HTK INSTALLATION MANUAL 4List of Figures

UNPACKING

Figure 1.1: HTK pallet (face) .................................................................

Figure 1.2: HTK pallet (side) .................................................................

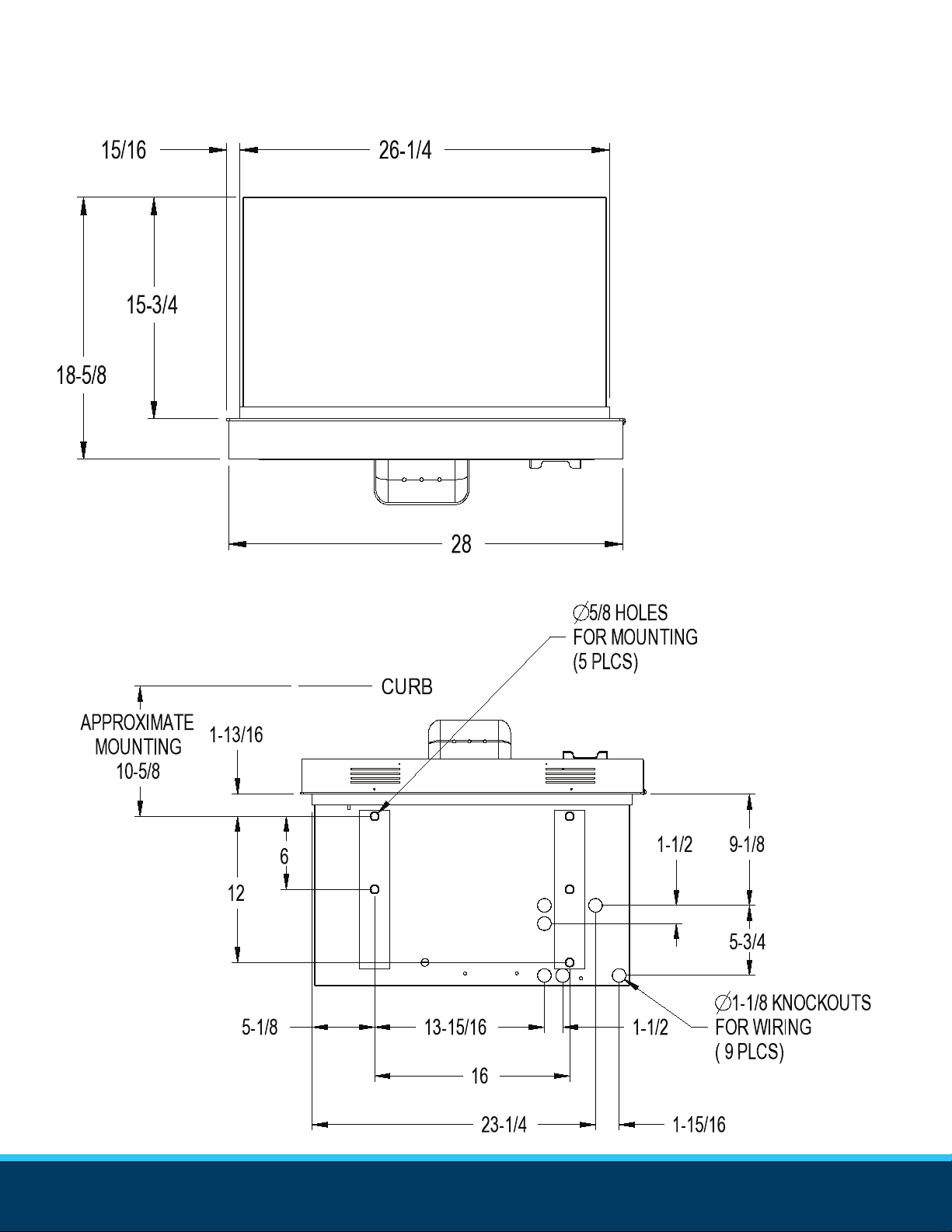

DIMENSIONS - BRICK-IN

Figure 2.1: Top of cabinet ....................................................................

Figure 2.2: Base of cabinet ..................................................................

Figure 2.3: Side of cabinet ....................................................................

Figure 2.4: Rear of cabinet ...................................................................

Figure 2.5: Door ..................................................................................

BRICK-IN BOLT PATTERN

Figure 3.1: Brick-in HTK bolt pattern ...................................................

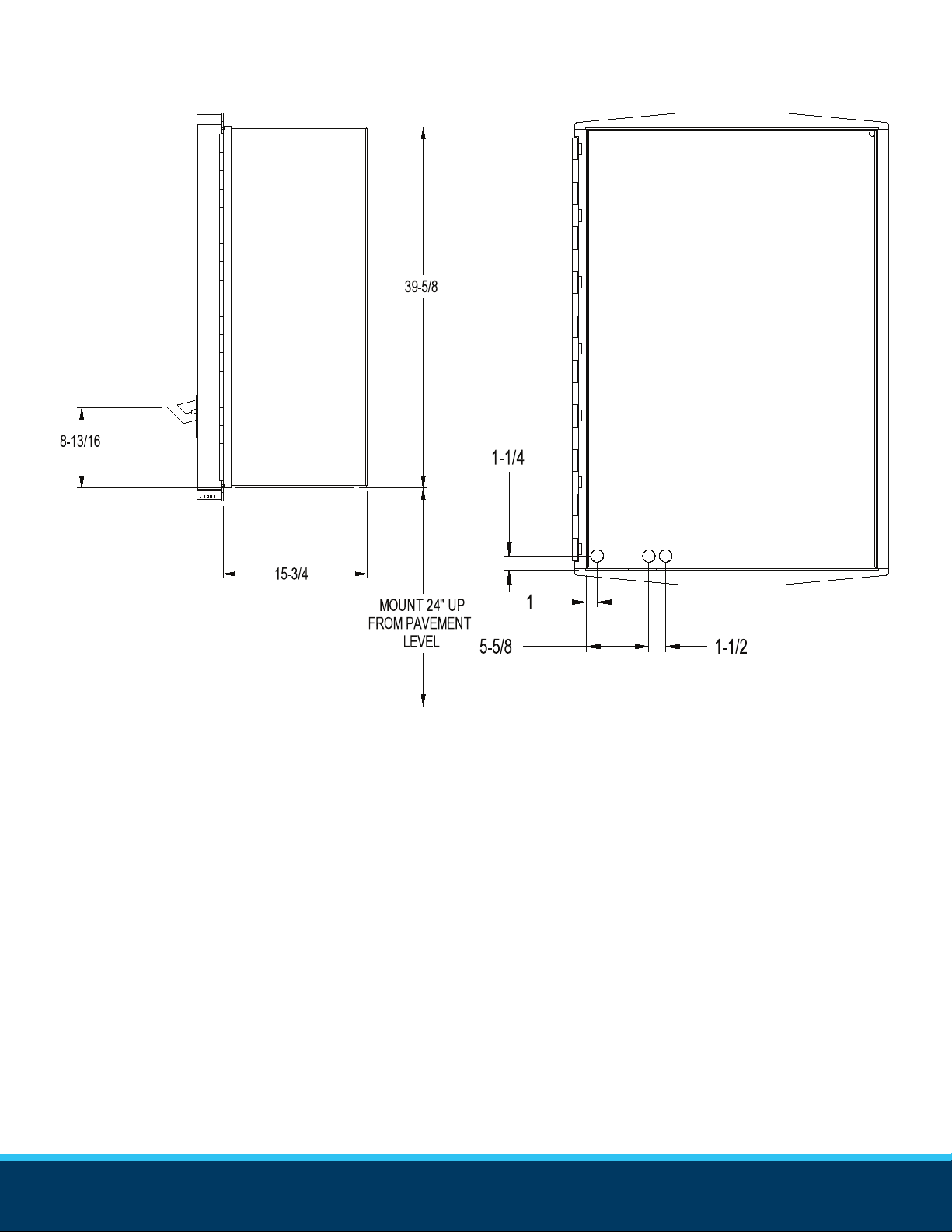

DIMENSIONS - FREE-STANDING

Figure 4.1: Top of cabinet .....................................................................

Figure 4.2: Base of cabinet ...................................................................

Figure 4.3: Sides of cabinet ..................................................................

Figure 4.4: Rear of cabinet ...................................................................

Figure 4.5: Door & base of HTK ............................................................

FREE-STANDING BOLT PATTERN

Figure 5.1: Free-standing HTK bolt pattern ............................................

LANE LAYOUT

Figure 6.1: Front view of brick-in lane layout ..........................................

Figure 6.2: Front view of free-standing lane layout .................................

Figure 6.3: Overhead view of lane layout ...............................................

Figure 6.4: Service door orientation .......................................................

ELECTRICAL DIAGRAMS

Figure 7.1: Power supply wiring connection ..........................................

Figure 7.2: Wash Interface diagram ......................................................

Figure 7.3: Wash Interface diagram, angled ..........................................

Figure 7.4: Gated Sequence Software Ether Vend (MIB Gate) ................

Figure 7.5: Gated Sequence Software Ether Vend (Micro Drive Gate) ......

Figure 7.6: Passive Cycles ....................................................................

Figure 7.7: Active Cycles ......................................................................

COMPONENT CONNECTIONS

Figure 8.1: Power supply connections ...................................................

Figure 8.2: Gen 5 controller connections ...............................................

Figure 8.3: Gen 4 controller connections ...............................................

Figure 8.4: Gen 3 controller connections ...............................................

Figure 8.5: Distribution board connections .............................................

Figure 8.6: Smart Bus Hub connections .................................................

Figure 8.7: Bill dispenser connections ....................................................

Figure 8.8: Stacker interface connections ...............................................

List of Figures

6

6

8

8

9

9

10

11

12

12

13

13

13

14

15

15

16

16

20

21

21

22

23

22

22

25

26

27

28

29

30

31

32