3

GB

Safety notes

• Installation is only possible in frost-free rooms.

• The control electronics are only suitable for indoor use.

• In the case of damage to the external connection cable

of the control unit, the cable must be replaced by the

manufacturer or his customer service department or an

equally qualified person, in order to prevent a hazard.

• When cleaning the fitting (of the wash basin) it must be

ensured that the tile frame behind which the electronics are

installed is not sprayed directly with water.

• In order to provide optimum water protection, the tile frame

must be sealed.

• Use only genuine replacement parts and accessories.

The use of other parts will result in voiding of the warranty

and the CE identification.

Technical data

• Flow rate at 3 bar flow pressure Approx. 6 l/min

• Supply voltage: 230 V AC, 50/60 Hz

(transformer 230 V AC/12 V AC)

• Power consumption: 3.2 VA

• Automatic safety shut-off

(factory setting): 60 s

• Cleaning mode (factory setting): 3 min

• Automatic flushing (factory setting deactivated)

• Reception range according to Kodak Gray Card,

grey side, 8 x 10", landscape (factory setting): 22cm

• Run-on time: 2 s

The test for electromagnetic compatibility (interference

emission test) was performed at the rated voltage and rated

current.

Approval and conformity

The conformity declarations can be obtained from the following

address:

GROHE Deutschland Vertriebs GmbH

Zur Porta 9

D-32457 Porta Westfalica

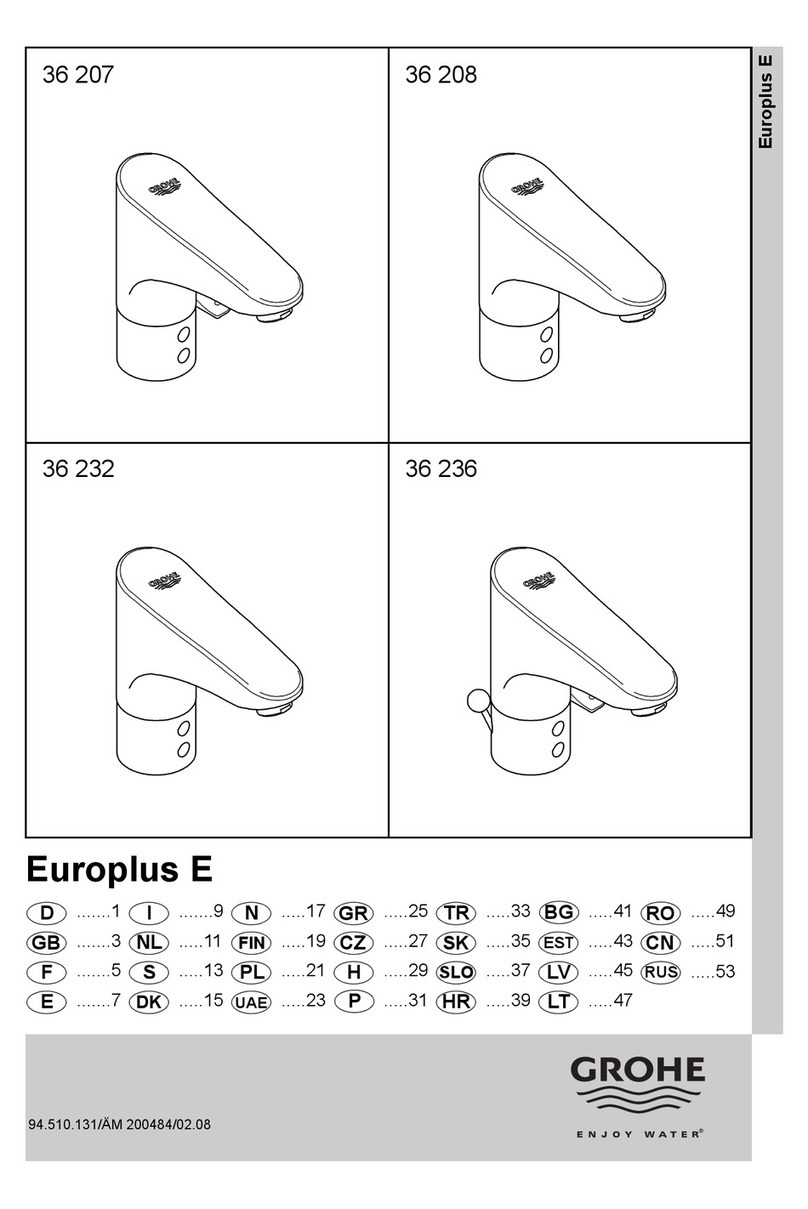

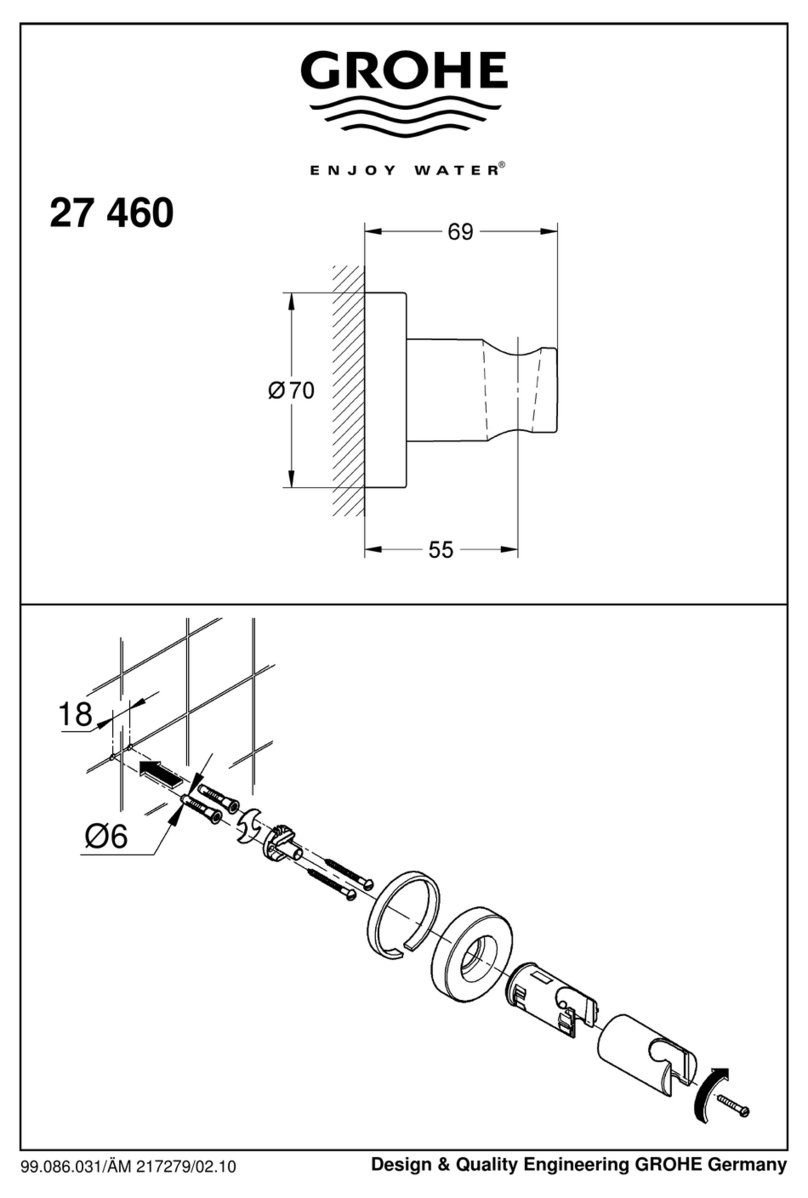

Special accessory

Infrared remote control (Prod. no. 36 206) for changing the

factory settings and selecting special functions.

Installation

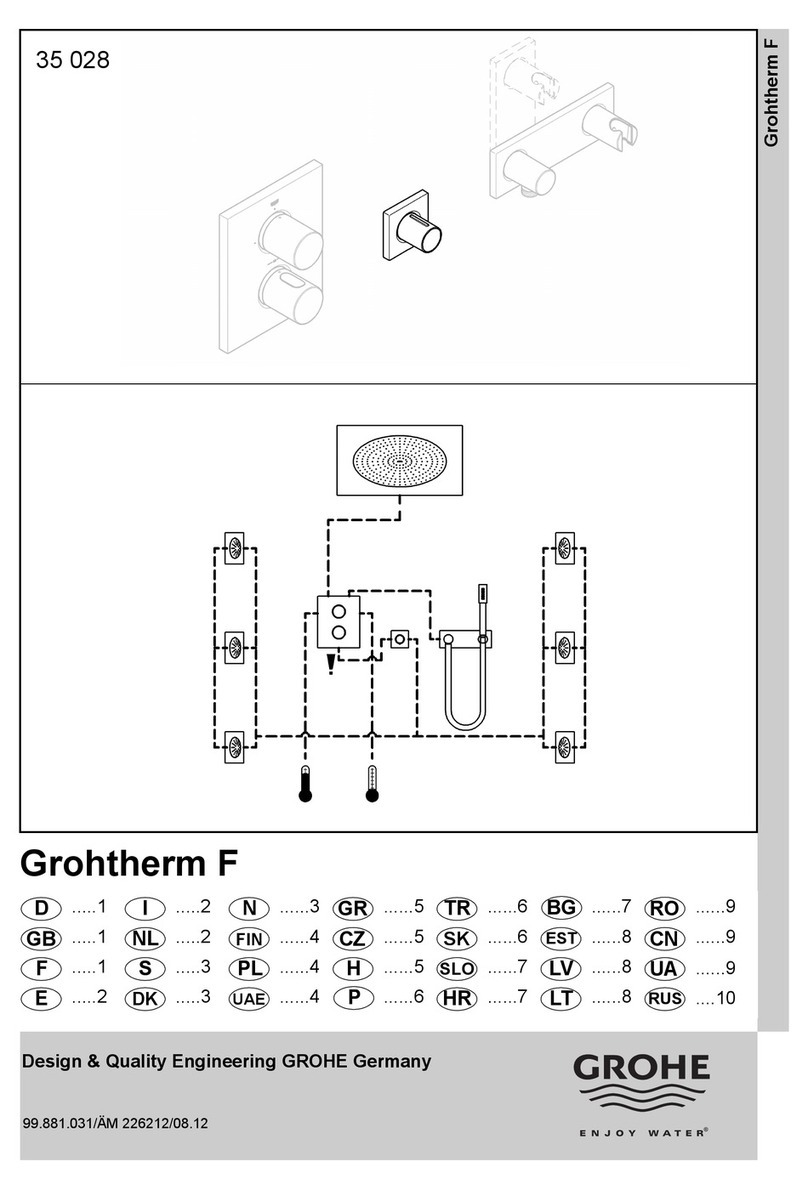

Preparations, see fold-out page II, Fig. [1].

1. Remove cover (A).

2. Open isolating valve (B).

Flush pipes thoroughly before and after installation

(observe EN 806).

Important: the water must be directed from the spout into the

room during flushing.

3. Close isolating valve (B).

Installing solenoid valve, see Fig. [2].

• Replace spacer (C) with solenoid valve (D) together with

seals (D1).

Important: install solenoid valve in flow direction.

Installing transformer, see Figs. [3] and [4].

1. Fit upper part (E) of the transformer to base (E1), see Fig. [3],

remove protection first.

2. Establish plug-in connection between solenoid valve

cable (F1) and solenoid valve (D), see Fig. [4].

3. Connect electronics cable (F2) to connecting wire of

transformer (E2).

Installing infrared electronics, see Figs. [5] to [8].

1. Cut off inspection chamber (G) flush with tiles, see Fig. [5].

2. Pull electronics cable (F2) and solenoid valve cable (F1) out

of the opening, see Fig. [6].

3. Connect infrared electronics cable (H) to electronics

cable (F2) and solenoid valve cable (F1).

4. Align infrared electronics (H) horizontally and fasten to

inspection chamber (G) using screws (K), see Fig. [7].

5. Position escutcheon (J) on the infrared electronics and

fasten using a 2mm allen key, see Fig. [8].

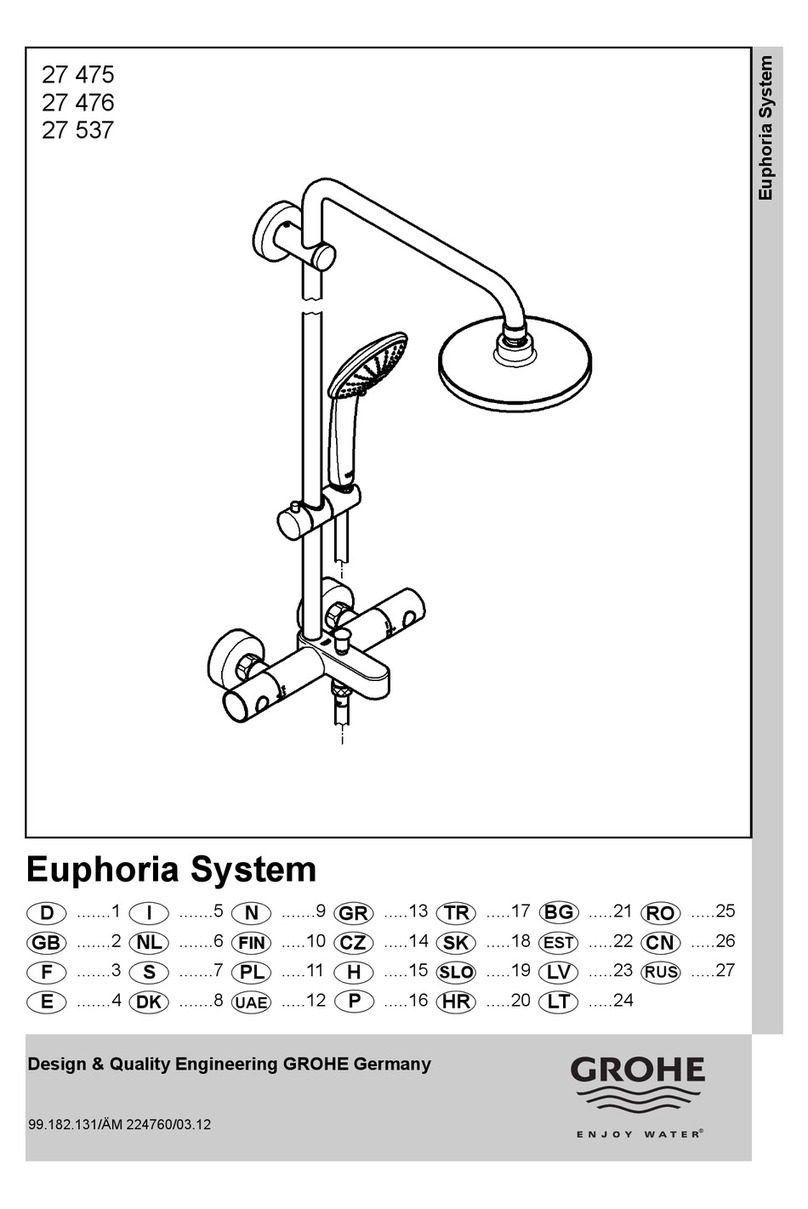

Installing spout, see Figs. [9] to [11].

1. Fasten spout (M) to escutcheon (N) using a 2mm allen key,

see Fig. [9].

2. Determine dimension "X" from upper edge of elbow union to

face of tiles, see Fig. [10].

3. Cut connection nipple (L) so that the installation dimension

is "X"+24mm.

4. Using a 12mm allen key, screw connection nipple (L) into

the elbow union until the installation dimension is 6mm,

see Fig. [11].

5. Attach spout (M) to connection nipple (L) using a 2.5mm

allen key.

Adjusting

Only in conjunction with wall-mounting box 38 892.

Check the temperature of the water at the spout with a

thermometer, see Fig. [12]. If the desired temperature has not

been reached, proceed as follows:

1. Remove cap (O), see Fig.[13].

2. Remove stop ring (P) and scale ring (Q).

3. The temperature can be adjusted, using a 3mm allen key in

the hexagon aperture on the thermostatic cartridge (R).

4. After reaching a temperature of 40 °C, attach scale ring (Q),

so that the 40 °C marking aligns with the red pin (S) of the

thermostatic cartridge (R).

5. Attach stop ring (P), so that the red pin (S) is located in the

aperture (P1).

Temperature adjustment

For operation with the thermostat, the mixed water

temperature is pre-adjusted at the thermostatic cartridge (R),

see Fig. [13].

The cap (O) and the stop ring (P) must be removed to adjust

the temperature. The temperature can now be adjusted using

the 3mm allen key. Turn clockwise (to decrease temperature),

turn anti-clockwise (to increase temperature), see also indicator

on the scale ring (Q). Reinstall stop ring (P) and cap (O).

Caution:

To prevent self-adjustment of the temperature, operation only

with installed cap (O).

Operation

The infrared electronics emit invisible, pulsed light.

The infrared-electronics are adjusted so that water flow is

initiated when the hands approach the vicinity of the spout.

When the hands are withdrawn from the vicinity of the spout,

water flow is stopped after 2 s (factory setting).

The range of the sensor system is dependent upon the

reflective properties of the detected object.

This product conforms to the requirements of the

relevant EU guidelines.