2 OM-HY/3E(CE) & HY/5E(CE)

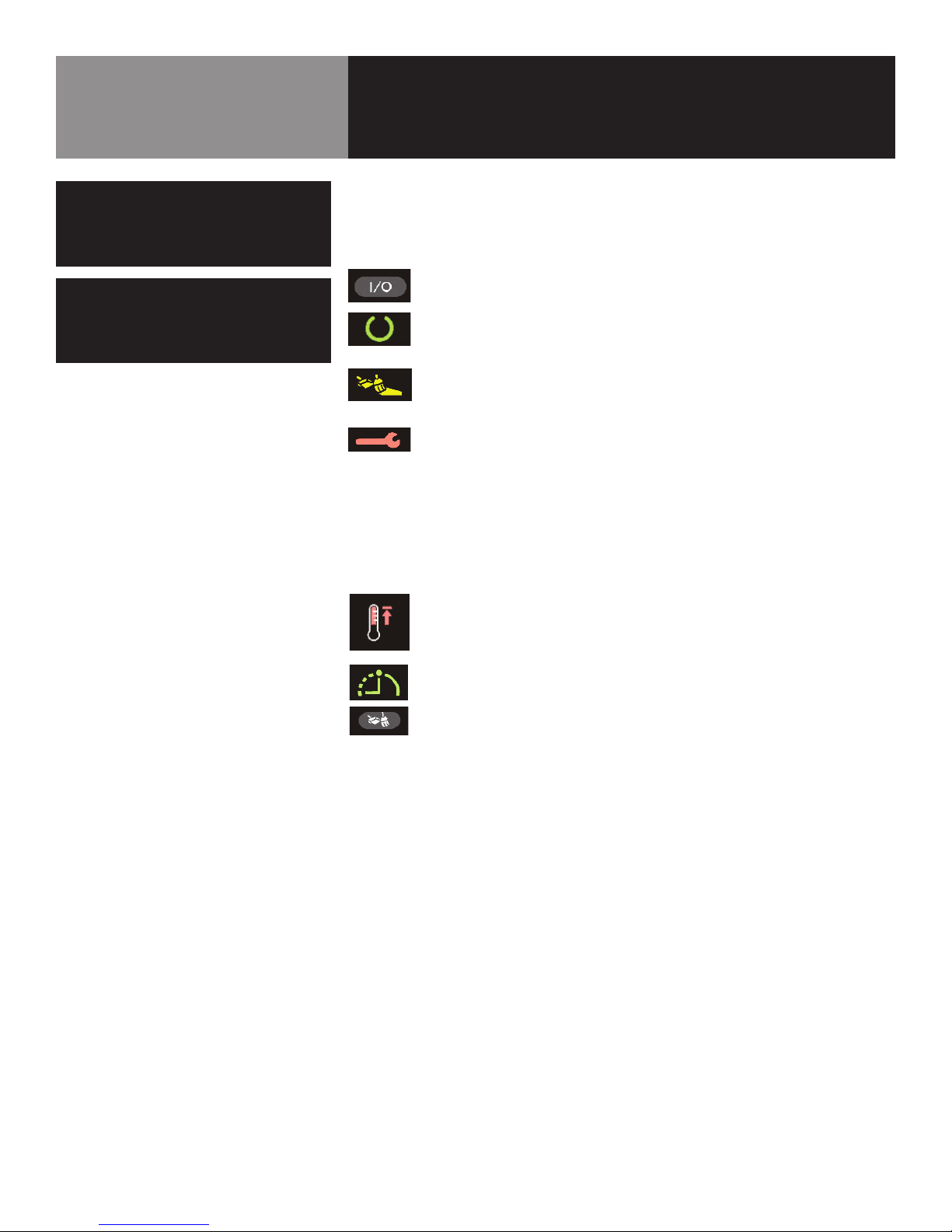

IMPORTANT - READ FIRST - IMPORTANT

THESE APPLIANCES MUST BE INSTALLED BY A COMPETENT PERSON IN CONFORMITY WITH THE INSTALLATION

AND SERVICING INSTRUCTIONS AND NATIONAL REGULATIONS IN FORCE AT THE TIME. PARTICULAR ATTENTION

MUST BE PAID TO THE FOLLOWING:

I. E. E. REGULATIONS FOR ELECTRICAL INSTALLATIONS

ELECTRICITY AT WORK REGULATIONS

HEALTH AND SAFETY AT WORK ACT

FIRE PRECAUTIONS ACT

LOCAL AND NATIONAL BUILDING REGULATIONS

USERS SHOULD BE CONVERSANT WITH THE APPROPRIATE PROVISIONS OF THE FIRE PRECAUTIONS ACT. IN

PARTICULAR THEY SHOULD BE AWARE OF THE NEED FOR REGULAR SERVICING BY A COMPETENT PERSON TO

ENSURE THE CONTINUED SAFE AND EFFICIENT PERFORMANCE OF THE APPLIANCE.

WARNING: TO PREVENT SHOCKS, ALL APPLIANCES WHETHER GAS OR ELECTRIC, MUST BE EARTHED.

UPON COMPLETION OF THE INSTALLATION, THE OWNERS MANUAL SHOULD BE HANDED TO THE

USERS AND THE INSTALLER SHOULD INSTRUCT THE RESPONSIBLE PERSON(S) IN THE CORRECT

OPERATION AND MAINTENANCE OF THE APPLIANCE.

THIS EQUIPMENT IS ONLY FOR PROFESSIONAL USE, AND SHALL BE OPERATED BY QUALIFIED PERSONS. IT

IS THE RESPONSIBILITY OF THE SUPERVISOR OR EQUIVALENT TO ENSURE THAT USERS WEAR SUITABLE

PROTECTIVE CLOTHING AND TO DRAW ATTENTION TO THE FACT THAT, SOME PARTS WILL, BY NECESSITY,

BECOME VERY HOT AND WILL CAUSE BURNS IF TOUCHED ACCIDENTALLY.

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER ARE NOT TO BE

ADJUSTED BY THE INSTALLER.

WARNING: AVOID ANY EXPOSURE TO THE STEAM COMING OUT WHEN OPENING THE DOOR. BEFORE

ATTEMPTING ANY SERVICING, ENSURE THAT THE ELECTRICAL SUPPLY IS DISCONNECTED.

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY AND

PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO

THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES.

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION: DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE RIGHT SIDE VENTS, OR WITHIN 12

INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN, DEEP FRYER, CHARBROILER OR KETTLE.

CAUTION: LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO THE REAR, TO AVOID DRAINAGE

PROBLEMS.

WARNING: TO AVOID DAMAGE OR INJURY, FOLLOW THE WIRING DIAGRAM EXACTLY WHEN CONNECTING A

UNIT.

CAUTION: DO NOT USE PLASTIC PIPE. DRAIN MUST BE RATED FOR BOILING WATER.

WARNING: DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN.

WARNING: BLOCKING THE DRAIN IS HAZARDOUS.

IMPORTANT: IMPROPER DRAIN CONNECTION WILL VOID WARRANTY.