Power Consumption

Temperature Range

Temperature Stability

Power Consumption

Tip to Ground Resistance

Tip to Ground Potential

Cord

Total Length (w/o cord)

Weight (w/o cord)

●HAKKO FM-2027

* The temperature was measured using the HAKKO FG-101

thermometer.

* This product is protected against electrostatic discharge.

* Specifications and design are subject to change without

notice.

Multi Rework Station

Instruction Manual

Thank you for purchasing HAKKO FM-206 Rework System.

Please read this manual before operating the HAKKO FM-206.

Keep this manual readily accessible for reference.

2. SPECIFICATIONS

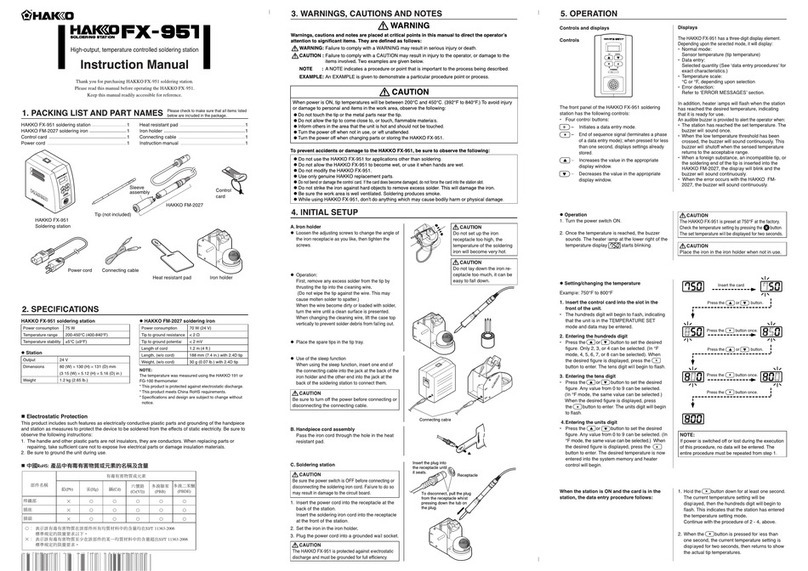

3. WARNINGS, CAUTIONS, NOTES AND EXAMPLES

Warnings, cautions and notes are placed at critical points in this manual to direct the operator’s attention to

significant items. They are defined as follows:

WARNING: Failure to comply with a WARNING may result in serious injury or death.

CAUTION : Failure to comply with a CAUTION may result in injury to the operator, or damage to the

items involved.

NOTE: A NOTE indicates a procedure or point that is important to the process being described.

CAUTION

When power is ON, the tip will be hot. To avoid injury or damage to personnel and items in the work

area, observe the following:

●Do not touch the tip or the metal parts near the tip.

●Do not allow the tip to come close to, or touch, flammable materials.

●Inform others in the area that the unit is hot and should not be touched.

●Turn the power off when not in use, or left unattended.

●

Turn the power off when connecting the handpieces or storing the HAKKO FM-206.

●

This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

●

Children should be supervised to ensure that they do not play with the appliance.

●

To prevent accidents or damage to the HAKKO FM-206, be sure to observe the following:

●

Do not use the HAKKO FM-206 for applications other than soldering.

●

Do not strike the iron against hard objects to remove excess solder. This will damage the iron.

●

Do not modify the HAKKO FM-206.

●

Use only genuine Hakko replacement parts.

●

Do not allow the HAKKO FM-206 to become wet, or use it with wet hands.

●

Remove power and iron cords by holding the plug − not the wires.

●

Be sure the work area is well ventilated. Soldering produces smoke.

●

While using HAKKO FM-206, don’t do anything which may cause bodily harm or physical damage.

4. INITIAL SETUP

Jack**(1, 2, 3)

Power

Receptacle

Fuse

Power Switch

Control Button(1, 2, 3)

Filter Case Cover

■Part Names

Compatible with

FM-2024

FM-2026

FM-2027

FM-2032

Control Knob

Flow Control Knob

Air Output

Compatible with

FM-2022

FM-2023

FM-2024

FM-2026

FM-2027

FM-2030

FM-2031

FM-2032

Compatible with

FM-2024

FM-2026

FM-2027

FM-2029

FM-2030

FM-2031

FM-2032

* Each receptacle connector differs, please be careful not to connect an

incompatible device.

Errors will result.

**F

or connecting iron holders. Make sure to connect the correct holder.

While both vacuum and hot air can be used, only one can be operated at once. One

cannot use a combination of hot air and vacuum or two vacuums simultaneously.

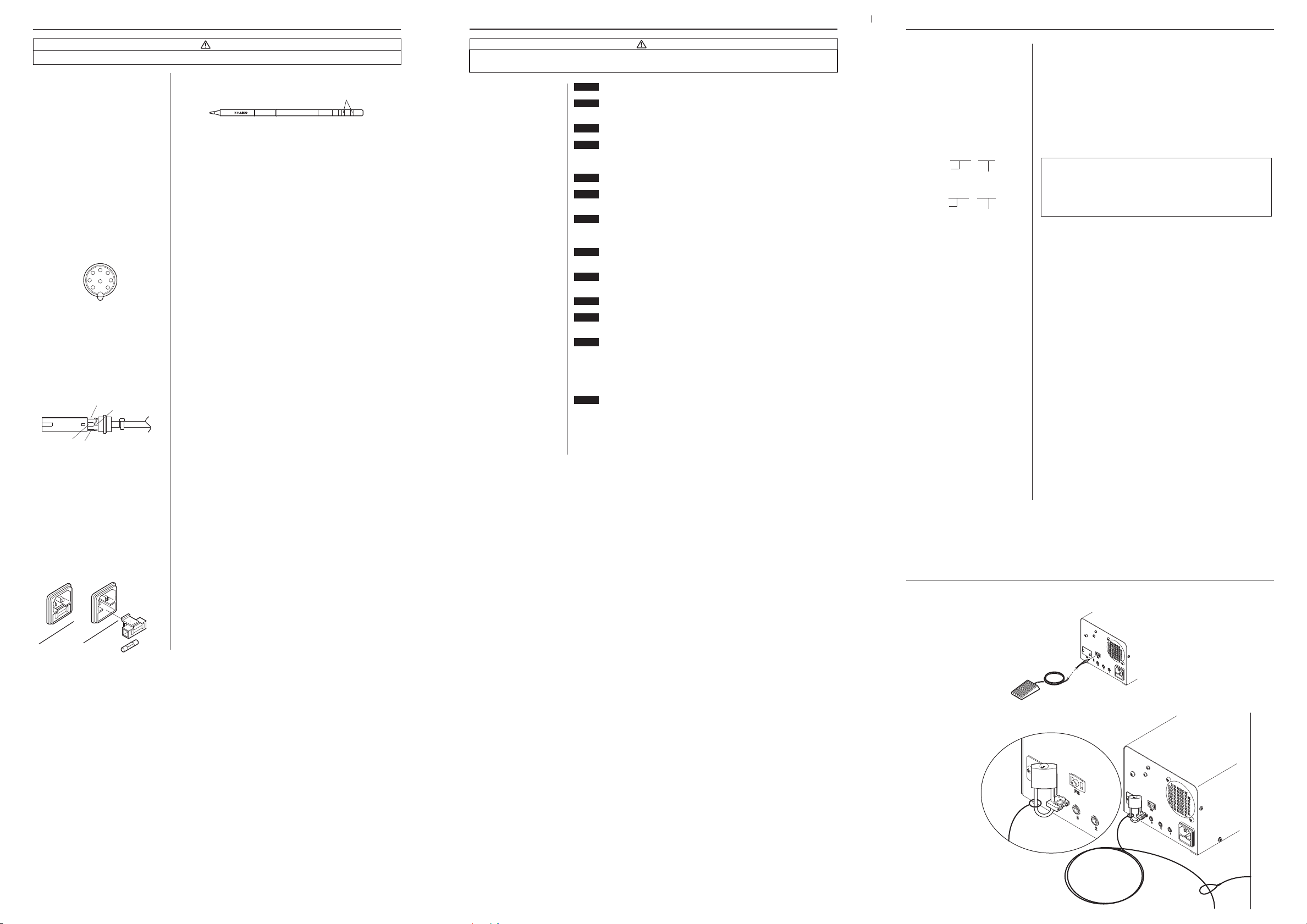

■Setup

●Hooking up the iron and connecting cable.

Connecting

Cable

Plug the iron's connector

cord into the receptacle.

Plug in power and connecting cables.

Power

Cable

•Please make sure the power is off when you plug in cables.

•Please make sure to hook up the connector cable and the iron holder on the same

channel and not to place the iron in a holder connected to a differing channel.

•Please take care not to mix up the hose connections, the MODEL FM-2024 connects

to the filter case cover and the HAKKO FM-2029 to the air output.

•Securely insert the connecting cable all the way in to the jack.

CAUTION

Connection for

FM-2024 Suction

Hose

Connection for

FM-2029 Air Hose

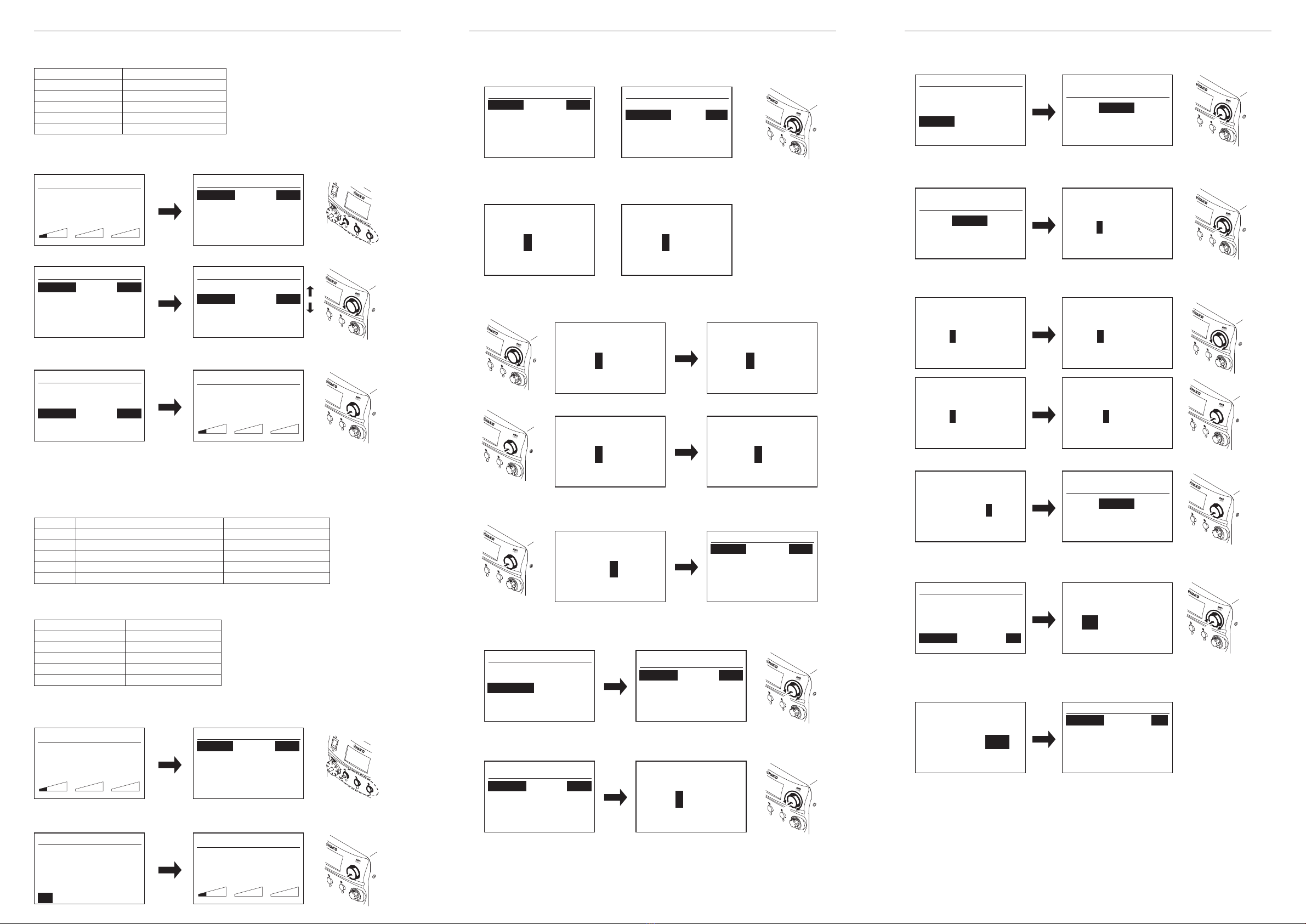

■Switch, Control

Button

and

Knob

Usage

Power switch

Use the power switch to turn

the power on and off.

Control Buttons

Use to change settings such as

temperature.

When pressed briefly:

Displays the preset screen.

When pressed and held:

Displays the change settings

screen.

Change Settings Screen Details

1. Temperature Settings

2. Offset Settings

3. Preset Temperature Settings

4. Preset Names

5. Channel Power (On/Off)

6 Exit

Control Knob Usage

Use to change settings

Turning the control knob:

Changes setting values

or moves the cursor

Pushing the control knob:

Makes selection

* If you press a control button while on the Preset or Change

Settings screen, the corresponding channel screen will be

displayed.

Plugged in irons will be heated according to the settings

when the power is turned on.

MAX 410W (450W)

HAKKO FM-2026/2027 200 - 450℃ (400 - 840℉)

MODEL FM-2022/2023 200 - 400℃ (400 - 750℉)

MODEL FM-2024 350 - 450℃ (660 - 840℉)

HAKKO FM-2029 100 - 550℃ (200 - 1030℉)

HAKKO FM-2030/2031 200 - 500℃ (400 - 930℉)

±5°C (±9°F) at idle temperature

70 W (24 V)

< 2 Ω

< 2 mV

1.2 m (4 ft)

188 mm (7.4 in.) with 2.4D tip

30 g (0.067 lb./1.07 oz.)with 2.4D tip

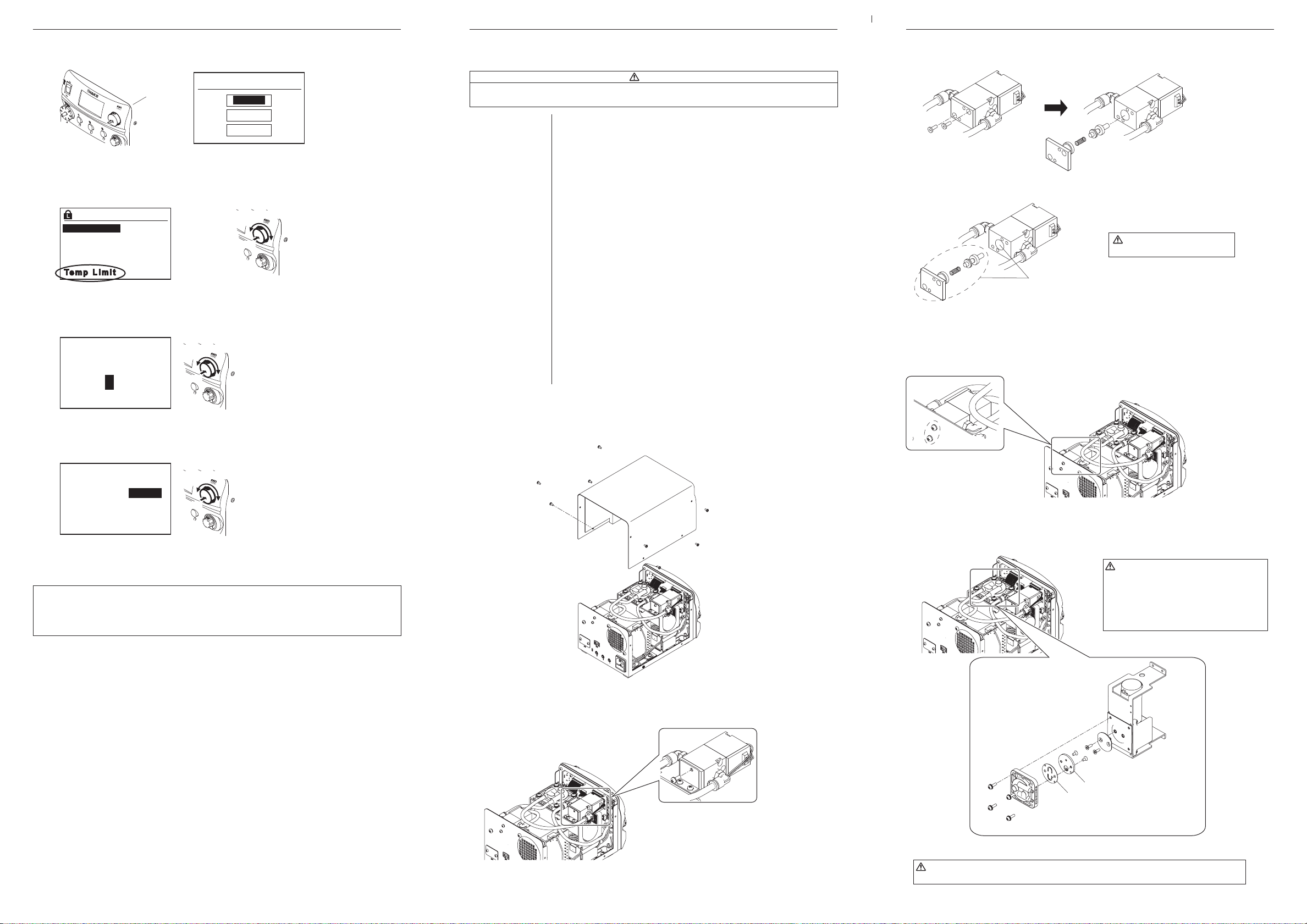

●Replacing the tip (HAKKO FM-2027)

The tip may be hot. Avoid holding the hot tip for a long time even if

using the heat-resistant pad. Otherwise burns may result.

CAUTION

Removing the tip:

●Hold down the lock release buttons in the sleeve assembly, pull out

the tip together with the sleeve assembly from the connector.

●While holding the front end of the sleeve assembly, pull out the tip.

• Be sure to keep the lock release buttons held down while pulling

out the sleeve assembly. Failure to do so will damage the locking

mechanism.

• Be sure to pull out the tip only after separating the sleeve assembly

from the connector. Otherwise, the sleeve assembly may fall down

and break.

CAUTION

Insert the tip:

●Reassemble in the reverse order of disassembly.

• Insert the tip into the sleeve assembly until it clicks into place. When

you hear it click, avoid forcing the tip into the sleeve assembly.

• When holding the head of the tip, there is a danger of burn. Be sure

to use the heat-resistant pad.

CAUTION

Output

Dimensions (W x H x D)

Weight

Capacity (Max)

Vacuum Generator

Vacuum Pressure (Max.)

Suction Flow

●Station

24V

162 × 136 × 245 mm (6.4 × 5.4 × 9.7 in)

6.2 kg (13.7 lb.)

6L/min.

Vacuum pump, cylinder type

80kpa (600 mm Hg) (24 in. Hg)

14L/min.

Instruction manual in the language of Japanese, English, Chinse, French, German and Korean

can be downloaded from the HAKKO Document Portal.

(Please note that some languages may not be available depending on the product.)

Flow Control Knob

When HAKKO FM-2029 is connected to

HAKKO FM-206, air flow will be displayed.

By turning the flow control knob, air flow

can be changed.

CH1 CH2 CH3

350

℃

Off

Ready

SOL

100%M

*Each Hakko handpiece with the exception of the HAKKO

FM-2027 has their own instruction manual. Please refer to

this manual for specifications and replacement parts.

Jack

(equipotential)

Receptacle* (1, 2, 3)

Jack

(for foot switch)

I/OCoverPlate

2014.7

MA02390XZ140723

CAUTION

Power consumption is different depending on

Standards.

1. PACKING LIST

Please check to make sure that all items listed

below are included in the package.

HAKKO FM-206

Power cord

Tip tray

Instruction manual

1

1

1

1

■Use this product with the following models.

HAKKO FM-2027 (Soldering Iron)

MODEL FM-2022 (Parallel Remover)

MODEL FM-2023 (Mini Parallel Remover)

MODEL FM-2024 (Desoldering Tool)

HAKKO FM-2026 (Soldering Iron N2 Type)

HAKKO FM-2029 (Hot Air Handpiece)

HAKKO FM-2030 (Heavy Duty Soldering Iron)

HAKKO FM-2031

(Heavy Duty Soldering Iron N2 Type)

HAKKO FM-2032 (Soldering Iron)

HAKKO FM-206

Power cord

Tip tray

*Each Hakko handpiece with the exception of the HAKKO

FM-2027 has their own instruction manual. Please refer to

this manual for specifications and replacement parts.

Copyright © 2013 HAKKO Corporation. All Rights Reserved.

連接部

隔離器

電路板

插座

電磁蓋

真空泵組件

螺釘

坦克組件

排出閥門

×

×

×

×

×

×

×

×

×

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

http://www.hakkousa.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

http://www.hakko.com.hk

SINGAPORE: HAKKO PRODUCTS PTE., LTD.

TEL: 6748-2277 FAX: 6744-0033

http://www.hakko.com.sg

Please access to the following address for the other Sales affiliates.

http://www.hakko.com

HEAD OFFICE

4-5, Shiokusa 2-chome, Naniwa-ku, Osaka 556-0024 JAPAN

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466