(QJOLVK*%

3

Installation and operating instructions

! " " # $ # % & " ! " ' ( " # ! )

* + , - , - .

/ &

0 1 . 2 3 4 5 6 7 8 9 8 5 : 637 9

; 1 < 9 = 58 6 :9 5

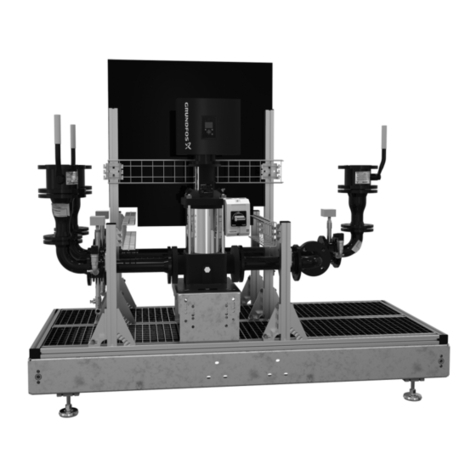

This manual introduces all aspects of your Grundfos CUE

frequency converter in the power range of 0.55 to 90 kW.

Always keep this manual close to the CUE.

> ? @ A B C B D E F G B H I D J K L J M C

CUE is a series of external frequency converters especially

designed for pumps.

Thanks to the start-up guide in the CUE, the installer can quickly

set central parameters and put the CUE into operation.

Connected to a sensor or an external control signal, the CUE will

quickly adapt the pump speed to the actual demand.

> ? > N K K F J I E L J M C H

The CUE series and Grundfos standard pumps are a supplement

to the Grundfos E-pumps range with integrated frequency

converter.

A CUE solution offers the same E-pump functionality

• in the mains voltage or power ranges not covered by the

E-pump range.

• in applications where an integrated frequency converter is not

desirable or permissible.

> ? O P B Q B D B C I B H

Technical documentation for Grundfos CUE:

• The manual contains all information required for putting the

CUE into operation.

• The data booklet contains all technical information about the

construction and applications of the CUE.

• Service instructions contain all required instructions for

dismantling and repairing the frequency converter.

Technical documentation is available on www.grundfos.com >

International website > WebCAPS.

If you have any questions, please contact the nearest Grundfos

company or service workshop.

R) S T U V # ! ' ! & $ " W ! $ # ( ' U & " X

Y) Z " # $ ' ( " # X

2.1 General description 3

2.2 Applications 3

2.3 References 3

X

) S [ & " T $ \ ! ]

3.1 Warning 4

3.2 Safety regulations 4

3.3 Installation requirements 4

3.4 Reduced performance under certain conditions 4

]

) Z $ & " [ ( " # ]

4.1 Nameplate 4

4.2 Packaging label 4

^

) _ & ( W ( ! " " #

^

5.1 Reception and storage 5

5.2 Transportation and unpacking 5

5.3 Space requirements and air circulation 5

5.4 Mounting 5

`) a & ( " ( ( # & ( " #

`

6.1 Electrical protection 6

6.2 Mains and motor connection 6

6.3 Connecting the signal terminals 10

6.4 Connecting the signal relays 12

6.5 Connecting the MCB 114 sensor input module 14

6.6 EMC-correct installation 14

6.7 RFI filters 15

6.8 Output filters 15

6.9 Motor cable 15

b

) % & " U # $ & !

R `

c) d # " # U # $ & !

R `

8.1 Uncontrolled operation (open loop) 16

8.2 Controlled operation (closed loop) 16

e) _ & ' # f & f & \

Rb

R g ) S & " " V T U & ! # [ " W & ( # " # % &

R e

10.1 Control panel 19

10.2 Back to factory setting 19

10.3 CUE settings 19

10.4 Start-up guide 20

10.5 Menu GENERAL 23

10.6 Menu OPERATION 24

10.7 Menu STATUS 25

10.8 Menu INSTALLATION 26

R R ) S & " " V T U & ! # [ /d h # # a i % # $ ' ( " ! X

Y

R Y )/ # " T # [ ! & " " ! X X

12.1 Control without bus signal, local operating mode 33

12.2 Control with bus signal, remote-controlled operating

mode 33

R

X

) a j " & ( # " # ! ! X X

13.1 Digital inputs 33

13.2 External setpoint 33

13.3 GENIbus signal 34

13.4 Other bus standards 34

R

]

) _ " & ( & $ ! & f ( & X ]

14.1 Cleaning the CUE 34

14.2 Service parts and service kits 34

R^

) k ' " [ $ X ]

15.1 Warning and alarm list 34

15.2 Resetting of alarms 35

15.3 Indicator lights 35

15.4 Signal relays 35

R ` ) h & ( W ( $ " X

`

16.1 Enclosure 36

16.2 Cable entry 36

16.3 Main dimensions and weight 37

16.4 Surroundings 37

16.5 Terminal tightening torques 37

16.6 Cable length 38

16.7 Fuses and cable cross-section 38

16.8 Inputs and outputs 40

16.9 Sound pressure level 40

Rb

) l ! % # ! ]

g

m n o p q p r

s o q t o u t q p v u n w w n u q t p x o y n z u { y v y q p v u n w w n u q t p n p z

t | y o n u q p r q p v u o } ~ u q t p v p v u n w w n u q t p n p z t | y o n u q t p

} v u ~ t

| w q u { w t ~ n w o y r } w n u q t p v n p z n ~ ~ y | u y z

~ t z y v t r t t z | o n ~ u q ~ y

m n o p q p r

u { y v y v n y u q p v u o } ~ u q t p v n o y p t u t v y o y z x

q u

n o y v } w u q p | y o v t p n w q p } o

u { y v y v n y u q p v u o } ~ u q t p v n o y p t u t v y o y z x

q u

n o y v } w u q p

n w } p ~ u q t p t o z n

n r y u t u { y

y } q |

y p u

t u y v t o q p v u o } ~ u q t p v u { n u

n y u { y t y n v q y o

n p z y p v } o y v n y t | y o n u q t p

u { y | }

| v | y y z y ~ y y z v u { y o n u y z v | y y z x u { y

| }

| q w w y t y o w t n z y z