Halsey Taylor OVLEBPFR User manual

Other Halsey Taylor Outdoor Fountain manuals

Halsey Taylor

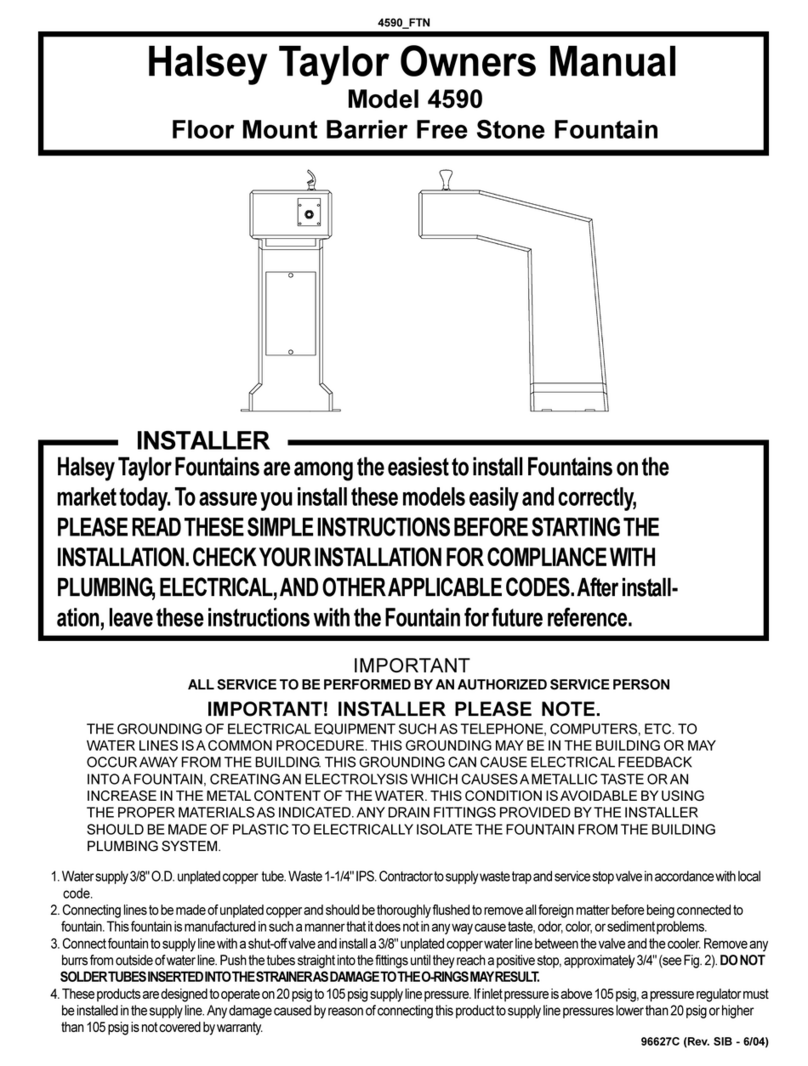

Halsey Taylor 4590 User manual

Halsey Taylor

Halsey Taylor 4710 Series User manual

Halsey Taylor

Halsey Taylor 4880 User manual

Halsey Taylor

Halsey Taylor 4880 User manual

Halsey Taylor

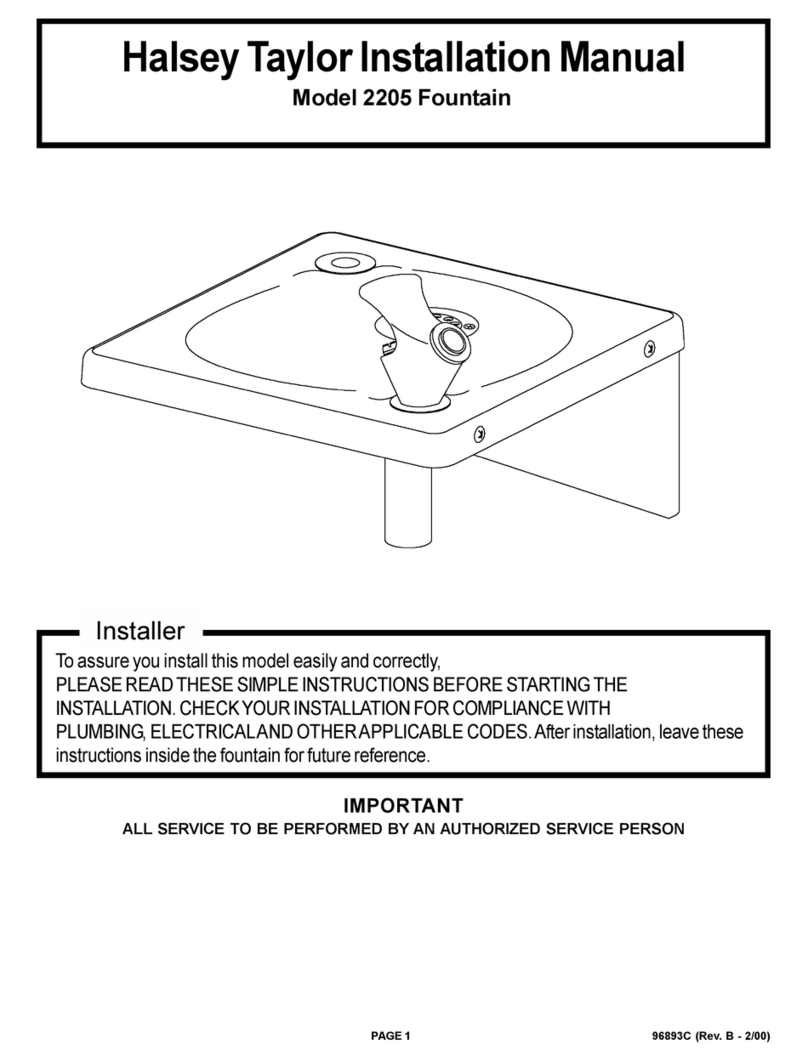

Halsey Taylor 2205 User manual

Halsey Taylor

Halsey Taylor HRFGEBP_A Series User manual

Halsey Taylor

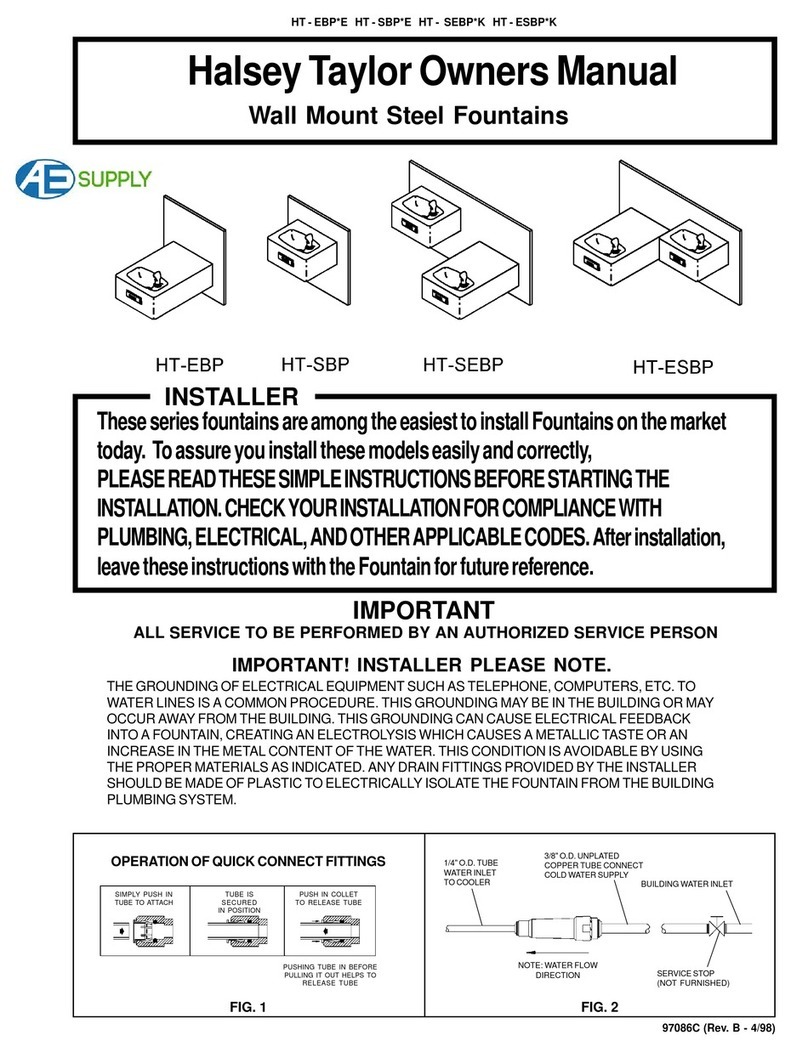

Halsey Taylor HT-EBP E Series User manual

Halsey Taylor

Halsey Taylor 4405BFFR User manual

Halsey Taylor

Halsey Taylor S300-2EQ 1N Series User manual

Halsey Taylor

Halsey Taylor OVL-EBP User manual

Halsey Taylor

Halsey Taylor 4410 User manual

Halsey Taylor

Halsey Taylor 4592FR User manual

Halsey Taylor

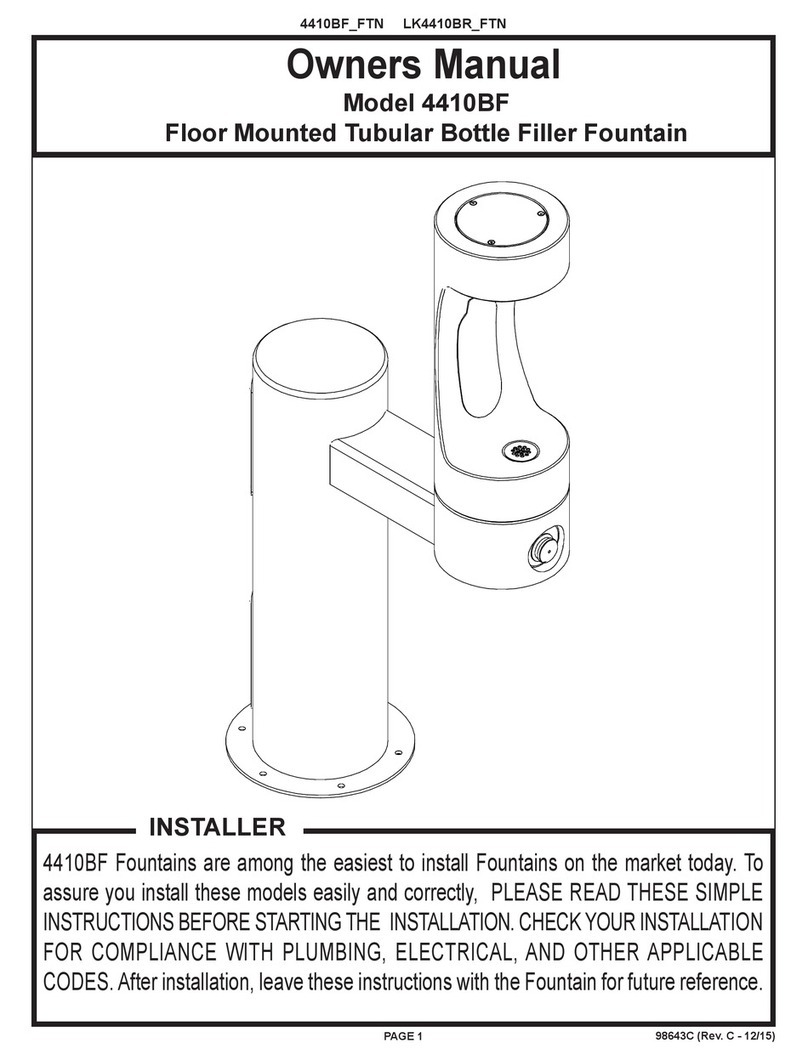

Halsey Taylor 4410BF User manual

Halsey Taylor

Halsey Taylor 4400BF User manual

Halsey Taylor

Halsey Taylor Endura II 4400BF User manual

Halsey Taylor

Halsey Taylor HCRF-EBP User manual

Halsey Taylor

Halsey Taylor 4592 FTN User manual

Halsey Taylor

Halsey Taylor 7020 User manual

Halsey Taylor

Halsey Taylor 4540 User manual

Halsey Taylor

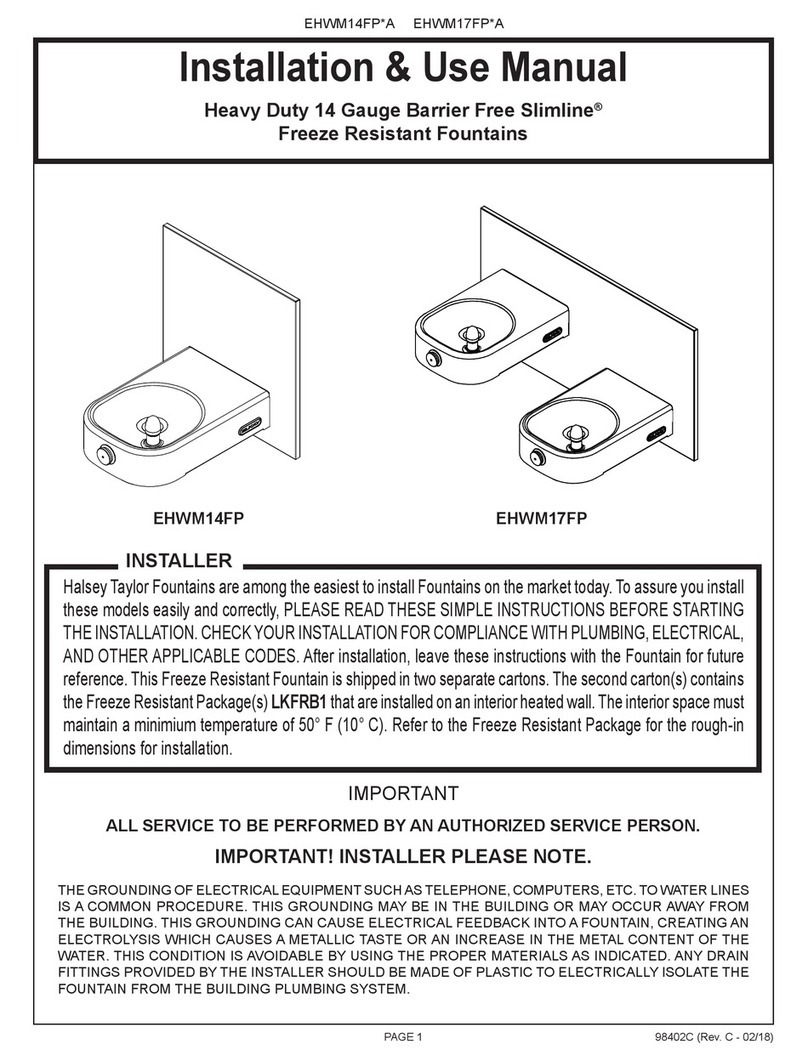

Halsey Taylor EHWM14FP A Series Instructions for use

Popular Outdoor Fountain manuals by other brands

Profi-pumpe

Profi-pumpe FELS-ZAUBER operating instructions

Hasley Taylor

Hasley Taylor 2501A owner's manual

Sunnydaze Decor

Sunnydaze Decor XSS-578 Assembly instructions

Campania International

Campania International Bibendum FT-400 Assembly instructions

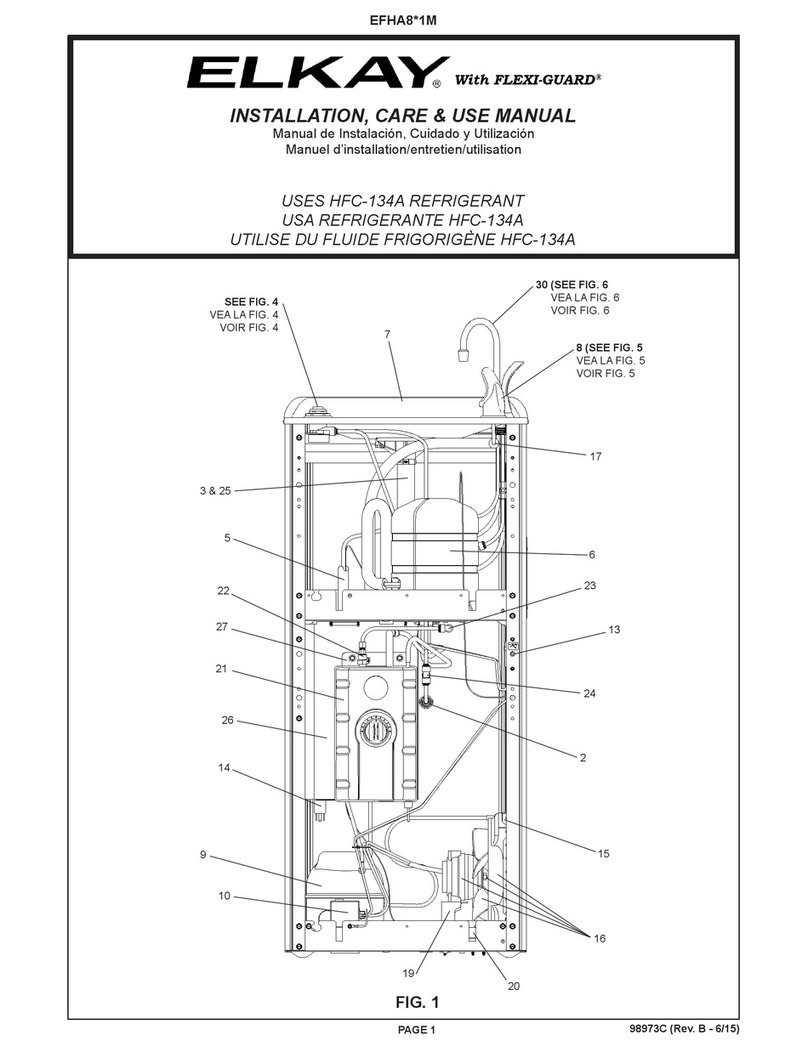

Elkay

Elkay FLEXI-GUARD EFHA8 1M Series Installation, care & use manual

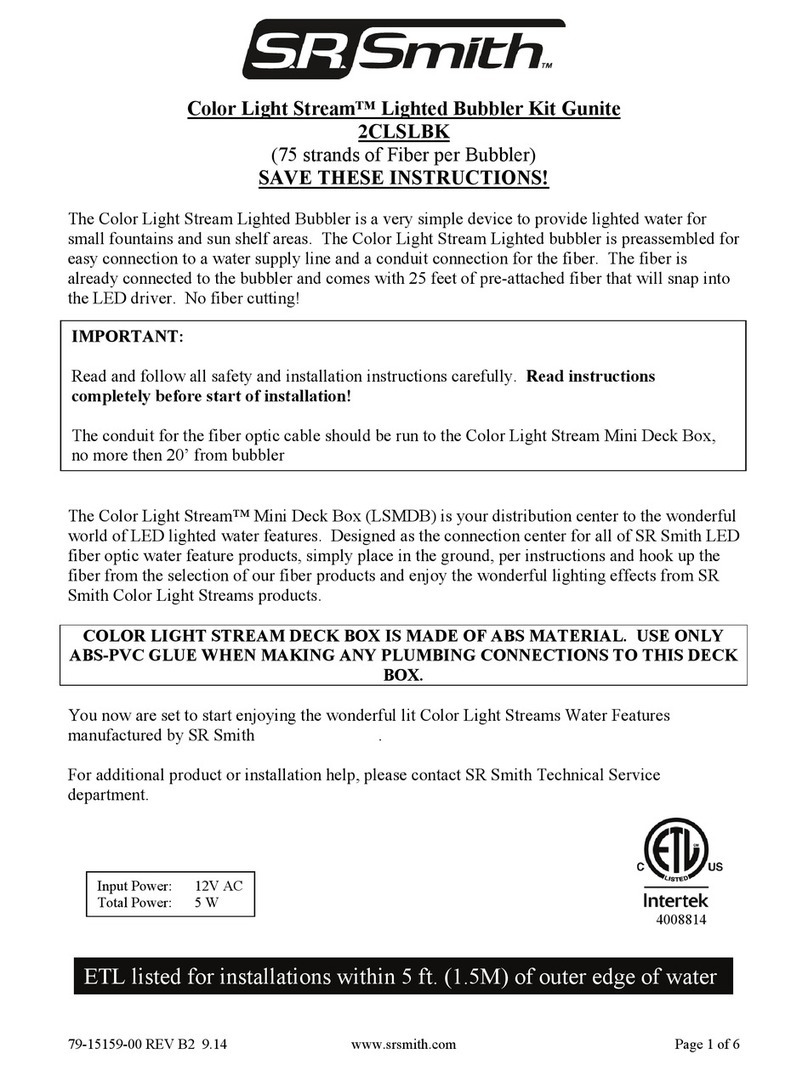

S.R.Smith

S.R.Smith Color Light Stream 2CLSLBK instructions

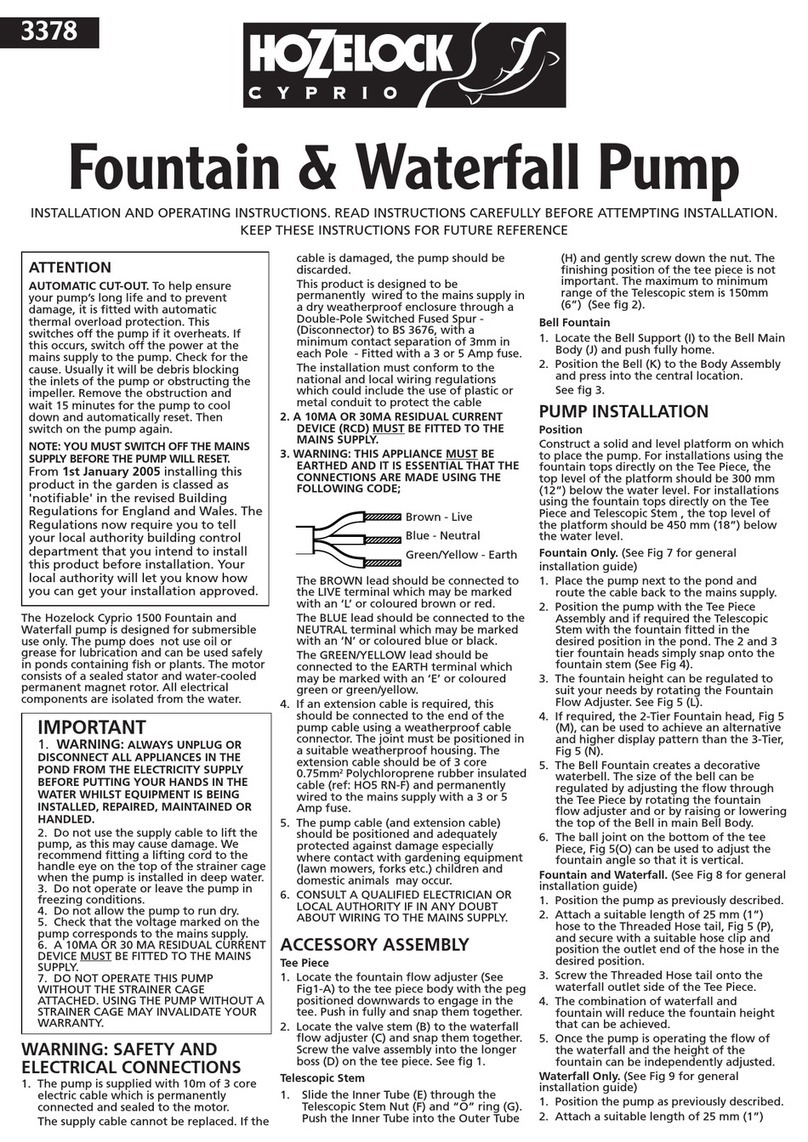

Hozelock Cyprio

Hozelock Cyprio Cascade 1500 Installation and operating instructions

Campania International

Campania International Juliet Fountain quick start guide

Alpine

Alpine WIN732 quick start guide

Campania International

Campania International FT-320 Assembly instructions

Kelkay

Kelkay Easy Fountain Rustic Windmill instructions

Alpine

Alpine WIN258 manual

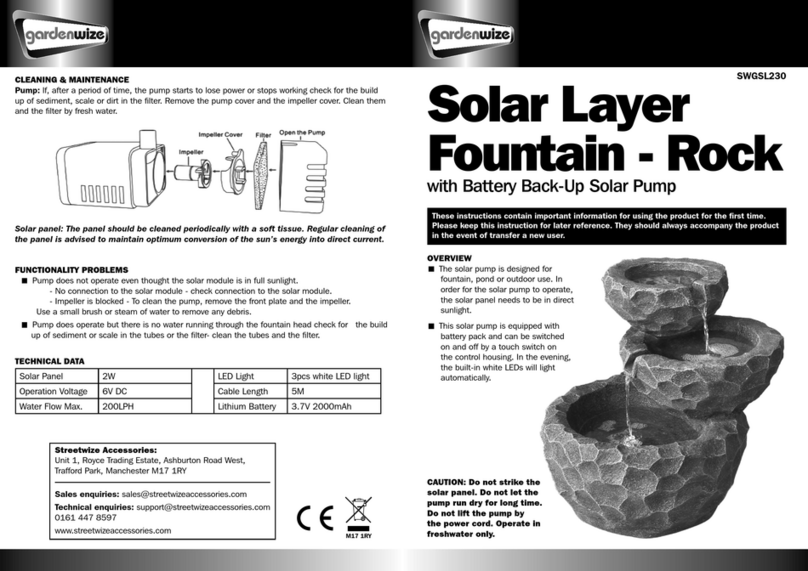

GardenWize

GardenWize SWGSL230 quick start guide

EasyPro

EasyPro Tranquil Décor HBB39 installation instructions

Campania International

Campania International Girona FT-102A Assembly instructions

Campania International

Campania International FT-271 quick start guide

Campania International

Campania International Bilbao GFRCFT-1111 Assembly instructions

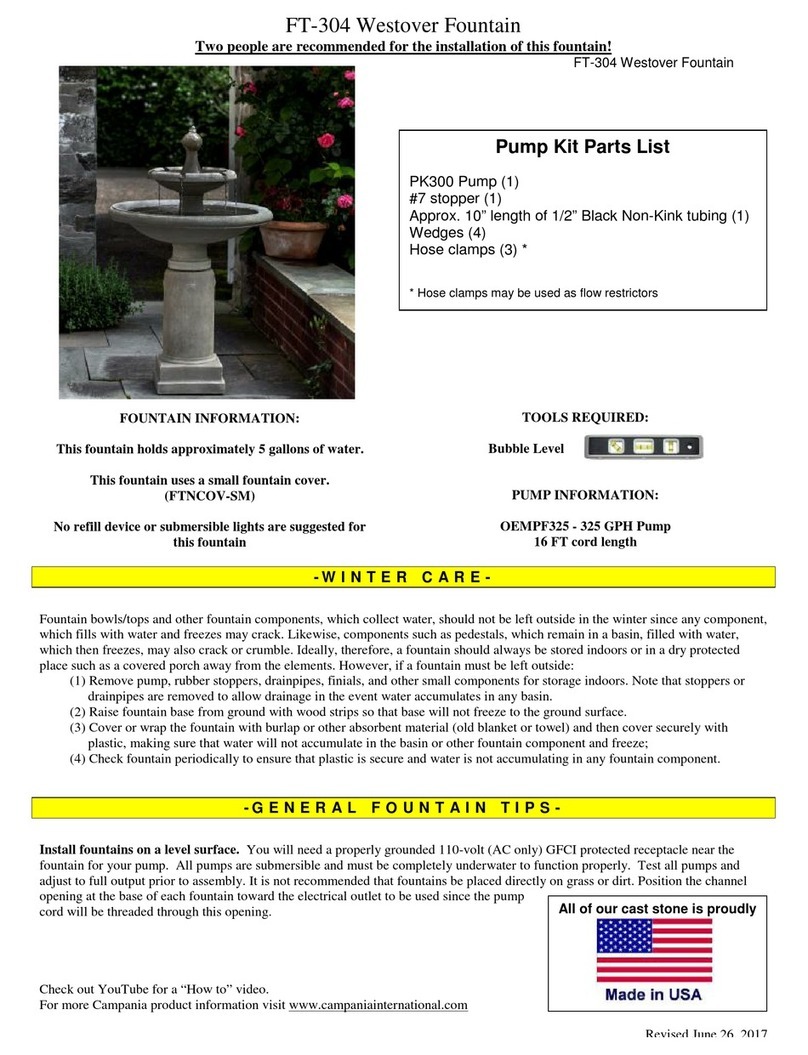

Campania International

Campania International Westover manual