4

S121c

APR 2006

Color Part No.

Red 70-1100

Amber 70-1101

Green 70-1102

Beacon Pilot Light Kits

ODS

STD ALSO STD

3/4" (20) 1" (25)

1 1/4" (32) 7/8" (22)

1" (25) 3/4" (20)

1 1/4" (32) 1 1/8" (28)

1 1/4" (32) 3/4" (20)

1" (25) 1 3/8" (35)

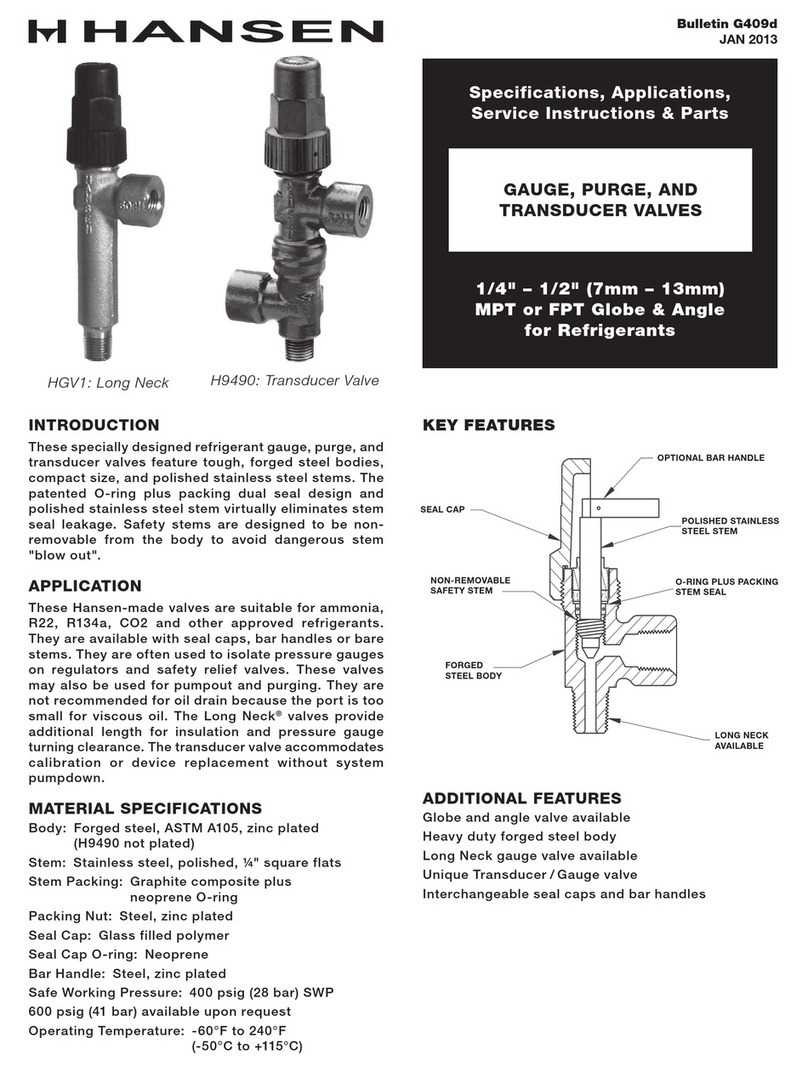

Flange Connection Style & Sizes

Inches (Millimeters)

FPT, SW, WN

Hansen Technologies Corporation

6827 High Grove Boulevard

Burr Ridge, Illinois 60527 USA

Tel: 630.325.1565 Fax: 630.325.1572 Toll: 800.426.7368

USA ∙Asia ∙Europe ∙India ∙Latin America ∙Middle East

© 2006 Hansen Technologies Corporation

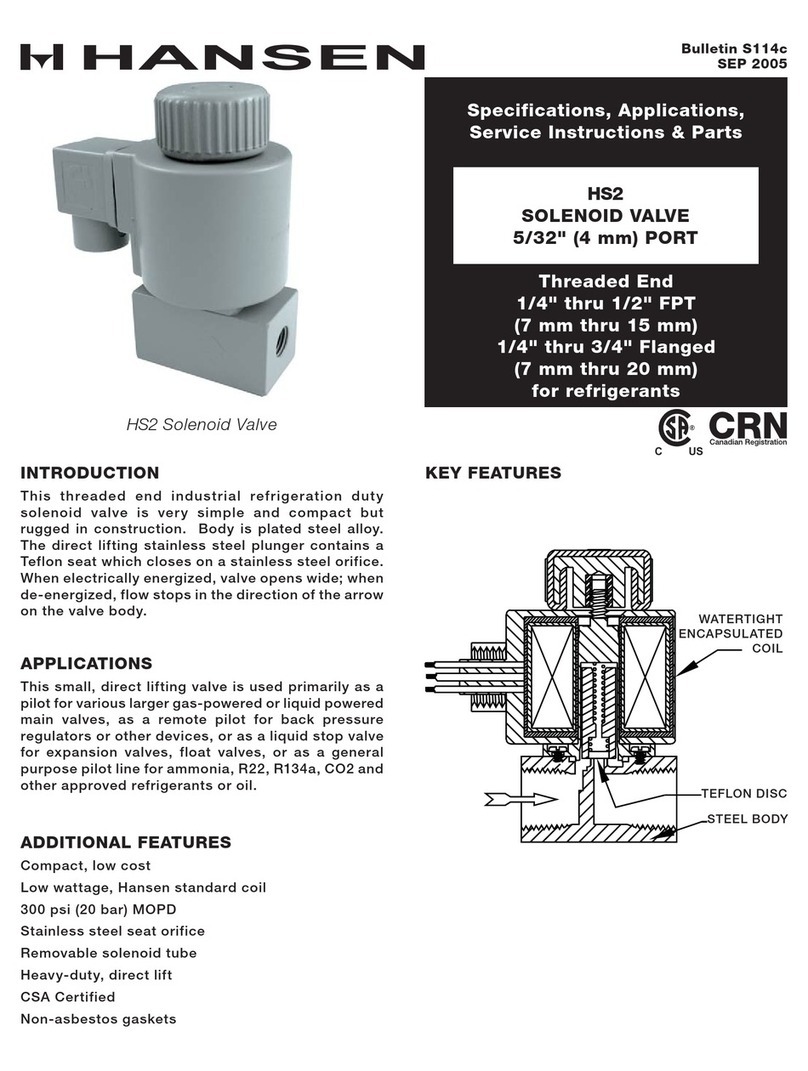

ELECTRICAL

The coil draws 16 watts and will operate properly

between 85% and 110% of rated voltage (24V coil

draws 19 watts). Standard coil connection is a 1/2”

fitting (NPSM) for conduit, with two 18” wire leads and

ground wire. Coils with DIN plug or 1/2” NPSM quick

disconnect plug are available. Contact the factory.

All coils are totally encapsulated and meet NEMA 3R

(rainproof) and NEMA 4 (splashproof, approx. IP65)

requirements. The coil should only be energized

while on the solenoid tube. Otherwise, immediate coil

burnout may occur. To avoid bending the solenoid

tube, remove the coil from valve before connecting

any electrical conduit. Pilot lights are available.

SERVICE AND MAINTENANCE

Failure to open: wrong voltage coil; low line voltage;

controlling switch or thermostat not contacting; coil is

burned-out; inlet/outlet pressure differential too high;

less than 2 psi (0.14 bar) pressure drop across valve;

piston or plunger is jammed closed with dirt.

Failure to close: controlling switch or thermostat

not opening contacts; manual opening stem is turned

in; piston or plunger is jammed upward by dirt; damage

or dirt at main valve seat or pilot valve seat.

Before opening the valve for service, be sure it is

isolated from the system and all refrigerant is removed.

Disconnect electrical power from coil. Remove the coil

by unscrewing the coil knob. Use a large wrench to

unscrew the bonnet-cartridge proceeding cautiously

to avoid any refrigerant still remaining inside the

valve. Remove closing spring and piston. Check for

dirt on piston or seat. Polish with fine emery cloth

and replace or else install new parts. Check and

replace bonnet-cartridge O-rings if necessary, using

refrigerant oil or grease.

To check pilot section of valve, loosen four solenoid

tube screws, break seal between solenoid tube

and bonnet-cartridge; being careful to avoid any

refrigerant which may remain. Check face of Teflon

seat in plunger, plunger spring, and pilot seat orifice

on bonnet-cartridge. Clean, polish or replace parts

as necessary. Always replace plunger and solenoid

tube as a set. Pilot seat is integral with bonnet-

cartridge. Install new solenoid tube gasket and oil

lightly. Reassemble bonnet-cartridge to valve body,

using 75 foot-pounds torque to tighten secondary,

metal, knife edge seal. Carefully check the valve for

leaks before restoring to service.

CAUTION

Hansen valves are only for refrigeration systems.

These instructions must be completely read and

understood before selecting, using or servicing Hansen

valves. Only knowledgeable, trained refrigeration

mechanics should install, operate, or service these

valves. Stated temperature and pressure limits should

not be exceeded. Bonnets, solenoid tubes, etc. should

not be removed from valves unless system has been

evacuated to zero pressure. Must also see Safety

Precautions in current List Price Bulletin and Safety

Precautions Sheet supplied with product.

WARRANTY

All Hansen products, except electronics, are

guaranteed against defective materials or workmanship

for one year F.O.B. factory. Electronics are guaranteed

against defective materials or workmanship for 90

days F.O.B. factory. No consequential damages or

field labor is included.

ORDERING INFORMATION

FPT: Female Pipe Thread (American National Standard)

SW: Socket Weld to accommodate American and API pipe

WN: Weld Neck to match American Schedule 40 pipe

ODS: Outside Diameter Sweat, for copper tube size

Standard encapsulated solenoid coil is included

for 50/60Hz 208/230, 115, or 24 volts; other

voltages offered. Standard coil connection is

a 1/2” fitting (NPSM). Coils with DIN plug or

1/2” NPSM quick disconnect plug are available;

please specify when ordering. Pilot lights are

also available.

OPTIONAL BEACON PILOT LIGHTS

Pilot Light Kit includes Beacon pilot light, knob and

o-ring. A/C Coils Only.

TO ORDER:

Specify type, connection type and size, volts, and

strainer if required. Unless otherwise specified,

standard coil with 1/2” connection will be supplied.

TYPICAL SPECIFICATIONS

“Refrigerant solenoid valves shall have encapsulated,

watertight coils, Teflon seats, steel or ductile iron

bodies, spring closing pilot and main valve seats, and

be suitable for a safe working pressure of 400 psig

(27 bar), as manufactured by Hansen Technologies

Corporation or approved equal.”