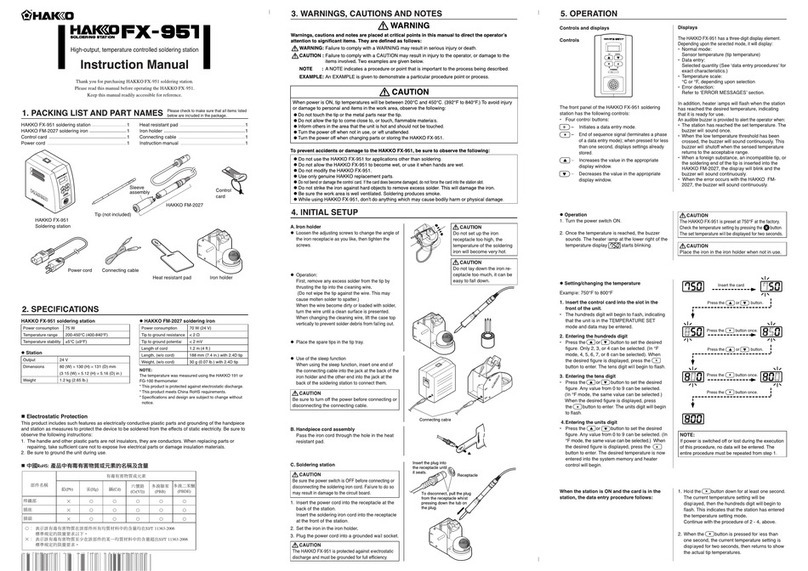

6. OPERATION

Controls and displays

Controls

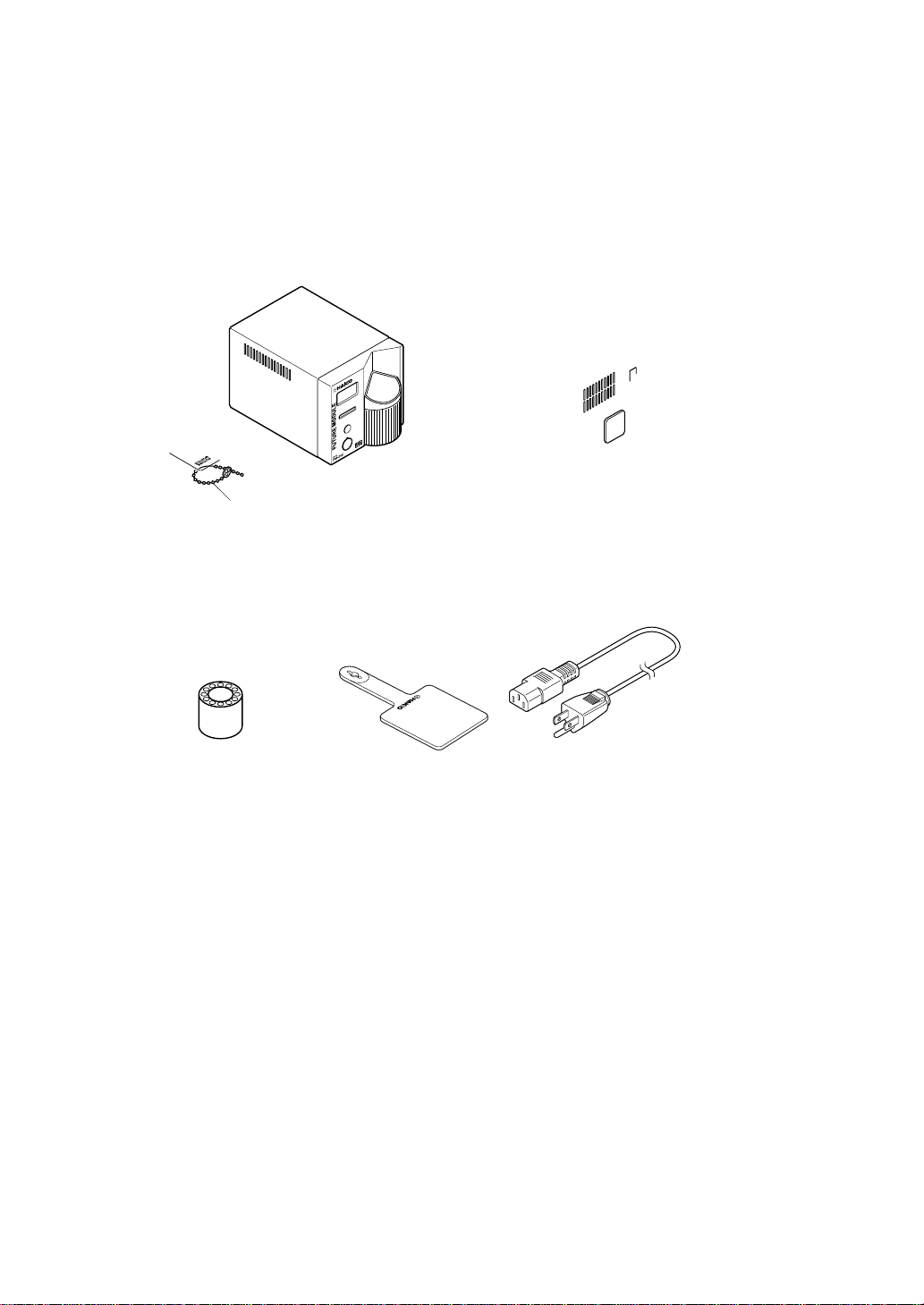

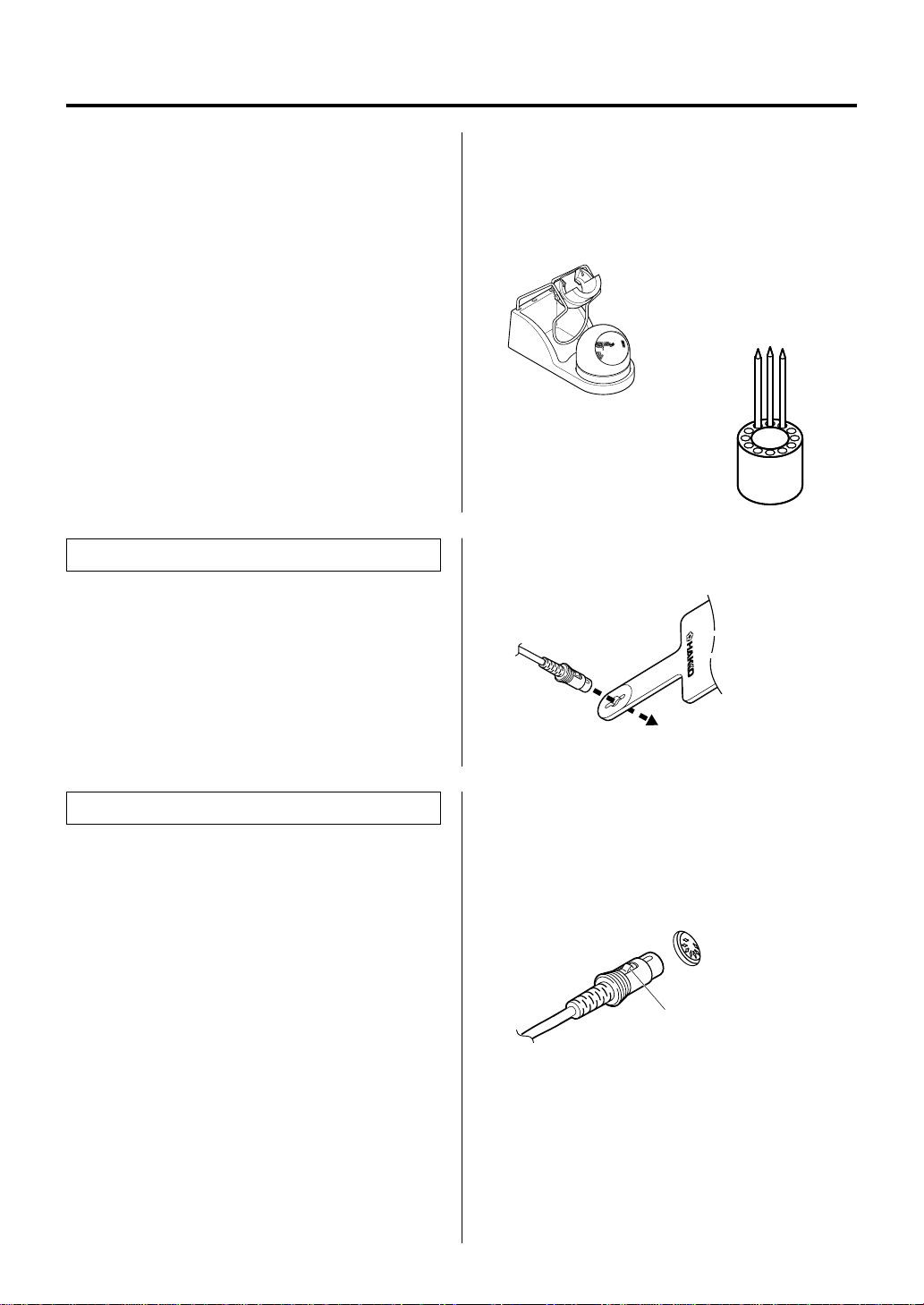

The front panel of the FM-202 soldering station

has four control buttons, the process gate, the

receptacle, and the card slot. The power switch

is on the back panel.

•Four control buttons:

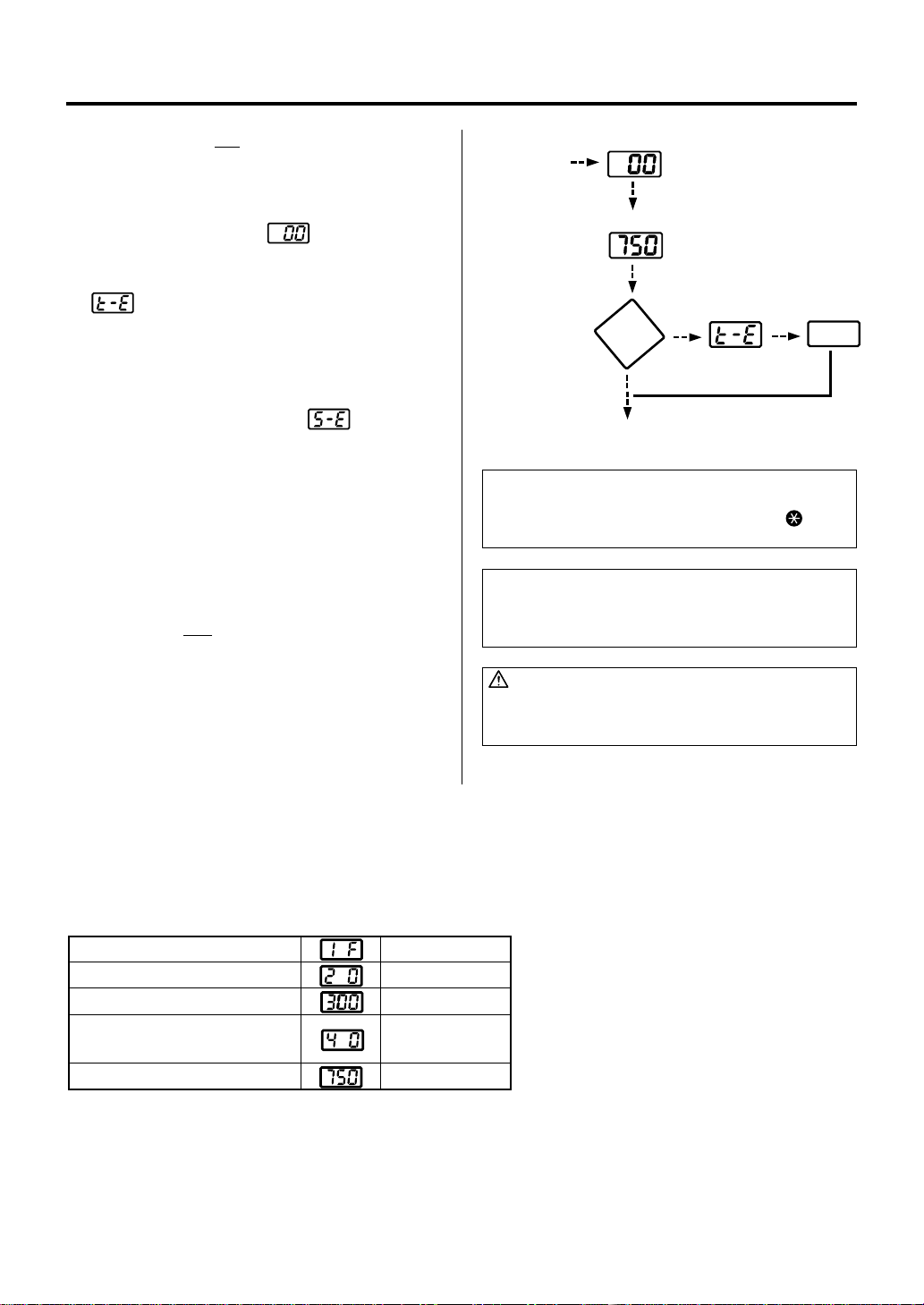

–Initiates the Tip ID entry mode. When

pressed for less than one second, the

stored Tip ID is displayed. When pressed

for more than one second, the Tip ID

entry mode is activated.

–Initiates the temperature setting mode.

When pressed for less than one second,

the stored temperature is displayed.

When pressed for more than one

second, the temperature entry mode is

activated.

–Increases the value in the appropriate

display window.

–Decreases the value in the appropriate

display window.

Displays

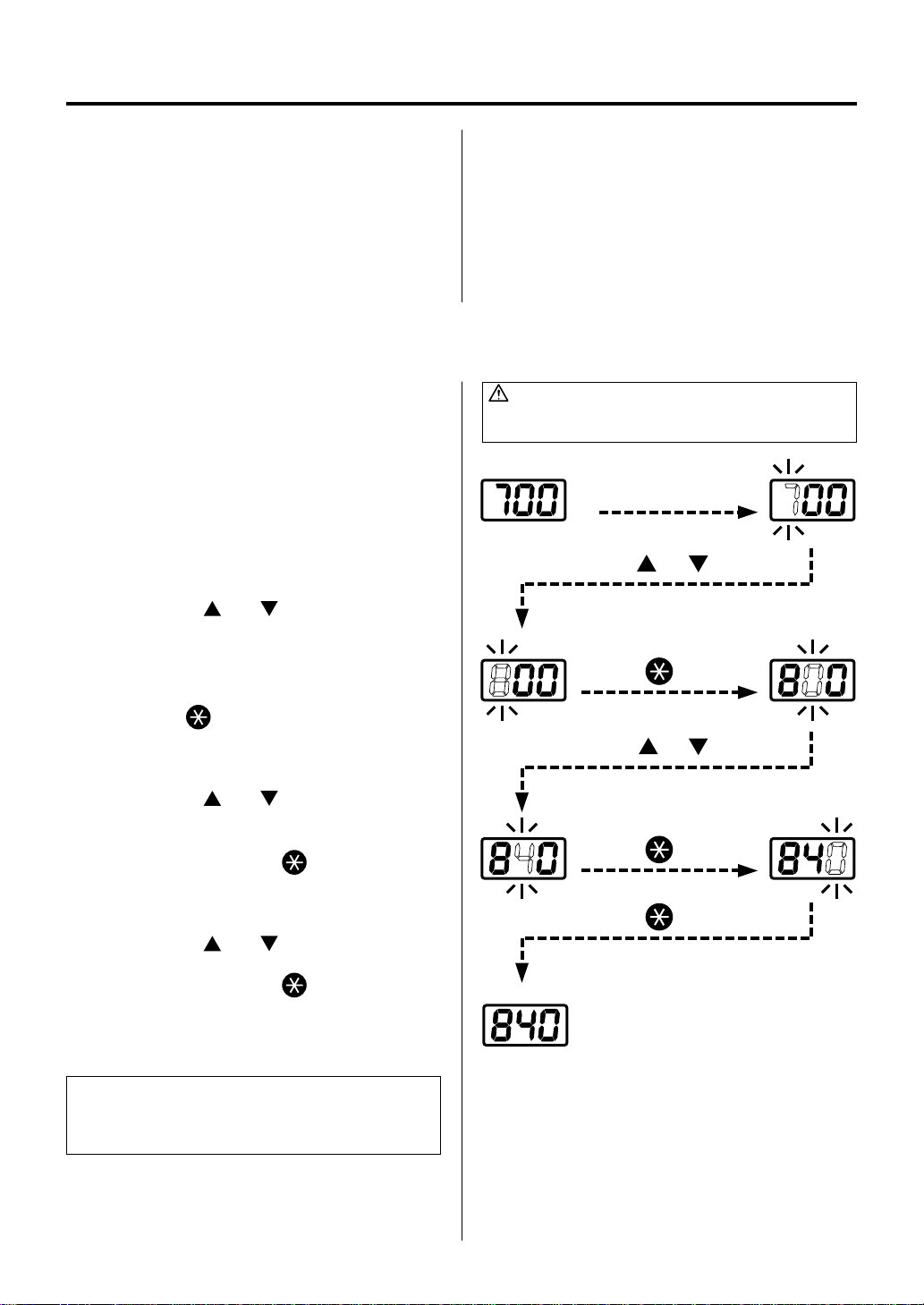

The FM-202 has a three-digit display element.

Depending upon the selected mode, it will

display:

•Normal mode:

Sensor temperature (tip temperature)

•Data entry:

Selected quantity (see ‘data entry procedures’

for exact characteristics)

•Temperature scale:

°C or °F, depending upon selection

•Error detection:

Refer to ‘ERROR MESSAGES’section

In addition, a single heater lamp will flash when

the station has reached the desired temperature,

indicating that it is ready for use.

An audible buzzer is provided to alert the

operator:

•When the station has reached the set tem-

perature. The buzzer will sound once.

•When the tip is inserted into the process gate,

the buzzer will sound once when the Tip ID

bar code has been read.

•When the low temperature threshold has

been crossed, the buzzer will sound

continuously. The buzzer will shut off once the

sensed temperature returns to the acceptable

range.

•When a foreign substance, an incompatible

tip, or the soldering end of the tip is inserted

into the FM-2021, the display will flash and

the buzzer will sound continuously.

•When the auto power shutoff is activated and

power to the heating element is turned off, the

buzzer will sound three times.

•When the process gate cannot read the Tip ID

bar code, the buzzer will sound three times.

•When a tip is inserted into the process gate

while the tip is already in the FM-2021, buzzer

will sound irregularly.

•When the tip is properly inserted into the

connector, the buzzer will sound once.

5