Guidance Notes:

The total load must not exceed the rating of the incoming device or the assigned assembly rating (InA) whichever is the lower. Each neutral and earth

connection must correspond numerically to its outgoing way. Additional blanks (ref. JK01B) are available to cover spare ways.

A pack is provided to label this consumer unit, please consult us for spares or replacements.

Operating Instruction leaet is provided overleaf. This leaet should be left for the end user.

Single conductors below 1.5mm² need to be doubled back in the terminal bar.

Consumer Units incorporating RCDs in TT systems should incorporate an S type (time Delayed) RCCB, e.g. 100 mA s-type RCCB . Alternatively a main

switch with RCBO protection on all outgoing circuits should be used.

Precautions need to be taken to prevent faults to earth on the supply side of the RCD (as per BS7671 regulation 531.4.1)

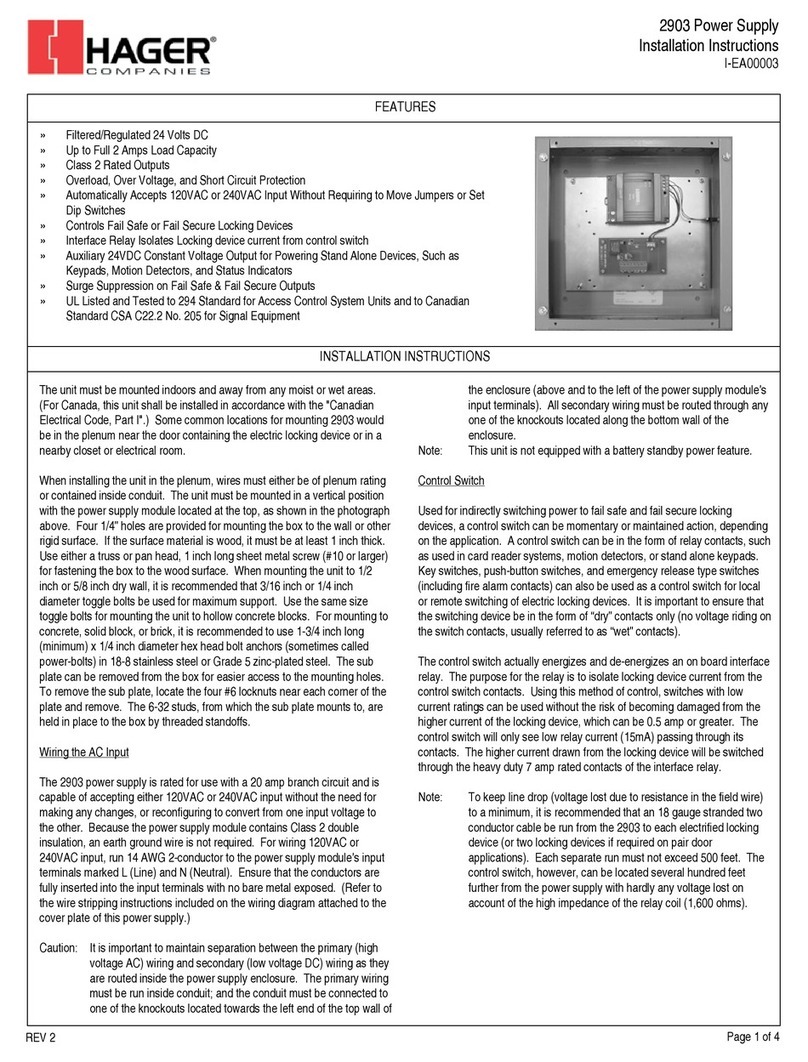

IP Ratings:

Cable access into the consumer unit must maintain the integrity so far as reasonably practicable. In essence, for surfaces accessible after installation,

this means maintaining the requirement for the horizontal top surface of the enclosure to provide a degree of protection of at least IP4X and elsewhere,

IP 2XC. For rear cable access, the minimum number of knockout(s) shall be removed.

Warranty

This distribution board is offered with a 24 month warranty against defective material or manufacture. If a warranty claim is necessary, please call the

technical support number given at the bottom of the page and we will be pleased to help.

For dimensional information and weights please consult the Hager catalogue.

Hager Technical Help Line: 01952 675 689

Hager Technical Fax: 01952 675 557

Website: www.hager.co.uk

E-mail us: info@hager.co.uk

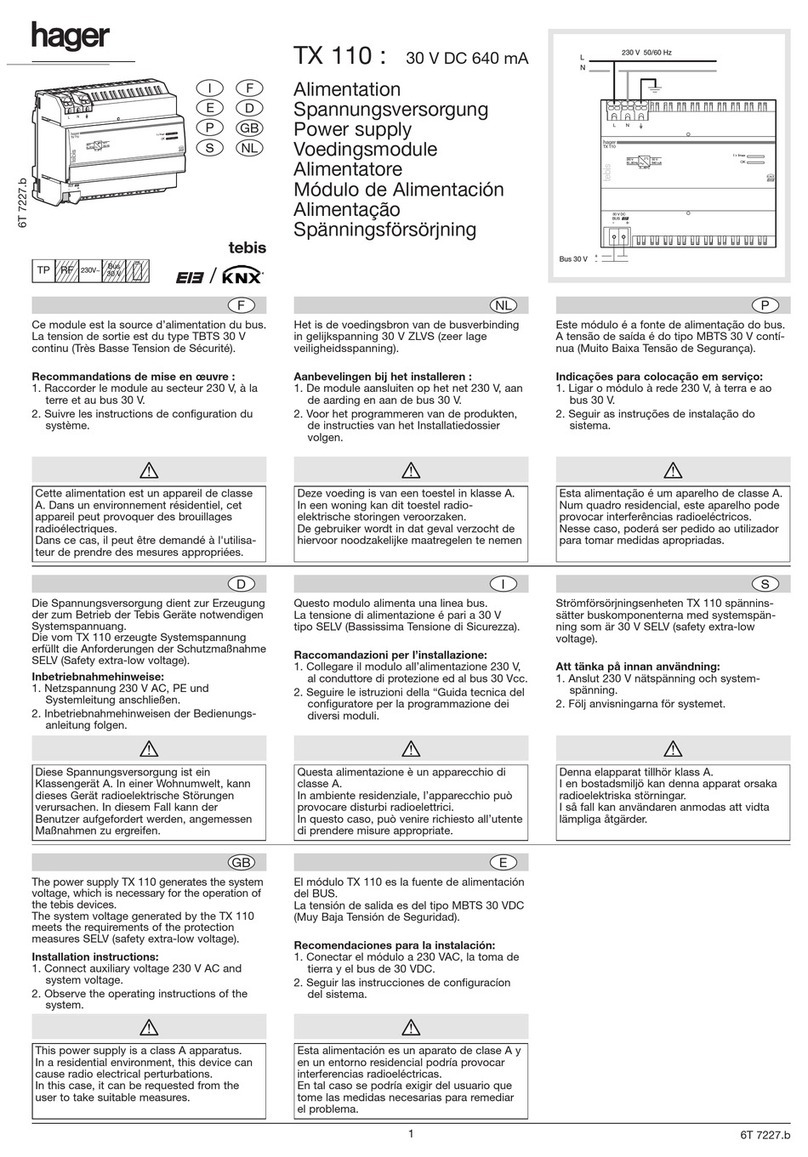

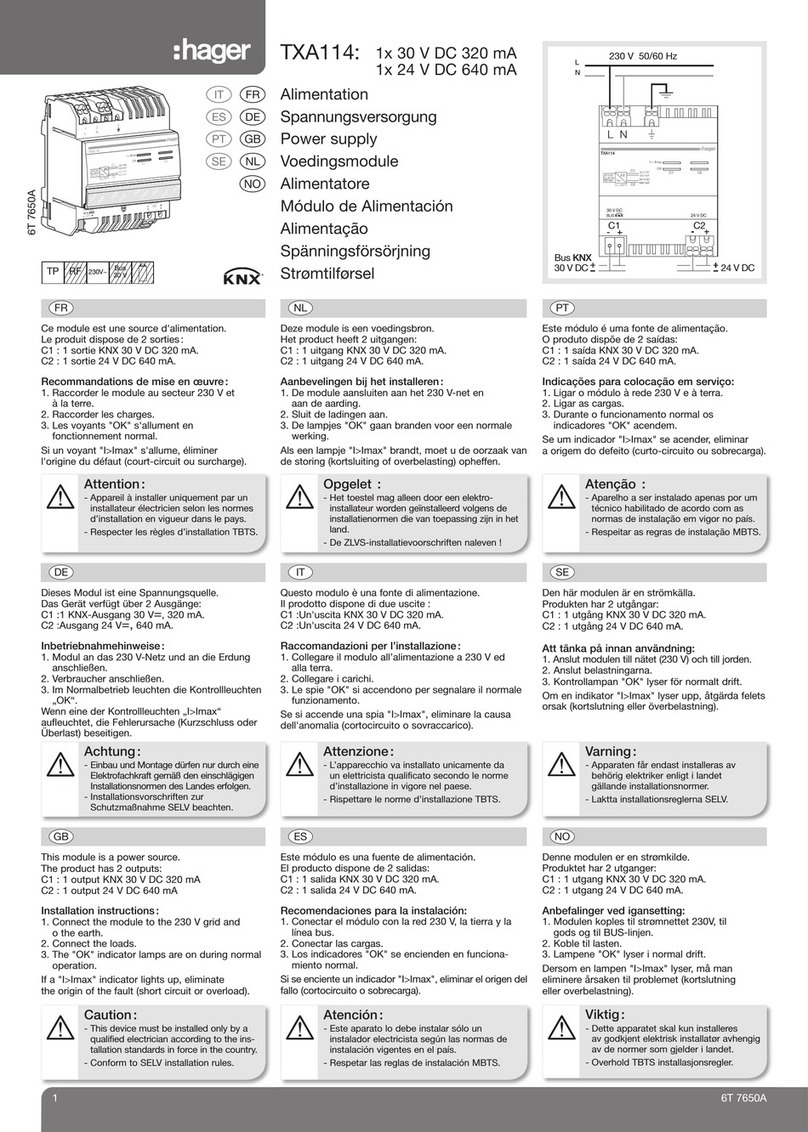

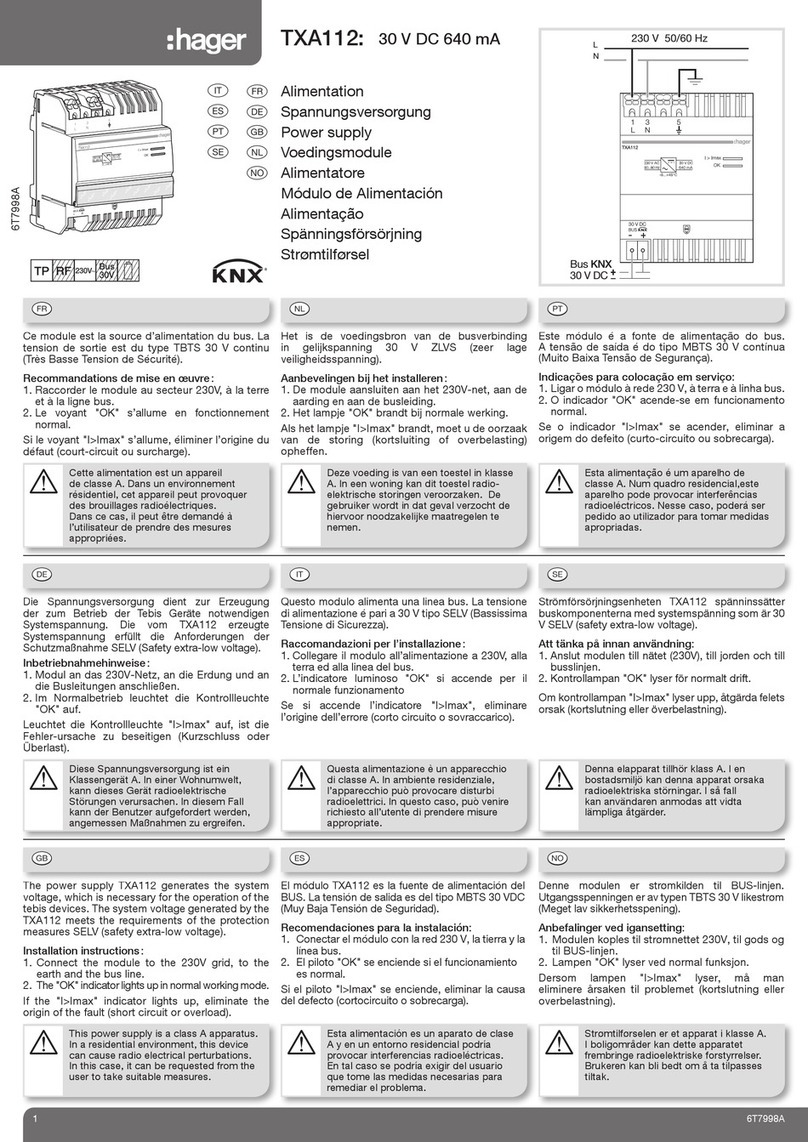

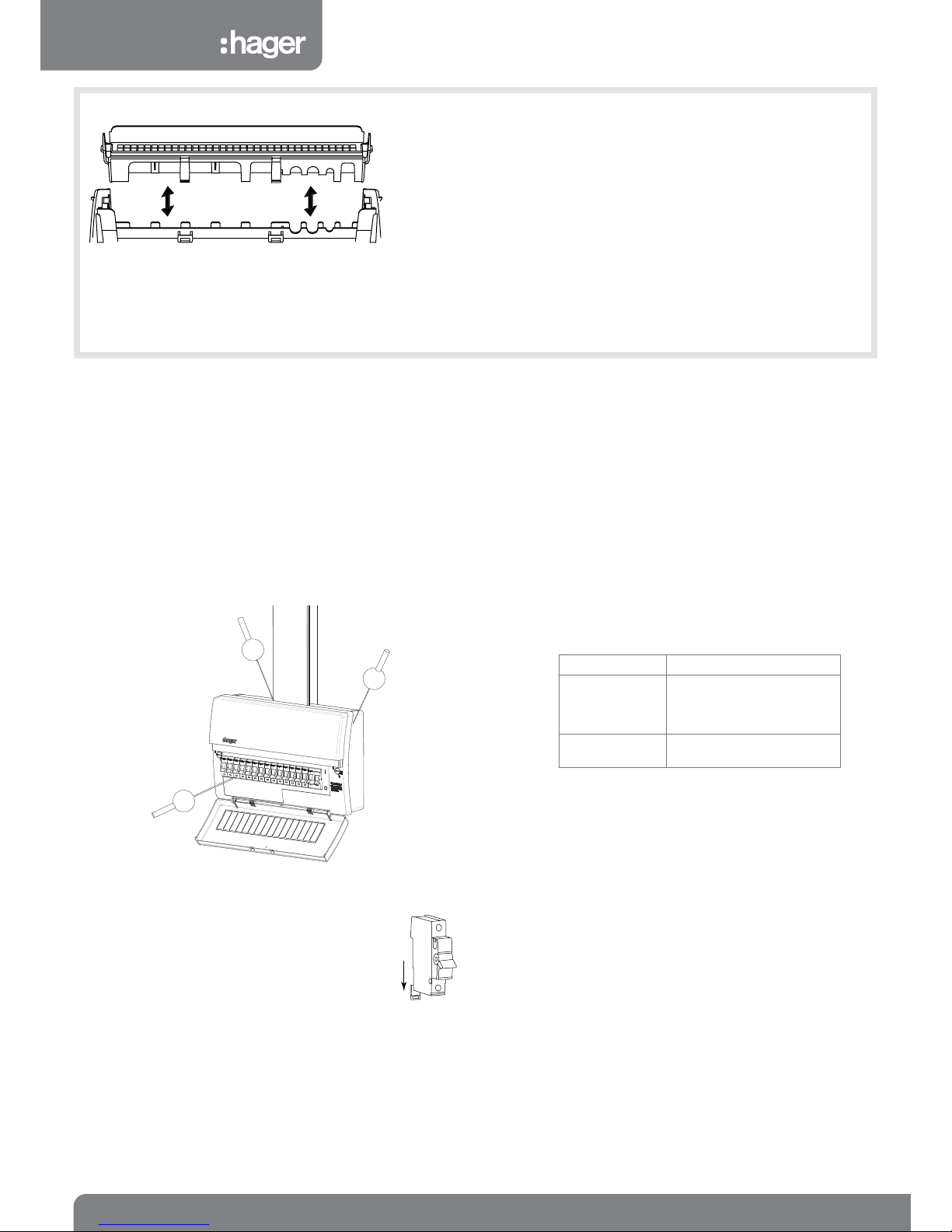

Fitting Hager MCBs and RCBOs:

Only equipment and arrangements specied in Hager’s technical

documentation / catalogue shall be used.

Isolate the electrical supply from the consumer unit.

1. Isolate the electrical supply from the consumer unit.

2. Remove the front cover.

3. Fully slacken the lower terminal of the device.

4. Fully open the bottom device clip (g 1.)

5. Locate the device onto the din rail, and busbar. Ensure that the

busbar tooth is within the device terminal cage.

6. Close the bottom device clip.

7. While holding the device rmly onto the busbar, fully tighten the lower

terminal screw.

8. After tting all outgoing devices and connecting all outgoing cables,

please check the tightness of all cable connections. This should

include all factory made connections, which may have loosened

during installation or transit.

g 1.

IP Code Description

IP2XC Protection against access

with a tool (2.5mm diameter,

100mm long) making contact

with live hazardous parts

IP4X A probe of 1mm diameter

shall not enter the enclosure

Insulated Unit - Removing and replacing the top wall for top surface cabling

(IP4X using foam inserts; 1mm2- 10mm2 conductors BS6004)

1. Press in with index nger on one end release clip while pressing in with thumb

on the inner release clip repeat on the other and lifting the wall away from the

unit.

2. After xing the unit, to replace and reseal, place one of the foam seal strips in

the underside of the wall feature and the other in the base (behind the cables).

Locate the wall and press down. Additional xing points are provided.

Max outgoing top entry cable size 10mm2CSA.

Max incoming Main tails top entry cable size 25mm2CSA.

If larger cables are needed, then enter from any other cable entry point other than

top.

2ZD0632 - Issue 5 03-15

ZD0632 ZD0632

IP2XC

IP2XC

IP4X