Close-Punch Connection for a One-Ring Top Stiffener (10 – 14 Ga) and a Two-Ring Stiffener (8

– 14 Ga) .......................................................................................................................53

Close-Punch Connection for a One-Ring Top Stiffener (10 – 14 Ga) and a Two-Ring Stiffener

(15 – 16 Ga) .................................................................................................................54

Two-Ring Top Stiffener (15 – 16 Ga) to a Two-Ring Stiffener (15 – 16 Ga) Connection....................54

Two-Ring Top Stiffener (8 – 14 Ga) to a Two-Ring Stiffener (15 – 16 Ga) Connection......................55

Two-Ring Top Stiffener (8 – 14 Ga) to a Two-Ring Stiffener (8 – 14 Ga) Connection .......................55

Close-Punch Connection for a Two-Ring Top Stiffener (16 Ga) to a Two-Ring Stiffener (16

Ga) ..............................................................................................................................56

Close-Punch Connection for a Two-Ring Top Stiffener (16 Ga) to a Two-Ring Stiffener (8 – 14

Ga) ..............................................................................................................................56

Two-Ring Stiffener (15 – 16 Ga) to a Two-Ring Stiffener (15 – 16 Ga) Connection ..........................57

Close-Punch Connection for a Two-Ring Stiffener (16 Ga) to a Two-Ring Stiffener (16 Ga) .............57

Two-Ring Stiffener (8 – 14 Ga) to a Two-Ring Stiffener (8 – 14 Ga) Connection..............................58

Close-Punch Connection for a Two-Ring Stiffener (8 – 14 Ga) to a Two-Ring Stiffener (8 – 14

Ga) ..............................................................................................................................58

Close-Punch Connection for a Two-Ring Stiffener (2 – 6 Ga) to a Two-Ring Stiffener (2 – 6

Ga) ..............................................................................................................................59

Two-Ring Stiffener (8 – 14 Ga) to a Close-Punch Base Stiffener (8 Ga) Connection........................59

Two-Ring Stiffener (8 – 14 Ga) to a Close-Punch Base Stiffener (8 Ga) Connection........................60

Two-Ring Stiffener (8 – 14 Ga) to a Close-Punch Base Stiffener (2 – 6 Ga) Connection ..................60

Two-Ring Stiffener (8 – 14 Ga) to a Close-Punch Base Stiffener (2 – 6 Ga) Connection ..................61

Close-Punch Connection for a Two-Ring Stiffener (8 – 14 Ga) to a Base Stiffener (8 Ga) ................61

Close-Punch Connection for a Two-Ring Stiffener (8 – 14 Ga) to a Base Stiffener (8 Ga) ................62

Close-Punch Connection for a Two-Ring Stiffener (2 – 6 Ga) to a Base Stiffener (2 – 6 Ga).............62

Close-Punch Connection for a Two-Ring Stiffener (2 – 6 Ga) to a Base Stiffener (2 – 6 Ga).............63

Two-Ring Stiffener (8 – 14 Ga) to a Base Stiffener (10 – 14 Ga) Connection ..................................63

Two-Ring Stiffener (8 – 14 Ga) to a Base Stiffener (10 – 14 Ga) Connection ..................................64

Two-Ring Stiffener (15 – 16 Ga) to a Base Stiffener (10 – 14 Ga) Connection ................................64

Close-Punch Connection for a Two-Ring Stiffener (15 – 16 Ga) to a Base Stiffener (10 – 14

Ga) ..............................................................................................................................65

Close-Punch Two-Ring Stiffener (2 – 6 Ga) to a Laminated Stiffener (2 Ga) with an Insert (10 –

12 Ga)..........................................................................................................................65

Close-Punch Two-Ring Stiffener (2 – 6 Ga) to a Laminated Stiffener (2 Ga) with an Insert (10 –

12 Ga)..........................................................................................................................66

Close-Punch Laminated Stiffeners (2 Ga) with Inserts (10 – 12 Ga)...............................................66

Close-Punch Laminated Stiffener (2 Ga) with an Insert (10 – 12 Ga) to a Laminated Base Stiff-

ener (2 Ga) with a Base Insert (10 – 12 Ga).....................................................................67

Base Stiffener (10 – 14 Ga) to a Base Boot Connection................................................................67

Close-Punch Connection for a Base Stiffener (10 – 14 Ga) to a Base Boot ....................................68

Close-Punch Connection for a Base Stiffener (8 Ga) to a Base Boot..............................................68

Close-Punch Connection for a Base Stiffener (2 – 6 Ga) to a Base Boot ........................................69

Close-Punch Connection for a Base Stiffener (6 Ga) to a Base Boot..............................................69

Close-Punch Connection for a Base Stiffener (8 Ga) to a Base Boot..............................................70

Close-Punch Laminated Base Stiffener (2 Ga) with Insert (10 – 12 Ga) to a Base Boot ...................70

Close-Punch Standard Stiffener to a 12–Bolt Pattern Laminated Stiffener with Insert......................71

12–Bolt Pattern Close-Punch Laminated Stiffeners with Insert ......................................................71

Close-Punch 12–Bolt Pattern Laminated Stiffener to Laminated Base Stiffener with an Inserts to

a Base Boot..................................................................................................................72

Close-Punch 12–Bolt Pattern Laminated Stiffener to Laminated Base Stiffener with an Inserts to

a Base Boot..................................................................................................................73

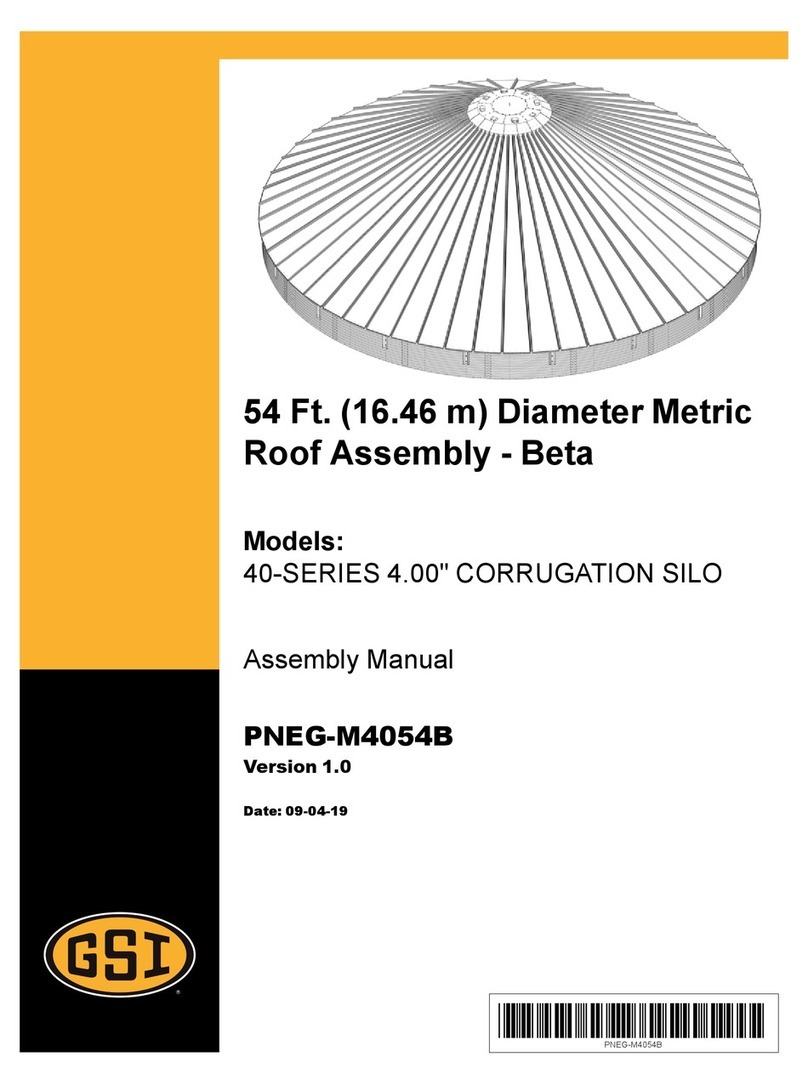

Chapter 7 Roof Assembly........................................................................................................................75

Installing the Roof Rafter Bracket to the Top Outside Stiffener.......................................................76

Installing the Eave clip and Intermediate Eave Angle to the Sidewall Sheet....................................77

Attaching the Center Collar Rafter Clips to the Rafter ...................................................................78

Assembling the Mounting Brackets to the Center Collar ...............................................................79

Center Collar Placement............................................................................................................80

4Pneg-4036-10 36 Ft Diameter Bin with 10K Roof