3

Subject to change without notice

Accessories supplied: Line Cord, Operators Manual, 2 Probes1:1/ 10:1

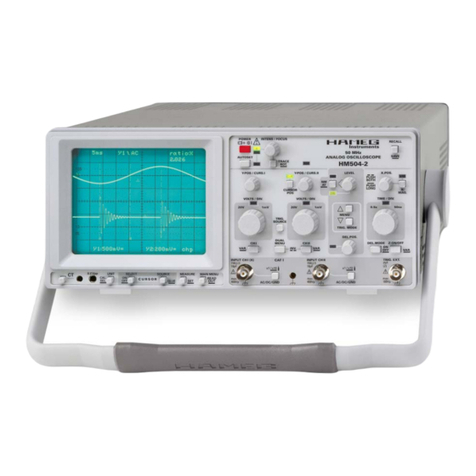

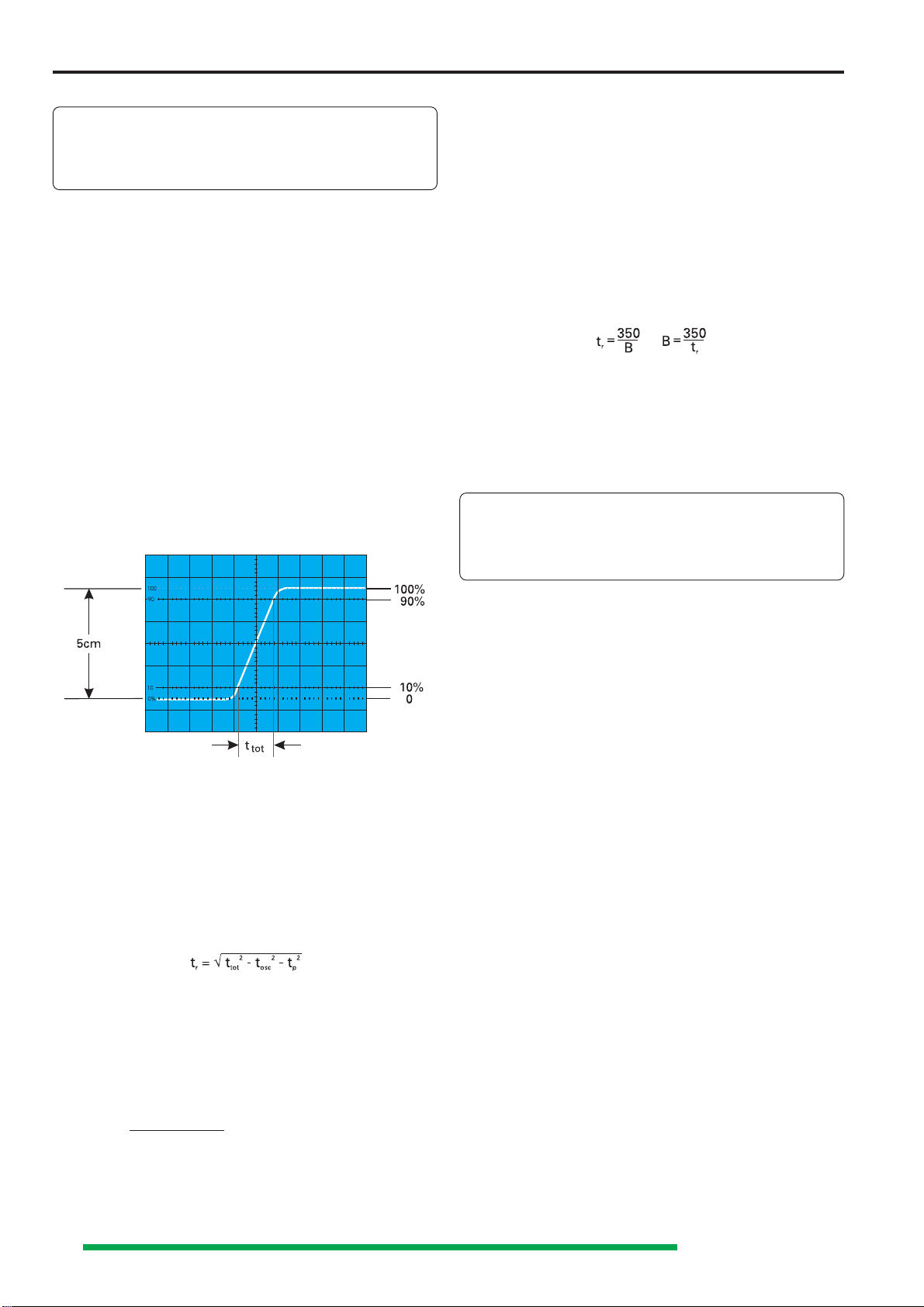

Screen photo of stored sinewave signals. Screen shot of measurement software.

The worldwide success of HAMEG´s HM205 and HM305 has led to the

introduction of the new microprocessor controlled HM407 Analog/Digital

oscilloscope. This instrument offers much more performance and specifications

over its predecessores. The HM407incorporates a microprocessor-basedsystem

that extensively automates operation. The majority of signals can be displayed by

simply pressing the “Autoset“ button. A “Save/Recall“ function is available for

storing frequently used setup parameters.

The increased maximum sampling rate of 100MS/s now allows to capture a

10MHzsignal in “Single“ mode with 10 samples(dots) per period. The automatic

Dot-Join function provides linear connections between the captured points,

ensuring that all digitized signals are displayed without gaps. New features are the

two reference memories, allowing their contents to be compared with the live

signal at any time. Cursors can be activated for waveform measurements. All

important parameter settings are displayed on the CRT screen. The built-in RS232-

Interface enables remote control operation and signal processing via a PC.

Unique in its price range is also the analog section of the HM407. The increased

bandwidth of 40MHz (-3dB) allows the stable display of signals up to 100MHz. As

always, the Component Tester with one-button control is a standard feature in

the HM407. This is also true for the switchable 1kHz/1MHz Calibrator which

permits you to check the transient characteristics from probe tip to the screen at

any time.

All in all, the new HM407 presents itself as a practical hands-on oscilloscope for

today’s progressive measurement requirements offering a price/performance ra-

tio that sets new standards world-wide.

Specifications

Vertical Deflection

Operating modes: Channel I or CH II separate,

Channel I and II: alternate or chopped

(Chopper Frequency approx. 0.5MHz)

Sum or Difference from Channel I and ± Ch. II,

XY-Mode: via CH I (X) and CH II (Y).

Frequency range: 2x DC to 40MHz (−3dB).

Risetime: <8.75ns. Overshoot: ≤1%.

Deflection coefficient: 14 calibrated positions

variable 2.5:1 to min. 50V/div.

1mV/div and 2mV/div: ±5% (0 to 10MHz (-3dB))

5mV/div to 20V/div: ±3% (1-2-5sequence).

Input impedance: 1MΩII 15pF.

Input coupling: DC - AC - GD (Ground)

Input voltage: max. 400V (DC + peak AC).

Triggering

Automatic(peak to peak):≤≤

≤≤

≤20Hz-100MHz(≤0.5div),

Normal: DC-100MHz, LED for trigger indication.

Slope: positive or negative.

Sources: CH I or II, line, ext.

CH I alternate CH II (≤ 0.8div.)

Coupling: AC (≥10Hz -100MHz), DC (0-100MHz),

HF (50kHz - 100MHz), LF (0 - ≤1.5kHz).

Triggering ext.: ≥0.3Vpp from DC to 100MHz

Active TV-Sync-Separator (field & line, pos, neg.)

2nd triggering (Del. Trig.): normal with level

control DC to 100 MHz.

Horizontal Deflection

Time coefficients: 1-2-5 sequence, Accuracy ±3%

Analog: 22 cal. positions from 0.5s - 50ns/div.

Digital:

25 cal. positions from 100s - 1µs/div.

Variable (analog) 2.5:1 up to 1.25s/div.

X-MAG. x10: analogto10ns/div.,dig.to0.1µs/div ±5%

.

Delay: 120ms - 200ns, variable,

Hold-off time (analog):variable to approx. 10:1.

Bandwidth X-amplifier (analog): 0-3MHz (−3dB).

InputX-amplifierviaChannelII, Sensitivitysee

ChannelII.

X-Y-phase shift : <3° below 120kHz.

Digital Storage

Operating modes: Refresh, Roll, Single, XY,

Envelope, Average (2 to 512 waveforms).

Automatic Dot Join function

Sample Rate: max. 100MS/s (8 bit)

Refresh rate: max. 180/s

Record length: 2048 x 8 bit per channel.

Reference memoryReference memory

Reference memoryReference memory

Reference memory: 2 x 2k x 8bit (EEPROM).

Resolution: Y: 25 points/div, X: 200 points/div.

Pre-/Posttrigger: 25, 50, 75, 100, -25,

-50, -75%.

Operation / Control

Manual (front panel switches);

Auto Set (automatic parameter selection).

Save/Recall of 9 user-defined parameter settings

RS232 interface for remote control via a PC.

Remote control (Option) HZ68.

Multifunction- Interface HO79-6(Option): RS232,

IEEE-488, Centronics (Postscript, HPGL, PCL, EPSON).

Readout: Display of parameter settings.

Cursor measurement of ∆V, ∆t or ∆1/t

(frequency),

separate or in tracking mode.

Component Tester

Test voltage: approx. 7Vrms (open circuit).

Test current: max. 7mArms (short circuit).

Test frequency: approx.50Hz

One test lead is grounded (Safety Earth).

GeneralInformation

CRT: D14-364GY/123 or ER151-GH/-,rectangular

screen (8x10cm) internal graticule

Acceleration voltage: approx 2000V

Trace rotation: adjustable on front panel

Calibrator: square-wave generator (tr<4ns)

≈1kHz/1MHz; Output: 0.2V ±1%.

Analog Intensitymodulation, max. +5V (TTL).

Line voltage: 100-240V AC ±10%, 50/60Hz

Power consumption: approx. 42 Watt at 50Hz.

Min./Max. ambient temperature: 0°C...+40°C

Protective system: Safety class I (IEC1010-1)

Weight: approx. 5.6kg, color: techno-brown

Cabinet: W 285, H 125, D 380 mm 3/98

Auto-Set, Save/Recall, Readout/Cursor, RS232 Interface

Analog: 2 x DC-40MHz, max. 1mV/div, Timebase 0.5s/div - 10ns/div

Triggering DC - 100MHz, Component Tester, 1MHz Calibrator

Digital: Max. Sampling Rate 100MS/s, Timebase 100s/div - 0.1µs/div

Storage 2 x 2048 x 8 bit, Reference Memory, Post/Pre-Trigger

Storage Modes: Refresh, Single, Roll, Average and Envelope

40MHz Analog-/Digital-Scope HM407