2Subject to change without notice

General information regarding the CE marking

HAMEG instruments fulfill the regulations of the EMC directive. The

conformity test made by HAMEG is based on the actual generic- and

product standards. In cases where different limit values are applicable,

HAMEG applies the severer standard. For emission the limits for

residential, commercial and light industry are applied. Regarding the

immunity (susceptibility) the limits for industrial environment have

been used.

The measuring- and data lines of the instrument have much influence

on emission and immunity and therefore on meeting the acceptance

limits. For different applications the lines and/or cables used may

be different. For measurement operation the following hints and

conditions regarding emission and immunity should be observed:

1. Data cables

For the connection between instrument interfaces and external devices,

(computer, printer etc.) sufficiently screened cables must be used.

Without a special instruction in the manual for a reduced cable length,

the maximum cable length of a dataline must be less than 3 meters and

not be used outside buildings. If an interface has several connectors

only one connector must have a connection to a cable.

Basically interconnections must have a double screening. For IEEE-bus

purposes the double screened cable HZ72 from HAMEG is suitable.

2. Signal cables

Basically test leads for signal interconnection between test point and

instrument should be as short as possible. Without instruction in the

manual for a shorter length, signal lines must be less than 3 meters

and not be used outside buildings.

Signal lines must screened (coaxial cable - RG58/U). A proper ground

connection is required. In combination with signal generators double

screened cables (RG223/U, RG214/U) must be used.

Die HAMEG Instruments GmbH bescheinigt die Konformität für das Produkt

The HAMEG Instruments GmbH herewith declares conformity of the product

HAMEG Instruments GmbH déclare la conformite du produit

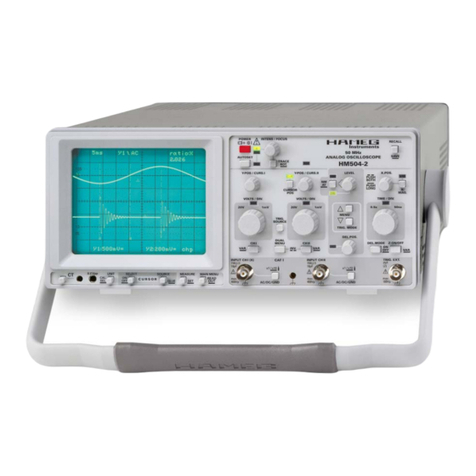

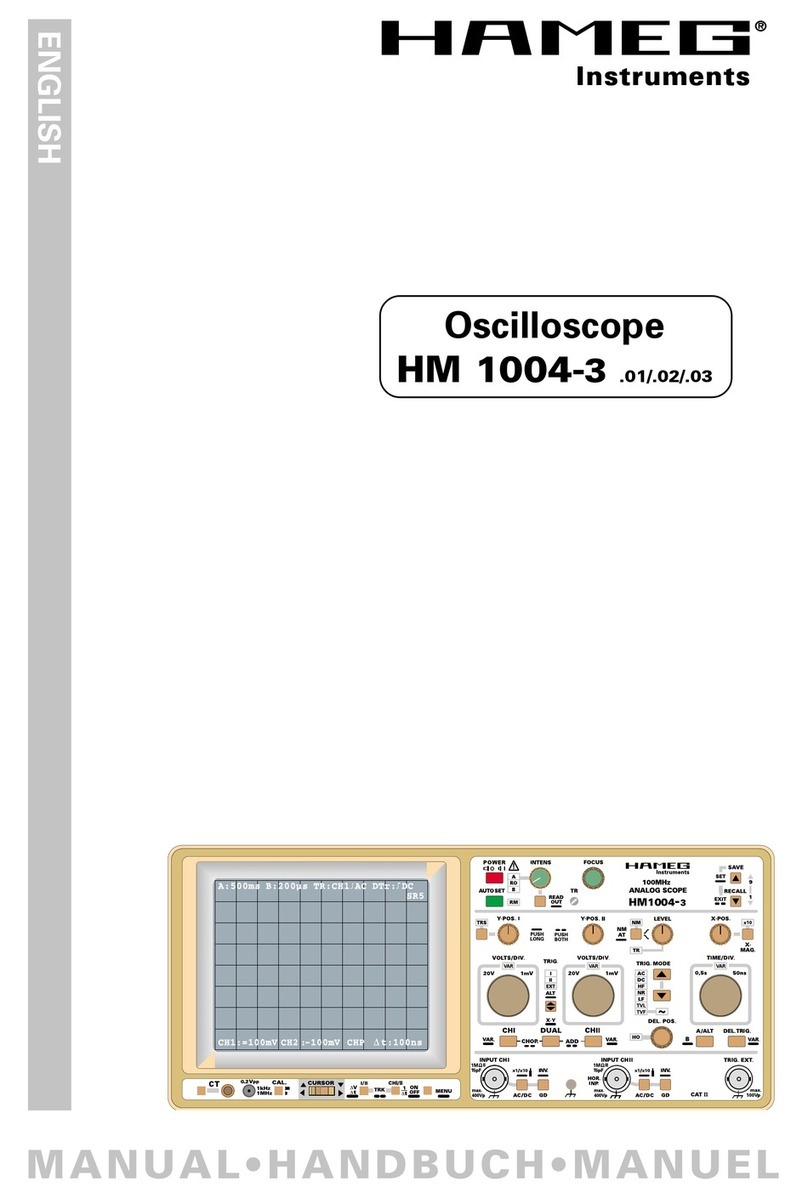

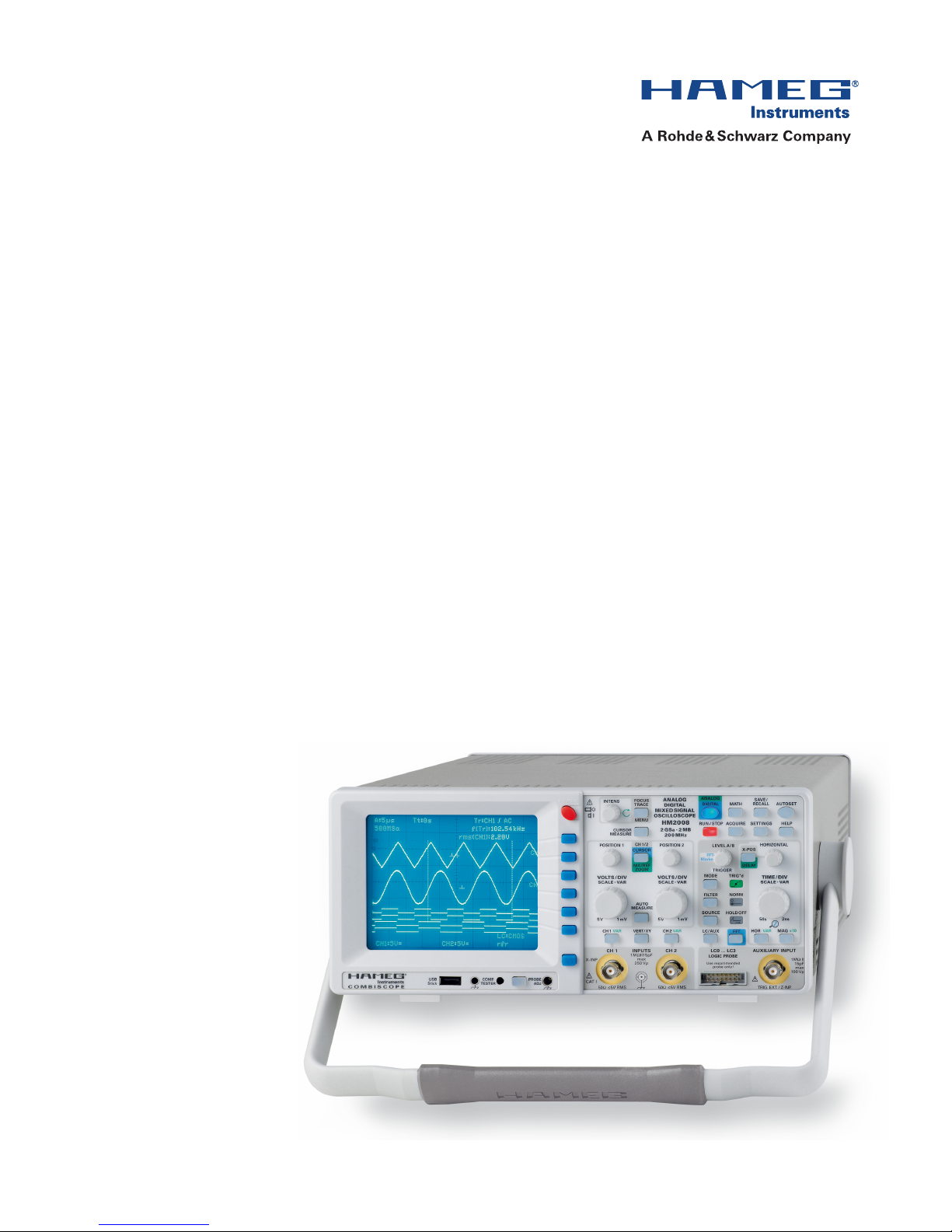

Bezeichnung / Product name / Designation:

Oszilloskop

Oscilloscope

Oscilloscope

Typ / Type / Type: HM2008

mit / with / avec: HO720, HZ200

Optionen / Options / Options: HO730, HO740, HO2010

mit den folgenden Bestimmungen / with applicable regulations / avec les

directives suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Directive 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par 93/68/CEE

Angewendete harmonisierte Normen / Harmonized standards applied / Normes

harmonisées utilisées:

Sicherheit / Safety / Sécurité: EN 61010-1:2001 (IEC 61010-1:2001)

Überspannungskategorie / Overvoltage category / Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility /

Compatibilité électromagnétique

EN 61326-1/A1 Störaussendung / Radiation / Emission:

Tabelle / table / tableau 4; Klasse / Class / Classe B.

Störfestigkeit / Immunity / Imunitée:Tabelle / table / tableau A1.

EN 61000-3-2/A14 Oberschwingungsströme / Harmonic current emissions /

Émissions de courant harmonique:

Klasse / Class / Classe D.

EN 61000-3-3 Spannungsschwankungen u. Flicker / Voltage fluctuations and flicker /

Fluctuations de tension et du flicker.

Datum /Date /Date

02. 04. 2007

Unterschrift / Signature / Signatur

Holger Asmussen

Manager

3. Influence on measuring instruments

Under the presence of strong high frequency electric or magnetic

fields, even with careful setup of the measuring equipment, influence

of such signals is unavoidable.

This will not cause damage or put the instrument out of operation. Small

deviations of the measuring value (reading) exceeding the instruments

specifications may result from such conditions in individual cases.

4. RF immunity of oscilloscopes.

4.1 Electromagnetic RF field

The influence of electric and magnetic RF fields may become visible

(e.g. RF superimposed), if the field intensity is high. In most cases

the coupling into the oscilloscope takes place via the device under

test, mains/line supply, test leads, control cables and/or radiation.

The device under test as well as the oscilloscope may be effected by

such fields.

Although the interior of the oscilloscope is screened by the cabinet,

direct radiation can occur via the CRT gap. As the bandwidth of

each amplifier stage is higher than the total –3dB bandwidth of the

oscilloscope, the influence of RF fields of even higher frequencies

may be noticeable.

4.2 Electrical fast transients / electrostatic discharge

Electrical fast transient signals (burst) may be coupled into the

oscilloscope directly via the mains/line supply, or indirectly via test

leads and/or control cables. Due to the high trigger and input sensitivity

of the oscilloscopes, such normally high signals may effect the trigger

unit and/or may become visible on the CRT, which is unavoidable.

These effects can also be caused by direct or indirect electrostatic

discharge.

HAMEG Instruments GmbH

Hersteller HAMEG Instruments GmbH KONFORMITÄTSERKLÄRUNG

Manufacturer Industriestraße 6 DECLARATION OF CONFORMITY

Fabricant D-63533 Mainhausen DECLARATION DE CONFORMITE

General information regarding the CE marking