Haklift Oy

Asessorinkatu 3-7

20780 Kaarina, Finland

Tel. +358 2 511 5511

www.haklift.com

Lifting Solutions Group

Axel Johnson International

3. Handle assembly

For safe transportation and packaging, handles of the truck have been disassembled when ex-

factory. Therefore, users should assemble the handles before use. Assembling procedure:

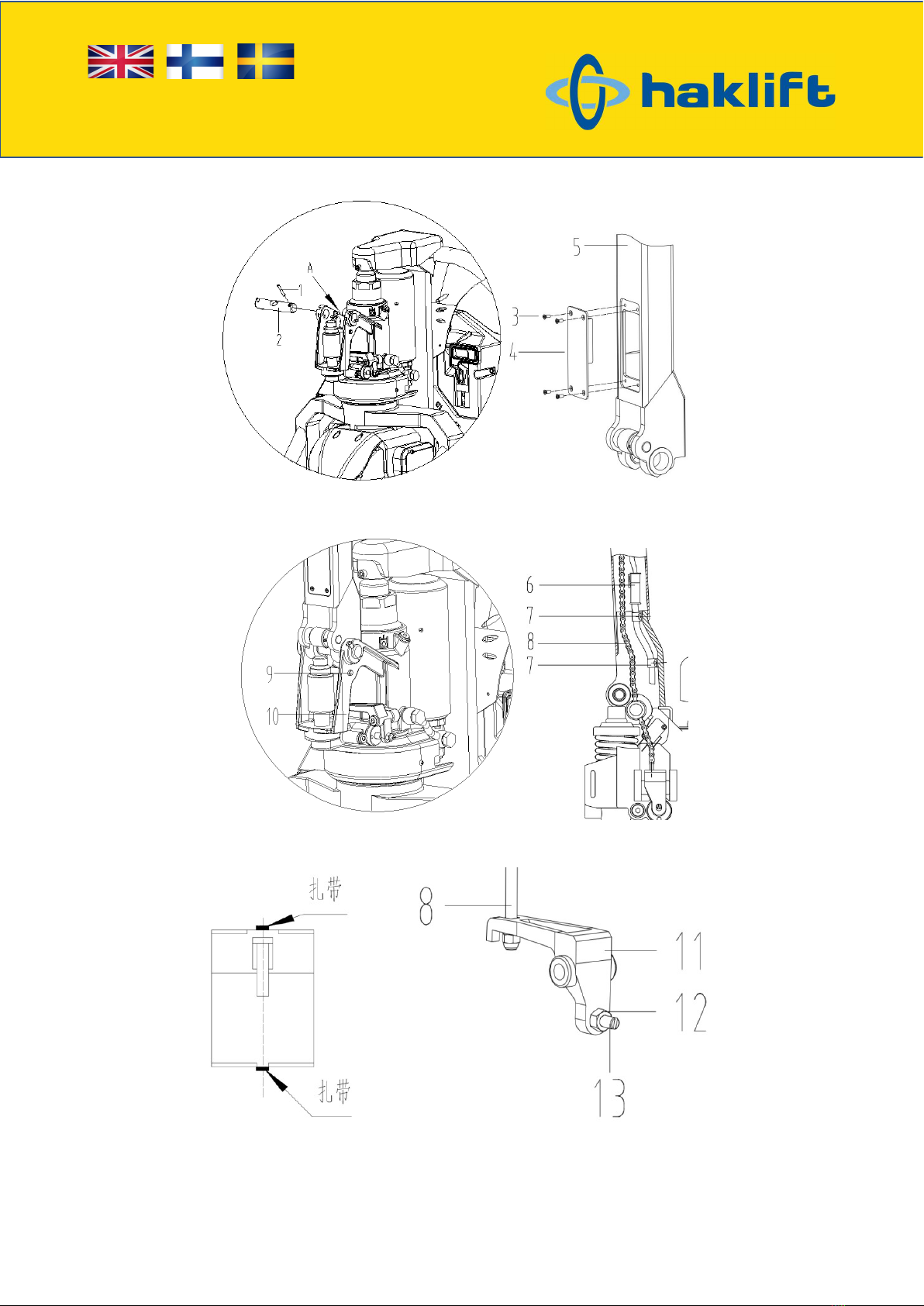

1. Refer to drawing 1, disassemble pin 1 from pin 2 and pull out pin 2.

2. Refer to drawing 2, unfasten screws 3 and remove cover plate 4 from handle assembly 5.

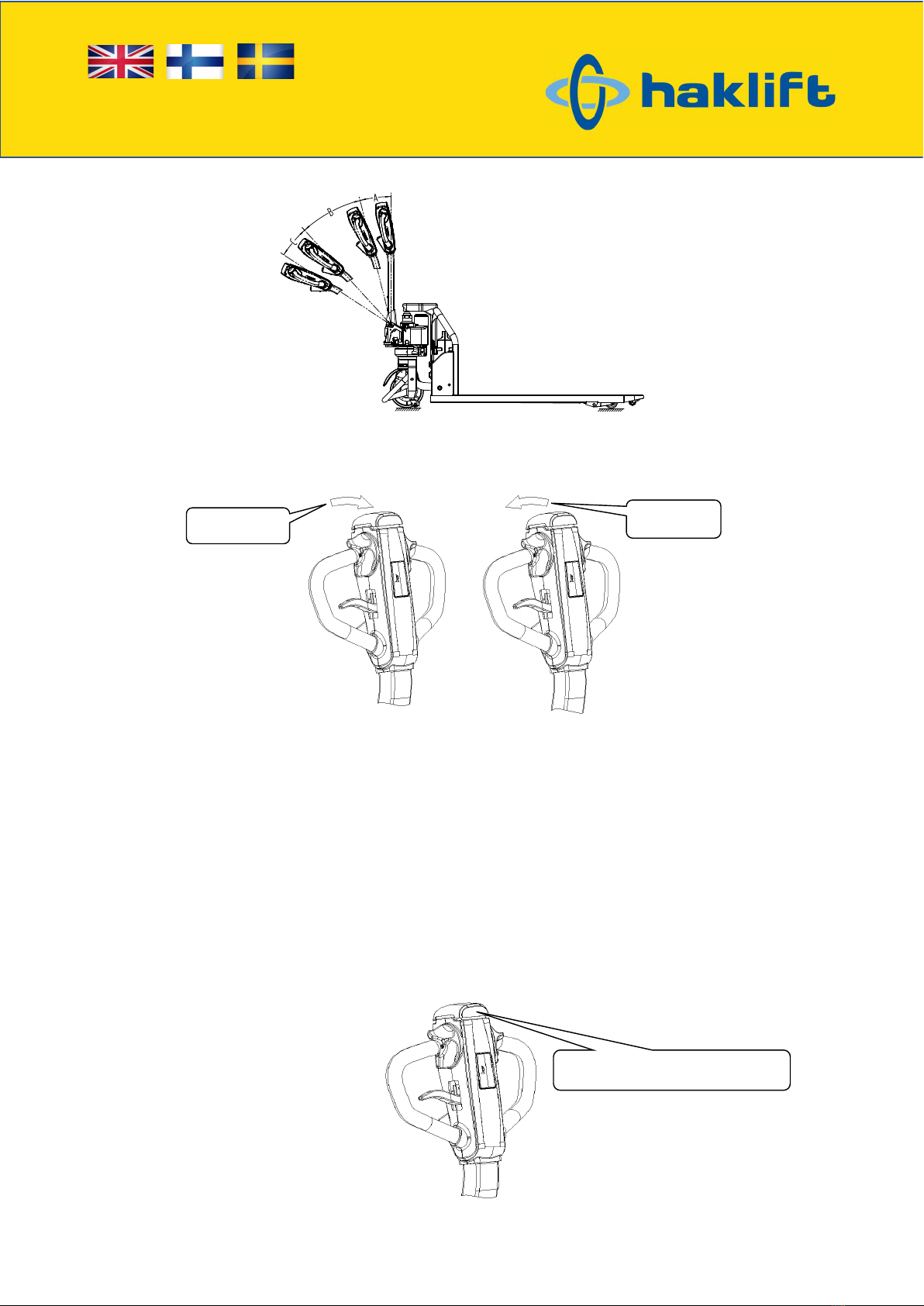

3. Refer to drawings 3 and 4, insert handle assembly 5 to A, connect handle assembly 5 and

pump 10 with pin 2, then make chain 8 go through hole of pin 2. Rotate handle 5 to horizontal

position and pull out pin 9 and keep pin 9 well for next use. Connect wiring harness in handle

assembly 5 and wiring harness on truck body by connector 6 and fasten with belt to ensure

reliable connection (refer to drawing 5). After connecting the wiring harness, fix wiring harness

to handle assembly 5 through line 7.

4. Refer to drawing 4 and 6, hook screwnut on the end of chain 8 into groove of lever plate 11.

5. Finally, fix pin 1 through pin 2 and install cover plate 4 back to handle assembly 5.

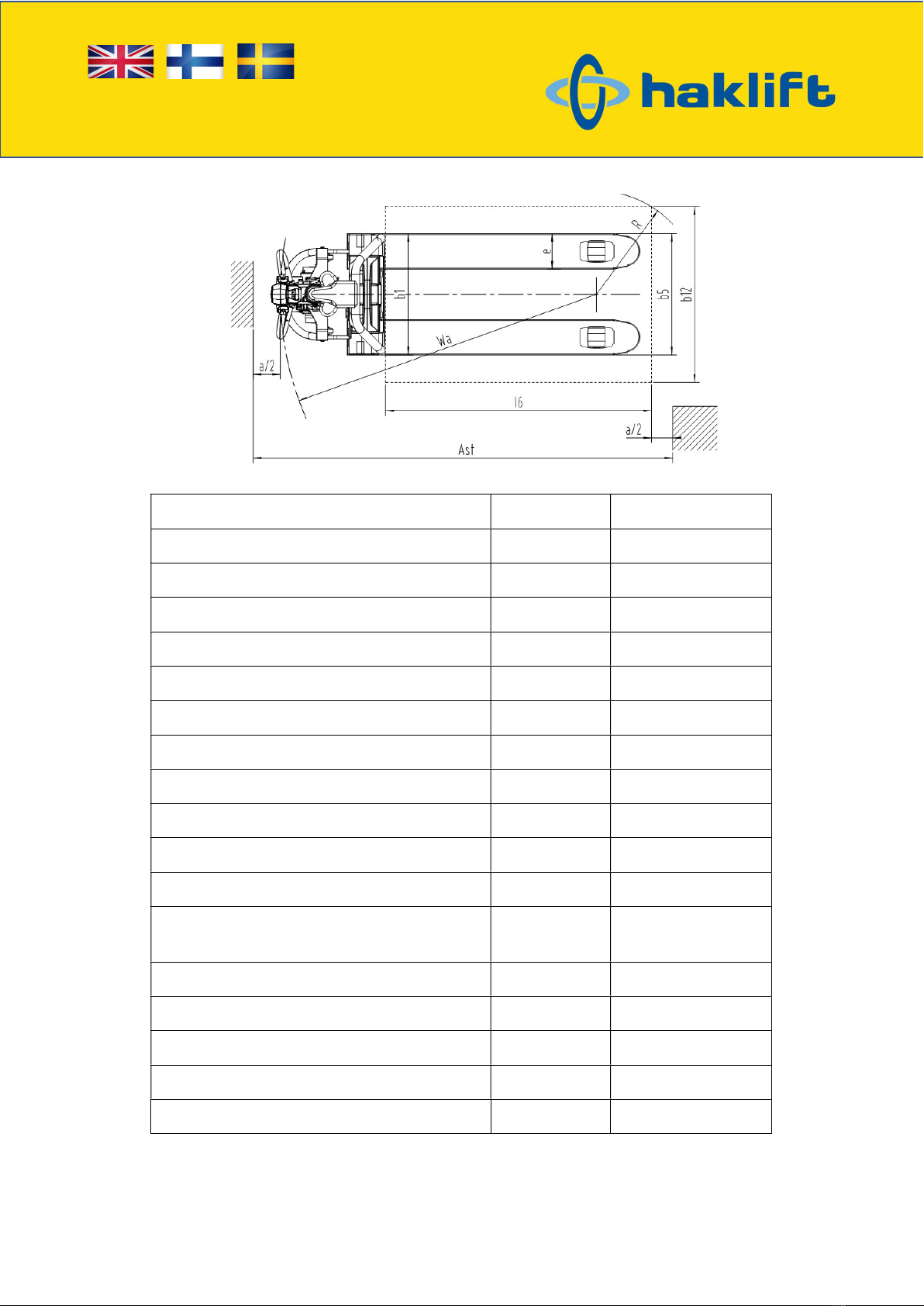

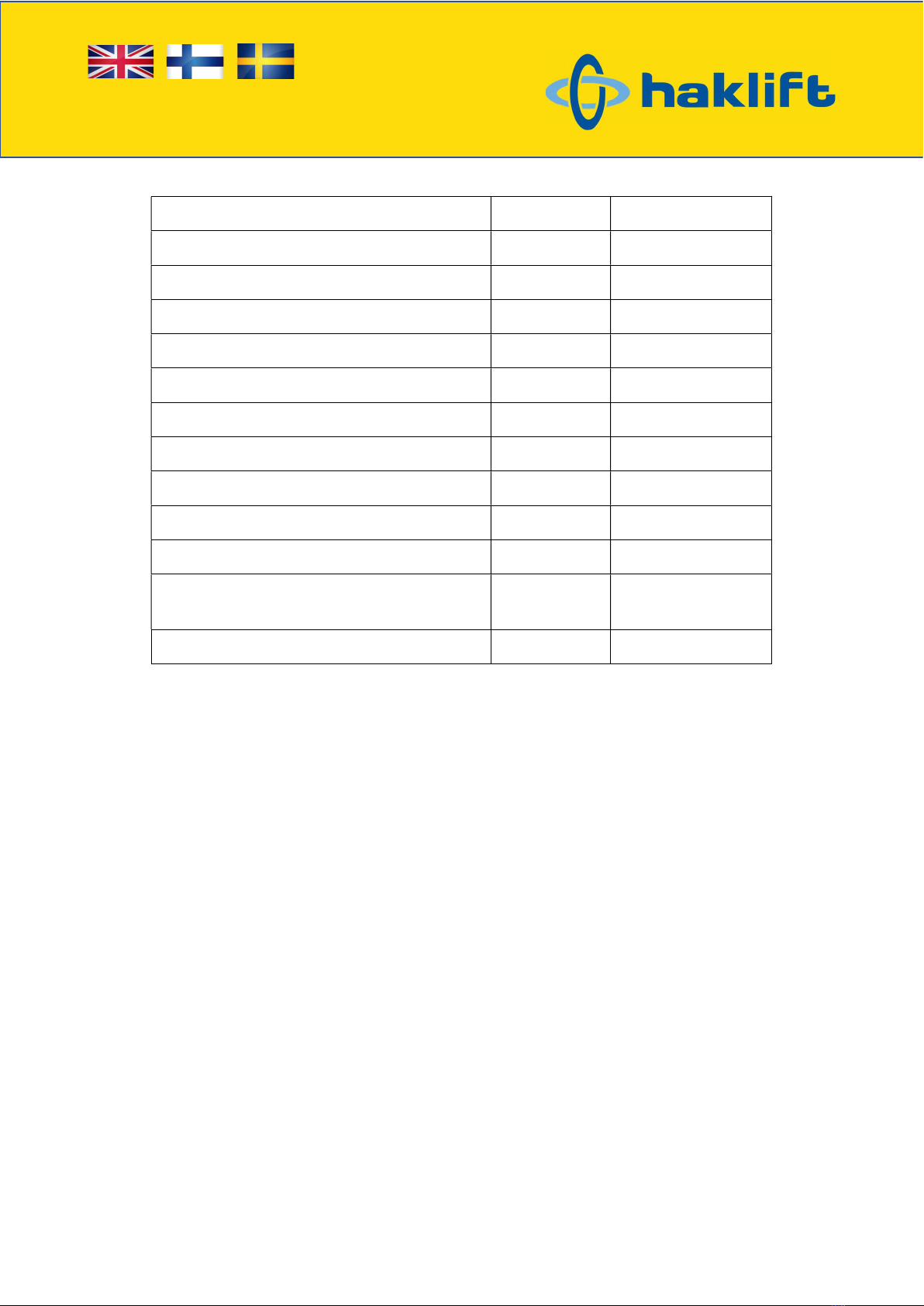

Model HAVA1500ELE

Wheelbase ground distance h1 (mm) 35

Aisle width for pallet 1000x1200 crosswise Ast (mm) 2226/2294

Aisle width for pallet 800x1200 lengthwise Ast (mm) 2095/2132

Turning radius Wa (mm) 1424/1494

Traveling speed, laden/unladen km/h 4,8/5

Max. gradeability, laden/unladen % 5/20

Driving motor power kW 0,65

Lifting motor power kW 0,8

Battery voltage/rated capacity V/Ah 48/20

Travelling brake Electric

Noise level at operator’s ear, according to

DIN12053 dB (A) 70

Weight (incl. battery) kg 136