ones, e.g. pregnant women, persons with cardiac or

pulmonary diseases or anaemia, persons under the

influence of alcohol and persons at heights. Make sure you

have read all the maintenance instructions and have

understood them. Keep these Operating Instructions for

future reference. They are your guide for safe and

professional handling of this heating unit.

●Use only oil to prevent fire and risk of explosion. Petrol,

crude oil, paint thinners, alcohol and other highly

flammable fuels must not be used in any case.

Fuel:

a) Staff providing refuelling must be trained and fully

familiarised with the manufacturer's instructions and

applicable directives for safe refuelling of heating

units.

b) Only oil may be used for refuelling.

c) Any flame including the pilot flame must be blown out

to allow the heating unit to cool down before

refuelling.

d) Fuel lines and connections must be checked for

leaking when refuelling takes place. Any leaking must

be repaired before putting the heating unit back into

operation.

e) The maximum fuel daily dose should only be stored

in buildings near the heating unit. Large fuel reserves

to be stored outside the building.

f) All fuel storages must be at least 7 m from heating

units, burners, welders and similar inflammable

sources (exception being a fuel tank integrated in the

heating unit).

g) If applicable, fuel storage should only be limited to

spaces where the flooring design prevents leaked

fuel accumulation and the fuel cannot catch fire as a

result of deeply stored inflammable sources.

h) Fuel must be stored in accordance with the local

official regulations.

General information:

•Never use the heating unit near petrol, paint thinners

or other easily combustible fumes.

•Follow all local provisions and regulations when using

this heating unit.

•Heating units used near reinforcement grids,

canvases or other coverings must be placed in a safe

distance from these materials. The recommended

minimum distance is 3,5 m. Moreover, using fireproof

coverings is recommended. Fireproof coverings must

be safely attached to be protected against catching

fire and prevent heating unit being touched and

turned over due to wind gust.

•To be used in well ventilated spaces only. Before

putting the appliance into operation, make sure air

vent of at least 2,800 cm² for fresh external air is

provided for heating output of 100,000 BTU per hour.

•To be used in spaces with no flammable vapours or

high dust levels only.

•To be used at voltage and frequency specified on the

type label only.

•A properly earthed extension cable with a three-pin

plug to be used at all times.

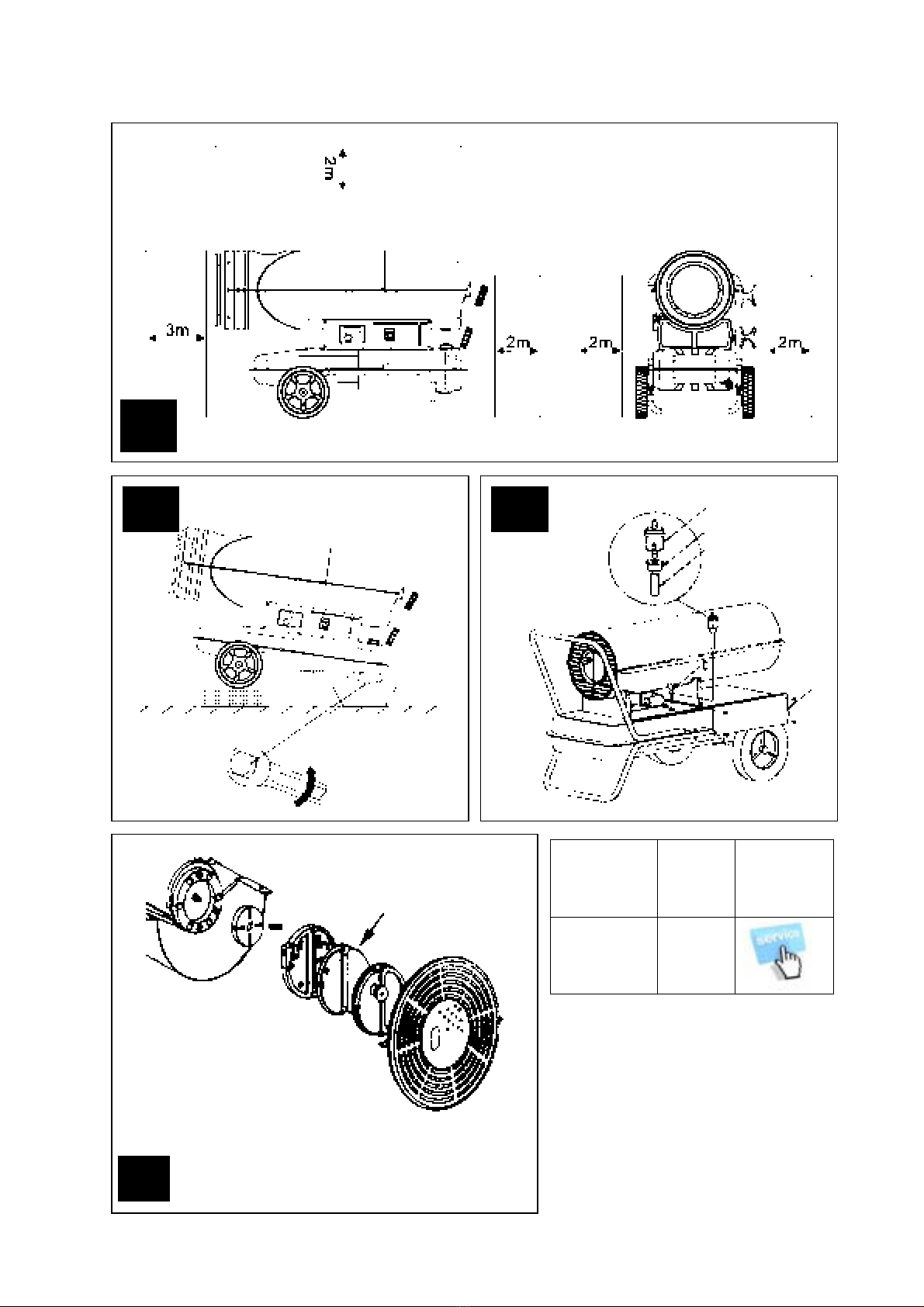

•Minimum distance from flammable materials and

persons:

exhaust: 3 m

at sides, upper and rear side: 2 m. (see pic. D)

•To prevent a risk of fire, the hot heating unit or

heating unit just being operated must be placed on a

safe and level surface.

•The heating unit must be transferred or stored in a

horizontal position to prevent fuel leaking.

•Keep children and pets in a sufficient distance from

the heating unit.

•Unplug the heating unit if not being operated.

•Never use the heating unit in residential rooms and

sleeping rooms.

•Never block the air inlet (rear side) and air outlet

(front side) of the heating unit.

•If the heating unit is hot, being operated or plugged, it

must never be transferred, handled, refuelled or

maintained.

•Do not fit any piping on the front and rear side of the

heating unit.

CAUTION:

Oil to be used only to prevent fire or explosion.

Using the appliance as a heat source for events

and parties or operating the appliance in stables is

strictly prohibited!

Use as designated

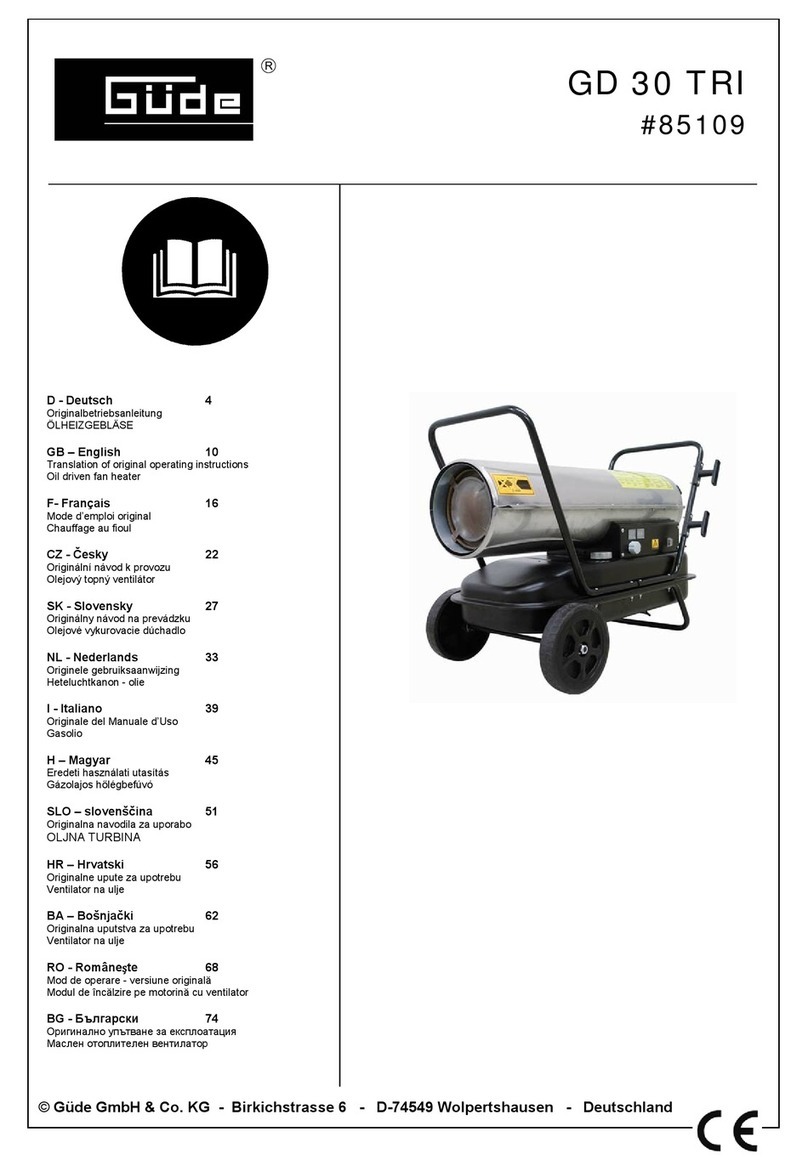

GD-series oil driven fan heaters are to be exclusively used

for indirect heating and drying out in well-ventilated rooms

or in dry outdoor areas, in a safe distance from flammable

materials and persons and animals. A stable and

horizontal surface must be provided for operation. Oil only

is allowed as fuel.

(As far as safety, functionality and service life are

concerned, the GD series follows the latest criteria: the

safety equipment guarantees appropriate working of the

appliance; operating noise have been reduced to minimum

levels and the careful material selection makes it as much

reliable as possible.)

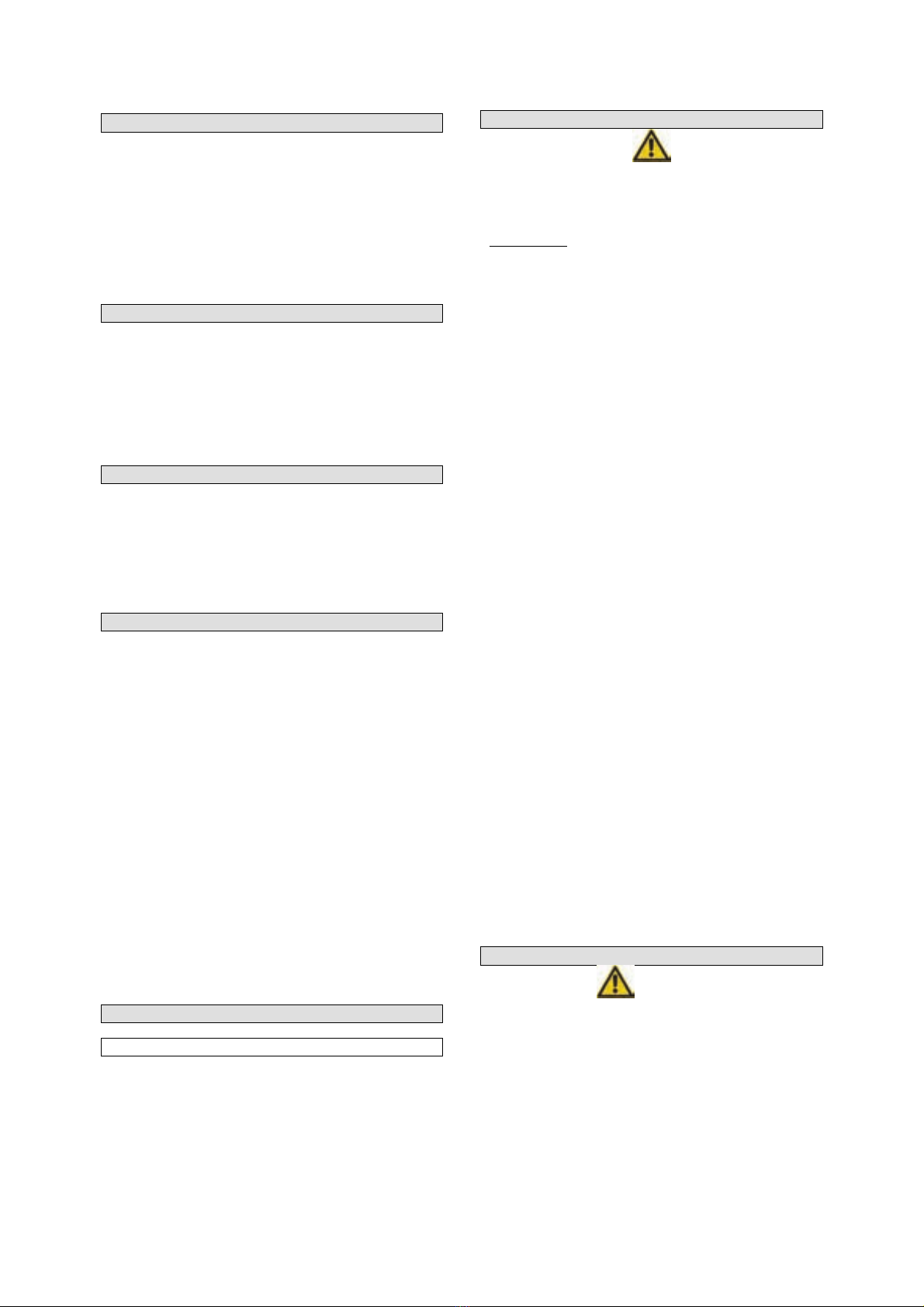

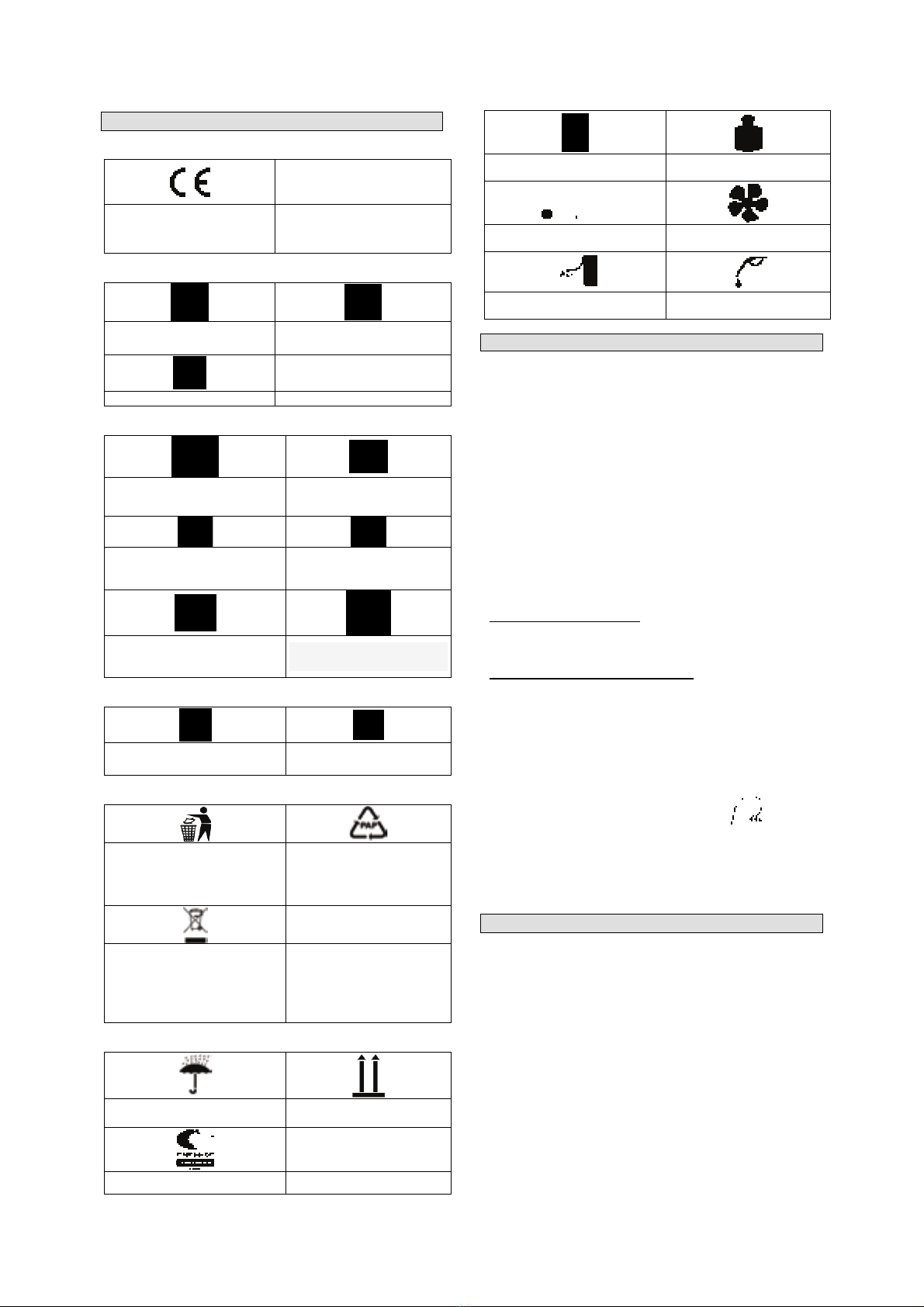

Assembly, pic. B

Description, pic. B

1. Frame

2. Screw

3. Washer

4. Wheel cover

5. Wheel

6. Case

7. Axis

These models are supplied including wheels and handles.

Wheels, handles and the respective fixing components can

be found in the shipment cardboard.

Necessary tools:

- PH 2 cross-head screwdriver

- Forked wrench

- Hammer

1. Put the axis through the supporting wheel frame.

Attach the wheels to the axis.

IMPORTANT: During installation, the extended

wheel hub must point in the supporting wheel frame

direction (see picture B)

2. Apply a cap nut on each axis end and fix it by slight

tapping with a hammer.

3. Put the fan heater on the supporting wheel frame.

Make sure the fan heater air inlet (at the back) is

above the wheels. The holes on the fuel tank flange

must match the holes on the supporting wheel frame.