10 OM-DEE/4

Operation

the temperature knob and display. Once the desired temperature

is reached, the user may either press the MANUAL button again or

wait 5 seconds and the set temperature will be accepted by the

controller and locked in. After the set temperature is accepted, it

may be changed at any time by pressing the MANUAL button and

resetting the temperature using the same process above.

h. HIGH TEMP button – Used to set operating temperature of the

kettle at a preset high intensity (default = 7). Can be pressed

at any time during operation of the unit to change the set

temperature to the preset value except when there is an active

TIMER enabled.

i. TIMER button - once the appropriate set temperature is selected

using the HIGH TEMP, MANUAL or LOW TEMP buttons; a

countdown timer can be set to remind the user when the cooking

process is completed.

1. Range – 1 minute to 10 hours

2. When the timer expires:

a. the set temperature will automatically change to the

LOW TEMP setting and will continue at this setting

until the user changes the temperature via MANUAL

or HIGH TEMP buttons

b. An audible alarm will notify the user that attention is

required, the alarm will continue to sound until the

user presses the TIMER button.

3. An active timer can be cancelled by pressing and holding

the TIMER button for 5 secs

4. Set temp can be changed during an active timer by

pressing the MANUAL button and adjusting the set temp

using the Temperature knob and display.

5. HIGH TEMP and LOW TEMP presets cannot be used to

change the setpoint once a TIMER has started.

j. READY alarm – The control will sound 3 beeps when the unit has

reached within 20 degrees of set point during pre-heat and when

a higher set temperature is selected.

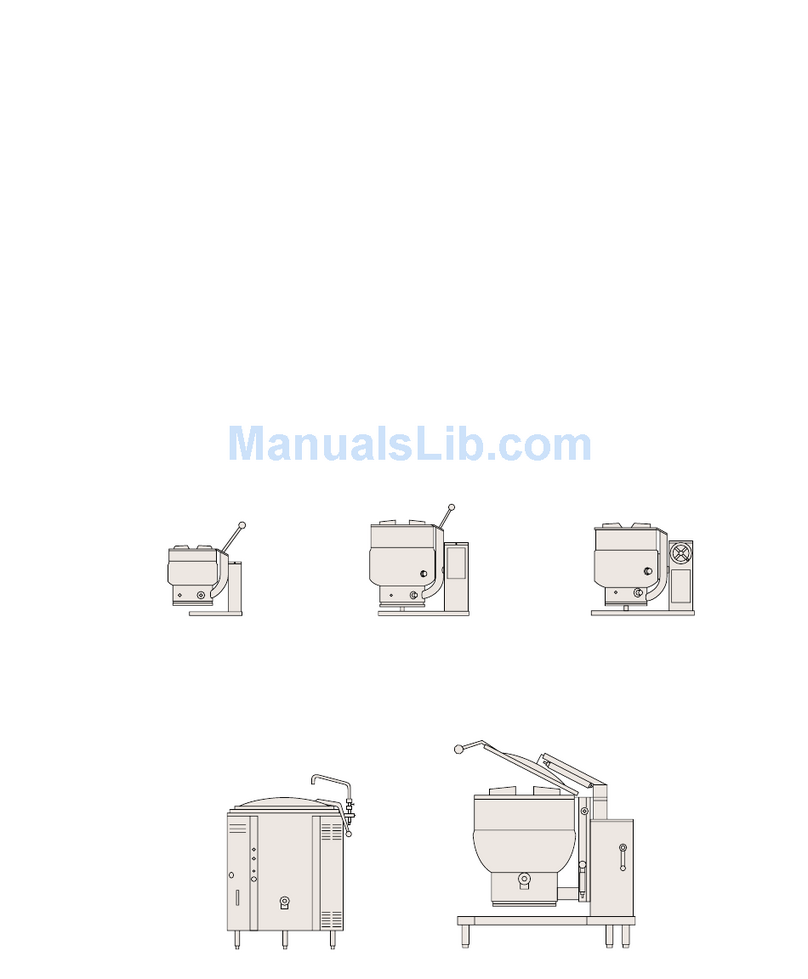

k. Crank tilt - a handle controls the worm and gear mechanism that

smoothly tilts the kettle body and holds it in the desired position.

B. To Start Kettle

1. To Start kettle with Classic controls

a. EVERY DAY make sure the jacket water level is above the mid-

point of the round sight glass. If the level is too low, see “Jacket

Filling” and “Water Treatment” on page 16 of this manual.

b. Check the pressure gauge. If the gauge does not show 20-30

inches of vacuum (that is, a reading of 20 to 30 below 0), see

“Jacket Filling” and “Water Treatment” on page 16 of this manual.

c. Turn on the electrical power to the unit.

d. Turn on the main power switch on the control face.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT COULD

RESULT IN SEVERE BURNS.

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE. DIRECT

CONTACT COULD RESULT IN SEVERE

BURNS.

TAKE SPECIAL CARE TO AVOID CONTACT

WITH HOT KETTLE BODY OR HOT

PRODUCT, WHEN ADDING INGREDIENTS,

STIRRING OR TRANSFERRING PRODUCT

TO ANOTHER CONTAINER.

CAUTION

DO NOT TILT KETTLE WITH LIFT-OFF

COVER IN PLACE. COVER MAY SLIDE OFF,

CAUSING INJURY TO OPERATOR.

CAUTION

KEEP FLOORS IN FRONT OF THE KETTLE

WORK AREA CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN AT ONCE TO AVOID

SLIPS OR FALLS.

CAUTION

DO NOT OVERFILL THE KETTLE WHEN

COOKING, HOLDING OR CLEANING.

KEEP LIQUIDS AT LEAST 2-3” (5-8 cm)

BELOW THE KETTLE BODY RIM TO

ALLOW CLEARANCE FOR STIRRING,

BOILING PRODUCT AND SAFE TRANSFER.