Subject to change without notice

10

Type of signal voltage

required rec. freq. F = 1:(0.7x10-6) = 1.428MHz.

Signal period T = 1s,

set time coefficient Tc = 0.2s/div,

required wavelength L = 1:0.2 = 5div.

Displayed ripple wavelength L = 1div,

set time coefficient Tc = 10ms/div,

required ripple freq. F = 1:(1x10x10-3) = 100Hz.

TV-Line frequency F = 15625Hz,

set time coefficient Tc = 10µs/div,

required wavelength L = 1:(15 625x10-5) = 6.4div.

Sine wavelength L = min. 4div, max. 10div,

Frequency F = 1kHz,

max. time coefficient Tc = 1:(4x103) = 0.25ms/div,

min. time coefficient Tc = 1:(10x103) = 0.1ms/div,

set time coefficient Tc = 0.2ms/div,

required wavelength L = 1:(103x0.2x10-3) = 5div.

Displayed wavelength L = 0.8div,

set time coefficient Tc = 0.5µs/div,

pressed X-MAG. (x10) button: Tc = 0.05µs/div,

required rec. freq. F = 1:(0.8x0.05x10-6) = 25MHz,

required period T = 1:(25x106) = 40ns.

If the time is relatively short as compared with the complete

signal period, an expanded time scale should always be applied

(X-MAG. (x10) active). In this case, the time interval of interest

can be shifted to the screen center using the X-POS. control.

When investigating pulse or square waveforms, the critical

feature is the risetime of the voltage step. To ensure that

transients, ramp-offs, and bandwidth limits do not unduly

influence the measuring accuracy, the risetime is generally

measured between 10% and 90% of the vertical pulse height.

For measurement, adjust the Y deflection coefficient using its

variable function (uncalibrated) together with the Y-POS.

control so that the pulse height is precisely aligned with the

0% and 100% lines of the internal graticule. The 10% and

90% points of the signal will now coincide with the 10% and

90% graticule lines. The risetime is given by the product of the

horizontal distance in div between these two coincident

points and the calibrated time coefficient setting. The fall time

of a pulse can also be measured by using this method.

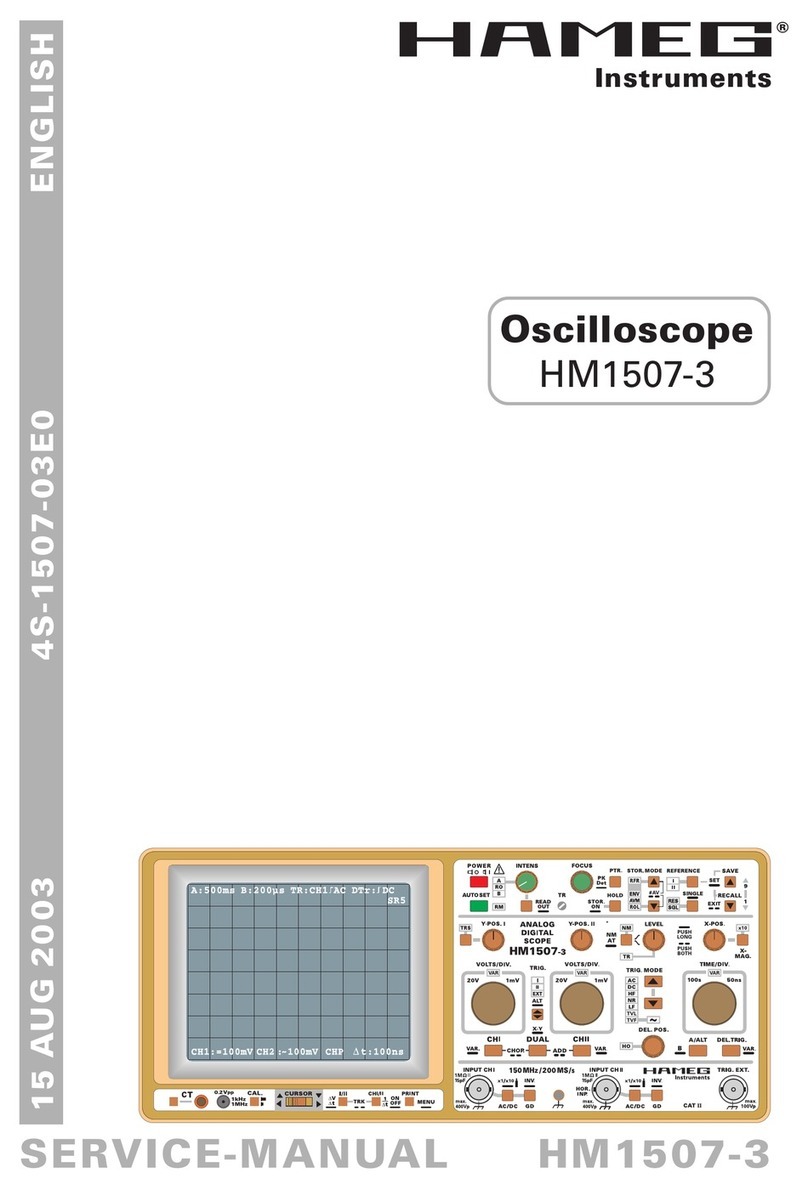

The following figure shows correct positioning of the

oscilloscope trace for accurate risetime measurement.

With a time coefficient of 10ns/div (X x10 magnification

active), the example shown in the above figure results in a

total measured risetime of

ttot = 1.6div x 10ns/div = 16ns

When very fast risetimes are being measured, the risetimes

of the oscilloscope amplifier and of the attenuator probe has

to be deducted from the measured time value. The risetime

of the signal can be calculated using the following formula.

tr= √ttot2- tosc2- tp2

In this ttot is the total measured risetime, tosc is the risetime

of the oscilloscope amplifier (approx. 8.75ns), and tpthe

risetime of the probe (e.g. = 2ns). If ttot is greater than 100ns,

then ttot can be taken as the risetime of the pulse, and

calculation is unnecessary.

Calculation of the example in the figure above results in a

signal risetime:

tr = √162- 8.752- 22 = 13.25ns

The measurement of the rise or fall time is not limited to the

trace dimensions shown in the above diagram. It is only

particularly simple in this way. In principle it is possible to

measure in any display position and at any signal amplitude.

It is only important that the full height of the signal edge of

interest is visible in its full length at not too great steepness

and that the horizontal distance at 10% and 90% of the

amplitude is measured. If the edge shows rounding or

overshooting, the 100% should not be related to the peak

values but to the mean pulse heights. Breaks or peaks

(glitches) next to the edge are also not taken into account.

With very severe transient distortions, the rise and fall time

measurement has little meaning. For amplifiers with

approximately constant group delay (therefore good pulse

transmission performance) the following numerical relationship

between rise time tr (in ns) and bandwidth B (in MHz) applies:

Connection of Test Signal

In most cases briefly depressing the AUTO SET causes a

useful signal related instrument setting. The following

explanations refer to special applications and/or signals,

demanding a manual instrument setting. The description of

the controls is explained in the section ”controls and

readout”.

Caution:

When connecting unknown signals to the oscilloscope

input, always use automatic triggering and set the

input coupling switch to AC (readout). The attenuator

should initially be set to 20V/div.

Sometimes the trace will disappear after an input signal has

been applied. Then a higher deflection coefficient (lower input

sensitivity) must be chosen until the vertical signal height is

only 3-8div. With a signal amplitude greater than 160Vpp and

the deflection coefficient (VOLTS/DIV.) in calibrated condition,

an attenuator probe must be inserted before the vertical

input. If, after applying the signal, the trace is nearly blanked,

the period of the signal is probably substantially longer than

the set time deflection coefficient (TIME/DIV.). It should be

switched to an adequately larger time coefficient.

The signal to be displayed can be connected directly to the Y-

input of the oscilloscope with a shielded test cable such as

HZ32 or HZ34, or reduced through a x10 or x100 attenuator

probe. The use of test cables with high impedance circuits is

only recommended for relatively low frequencies (up to

approx. 50kHz). For higher frequencies, the signal source

must be of low impedance, i.e. matched to the characteristic

resistance of the cable (as a rule 50Ω). Especially when

transmitting square and pulse signals, a resistor equal to the

characteristic impedance of the cable must also be connected

across the cable directly at the Y-input of the oscilloscope.