Table of Contents

PNEG-4018B 40-Series 2.66" Corrugation 18' Diameter Bin - Beta 3

Contents

Chapter 1 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

Cautionary Symbols Definitions ............................................................................................................ 6

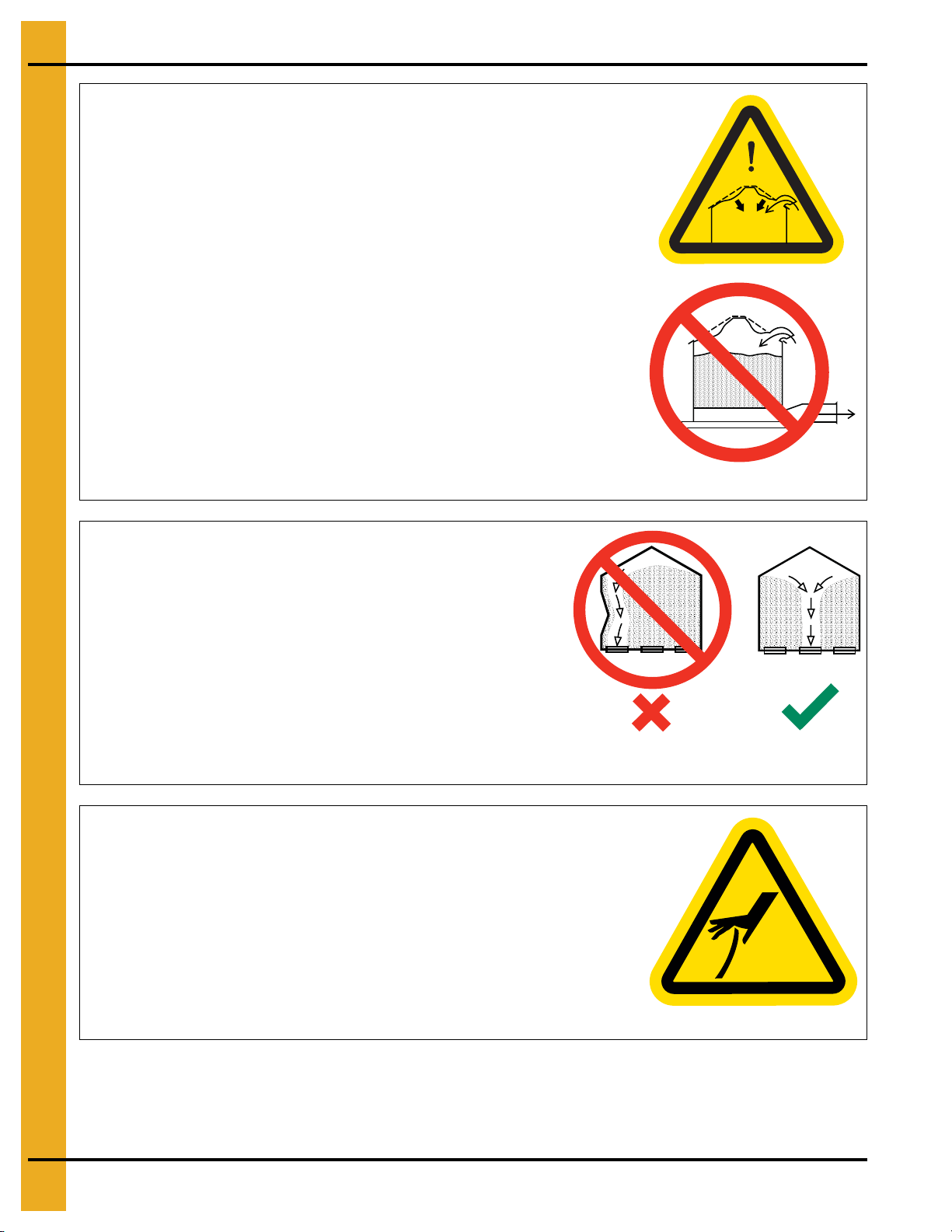

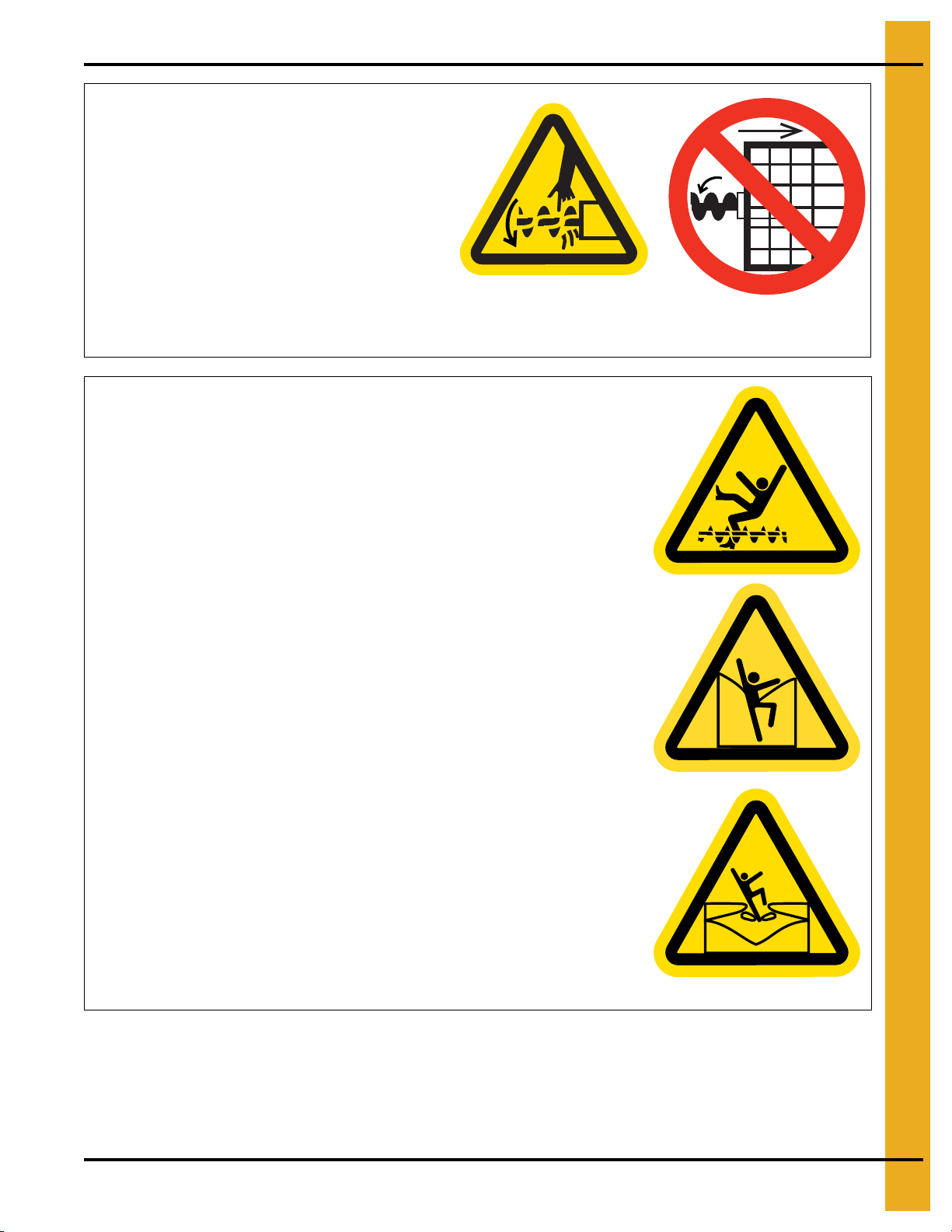

Safety Cautions ..................................................................................................................................... 7

Safety Sign-Off Sheet ......................................................................................................................... 11

Chapter 2 Decals .................................................................................................................................................. 12

Overfill Warning ................................................................................................................................... 14

Chapter 3 General Overview ............................................................................................................................... 15

General Information ............................................................................................................................ 15

Anchor Bolt Charts .............................................................................................................................. 15

Tools Required for Construction ......................................................................................................... 17

Guidelines for Proper Storage of Grain Bin Materials Prior to Construction ....................................... 17

Guidelines for Construction Procedures and Lifting Jack Usage ........................................................ 18

Instructions for Stirring Devices .......................................................................................................... 19

Guidelines for Placement of the Decal Sidewall Sheet ....................................................................... 20

Chapter 4 Bolt and Nut Usage ............................................................................................................................ 21

Hardware Requirements for Sidewalls and Stiffeners ......................................................................... 21

Bolt Identification ................................................................................................................................. 24

Color Chart for Bin Hardware Bucket Lids .......................................................................................... 28

Chapter 5 Assembling Sidewall Sheets ............................................................................................................. 29

Color Codes for Sidewall Gauge Identification .................................................................................... 29

Caulking Detail for Standard (Non-Laminated) Sheets ....................................................................... 30

Caulking Detail for Laminated Quad Pattern Sheets .......................................................................... 32

Chapter 6 Base Angle Installation ...................................................................................................................... 35

Installing the Base Angle ..................................................................................................................... 35

Anchor Bolt Detail ............................................................................................................................... 36

Installing the Base Angle Shims .......................................................................................................... 37

Anchor Bolt Washer Installation .......................................................................................................... 38

Chapter 7 Stiffeners ............................................................................................................................................. 39

Stiffener Part Number Description ...................................................................................................... 39

Color Codes for Stiffener Gauge Identification .................................................................................... 39

Outside Stiffened Laminated Stiffener to Sidewall

(10 Gauge Laminated and Thicker Only) ............................................................................................ 40

Standard Stiffeners ............................................................................................................................. 41

Top Stiffeners ...................................................................................................................................... 42

Stiffeners Splice .................................................................................................................................. 43

Base Stiffeners .................................................................................................................................... 44

Base Boots .......................................................................................................................................... 45

Close-Punch Connection for a 1 Ring Top Stiffener (15-16 Gauge) and

a 2 Ring Stiffener (15-16 Gauge) ........................................................................................................ 45

Close-Punch Connection for a 1 Ring Top Stiffener (10-14 Gauge) and

a 2 Ring Stiffener (8-14 Gauge) .......................................................................................................... 46

Close-Punch Connection for a 1 Ring Top Stiffener (10-14 Gauge) and

a 2 Ring Stiffener (15-16 Gauge) ........................................................................................................ 46

2 Ring Top Stiffener (15-16 Gauge) to a 2 Ring Stiffener (15-16 Gauge) Connection ....................... 47

2 Ring Top Stiffener (8-14 Gauge) to a 2 Ring Stiffener (15-16 Gauge) Connection ......................... 47

2 Ring Top Stiffener (8-14 Gauge) to a 2 Ring Stiffener (8-14 Gauge) Connection ........................... 48

Close-Punch Connection for a 2 Ring Top Stiffener (16 Gauge) to a 2 Ring Stiffener (16 Gauge) .... 48

Close-Punch Connection for a 2 Ring Top Stiffener (16 Gauge) to a 2 Ring Stiffener (8-14 Gauge) . 49

2 Ring Stiffener (15-16 Gauge) to a 2 Ring Stiffener (15-16 Gauge) Connection ............................... 49

Close-Punch Connection for a 2 Ring Stiffener (16 Gauge) to a 2 Ring Stiffener (16 Gauge) ........... 50