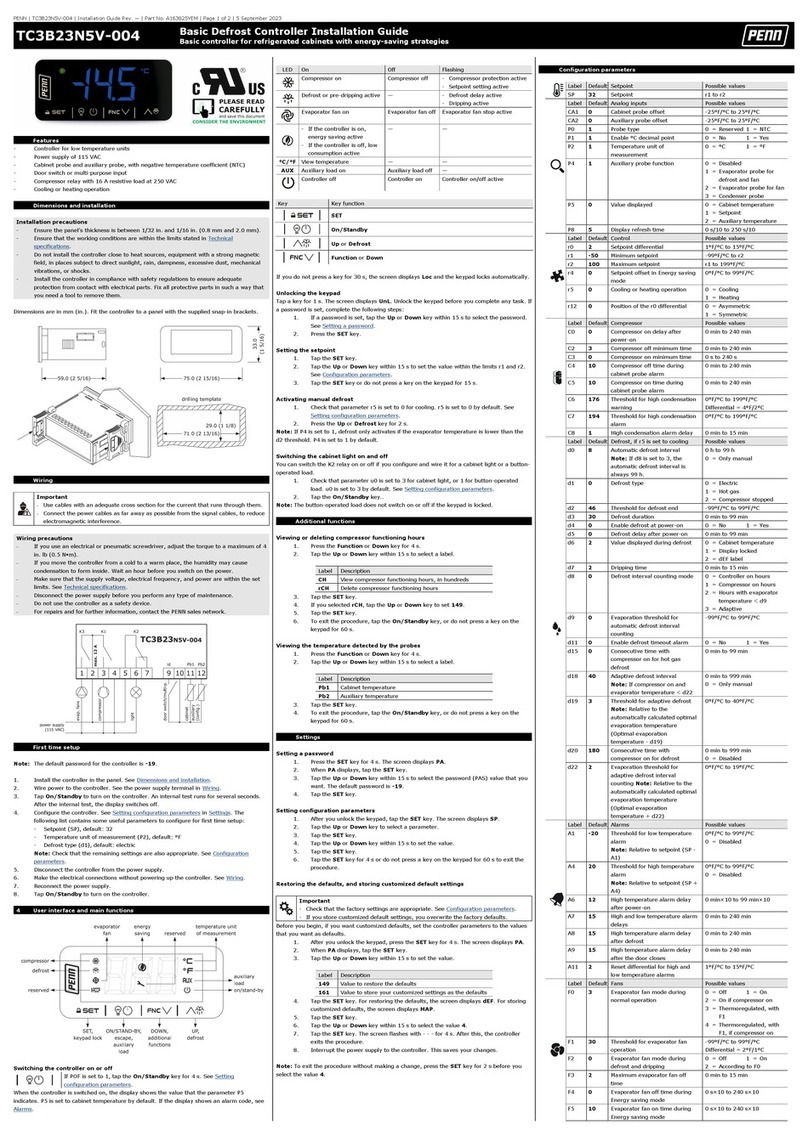

Additional Features

User interface

The controller’s system status and setup information

displays on an LCD UI. The status indicator icons show

the defrost, cooling, evaporator fan, and alarm features

and provide a visual indication of the system status and

alarms. The defrost and alarm icons also function as keys

to initiate unscheduled defrost cycles and clear system

alarms. You can use four touchpad keys to navigate

the system, see detailed system information, change

parameter settings, and respond to system alarms.

Refrigeration mode

Refrigeration mode is the normal operating mode of the

MR5 Controller. The system cycles the compressor on and

off, and operates the evaporator fans according to the

setup selections to maintain the setpoint temperature in

the refrigerated space. While in refrigeration mode, the

Fan icon indicates the evaporator fan relay status and

the defrost relay and Defrost icon remain off. The LCD UI

displays the HOME screen, which shows the system name,

date, time, space temperature, and setpoint.

Defrost mode

The selections you make for defrost type, defrost

termination type, and evaporator fan behavior determine

how the refrigeration system operates during defrost

mode. To manually start or stop a defrost cycle, press the

Defrost icon for several seconds.

The MR5 Controller includes the following defrost modes:

• You commonly use off-cycle defrost on medium

temperature refrigeration applications. During off-

cycle defrost, refrigerant flow to the evaporator is

interrupted. The evaporator fans remain on to move air

over the evaporator coil and melt any accumulated frost

or ice.

• Electric defrost uses electric resistive heating elements

that the defrost relay controls to melt the ice, which

accumulates on the evaporator coil during normal

cooling operation. Low-temperature refrigeration

applications often use electric defrost.

• Hot gas defrost systems use a bypass valve controlled

by the defrost relay and extra refrigerant piping to

temporarily reroute the hot gas discharge from the

compressor through the evaporator coil. Low and very

low temperature refrigeration applications use hot gas

defrost.

Defrost termination types

The MR5 Controller can terminate defrost durations

based on time or temperature. Temperature termination

applications use a temperature sensor (SN2) that you

install on the evaporator.

• Time-based defrost terminates the defrost cycle when

the user-defined maximum defrost duration elapses.

• Temperature-sensor defrost terminates the defrost

cycle when the temperature sensed at the evaporator

sensor (SN2) reaches the user-defined defrost

termination temperature.

• Temperature-switch based defrost terminates the

defrost cycle when the temperature at the defrost

termination switch on the evaporator reaches the

switch’s cutout temperature.

Note: The maximum defrost duration overrides both

temperature-sensor and temperature-switch defrost

termination and terminates the defrost cycle, even

if the evaporator does not reach the termination

temperature.

Defrost schedule types

You can set up the following defrost schedule types on the

MR5 Controller:

• Scheduled defrost facilitates the set up of zero defrost

cycles to eight defrost cycles per day on a fixed

schedule. Automatic scheduled defrost sets up the

defrost intervals at equal time frequencies based on

the selected number of defrost cycles per day. Manual

scheduled defrost facilitates the selection of specific

times at which each defrost cycle starts during the day.

• Adaptive defrost does not follow a user-defined time

schedule, but instead continuously adapts to the

refrigeration system conditions and schedules defrost

cycles as needed. Adaptive defrost adjusts the defrost

schedule to achieve a user-defined defrost duration.

You set up the expected defrost duration, the first

defrost interval, and a defrost termination temperature.

The adaptive defrost system adjusts the length of the

defrost interval so that the expected defrost duration

coincides with the time that the evaporator reaches the

termination temperature.

Adaptive defrost setup parameters

The MR5 Controller includes the following adaptive defrost

setup parameters:

• The expected defrost duration is the estimated duration

for a complete defrost of the evaporator coil and how

long it takes for the evaporator to reach the defrost

termination temperature after a typical defrost interval.

During the set up of the adaptive defrost, select from

0 minutes to 99 minutes for the expected defrost

duration.

• The defrost interval is the interval in hours between

the start of consecutive defrost cycles. You can define

the initial defrost interval when you set up the adaptive

defrost feature, and the adaptive defrost feature

shortens or lengthens the defrost interval to adapt to

the required interval. Select from 1 hour to 48 hours for

the initial defrost interval.

• Maximum time between defrosts defines the maximum

hours for any adaptive defrost interval. If the system

calculates a defrost interval greater than the maximum

time that you set, the MR5 Controller ignores the

calculation and starts the next defrost duration based

on the maximum time. Select from 3 hours to 24 hours

for the maximum time between defrosts.

MR5 Series Panel Mount Case Controller Product Bulletin2