2

G409d

JAN 2013

Hansen Technologies Corporation

400 Quadrangle Drive, Suite F

Bolingbrook, Illinois 60440 USA

Tel: 630.325.1565 Fax: 630.325.1572 Toll: 866.4HANSEN

USA ∙ Asia ∙ Europe ∙ India ∙ LatinAmerica ∙ MiddleEast

© 2013 Hansen Technologies Corporation

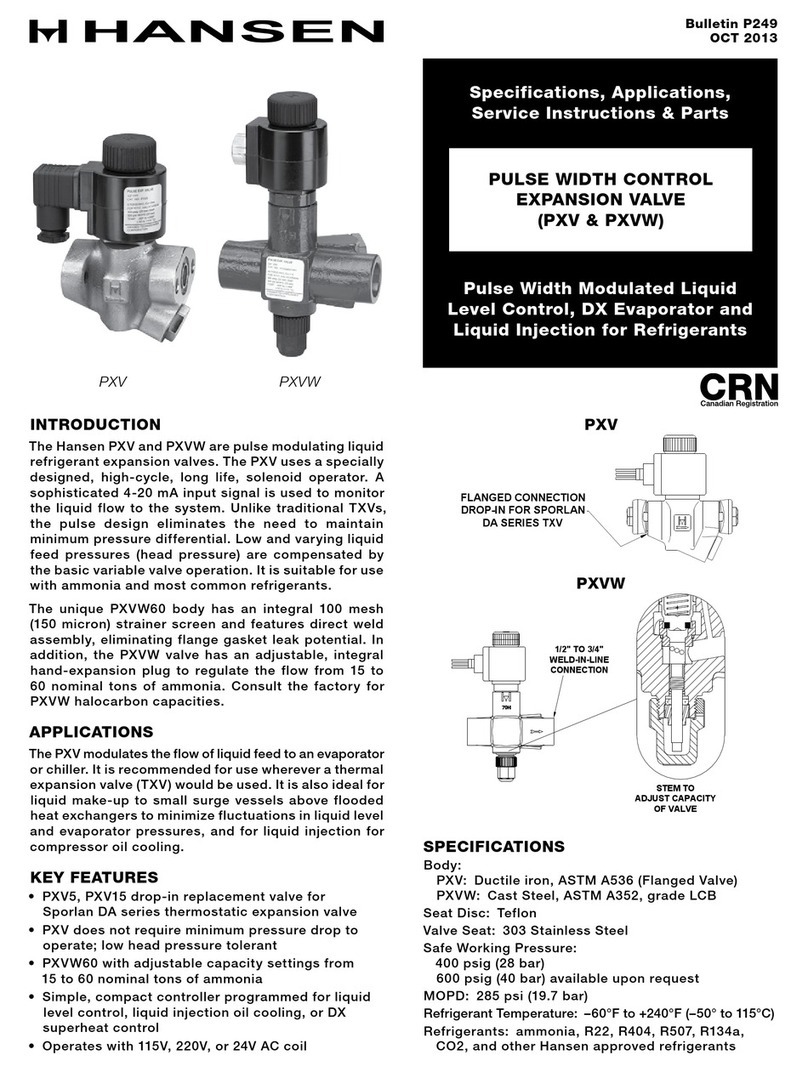

INSTALLATION DIMENSIONS (inches)

SERVICE AND MAINTENANCE

Hansen gauge valves require practically no service

or maintenance due to the combination of polished

stainless steel stem and reliable O-ring stem seal plus

graphite composite packing. However, if tightening

is ever needed, use a 3/8" open end wrench or an 8"

adjustable wrench. Extrusion of some black graphite

packing material along the stem is normal.

If the O-ring or the adjustable packing ever needs

replacement as evidenced by refrigerant or oil leakage at

the stem, isolate valve from the system and evacuate to

zero pressure in accordance with appropriate practices.

Seal caps [1/4" (P/N 50–1071), 3/8"–1/2" (P/N 50–1036)]

or bar handles [1/4" (P/N 50–1069), 3/8" (P/N 50–1075)]

can be easily retro-fitted to valves in the field. All

bodies have seal cap threads; simply screw seal cap

with O-ring onto these threads. Bar handle kit comes

with pin partially installed in handle Place handle on

stem and turn clockwise to close valve. Begin to push

pin through handle and valve stem using pliers, then

tap with hammer to finish.

CAUTION

Hansen valves are for refrigeration systems only. Read

these instructions completely before selecting, using,

or servicing these valves. Only knowledgeable, trained

refrigeration technicians should install, operate, or

service these valves. Stated temperature and pressure

limits should not be exceeded. Bonnets should not

be removed from valves unless the system has been

evacuated to zero pressure. See also Safety Precautions

in the current List Price Schedule and the Safety

Precautions Sheet supplied with the product.

WARRANTY

Hansen valves are guaranteed against defective materials

or workmanship for one year F.O.B. our factory. No

consequential damages or field labor is included.

FPT X FPT, ANGLEFPT X FPT, GLOBE

1/4" Transducer Valve

MPT X FPT, ANGLEMPT x FPT, LONG NECK

ORDERING INFORMATION

SIZE

(mm)A A' B C E F G H H' J

1/4"

(7)

2.09

(53)

2.57

(65)

1.11*

(28)

1.26

(32)

1.00

(25)

0.59

(15)

2.28

(58)

2.22

(56)

2.71

(69)

0.47

(12)

3/8"

(10)

2.94

(75)

3.57

(91)

1.44

(37)

1.88

(48)

1.63

(41)

0.72

(18)

3.22

(82)

3.07

(78)

3.70

(94)

0.59

(15)

1/2"

(13)

2.94

(75)

3.57

(91)

1.44

(37)

1.88

(48)

1.63

(41)

0.72

(18) ––––

* THE B DIMENSION FOR HGV1, HGV1H, & HGV2 IS 3.25"(83MM)

DESCRIPTION SEAL

CAP

BAR

HANDLE

BARE

STEM

1/4" MPT x FPT, Angle, Long Neck†HGV1* HGV1H HGV2

1/4" MPT x FPT, Angle H7771* H7771H H965

1/4" FPT x FPT, Angle H7772 H7772H H967

1/4" FPT x FPT, Globe H957C H957H H957

1/4" MPT x FPT x FPT, Transducer Valve H9490 – –

3/8" MPT x FPT, Angle H7773 H7773H –

3/8" FPT x FPT, Angle H7774 H7774H –

3/8" FPT x FPT, Globe H958C H958H –

1/2" MPT x 3/8" FPT, Angle H7777 – –

1/2" MPT x 1/4" FPT Angle H7778 – –

†LONG NECK VALVES PROVIDE ADDITIONAL LENGTH FOR INSULATION AND

PRESSURE GAUGE TURNING CLEARANCE.

* HGV1 AND H7771, AVAILABLE AS WELDED INLET VERSIONS, HGV1W AND

H7771W PAINTED BODY.

TO ORDER: Specify Catalog Number.

TRANSDUCER VALVE

The H9490 Transducer Valve can be installed wherever

pressure monitoring is desired. Turn stem all the way

in (clockwise) and seat to isolate pressure from both

gauge and transducer ports. Turn stem all the way out

(counter-clockwise) and seat to isolate pressure from

the gauge port. With stem in middle position, both

ports are active.