HappyJapan HCD3 User manual

Industrial Single-head Embroidery Machine

INSTRUCTION BOOK

Program Ver. *2.15~

HCD3

PROVISIONAL

VERSION

D3RB01-1

-D3 -5

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS... 1-1

WARNING LABELS & THEIR LOCATIONS

..... 1-2

SETTING UP THE MACHINE

Assemble machine unit........................... 2-1

How to carry machine ............................. 2-2

Machine installation ................................ 2-3

Assemble safety sensor (Option)

...................... 2-4

Assemble table (Option) ......................... 2-5

Assemble border frame (Option)............ 2-5b

Assemble bobbin thread guide (Option) 2-6

Grounding instruction (for type of 120V) 2-7

Disposal of a battery ..............................2-7

MAIN PARTS............................................. 3-1

THE CONTROL BOX ................................ 3-3

DRIVE MODE.................................. 3-4

MENU................................................... 3-A

INSERTING A NEEDLE............................. 4-1

SELECT NEEDLES AND THREADS ....... 4-2

BACKING MATERIALS ............................. 4-3

BORDER FRAME CLIP............................. 4-3a

WINDING

Winding the bobbin (Option) ................... 4-4

Removing the bobbin.............................. 4-5

Inserting the bobbin ................................ 4-5

Adjusting bobbin thread tension.............. 4-5

Inserting the bobbin case........................ 4-5

THREADING THE MACHINE

How to thread upper thread .................... 4-6

HOW TO READ THESE INSTRUCTIONS, SCROLLBAR

... 4-8

DISPLAYING THE PATTERN IN SETTING MODE

... 4-9

TURNING THE MACHINE ON

How to turn on the machine.................... 5-1

Calendar and clock setting...................... 5-2

MESSAGES .............................................. 5-3

PREPARATION OF PATTERN DATA

Connecting to a PC................................. 5-4

Reading embroidery pattern data from the PC

. 5-4b

Reading embroidery pattern data ........... 5-5

Selection of folders ................................. 5-9

How to select patterns from memory ... 5-A

Erasing patterns from memory.............. 5-B

NEEDLE BAR SELECTION .................... 5--E

SEWING WITH TUBULAR FRAMES

Installing and removing the frame base.. 6-1

How to hoop............................................ 6-2

Mounting the hoop on the machine......... 6-3

Starting to embroider .............................. 6-4

CAP FRAME (option)

Cap frame settings.................................. 7-1

Installing and removing the cap drive frame...

7-2

Normal cap frames.................................. 7-5

Wide cap frames..................................... 7-8

Starting to embroider ........................... 7-B

ADJUSTING THE THREAD TENSION ..... 8-1

ADJUSTING THE LASER POINTER (OPTION)

.. 8-2

BORER (Option)........................................ 8-4

SEWING

What to do if the thread breaks while sewing

9-1

Stopping and resuming sewing............... 9-1

Loss of power while embroidering .......... 9-2

Moving the hoop while embroidering and then returning to

the correct location (Position)

............................. 9-3

Moving back to the starting point

(Origin)

9-3

Going back to the beginning of the design (Top)

... 9-4

Placing the design in the center of the selected

embroidery frame

(Center)

........................... 9-4

Rotating and mirroring designs (Convert)

..... 9-5

Starting in the middle of a design (Position) ...

9-6

POSITION ALIGNMENT BY DEFINING 2 POINTS

.. 9-8

POSITION ................................................. 9-B

Piece number..........................................9-C

Bobbin thread alarm..............................9-Cb

REGISTER ................................................9-D

Entry........................................................9-E

Return .....................................................9-F

READING

Join ....................................................... 10-1

Pattern read settings............................. 10-3

0_1 RC01

0-1

-DA -4

CONTENTS

0_2 R821

0-2

PATTERNS IN MEMORY

Locking pattern data ..............................11-1

Trace type ..............................................11-2

Export.....................................................11-3

Renaming patterns.................................11-5

Copying pattern data..............................11-6

Moving pattern data ...............................11-7

Renaming folders...................................11-9

Sort ........................................................11-A

Thread break report .............................. 11-B

Retrieve built-in design data .................11-C

Searching pattern data..........................11-D

NEEDLE BAR SELECTION .................... 12-1

Auto setting........................................... 12-2

Thread color.......................................... 12-4

Color change data registration.............. 12-6

Color change data read ........................ 12-7

Repetition of color group setting ........... 12-8

FRAME CONFIRMATION ....................... 13-1

Frame selection

....................................... 13-2

Adjusted for embroidery area................ 13-4

User-dened frames (1 ~ 5).................. 13-7

User-dened frames (6 ~ 20).................13-A

How to change center point of frame (1 ~ 5, 6 ~ 20) ........

13-H

Non registered frame .............................13-J

PATTERN SETTINGS ............................. 14-1

Scaling .................................................. 14-2

Width adjustment .................................. 14-3

Angle..................................................... 14-4

Repeat sewing ...................................... 14-5

Auto origin............................................. 14-7

Offset .................................................... 14-8

Frame out...............................................14-D

MACHINE SETTINGS............................. 15-1

LOCK STITCHES.................................... 15-5

OPTIONAL DEVICE SETTING ............... 15-6

LETTER................................................... 16-1

QUEUE.................................................... 17-1

Alter and Execution............................... 17-2

Needle bar selection and Pattern settings

... 17-4

Registration of QUEUE setting ............. 17-6

Read QUEUE setting............................ 17-7

OTHER SETTINGS

Create network...................................... 18-1

Version information and software update

.... 18-3

Language.............................................. 18-5

Calibrate................................................ 18-6

User maintenance mode....................... 18-8

Report...................................................... 19-1

GUIDE .................................................. 20-1

SCREEN SAVER..................................... 21-1

i-CUSTOM............................................... 22-1

LAN connection .........................................22-2a

TASK RESERVATION ............................... 22-2b

Reading................................................. 22-2c

Needle bar selection ............................. 22-2d

Setting................................................... 22-2e

Search................................................... 22-2f

List ........................................................ 22-2g

USER MANAGEMENT

Registration of administrator................. 22-3

Registration of user............................... 22-6

Selection of user (Login) ....................... 22-8

Selection of user (Login) at power ON.. 22-9

LAYOUT ...................................................22-A

SPECIFICATIONS • MAINTENANCE

Specications........................................ 23-1

Oiling..................................................... 23-1

Cleaning the rotary hook

Cleaning the thread cutting knife .......... 23-2

ERRORS AND WHAT TO DO ................. 24-1

INITIALIZING OF MACHINE SETTINGS

Re-Initialization of machine system ...... 25-1

Initializing of machine speed................. 25-2

HELPFUL HINTS..................................... 26-1

EMBROIDERY TERMS........................... 26-2

BUILT-IN FONT LIST............................... 26-3

BUILT-IN PATTERNS LIST...................... 26-4

-CD -5

IMPORTANT SAFETY INSTRUCTIONS

1_1 F701

1-1

When using an electrical appliance, basic safety precautions should always be followed, includ-

ing the following.

Read all instructions before using this appliance.

DANGER - To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this appliance

from the electric outlet immediately after using and before cleaning.

WARNING

-To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this appliance is used

by or near children.

2. Use this appliance only for its intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged, or dropped into water. Return the appliance to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical

adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation openings of the

sewing machine free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10.Keep fingers away from all moving parts. Special care is required around the sewing

machine needle.

11.Always use the proper needle plate. The wrong plate can cause the needle to break.

12.Do not use bent needles.

13.Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14.Switch the sewing machine off (“0”) when making any adjustments in the needle area, such

as threading needle, changing needle, threading bobbin, or changing presser foot, etc.

15.Always unplug sewing machine from the electrical outlet when removing covers, lubricating,

or when making any other user servicing adjustments mentioned in the instruction manual.

SAVETHESE INSTRUCTIONS

-D2 -5

WARNING LABELS &THEIR LOCATIONS

1_2 M101

1-2

Safety Instruction Sticker for servicing, operating and

maintaining

Caution Sticker for hot surface

( on all pulse motors, the motors may reach a certain temperature after

long time running, which can reach up to 60°(C )

Trapping hazard

( please see sketch for location )

Trapping hazard wherever this label is found

Injury risk warning for all needles

Shock hazard on all electrical components

Injury risk on moving head(s)

Injury risk on frame and carriage

Laser beam (Class 1)

Do not stare into the beam.

ES-HMF-5113-0

WARNING

Shut the cover when starting the

machine. Do not put hands in

while the machine is running.

Fearof serious injury.

ES-HMF-5127-0

SAFETY INSTRUCTIONS

1. Machine must be operated by well trained

person only.

2. Machine must be used for original purpose

only, do not use for other purpose.

3. Shut machine off to oil, adjust or service.

4. Do not operate machine fill close and fix

cover.

5. Do not leave running when unattende.

ES-HMF-5128-0

Donottouch

hotsurfaces.

CAUTION

ES-HMF-5112-1

Fearof serious injury.

Keep fingers away from

the needles while

the machine is running.

WARNING

ES-HMF-5117-0

CAUTION

Keep hands away from the

moving heads while the

machine is running.

Possibility of injury.

ES-HMF-5114-0

CAUTION

Possibility

of injury.

Keep hands away

from the drive

frame while

the machine

is running.

ES-HMF-5115-0

CAUTION

Possibility

of injury.

Do not put fingers

in holes or grooves

of the table.

Laser beam (Class 1)

CAUTION

Do not stare into the beam.

-D3 -11

SETTING UP THE MACHINE

2_1 RC01

2-1

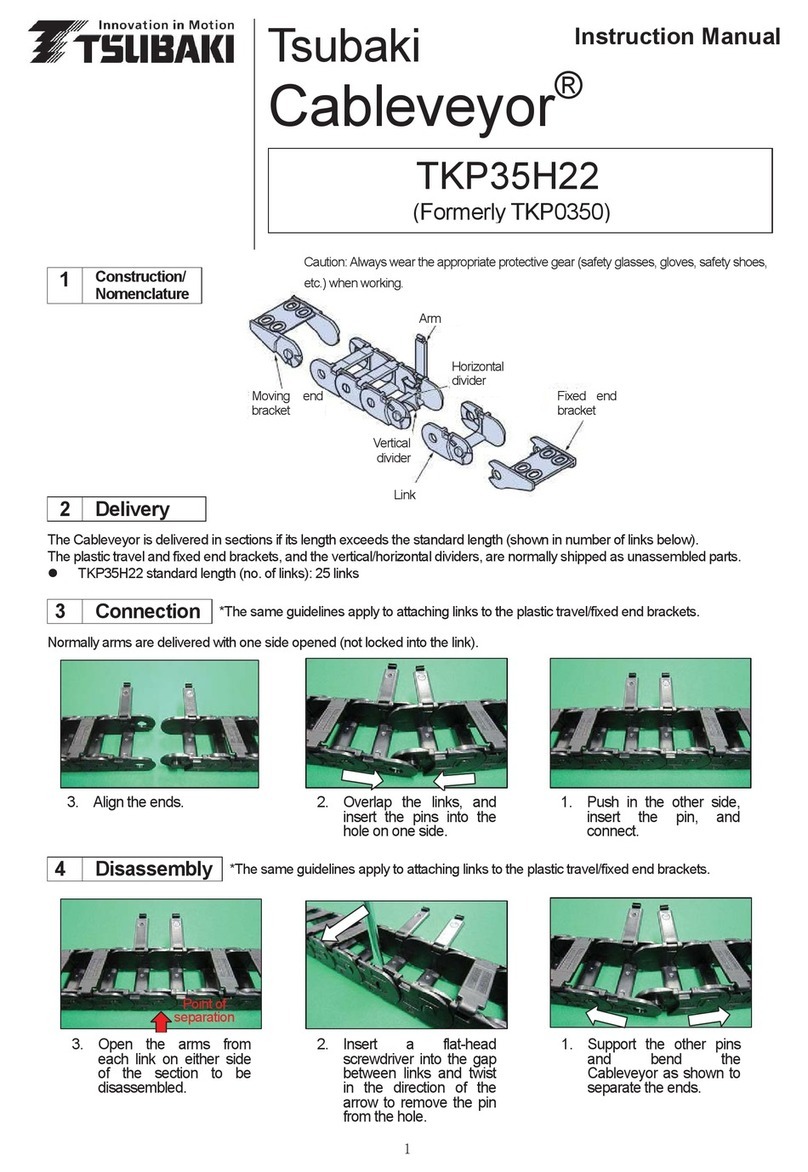

Assemble machine unit

1. Insert thread stand felt on the thread stand.

2. Turn the thread guide pillar clockwise with a

3 mm hexagonal driver until tight.

3. Install the thread guide bracket with supplied

screws (pan head screw M4 X 8 2 pcs).

4. Loosen the screw with a offset driver and

remove the red shipping collars that are

equipped on the both side of the guide bar.

(Keep the shipping collars. It is necessary

when packing.)

5. Raise slowly the control box to the front then

x it with 2 screws (upper and lower).

6. Install the tubular frame arm for embroidery.

Please refer to (page 6-1) “Installing and

removing the tubular frame arm”.

Or, Install the cap frame for the cap

embroidery. Please refer to (page 7-1)

“Installing and removing the cap drive

frame”.

7. Insert built-in stylus into the holder (slot) of

control box.

When taking the machine apart in case

of packing, the process is opposite of

assembling the machine. Please do exactly

the opposite way of assembling.

When packing the machine up for

transportation, be sure to select the eighth

needle and x it with shipping collars on the

both side of the guide bar.

1

2

3

Thread stand

Thread guide pillar

Thread guide

5

Screw

4

Screw

Screws

Stylus

7

-D2M4 -92-2 LC01

2-2

SETTING UPTHE MACHINE for qualified personnel only

How to carry machine

The unpacked machine should be carried by 3

person with the hand position at mark

shown in photos.

2Ocasional

adjusters

Adjusters

Rubber mount

1

Right side

Left side

Rear side

Machine installation

Do not run the machine before setting it

properly.

Make sure of taking the following steps to

set the machine.

1. Pick up rubber mount (3 places) on the

stand then mount machine on the stand.

Then adjust machine level by adjuster on

foot and lock the each nut.

Be sure to use rubber mounts. Also be sure

to use robust stand that enables to adjust

level of the machine and endure machine

weight and vibration.

2. Please two occasional adjuster light touch

to stand and lock.

-D3 -112-3 RC01

2-3

SETTING UP THE MACHINE

3. Remove needle plates and bobbin cases

from all the heads.

4. Lower the needle holder by pressing down

with ngers on Fig. 4.

5. Turn main shaft by using the hexagonal

driver in direction shown with arrow mark on

Fig. 5 and set the angle of the adjustment

disk as shown in g. 6.

6. Check the needle depth on all needles.

Pull white plastic f17 measuring gauge in

and out of rotary hook in g. 7. If height

gauge brushes lightly against tip of needle,

needle height is correct. If not, loosen

needle bar block screw to adjust, then re-

tighten after adjustment.

(Remove the gauge when nished).

Note: Height gauge is contained in tool box.

7. Turn main shaft slightly in direction shown

by the arrow mark.

Then set the angle of adjustment disc as

shown in Fig. 8.

Note the space or timing between needle

and tip of rotary hook as shown Fig. 9, 10.

If the space is too open or too close, loosen

3 screws of shuttle to adjust. Make sure to

tighten 3 screws after adjusted the space.

(The timing is set exactly at the factory.

However, in some cases timing is

inadvertently thrown off from handling during

shipment.)

8. Turn main shaft in direction and set to C

point.

Place the bobbin and bobbin case in the

hook and replace the needle plate and

tighten.

9. Machine is now ready for sewing.

L+5°

L+23°

Fig. 10

Fig. 9

Fig. 8

Fig. 7

Fig. 6

Fig. 5

Fig. 4

Needle holder

Needle holder

CordRotary hook

Needle

ø17 Measuring gauge

Rotary hook

Needle

f17 Measuring gauge

Tip of rotary

Needle

C

Screws

Needle

Tip of rotary hook

0.1~0.15mm

Head bed

0.1 ~ 0.2mm

-DA -112-4 Q701

2-4

SETTING UP THE MACHINE

Assemble safety sensor (Option)

Safety sensors are set at a provisional position

for transportation. Please reset the safety sen-

sors at normal positions for adjustment.

1. Unscrew set screws at lower points on the

safety sensors on right and left sides.

Loosen set screws slightly at upper points

on the safety sensors.

2. Set the right and left safety sensors at the

positions as shown in a photo by turning

them to the front side.

At this time, make sure the part on the

sensors indicated by an arrow shall be set

vertically, and set safety sensors both right

and left at parallel positions each other with

viewing them from the side.

The set screw on the right safety sensor

shall be tightened to the level that the

positions of the safety sensors can be

adjusted vertically.

3. Turnonthemachineandconrmalampfor

receiving ray (orange) is on when the way of

sensor ray is not blocked.

4. Conrmifthelampforreceivingray(orange)

is turned off by blocking the way of sensor

ray by a hand or other.

Tightenthesetscrewrmly.

1

2

3

Set screw

Sensor left

Sensor right

Sensor rightSensor left

Ray receiver

Ray projector

Power indicator

Lamp for receiving ray

Power indicator

Way of sensor ray

4

-DA -13

2-5 OC10

2-5

SETTING UP THE MACHINE

1. Insert Knob screw to right and left side of

machine.

And set table like right side picture.

Please insert table bracket trench to the

knob screw.

2. Tight 2 knob screw on under the table for x

table.

3. Tight 2 knob screw on side of the table.

Please reverse procedure when remove the

table.

Knob screw

Knob screw

1

Assemble table (Option)

Installing theTable or the Table (border).

2

-DA -14

2-5b OC10

2-5b

SETTING UP THE MACHINE

1. Fix the border frame under the bracket of

the X carriage and tighten the knob screw

completely.

Clearance between X-carriage and Border Frame

at right edge and left edge should be equal.

2. Select Frame Type “Border”.

Please refer in this manual page “FRAME

CONFIRMATION” for “Frame selection”.

20-2

Please reverse procedure when remove the

border frame.

1

X carriage

Border frame

Assemble border frame (Option)

Bracket

Knob screw

-CD -122-6 FB01

2-6

SETTING UPTHE MACHINE

Assemble bobbin thread guide

(Option)

1. Install the bobbin thread guide with supplied

screws (pan head screw M4 X 6 2 pcs).

( Showing following pictures, Please square

left end of sticker with right end of thread

stand)

Bobbin thread guideScrews

Sticker

1

-CS -11

Grounding instruction (for type of 120V)

This product must be grounded. In the event of malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock. This product is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a

risk of electric shock. The conductor with insulation having an outer surface that is green with or

without yellow stripes is the equipment-grounding conductor. If repair or replacement of the cord

or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded.

Do not modify the plug provided with the product – if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

This product is for use on a nominal 120 V circuit, and has a grounding plug that looks like the

plug illustrated in sketch A in Figure. A temporary adaptor, which looks like the adaptor illus-

trated in sketches B and C, may be used to connect this plug to a 2-pole receptacle as shown in

sketch B if a properly grounded outlet is not available. The temporary adaptor should be used

only until a properly grounded outlet can be installed by a qualified electrician. The green col-

ored rigid ear, lug, and the like, extending from the adaptor must be connected to a permanent

ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be

held in place by the metal screw.

2_6 I916

2-7

SETTING UP THE MACHINE

Disposal of a battery

A battery is had built-in to this embroidery machine.

When you dispose of a battery, according to each country or a method determined in each area,

please dispose appropriately.

Metal screw

Cover of grounded

outlet box

Grounding pin

Grounding means

Grounding methods

Adapter

AB

C

-D3 -18

MAIN PARTS

1. Keeper cover

2. Hook

3. Bobbin case

4. Needle plate

5. Take-up lever

6. Lower rectier

7. Thread tension

8. Upper rectier

9. Guide tube

10. Thread guide support

11. Thread guide

12. Thread check spring

13. Thread stand pin

14. Thread stand felt

15. Needle bar selection knob

16. Control box

17. LAN port

18. USB port

(Standard-A receptacle)

19. Frame hold arm

20. Carriage

21. Fuse (6A)

22. Terminal box

23. Power switch

24. USB port

(Standard-B receptacle)

3_1 RC01

3-1

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

19

20

21

17

22

23

18

6

24

-D2 -153_2 M717

3-2

MAIN PARTS

CONTROL BOX

45

1. Emergency stop button

2. Display (L.C.D.)

3. LAN port

4. Thread cut button

5. Start/Stop button

6

5

7

6

1

4

2

3

1. Thread guide

2. Thread tension

3. Spindle

4. Lever

5. Thread stand pin

6. Plastic spring

7. Thread stand felt

BOBBIN WINDING (Option)

37

1

2

16

8

6. USB port (Standard-A receptacle)

7. USB port (Standard-B receptacle)

8. Stylus

-DA -22

1. Emergency stop button

When pressed , the power is switched off

and the machine stops immediately.

The emergency button locks when

pressed.

To unlock, turn the button to the right, or

pull it up.

Use this button only for emergency.

2. Display (Touch screen)

Shows the embroidery design name, the number

of the current needle and other machine generated

messages.

Menu and keys in the display can be operated with

a nger or built-in stylus.

3. LAN port

You can connect PC with a LAN.

4. Thread trim button

The Machine will cut the upper and lower thread

when this button is pressed.

In case you press and keep (around 2 sec.), you

can cut only bobbin thread.

THE CONTROL BOX

3_8 RC01

3-3

5. Start/Stop button

This button starts the machine.

When pressed, while the machine is running, the

machine will stop.

Green .......... Machine ready to sew.

Main menu also accessible by

pressing MENU, which causes menu

to display.

Blinking red.. Indicates the upper thread has bro-

ken or the Bobbin thread has run out.

Red.............. Machine is running.

Orange ........ Machine has detected an error.

An error number will be shown on

the Display. 24-1

6. USB port (Standard-A receptacle)

USB memory socket.

USB mouse socket.

Menu and keys in the display can be operated with

a commercial USB mouse.

Press right mouse button to show a mouse pointer

in the display.

7. USB port (Standard-B receptacle)

Use this port to connect the machine with PC via

USB.

8. Stylus

Stylus can be used for pressing menu and keys in

place of ngers.

Most operation can be done by ngers. Stylus is

required for some operation such as calibration for

the touch panel LCD. 18-6

Insert a stylus into the holder (slot) of control box

when not used to prevent loss of the stylus.

CAUTION: To prevent accidents.

If you Press thread trim button, the needle will

penetrate the fabric. Please keep your hands

clear for your safety.

1

2

45

1. Emergency stop button

2. Display (L.C.D.)

3. LAN port

4. Thread cut button

5. Start/Stop button

6. USB port

6

16

7

3

8

CAUTION

The touch screen can be operated by nger, but in some cases sensitivity of the screen will

be affected by condition of the nger.

In such cases, please use the ngertip or built-in stylus to hit small touch targets.

-3A -27

3_9 R801

3-4

DRIVE MODE

Drive key

The each key menu will be shown.

3

Forward and Back-ward

2

Needle bar

selection

4

Needle change

6

Frame move

1

Speed

control

3

Forward and Back-ward

2

Needle bar

selection

4

Needle change

6

Frame move

1

Speed control

5

i-Custom

(default display)

5

i-Custom

(default display)

7

Quick menu

Menu

Display menu

mode. 3-A

Menu

Display menu

mode. 3-A

Home

Display drive mode

3-5

STANDARD CONTROL BOX

10.4” CONTROL BOX (Option)

-3A -28

3_9b R801

3-5

DRIVE MODE

4

Needle change

Change the needle bar directly to the indicated

needle number on the button.

Change

Move the sewing head to the adjacent needle in

the direction of the arrows.

Although the needl bar setting has been done,

needle bar setting is changed and pressed

, following dialogue will be displayed.

Needle bar setting will be changed

and the display will return to Drive mode.

Needle bar setting will not be changed

and the display will return to Drive mode.

Jump (Off)

The machine can embroider.

Jump (On)

Machine becomes jump and the machine

doesn’t embroider.

3

Frame forward

This creates direct designations to the position and

data to the designated sewing position.

Piece 9-C

If “Repeat” is set, this allows the frame to move to

the beginning of any piece at will.

Change (Color position ) 9-7

This moves the frame to the beginning of any Color

change number at will beginning of color.

Stitch (Number of stitches ) 9-6

This moves the frame to any stitch at will.

1

Drive speed

Control embroidery speed.

The speed can be controlled while embroidering.

Speed control

Press the + button to increase the machine sewing

speed and the - button to lower the machine speed.

is displayed on the LCD display.

2

Needle bar selection 5-E

For each color change in a given pattern, the needle number loaded with the correct color thread is as-

signed by the operator.

Low speed operation (OFF state)

Press the button to turn “ON” state.

Low speed operation (ON state)

The drive speed will be reduced to “200 rpm”.

Press the button to turn “OFF” state.

Speed setting by needle (OFF state) 3-8

Press the button to turn “ON” state.

Speed setting by needle (ON state)

Press the button to turn “OFF” state.

Color position forward

Move the frame to the beginning embroidery

position of the previous or later color position

number

Stitch number forward

Move the frame forward or backward by the

stitch number displayed in each button.

Bobbin thread alarm 9-Cb

Alarm message will be displayed when the re-

maining amount of bobbin thread becomes low.

-SJ -24

3_9c RC01

3-6

DRIVE MODE

Original point return

This returns the frame to *pattern origin point.

After performing this action once, repeating this

again will cause the frame to return to the previous

position.

Origin registration

Register the current frame position as origin.

Trace

When pressed while at the beginning of design,

the embroidery frame moves following the outer

edge of the design. This allows you to compare

the design size and position against the frame

before sewing.

Indicate target design on LCD panel when

non-showing design.

If you press this key and hold, re-display your

Register

Register will restore the position of the frame to the

last point before a power failure even if the

point of origin or the pattern itself were changed.

6

Frame move

Selection the way of frame movement and

Move frame.

Frame change

Change the frame to be used.

Design centering

Move design to the center of frame.

Center

Moves the embroidery frame to the center auto-

matically.

Frame out

Move frame to the front position which was set on

the Machine setting ( 15-1b) before.

Press (Position) to return the frame to the

original position before frame out position.

It is convenience if hand work is required in the

middle of embroider process.

Position

When sewing is interrupted in the middle of a

design, this returns the frame to current sewing

position regardless of where frame may have

been moved with the arrow keys after interrupt.

target design.

5

i-Custom 22-1

The following display and key icons are set as default. You can place other frequently used icons freely on

the right side of Drive mode screen.

Calendar

Current year, month date is displayed.

Clock

Current time is displayed.

Stitch number forward

Move the frame forward or backward by the

one

When the key is pressed continuously, the “Key

lock” function is activated and the frame will move

continuously even the nger is released from the

key.

When the key is pressed much longer, the step of

“Stitch number forward” will be changed from one

stitch to 10 stitches.

When you stop it, press (Start/Stop button).

The “Key lock” and “Fast forward” function will

be activated after setting through “Machine Set-

ting” menu. 15-2

Table of contents

Other HappyJapan Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Arrowquip

Arrowquip Q-POWER 106 SERIES product manual

Reliable

Reliable N2-Blast DDX-LP PrePaK Instructions for installation, operation care and maintenance

Ecolab

Ecolab ECO Short operating instructions

TigerStop

TigerStop TigerSPC user manual

JUKI

JUKI RS-1 Repacking guide

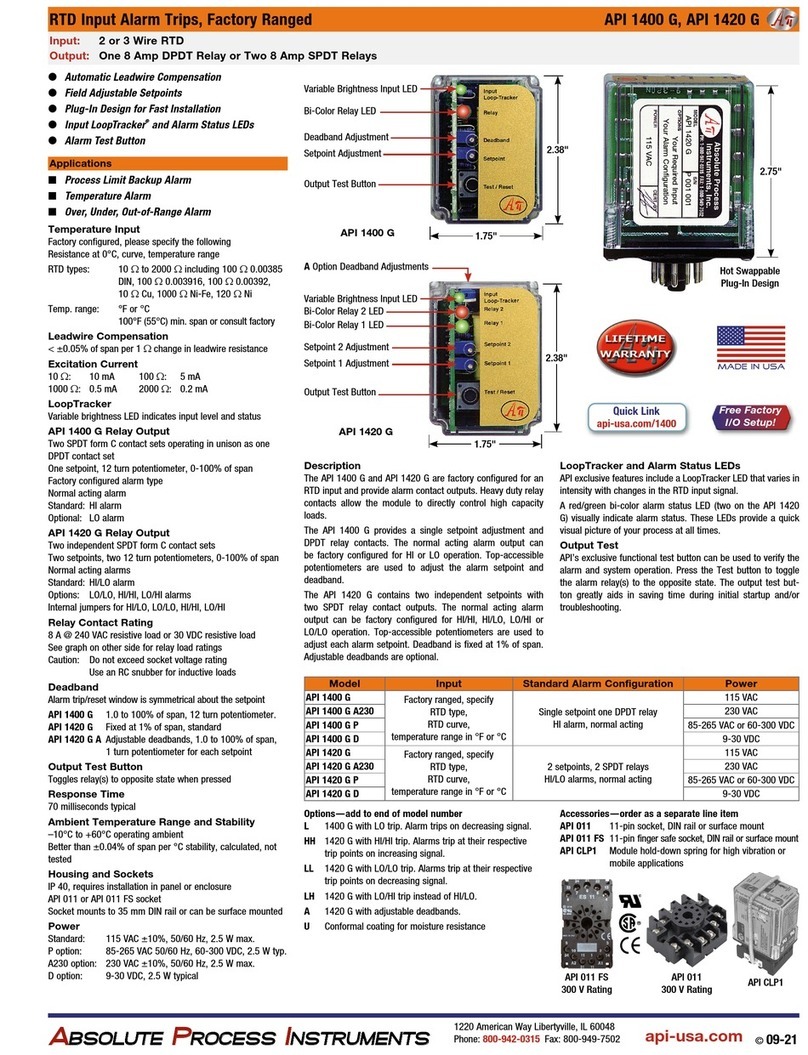

Absolute Process Instruments

Absolute Process Instruments API 1400 G quick start guide