www.groz-tools.com

2

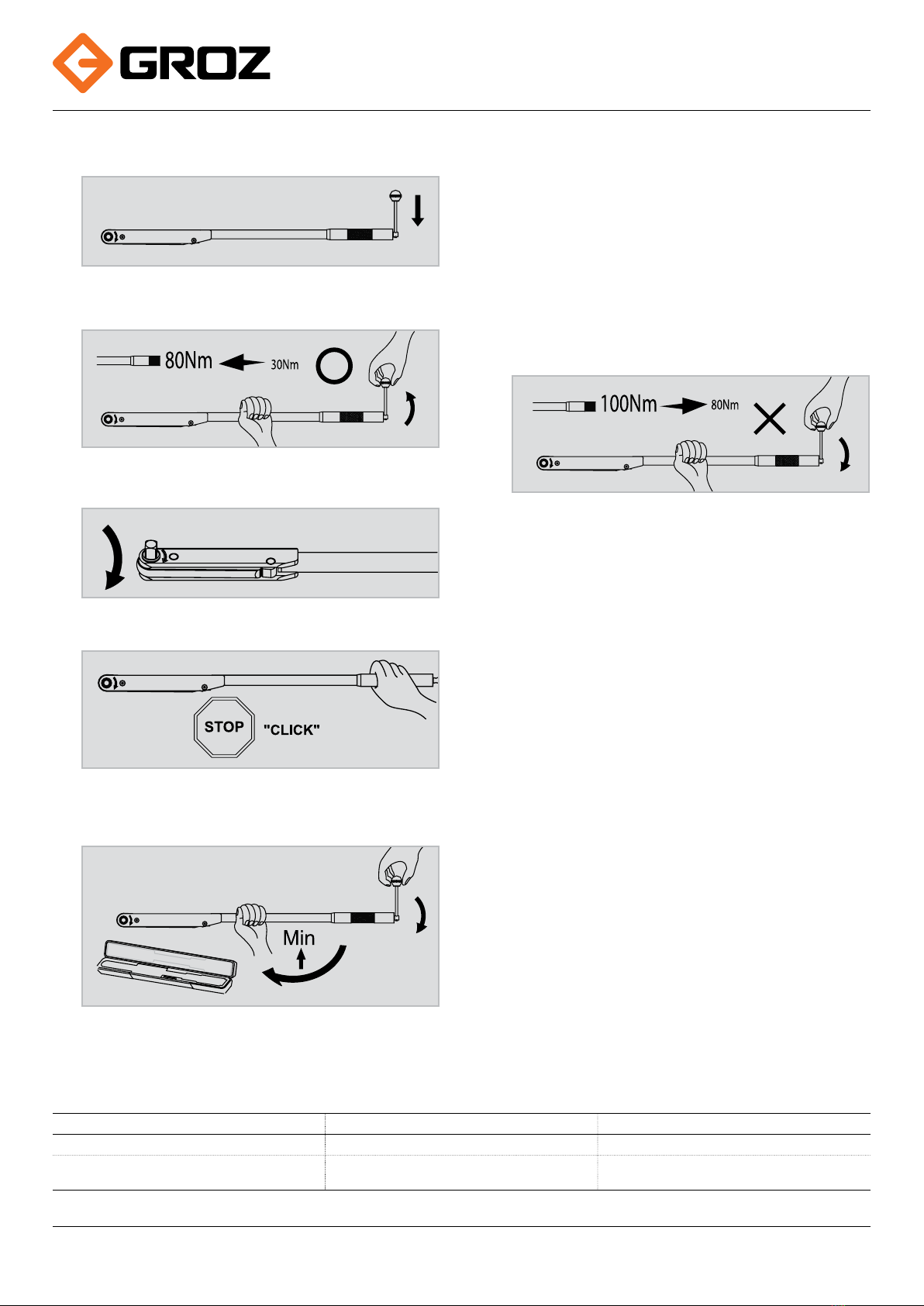

OPERATION

1. Set the Torque Wrench to the desired torque by pulling the

lever at the end,

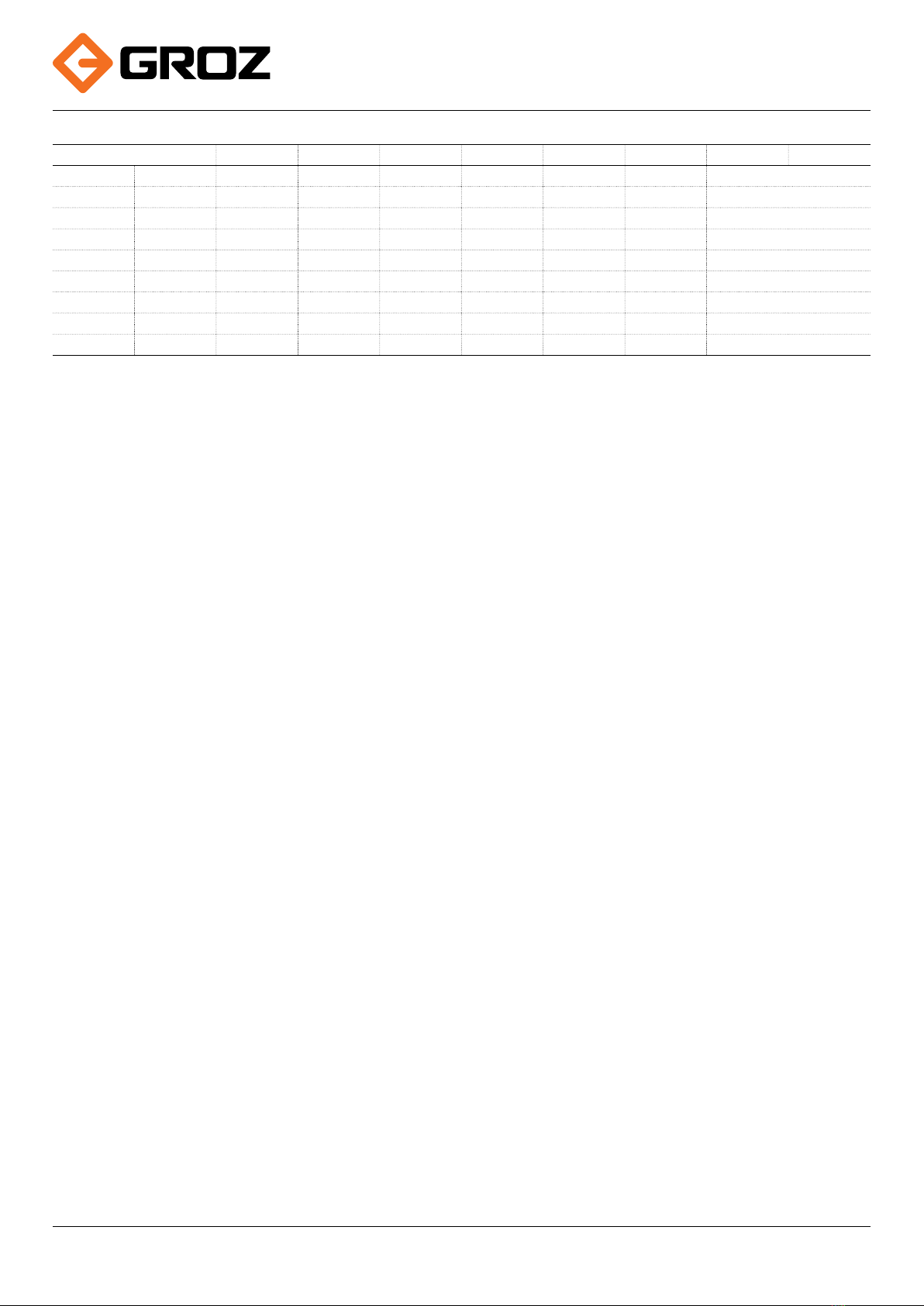

2. Rotate it clockwise to increase the torque limit and lock the

lever when desired torque level is reached on the Graduation

Scale present on the handle.

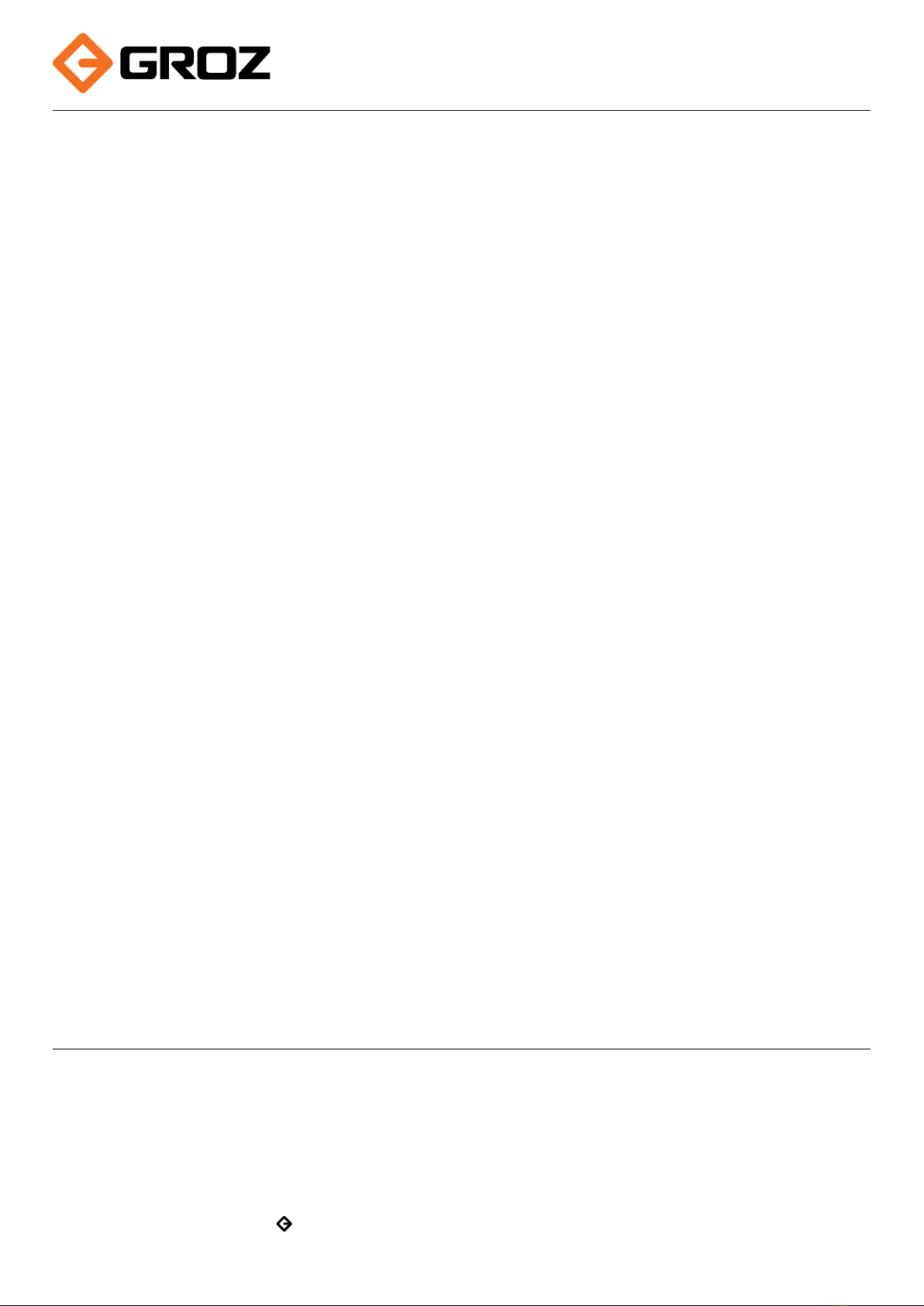

3. Mount the Socket on the Square Drive and Install the Torque

Wrench on the Fastener and apply force on the Middle of

the Handle for Accurate Torque Measurement.

4. Stop applying force when “Click Sound” is heard as the

desired Torque level is reached.

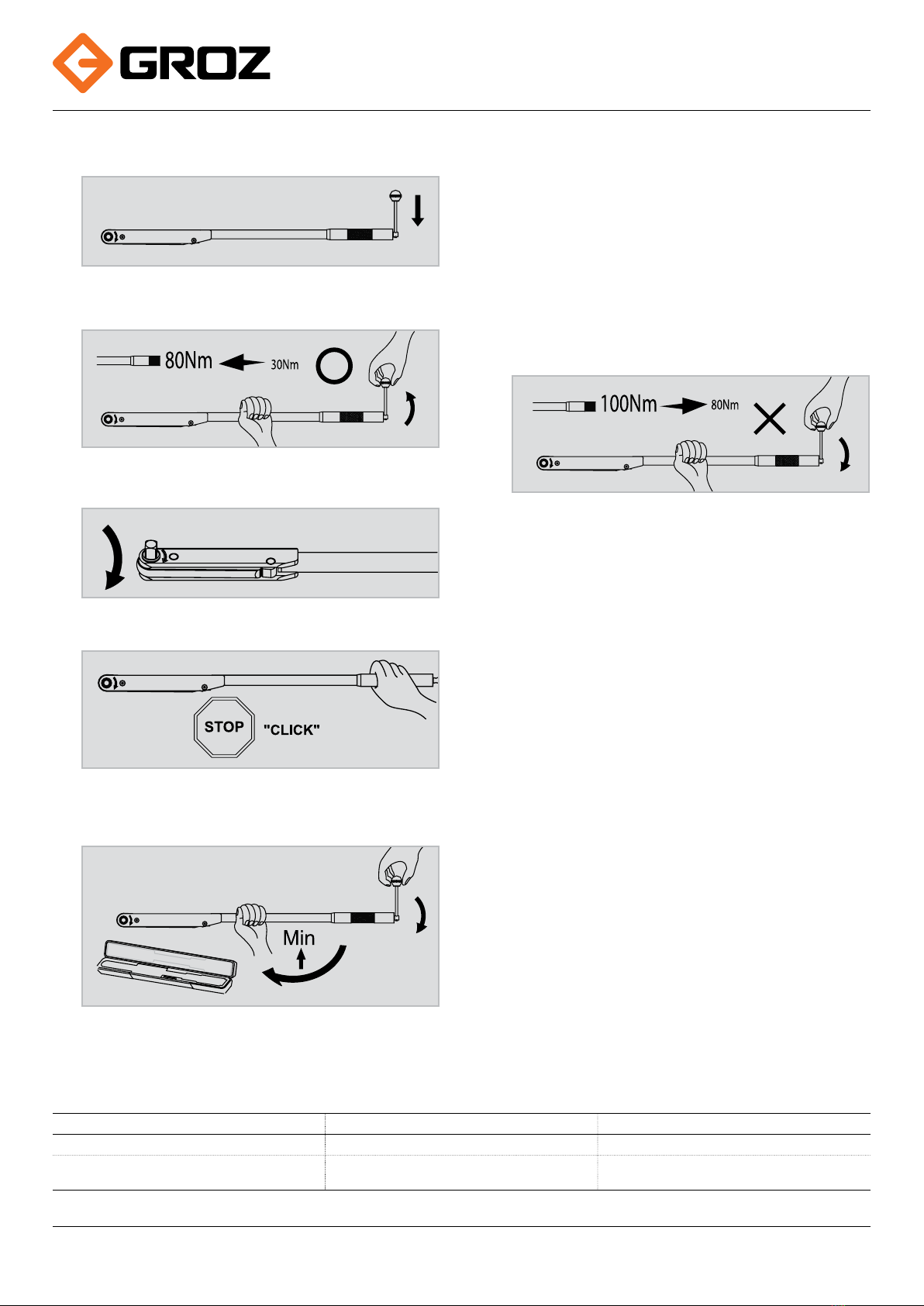

5. After useage, unmount the Torque Wrench from the

Fastener, remove the socket, release the lever and rotate it

anti-clockwise and bring it to the default position and store

it in the box provided.

SAFETY INSTRUCTIONS

• Never use Torque Wrench to break loose fasteners.

• Never use Torque Wrench as a Lever Bar.

• Useage of Damaged Hand Tools, Sockets, Extensions and

Accessories may lead to injury.

• Do not use Torque Wrench as a Hammer.

• Torque Wrenches out of calibration may cause damage to

fastner and /or equipments.

• Do not use Extensions on Handle as it will result in

inaccurate Torque values as well as damage the Fastener

and Torque Wrench.

• Over Tightening of Fasteners may result in Breakage.

• Always use Eye Protection while using hand tools.

• Handle is not Insulated, do not use on live electrical or high

voltage circuits.

• While setting the torque, do not rotate the lever of the

Torque Wrench anti-clockwise as it may result in damage.

MAINTENANCE

• The torque wrench is a precision instrument, and should be

stored with care. Don’t throw it around, use hammer with it,

or use it as lever bar.

• The torque wrench is lubricated for life and should not

be oiled. The only exception is the head which may be

lubricated as needed for smooth operation.

• Always store the torque wrench in the box after use, to

prevent dirt and humidity from damaging the tool.

• Never disassemble the torque wrench by yourself. For any

need to disassemble the torque wrench or repair it, please

look for assistance from Groz Approved service centers.

Any incorrect action to disassemble the torque wrench may

result in damage of this instrument.

• The Calibration of the Torque Wrench must be done

regularly to ensure accuracy and it’s owner’s responsibility

. Suggested Calibration period is at least every 12 Months or

even shorter depending on the usage.

STANDARDS

• Each torque wrench is calibrated at the Factory using

Torque Standards according to DIN ISO 6789 & ASME

B107.300-2010, and it is certified that it meets the accuracy

requirements according to DIN ISO 6789 and ASME

B107.300-2010

WARNING

• Do not use the torque wrench for applications exceeding

the maximum torque value of the torque wrench.

• Do not use the torque wrench as a hammer or use hammer

with this tool.

• Do not use torque wrench as a general wrench.

• Do not use non-original extension along with this torque

wrench. It might result in failure.

• Do not over torque.

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Variation in set and actual torque Calibration problem Send for calibration

Not able to pull down the adjustment ring down Safety button not pressed properly Press and hold the safety button properly and

simultaneously pull out the adjustment ring