18 19

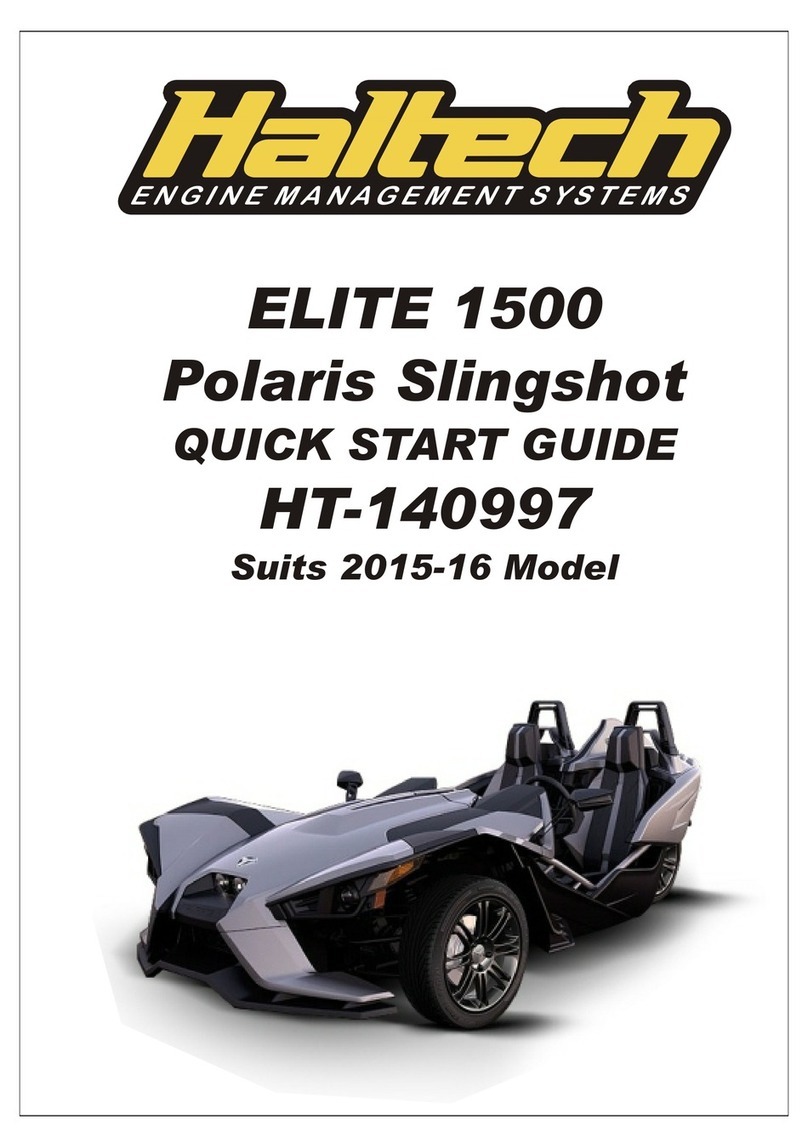

NEXUS R3 WIRING

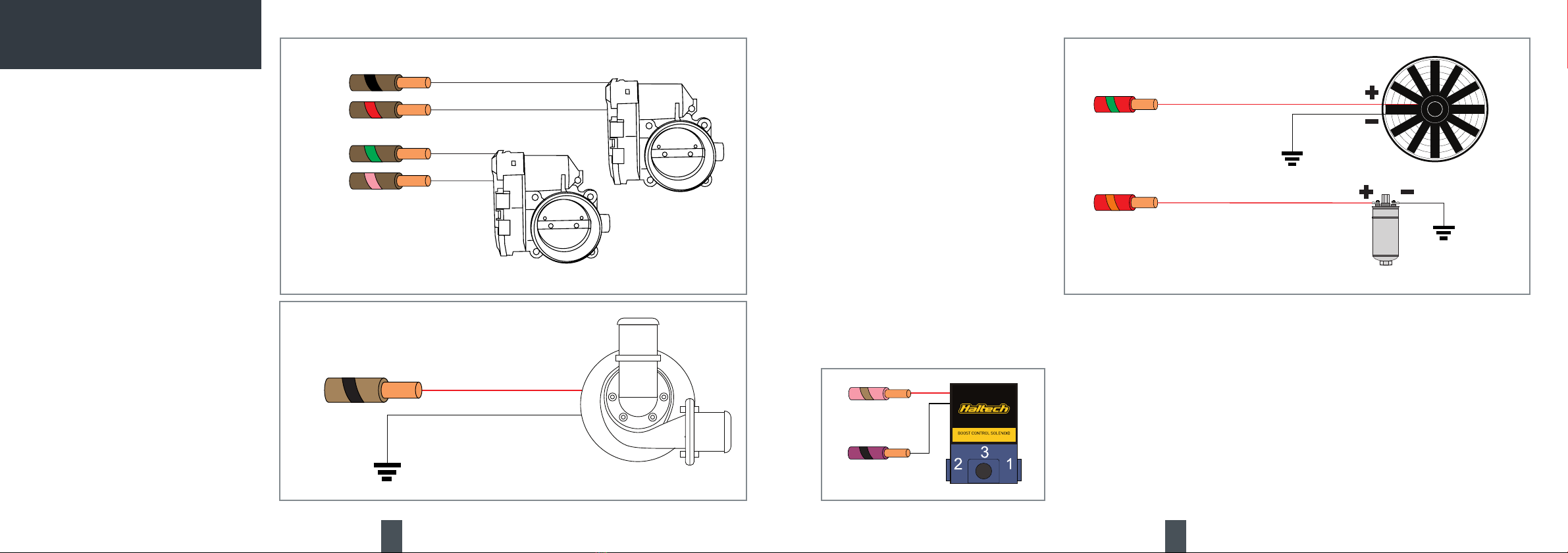

25A-HCO3

25A-HCO4

THERMOFAN

FUEL PUMP

BATTERY

GROUND

BATTERY

GROUND

Example Wiring Connections

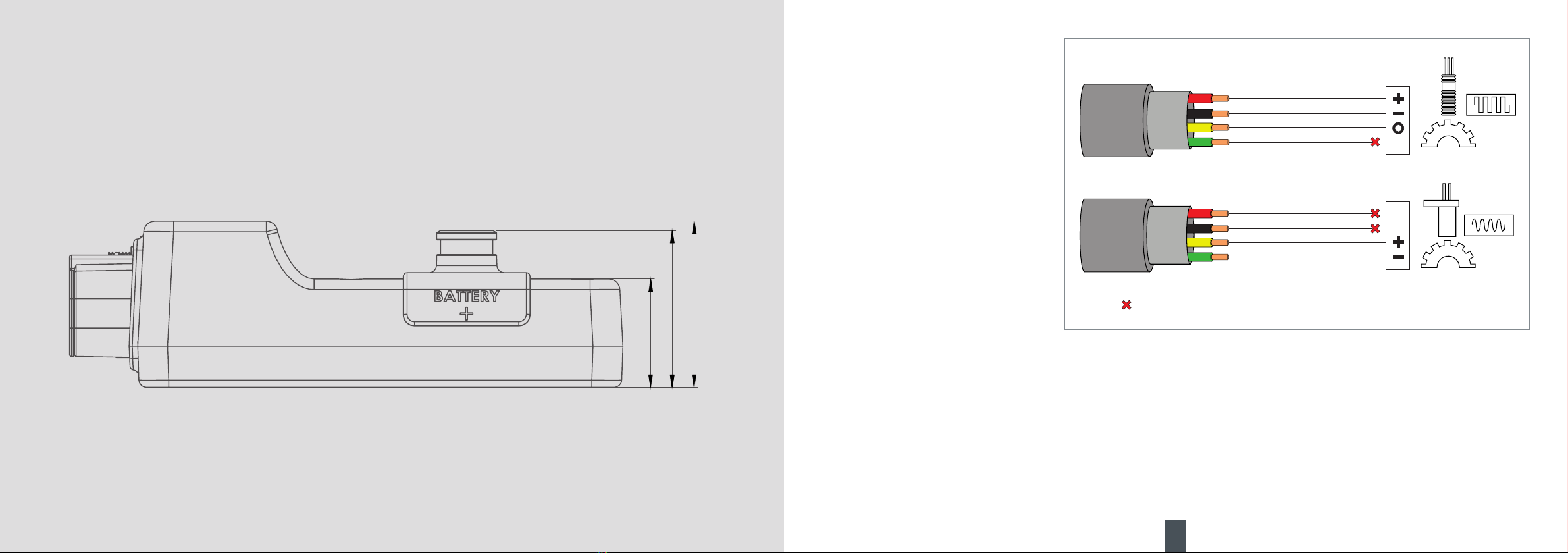

Half Bridge Outputs (HBO)

Half Bridge Outputs are push-pull Pulse Width

Modulated (PWM) outputs that can be used to

control DBW throttle motors, idle air stepper

motors or electronic wastegates.

If not being used as push-pull drivers, Half Bridge

Outputs on the NEXUS R3 can also be used as

generic high side or low side outputs capable of

driving 8A to 12V, or sinking 8A to ground.

When used for DBW throttle motors, any HBO pair

can be arbitrarily used and assigned (e.g. HBO 1

and HBO 4) in the DBW wiring settings in the NSP

software.

Specs:

• Number of channels: 6

• 8A to 12V (high), or 8A to ground (low) output

• 5A max when used as push-pull PWM (eg DBW)

• Automatic overcurrent and overtemperature

protection

• 0 to 27V feedback

• High side current feedback

• 18kHz switching speed in DBW mode

Unused HBOs can be used as:

• Generic push/pull 2.2kHz PWM output

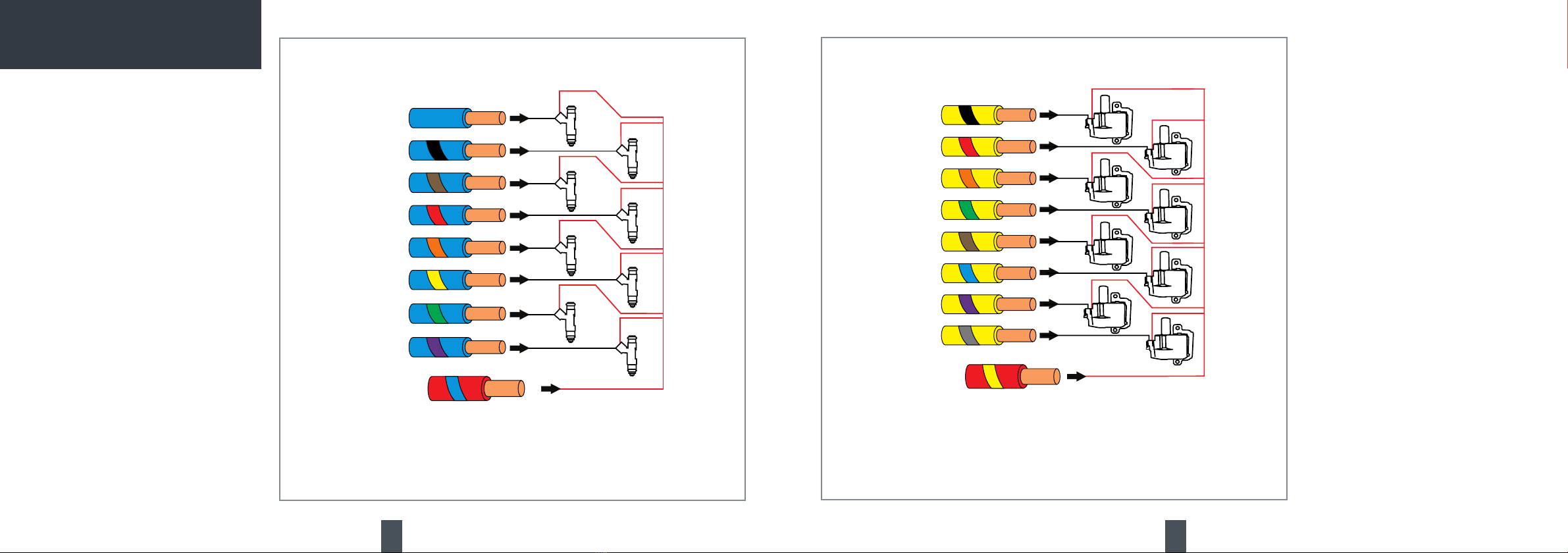

DPO

BOOST

CONTROL

SOLENOID

BOOST

CONTROL

SOLENOID

+12V (HBO6)

BOOST SOLENOID

Example Wiring Connection

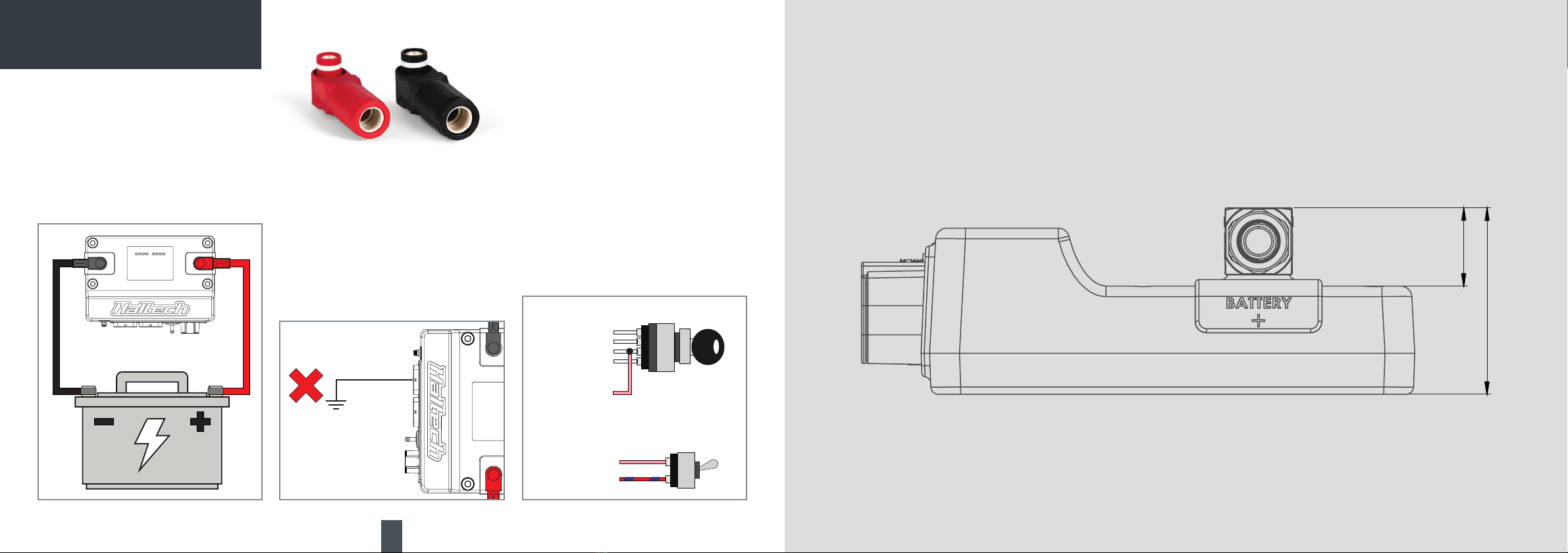

25A High Current Outputs

The NEXUS R3 features four high/low outputs

capable of sinking 25A to ground and driving 25A

to 12V. Each output has a programmable fuse

current, slow-start current and duration. Once the

electronic fuse blows the output turns off for a pre-

programmed delay duration before reactivating

the output. You can use the NSP software to define

the maximum number of retries before the output

is deactivated until the next VCU reboot. The VCU

LEDs conveniently display the output state.

25A HCOs are PWM capable and can be used

for ignition power and injector power as well

as to PWM thermofans and fuel pumps, control

HBO1

HBO4

HBO2

HBO3

DBWTHROTTLE2

DBWTHROTTLE1

The NEXUS R3 supports up to two DBW

throttles, independently controlled in

closed loop. Any pair of HBOs can be

assigned in NSP to control each throttle

motor.

Example Wiring Connections Digital Pulsed Outputs (DPO)

Digital Pulsed Outputs are capable of producing

pulsed waveforms with varying duty, varying

frequency, or switched states. When a DPO is

activated by the VCU the output will switch to

ground.

DPOs can be used to control various low-current

devices such as shift lights, bypass air control

valves, boost control solenoids, tachometers etc.

Specs:

• Number of channels: 6

• Selectable 4k7 pullup to 12V, to 5V, or disable.

• Overcurrent, overheat, and flyback protection

• Low side drive (3A max current)

• 10kHz switching speed

• 0 to 27V feedback

Unused DPOs can be also be used as:

• Generic PWM outputs

• Low speed digital switch inputs (0-12V) with

pullup enable

BATTERY

GROUND

HBO

ELECTRIC WATER PUMP

transbrake solenoids, nitrous solenoids etc.

Specs:

• Number of channels: 4

• 25A source or sink current output

• Automatic high and low side overcurrent

and undervoltage lockout protection

• 0 to 30V feedback

• High and low side current feedback

• 1kHz switching speed

• Capable of 0-100% duty cycle

Example Wiring Connections