2

Table of Contents

1 Safety.............................................................................................................................................3

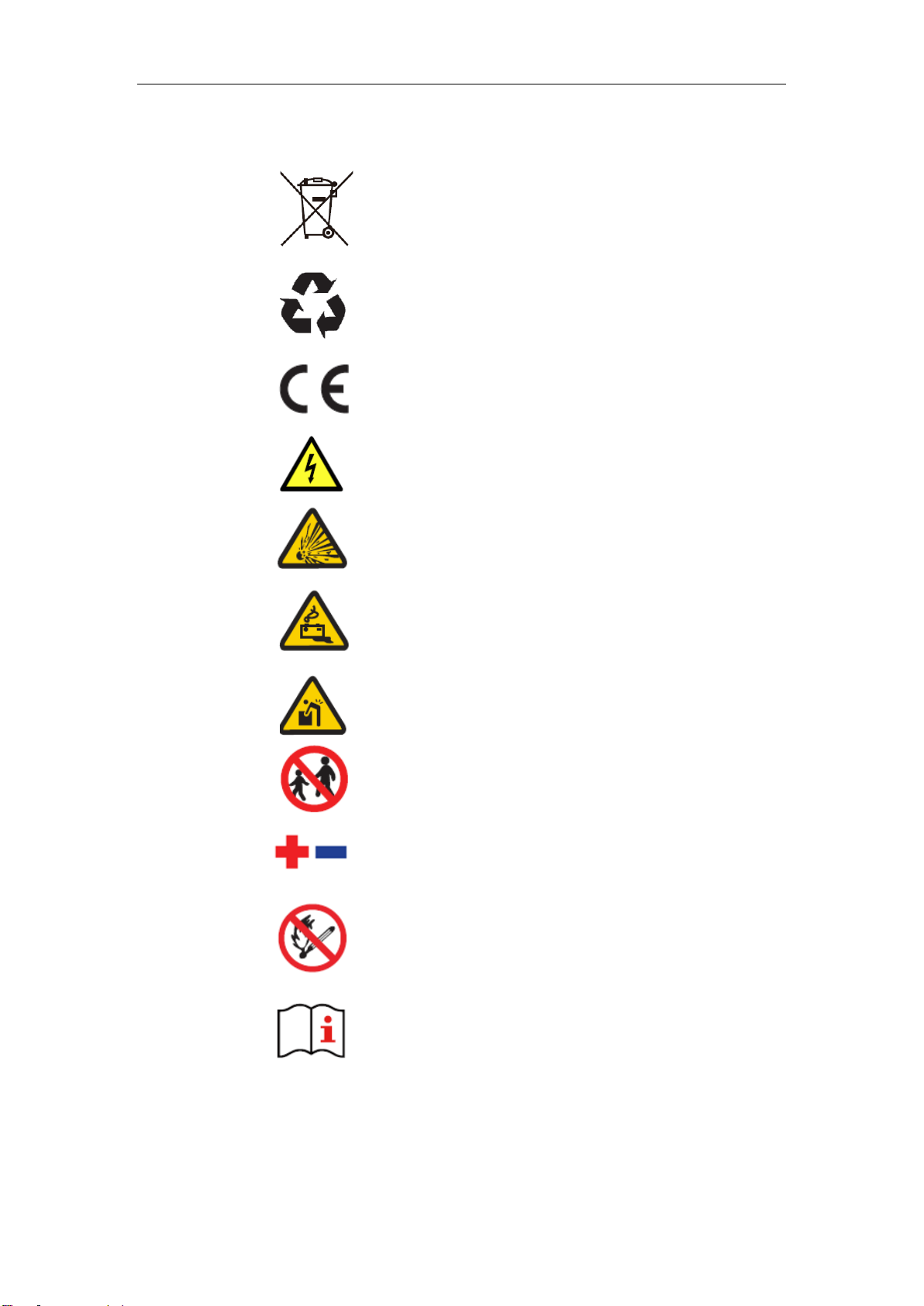

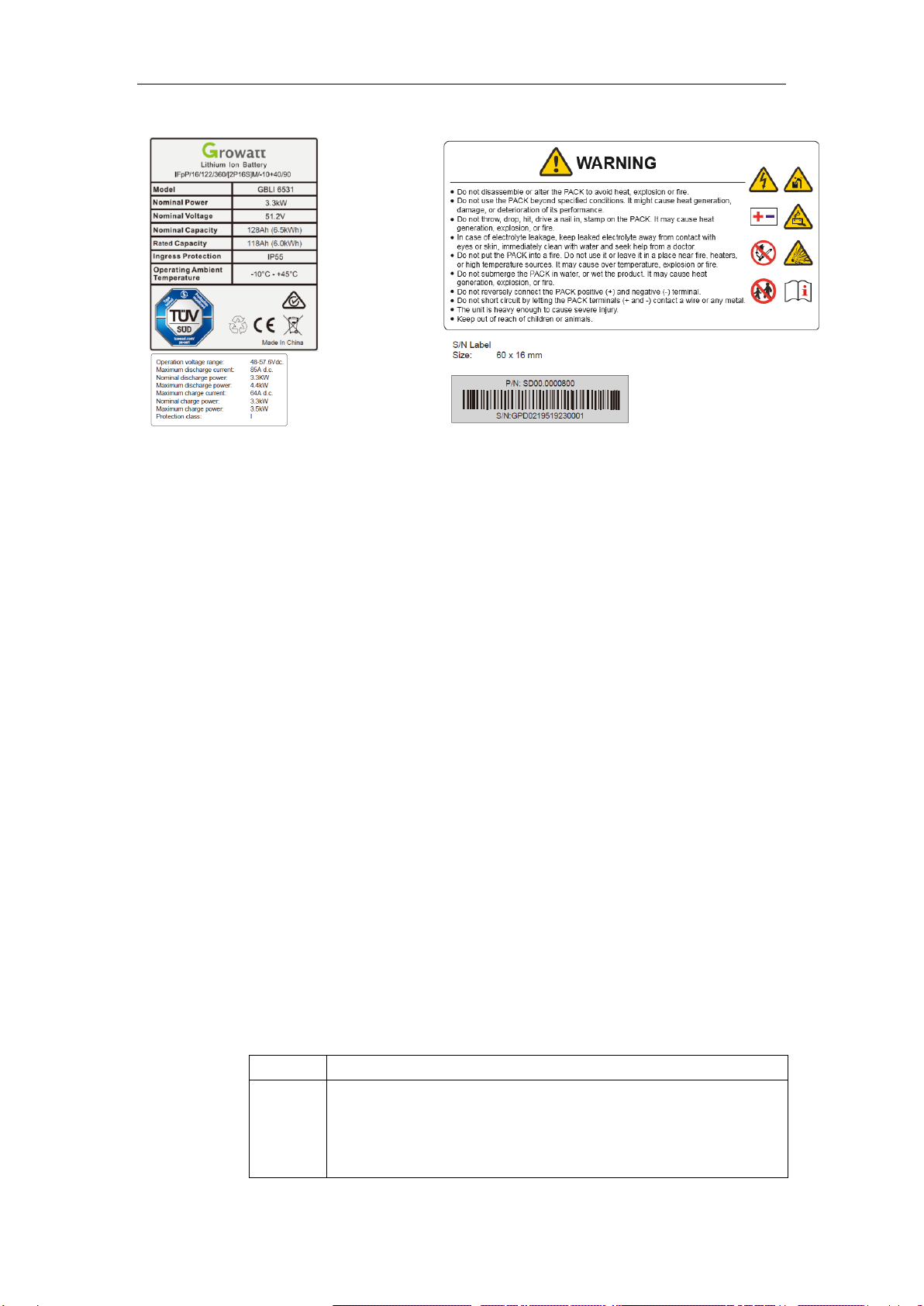

1.1 Warning Label.....................................................................................................................3

1.2 Precautions..........................................................................................................................4

1.3 Responses to Emergencies..................................................................................................4

1.4 Storage safety......................................................................................................................5

1.5 Transportation Safety..........................................................................................................5

2. Introduction to Product..............................................................................................................7

2.1 Intended Purpose.................................................................................................................7

2.2 Function ..............................................................................................................................7

2.3 Appearance..........................................................................................................................8

2.4 Technical Parameters...........................................................................................................9

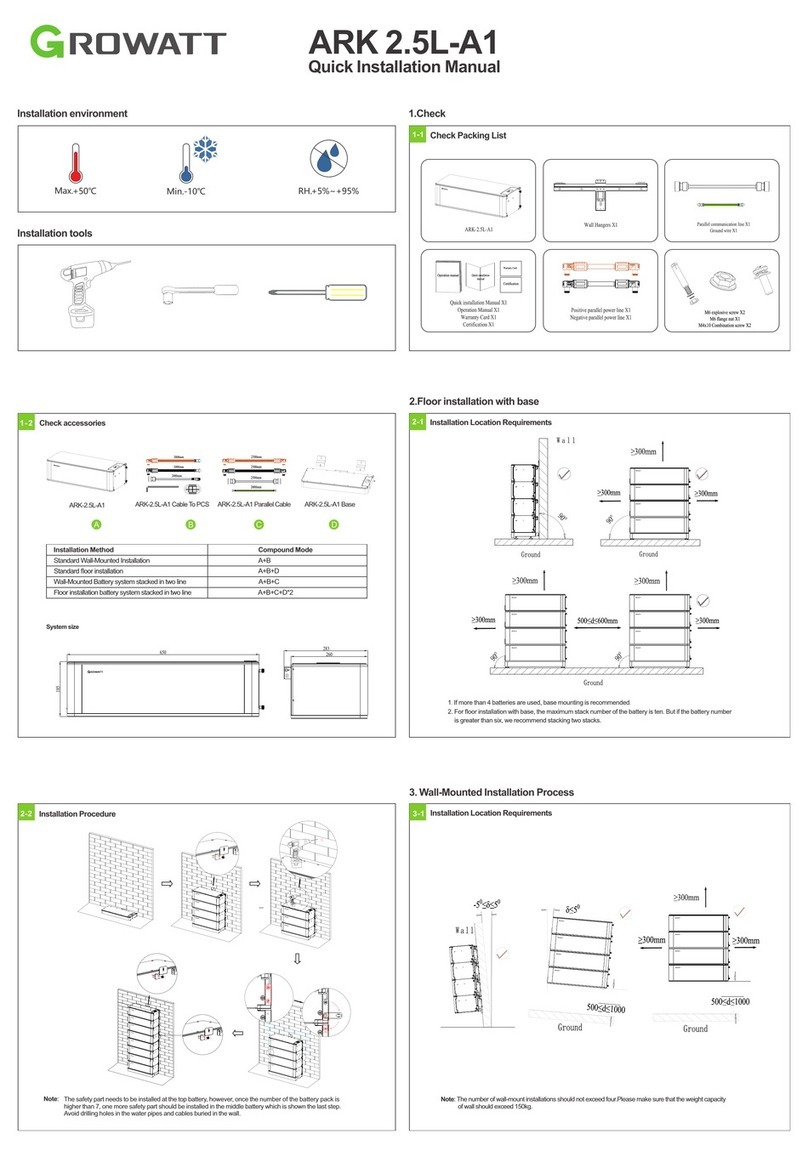

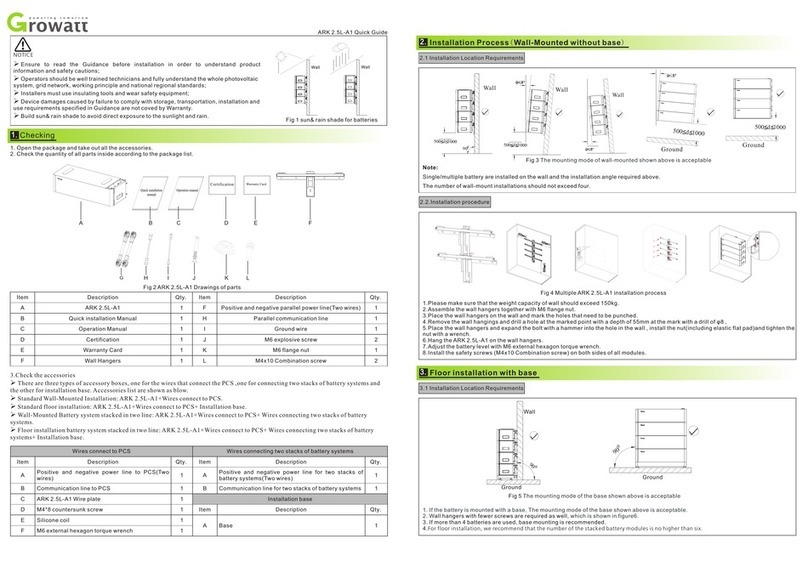

3 Installation..................................................................................................................................10

3.1 Basic Installation Requirements........................................................................................10

3.2 Installation Required Tools ...............................................................................................11

3.3 installation Procedures......................................................................................................11

3.3.1 Wall Mounted Installation..............................................................................................12

3.3.2 Floor Standing Installation.............................................................................................14

4 Electrical Connection.................................................................................................................15

4.1 Preparation........................................................................................................................15

4.2 Electrical Connection Procedures......................................................................................15

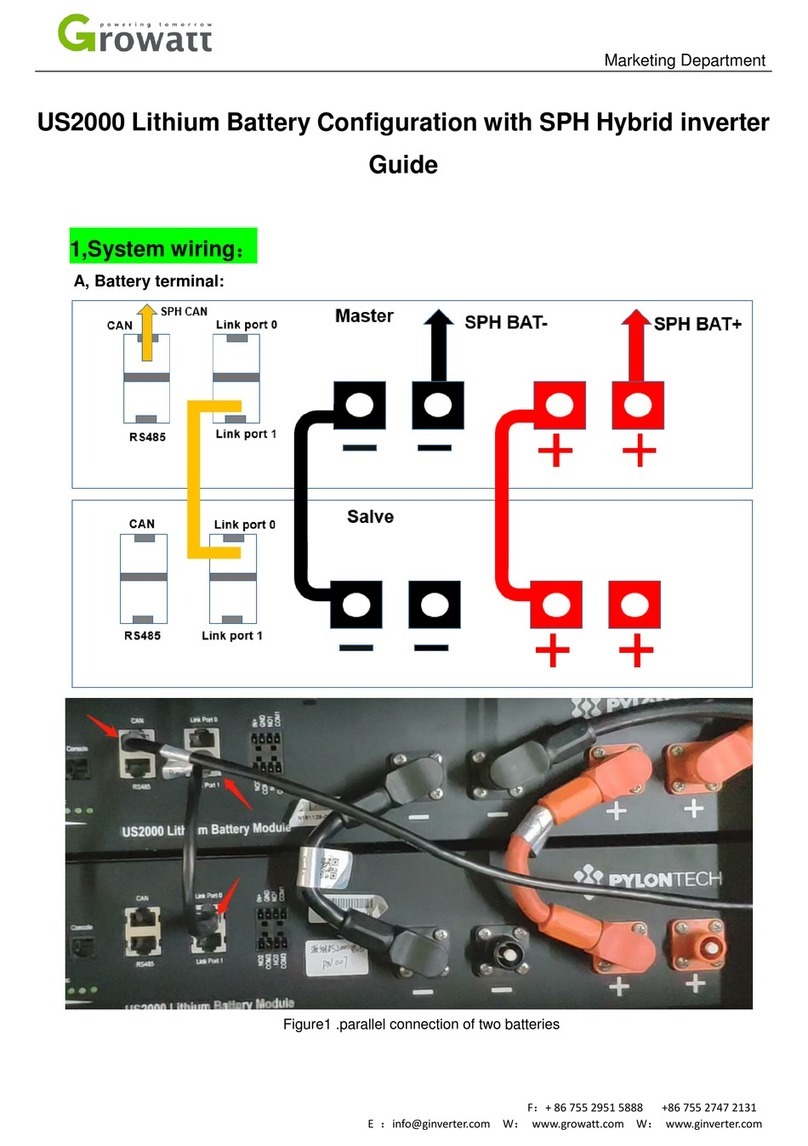

5 Installation Steps under Parallel Connection..........................................................................17

6 Power on/off Battery..................................................................................................................19

6.1 LED Indication..................................................................................................................19

6.2 Power on Battery...............................................................................................................20

6.3 Power off Battery..............................................................................................................21

7 Maintenance ...............................................................................................................................22

7.1 Preparation........................................................................................................................22

7.2 Battery Replacement.........................................................................................................22

7.3 Firmware Upgrade ............................................................................................................22

7.4 Troubleshooting ................................................................................................................23