094204_c_gb_hebvrr_v haacon hebetechnik gmbh – Phone +49 (0) 9375 - 84-0 – Fax +49 (0) 9375 - 8466 3

1. Safety instructions

Duty of care of the operator

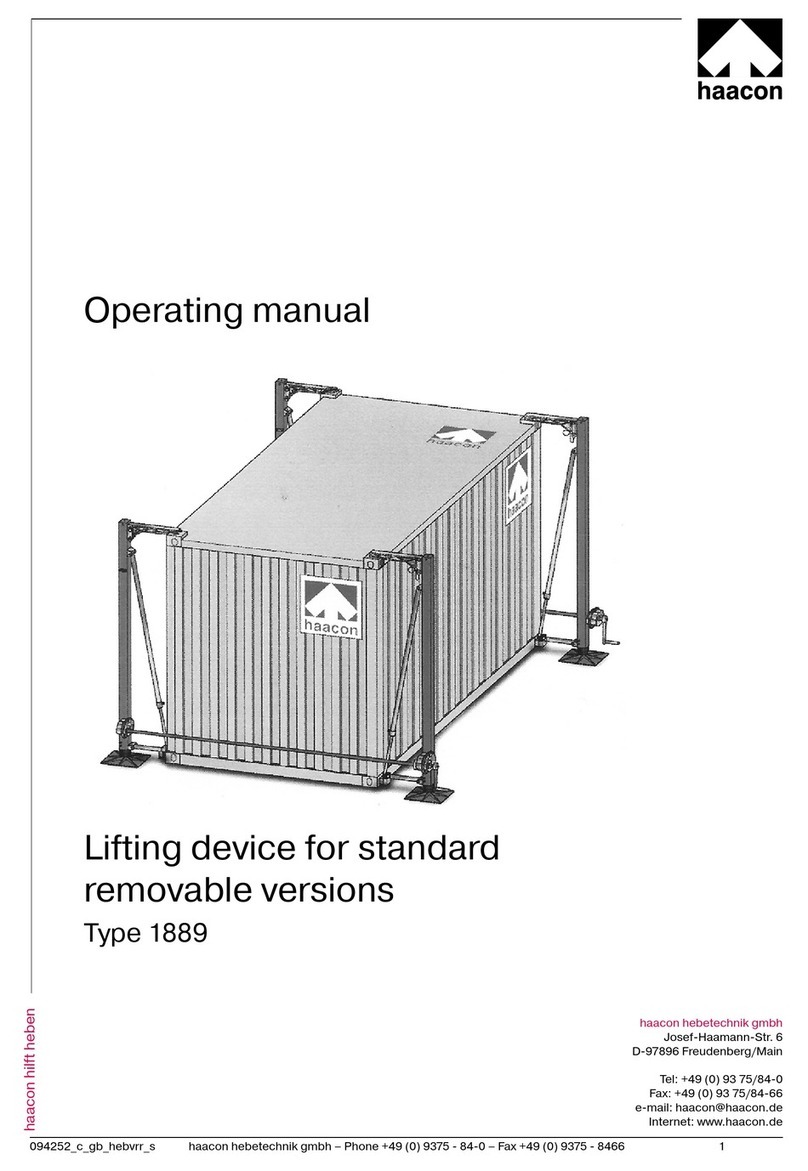

The lifting device Type 1889 has been designed and

built to after the careful selection of the

harmonised standards with which it must comply and

other technical specifications. It is therefore state of

the art and offers maximum safety.

However, this safety level can only be achieved in

practice if all the action required for it is actually taken.

It is a matter for the operator of the lifting device to

plan this action and to check that it is implemented.

The operating must in particular ensure that

the lifting device is only used for the purpose for

which it is design (see the section entitled General).

the lifting device is only operated if it is in perfect

working order and special safety equipment is

checked regularly to ensure that it remains fully

functional.

the operating manual is available at the place of use

of the lifting device at all times in legible

condition.

only suitably qualified and authorised personnel is

allowed to operating, service and repair the lifting

device.

this personnel is instructed at regular intervals in

all matters of industrial safety and environmental

protection and that they are familiar with the opera-

ting manual and the safety instructions contained

there in.

all the safety and warning notices on the lifting

device remain on the device and are kept in legible

condition.

nobody is on, in or under the container with the

mounted lifting device during the lifting or lowering

procedure.

persons only enter the system if the distance bet-

ween the bottom of the container and the ground is

less than 400 mm or load holders are fitted to act as

additional safety devices pursuant to VBG 14.

Basic safety action

To prevent damage and fatal injuries when operating

the lifting device, do not

exceed the maximum (see section entitled Techni-

cal data).

allow people to ride on the device.

work in, on or under the raised load if it exceeds

the maximum height off the ground or load holders

pursuant to VBG 14 are fitted.

–

–

–

–

–

–

–

–

–

–

–

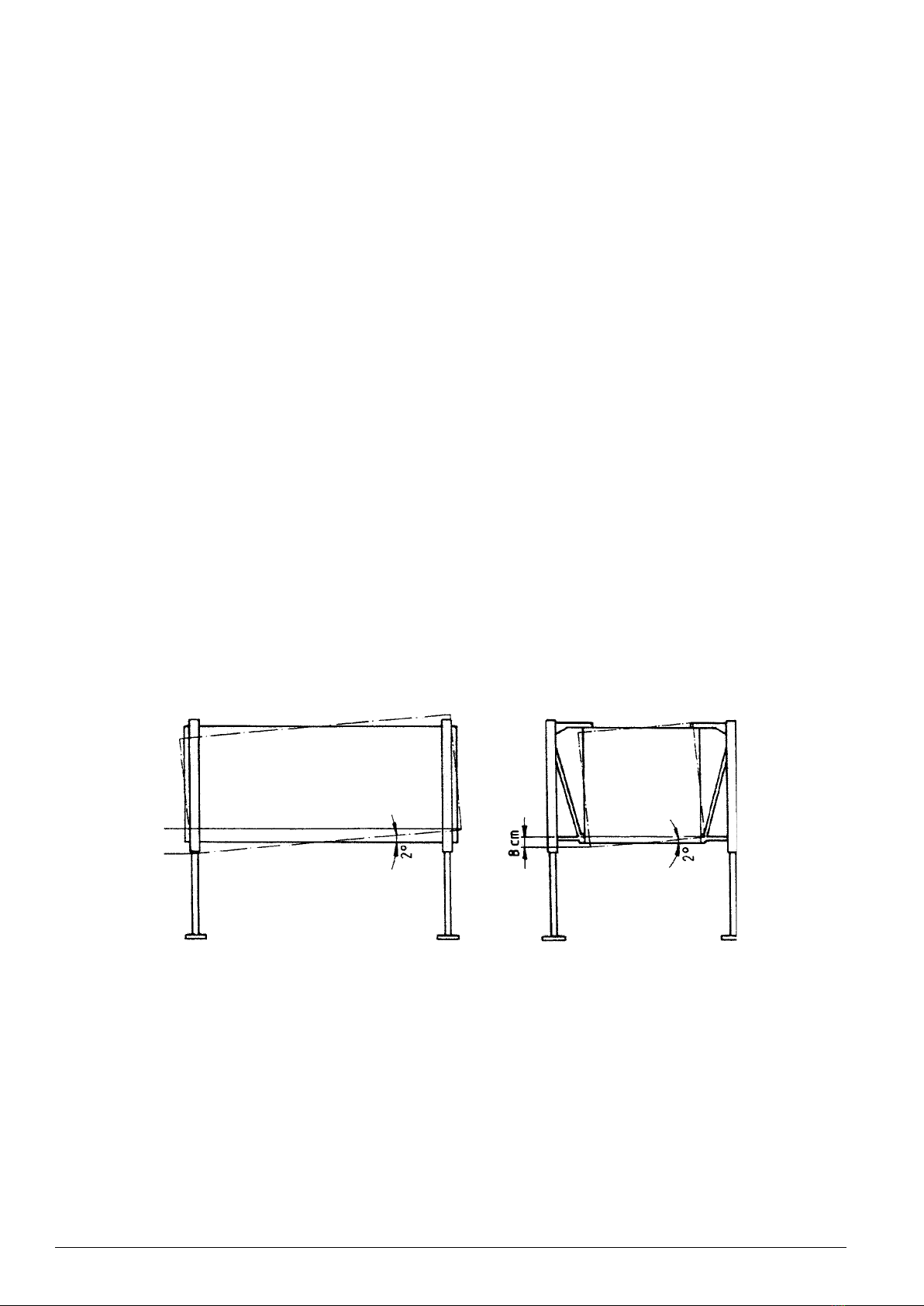

exceed the maximum angle (see section entitled

Other instructions).

set up the device in wind speeds in excess of

64 kph.

You must also ensure that if you wish to lift the maxi-

mum load the centre of gravity of the load is positioned

as centrally as possible between the supports.

Requirements on the operating personnel

The lifting device Type 1889 may only be operated by

people who have been trained, instructed and autho-

rised to do so. These people must be familiar with the

operating manual and act accordingly. The authority of

the operating personnel must be defined clearly.

Damage or defects on the lifting device are to be re-

ported to the appropriate person without delay. Do not

work with the lifting device until the damage or defect

has been rectified.

Servicing and repair work

Servicing and repair work may only be completed by

trained personnel.

Do not make any unauthorised modifications to the

lifting device for safety reasons – this particularly

applies to welding work on load-bearing parts. All

planned modifications must be approved in writing by

haacon hebetechnik gmbh.

Only use original spare parts / original wear parts.

These parts have been specially designed for the

machine. If you use other parts it cannot be guaran-

teed that they are designed and built to withstand the

stresses safely. Parts and special equipment that are

not supplied by haacon hebetechnik gmbh have not

been approved for use on the lifting device.

The maintenance work set out in the operating manual

(cleaning, lubrication, servicing, inspection, etc.) must

be completed on schedule.

–

–