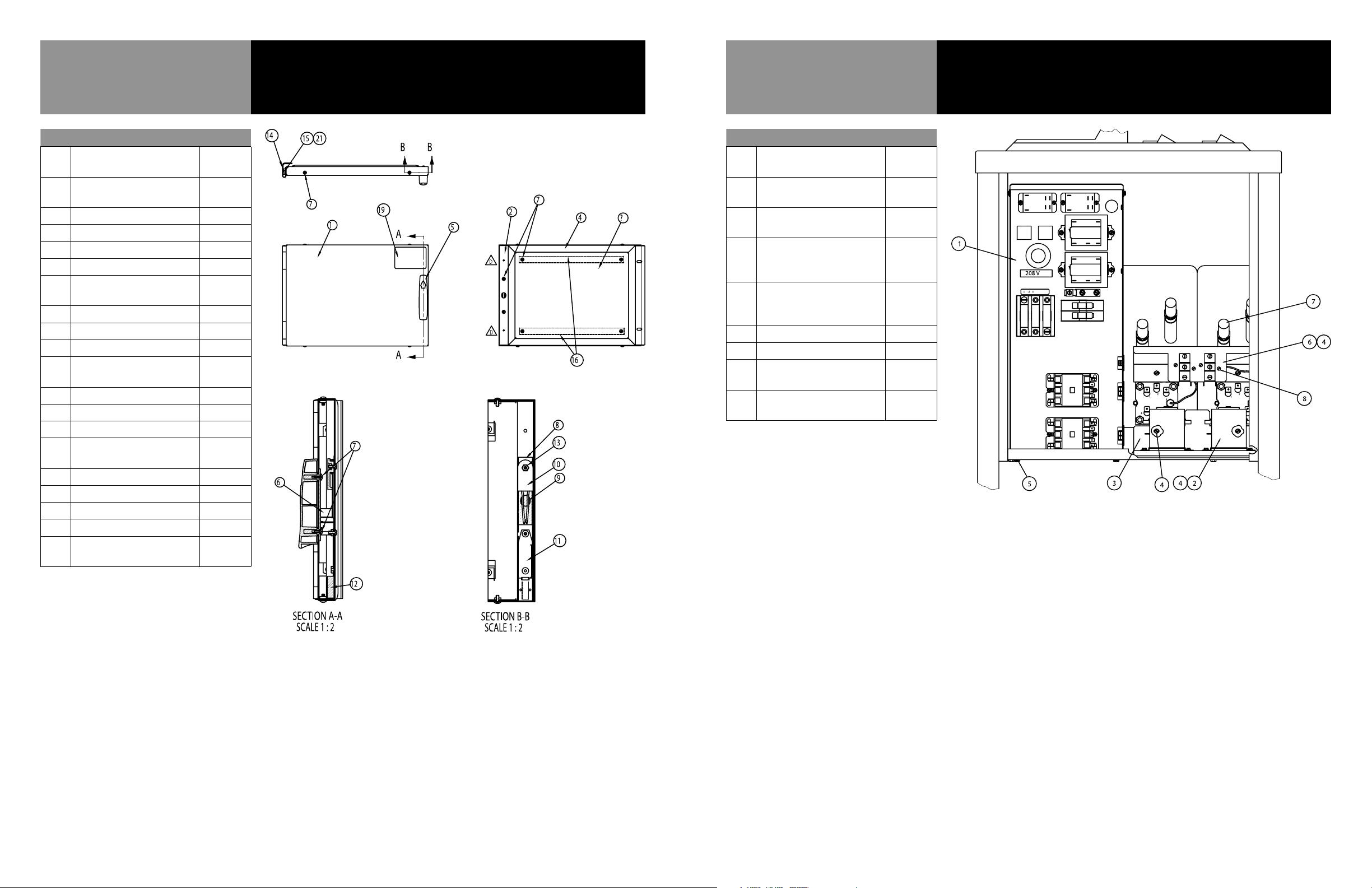

Cleaning

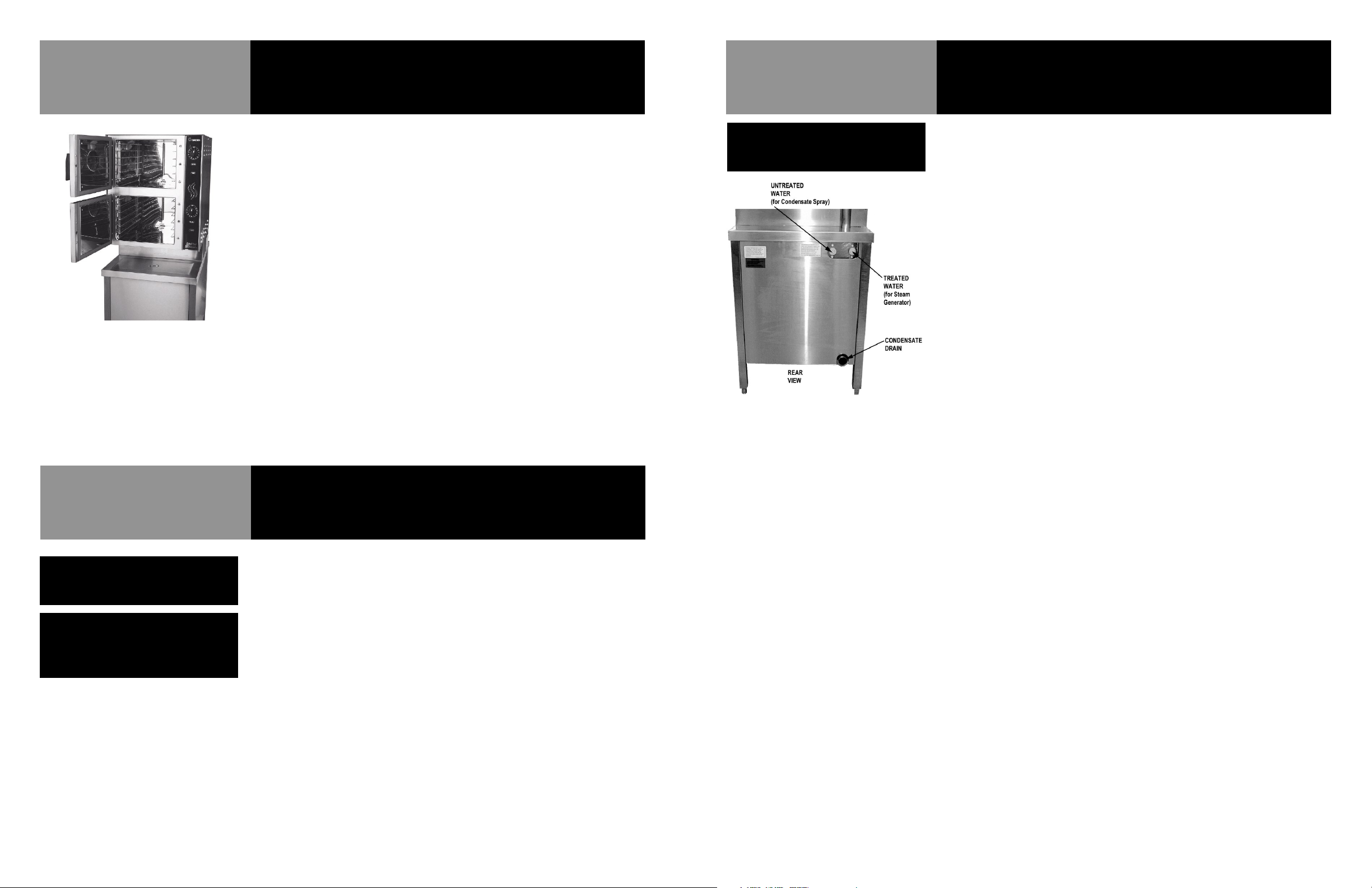

DELIMING STEPS (Use Touch Pad)

STEP 1

Press ON/OFF to turn steamer off. Open door.

STEP 2

Let cavity cool for 5 minutes or longer. While cool, wipe out cavity. Close door.

STEP 3

Press and hold CLEAN while also turning steamer on by pressing ON/OFF, until only

DELIME and POWER lights remain on (all lights will turn on, then off, except DELIME

and POWER).

STEP 4

After 5 minutes, beeper will beep rapidly, signaling you to add Groen Delimer/ Des-

caler. Door(s) must remain closed for entire delime cycle.

STEP 5

Pour 1 pint (2 cups) of delimer PER CAVITY into upper and /or lower deliming port(s)

and then close port(s). Press CLEAN. Double-stacked unit cavities may be delimed

together or seperately

STEP 6

Delime cycle will start, taking about 30 minutes. When delime cycle is complete, DE-

LIME light will appear, DONE light will ash and beeper will beep.

STEP 7

Press ON/OFF to turn steamer off. Let cavity cool for 5 minutes or longer. Open door,

wipe out inside of cavity and wipe door gasket. Close door.

STEP 8

To use steamer, press ON/OFF. When READY light appears, steamer is ready to use.

NOTES:

• If DELIME light ashes rapidly (5 times per second), press DELIME to restart

delime cycle.

• If power outage occurs during deliming, delime cycle must be restarted. Press

DELIME.

• For best performance, do not interrupt delime cycle. If delime cycle must be

stopped, press ON/OFF to turn on. Set timer for 5 minutes. After beeper beeps,

press ON/OFF to turn off. Let cavity cool for 5 minutes or longer, carefully open

door(s) and wipe out cavity completely.

CAUTION

NEVER LEAVE A CHLORINE SANITIZER IN

CONTACT WITH STAINLESS STEEL

SURFACES FOR LONGER THAN 30

MINUTES. LONGER CONTACT CAN

CAUSE CORROSION.

Once the cavity has cooled, reach in and

remove the fan bafe partition by lifting it

upward and drawing it toward the center of

the cavity.

Pour two cups of Groen de-liming solution into

the de-liming port.