5

Revision date: 11.16.18

Important Information

To achieve the best results from your evaporative cooling

system, read and follow the instructions on this page and

throughout this guide.

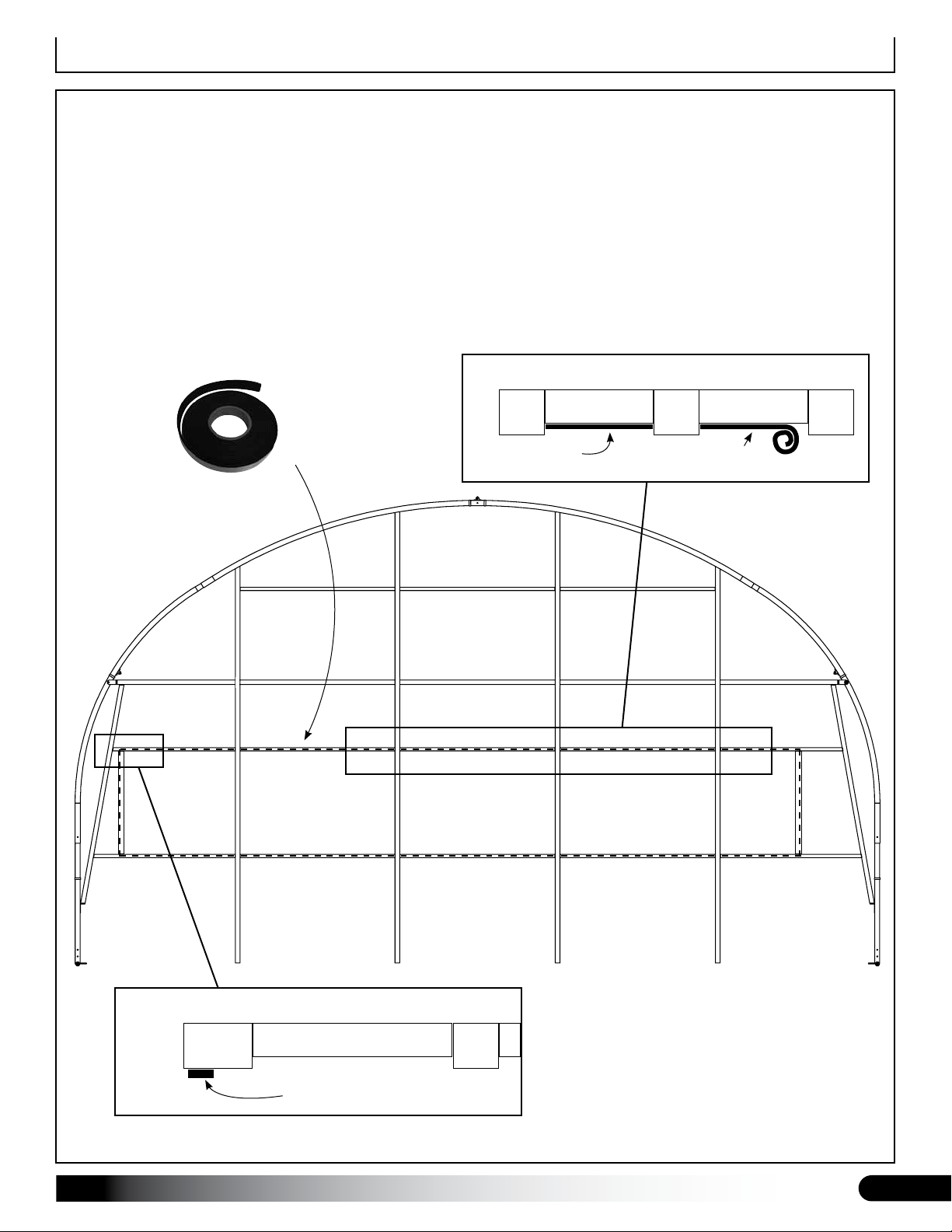

Cooling Pads: Break-In Period

New cooling pads function best after preforming an initial

break-in procedure. Complete these steps before normal

operation begins:

1. Verify that pads have been installed according to the

information provided with those pads.

2. Turn on water pump for the evaporative cooling

system and adjust water flow using upper ball valve.

3. Pump water through the system and over the pads

for 24 to 36 hours depending on water hardness in

the area.

4. After completing Step 3, turn water off and inspect

the pads. Pads should be fully saturated with no dry

areas. If dry areas are present, inspect the supply

header tube for obstructions and consult the supply

header maintenance information near the back of

this guide. Check the spray hole angle and make the

necessary adjustments.

Cooling Pad Inspection, Cleaning, and Care

Daily inspection of the cooling pads during normal

operation will help to identify any areas that need

attention. Consult the following information to identify

issues common to most evaporative cooling systems.

• Controlling Scale Deposits

Water evaporation can lead to the deposit of solids on

the cooling pads. Water quality, environmental conditions,

and system operation can all contribute to the buildup of

solids.

Minimize or eliminate On/Off cycling of the system.

Set evaporative cooling system to run continuously to

minimize scale buildup on pads. Control water flow using

the upper ball valve above water screen. Allowing the

pads to dry out due to repeated cycling of the system

increases the deposits of solids on the pads; keep the

pads wet to reduce these deposits.

NOTE: Anytime air flows through wet pads, water should

also be running to keep pads wet and to increase flushing

of solids from the pads.

• Maintain Proper Water Level

Do not allow the bottoms of the cooling pads to sit in

water at any time. Submerged pad sections become

waterlogged and will deteriorate, which decreases pad

life. Adjust the water level as needed to prevent this

condition.

• Algae Growth and Treatment

Some environments and conditions can cause algae

growth on the cooling pads. In those instances, it may be

necessary to treat the water to reduce or eliminate algae.

Contact water conditioning experts in your area for details

and possible solutions.

• Diluting or Changing the Recycled Water

In instances where solids become concentrated in

the recycled water, deposits on the cooling pads can

increase. If this happens, dilute or change the water in

the sump. To dilute, drain water from and add it to the

system. Complete these steps:

1. Turn off the water pump and main water supply to the

system and attach a garden hose to the valve below

the water screen.

2. Close the valve above the water screen and open the

valve below the water screen.

3. Turn on the water pump and pump 1/4 to 1/2 of the

water from the sump, depending on the amount of

scaling on the pads. Use a bucket or barrel to gauge

gallons removed. A system with an 8" PIP drain

trough holds approximately 1.2 gallons per foot of

drain trough.

NOTE: To prevent pump damage, never allow sump

to run dry.

4. After flushing the desired amount of water from the

system, turn off the pump, close the lower valve, and

open the upper valve to its previous setting.

5. Turn main water back on and allow the system to fill

to the set water level.

6. Turn the water pump on and resume normal

operation.

NOTE: To completely change the water, pump all

water from the system, clean the sump, and refill to

resume normal operation. Do not allow the pump to

run when sump is empty.