Table of Contents

PNEG-1510 Top Dry 24', 30' and 36' Manual Batch 3

Contents

Chapter 1 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

Chapter 2 Decals .................................................................................................................................................... 6

Roof Damage Warning and Disclaimer ................................................................................................. 6

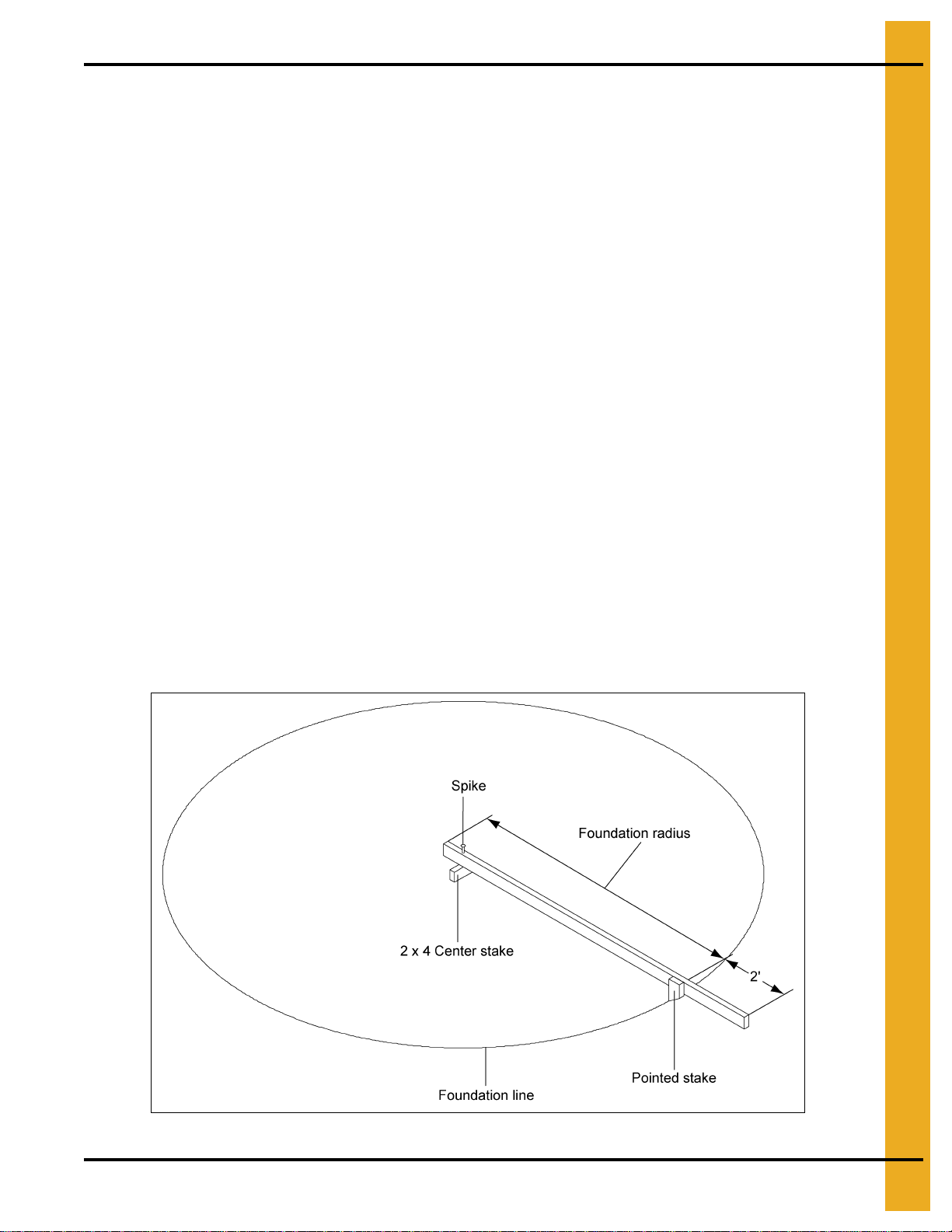

Chapter 3 Foundation Requirements ................................................................................................................... 9

Foundation Requirements for Top Dry Bins (4.00" Top Dry Bin Corrugation) ...................................... 9

Circular Foundation Form ................................................................................................................... 10

Octagonal Foundation Form ............................................................................................................... 11

Inline Centrifugal Fan Pad ................................................................................................................... 12

Duct and Drying Fan Pad Optional ..................................................................................................... 13

Frost Free Foundation Top Dry Bins ................................................................................................... 14

Frost Free Pad .................................................................................................................................... 15

Anchor Bolt Placement ........................................................................................................................ 16

Chapter 4 Hardware ............................................................................................................................................. 17

Hardware/Bolting Requirements ......................................................................................................... 17

Location of Accessories ...................................................................................................................... 20

Very Important ..................................................................................................................................... 21

Chapter 5 Sidewall Construction ........................................................................................................................ 22

Sidewall Gauges ................................................................................................................................. 22

Sidewall Erection Instructions ............................................................................................................. 23

Caulking Detail .................................................................................................................................... 24

Sidewall Construction Instructions ...................................................................................................... 25

Lifting Jacks and Brackets .................................................................................................................. 26

Lifting Jack Usage ............................................................................................................................... 27

Chapter 6 Stiffener Details .................................................................................................................................. 28

Stiffener Gauges ................................................................................................................................. 28

Outside Stiffeners ................................................................................................................................ 29

Top Stiffener Starting Location ............................................................................................................ 31

Stiffener Installation and Location ....................................................................................................... 32

Bolting Requirements Two (2) Stiffeners per Sidewall Sheet ............................................................. 33

Stiffener and Seam Locations ............................................................................................................. 34

Chapter 7 “C” Channels ...................................................................................................................................... 35

Stiffener to “C” Channel Bracket Installation....................................................................................... 35

“C” Channel Installation ....................................................................................................................... 36

Center Collar Assembly ...................................................................................................................... 37

Chapter 8 Installation .......................................................................................................................................... 38

Rafter Installation and Floor Support Angle Attachment ..................................................................... 38

Purlin Installation ................................................................................................................................. 39

Dump Hopper Installation .................................................................................................................... 42

Floor Sheet Installation ....................................................................................................................... 42

24' Leveling Band Post Installation ..................................................................................................... 43

30' Leveling Band Post Installation ..................................................................................................... 44

36' Leveling Band Post Installation ..................................................................................................... 45

Flashing Bolt Installation ..................................................................................................................... 46

Eave Flashing Installation ................................................................................................................... 46

Eave Flashing Splice ........................................................................................................................... 47

Outer Dump Chutes ............................................................................................................................ 48

Intermediate Dump Chutes ................................................................................................................. 49

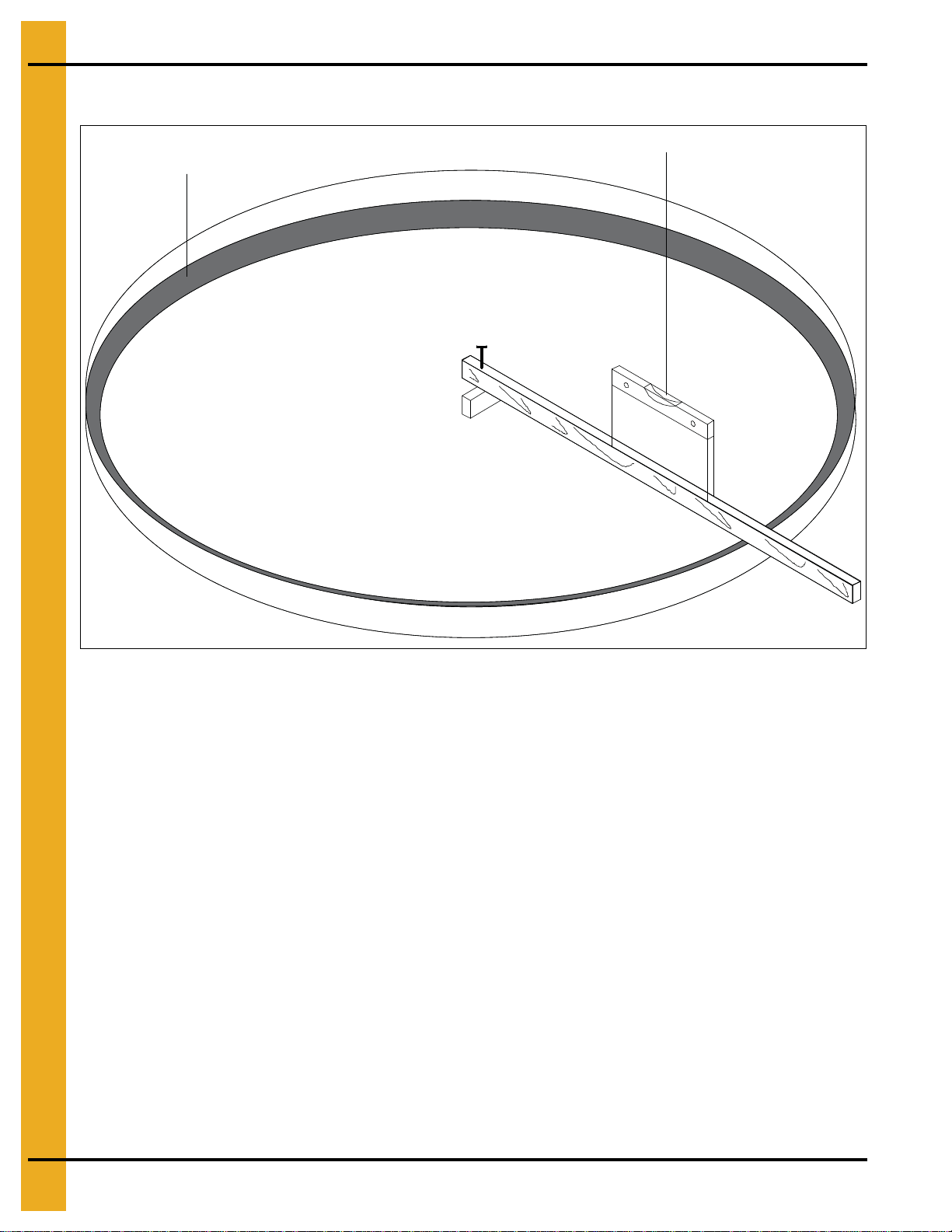

24' Leveling Band Location ................................................................................................................. 50

30' Leveling Band Location ................................................................................................................. 51

36' Leveling Band Location ................................................................................................................. 53