© 2016 General Electric. All rights reserved. i

Table of Contents

General Information ................................................................... iii

Hazard Classifications .............................................................................iii

Trademarks................................................................................... iii

Warranty .............................................................................iii

Section 1. Introduction ................................................................1

General Information.................................................................................. 1

Instruction Manual Arrangement....................................................... 1

Section 1, Introduction....................................................................... 1

Section 2, Receiving, Handling, and Storage.......................... 1

Section 3, Switchgear Description...............................................1

Section 4, Equipment Installation.................................................1

Section 5, Exhaust Plenum Installation.....................................1

Section 6, Installing and Removing Circuit Breakers ......... 1

Section 7, Testing and Inspecting ................................................ 1

Section 8, Operating the Switchgear..........................................2

Section 9, Energizing the Switchgear......................................... 2

Section 10, Maintaining the Switchgear................................... 2

Section 11, Common Switchgear Accessories and Kits... 2

Appendices A, B, C, D, E, F, and G .................................................2

Related Publications..................................................................................2

General Arrangement Drawings................................................... 2

Elementary and Connection Drawings ..................................... 2

Summary of Switchgear Equipment........................................... 2

Section 2. Receiving, Handling, and Storage...........................3

Receiving .........................................................................................................3

Equipment Packaging ........................................................................ 3

Inspecting for Damage......................................................................3

Filing a Claim...........................................................................................3

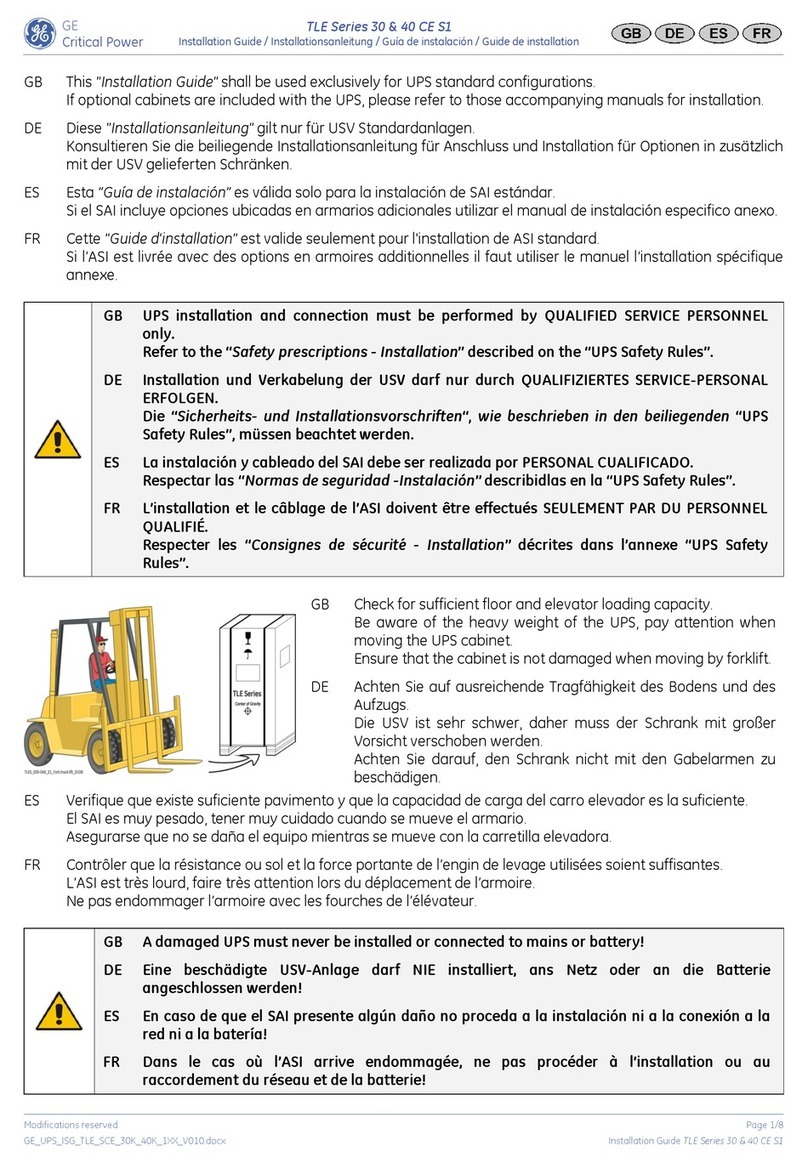

Handling ..........................................................................................................4

Indoor Enclosure Lifting.....................................................................4

Rollers..........................................................................................................5

Forklifts....................................................................................................... 5

Storage............................................................................................................. 6

Switchgear ...............................................................................................6

Circuit Breakers...................................................................................... 6

Exhaust Plenum Components........................................................6

Section 3. Switchgear Description ............................................7

General.............................................................................................................7

Summary Description............................................................................... 8

Front Compartments ............................................................................. 10

Instrument Panel (AKD-20 AR Only) ......................................... 10

Circuit Breaker Control Fuse Panel (Entellisys AR Only) . 10

EntelliGuard Messenger (Entellisys AR Only)........................ 10

Instrument/Auxiliary Compartment......................................... 10

Entellisys Instrument/Auxiliary Compartment (Entellisys

AR Only) ................................................................................................... 11

Auxiliary/Transition Sections ....................................................... 11

Circuit Breaker Compartments......................................................... 12

Primary Disconnect Shutter ......................................................... 14

Breaker Compartment Door ........................................................ 15

Future Circuit Breaker Compartment ..................................... 15

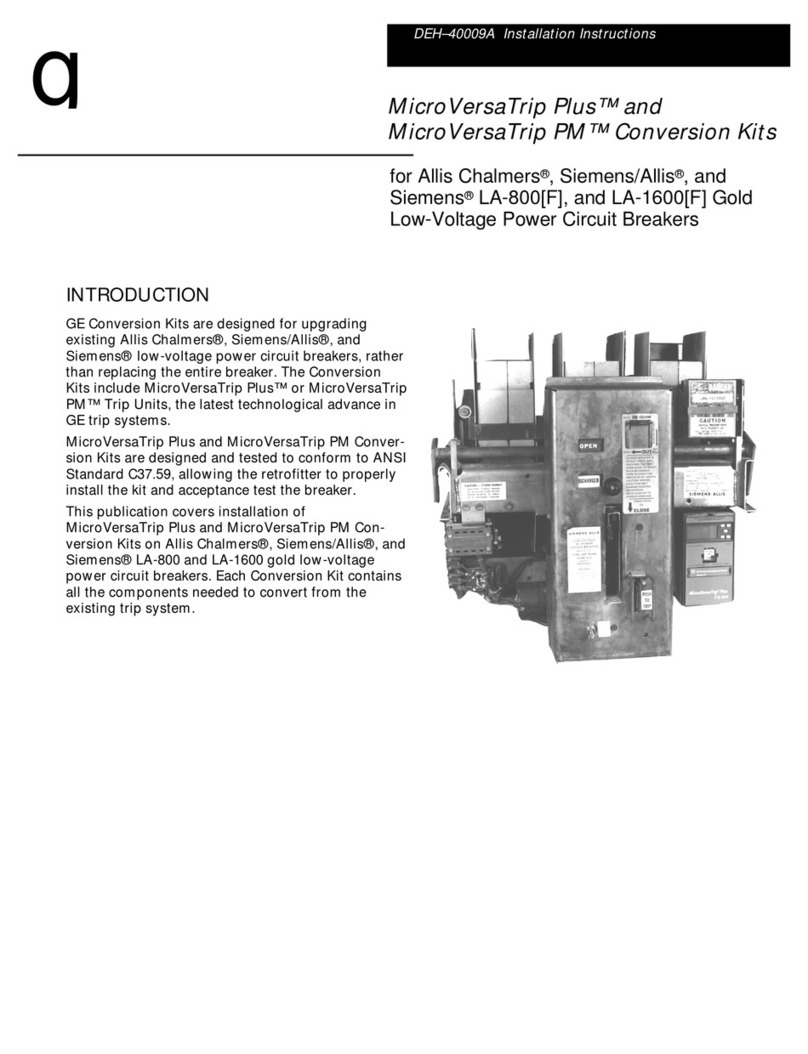

Circuit Breakers......................................................................................... 16

Bus Area........................................................................................................ 17

Busing System..................................................................................... 17

Insulated/Isolated Bus System ................................................... 18

Cable Compartment ...............................................................................19

Cable Compartment Floor Plates...............................................19

Ground Bus ............................................................................................20

Heaters.....................................................................................................20

Section 4. Equipment Installation ...........................................21

General...........................................................................................................21

Site Location................................................................................................21

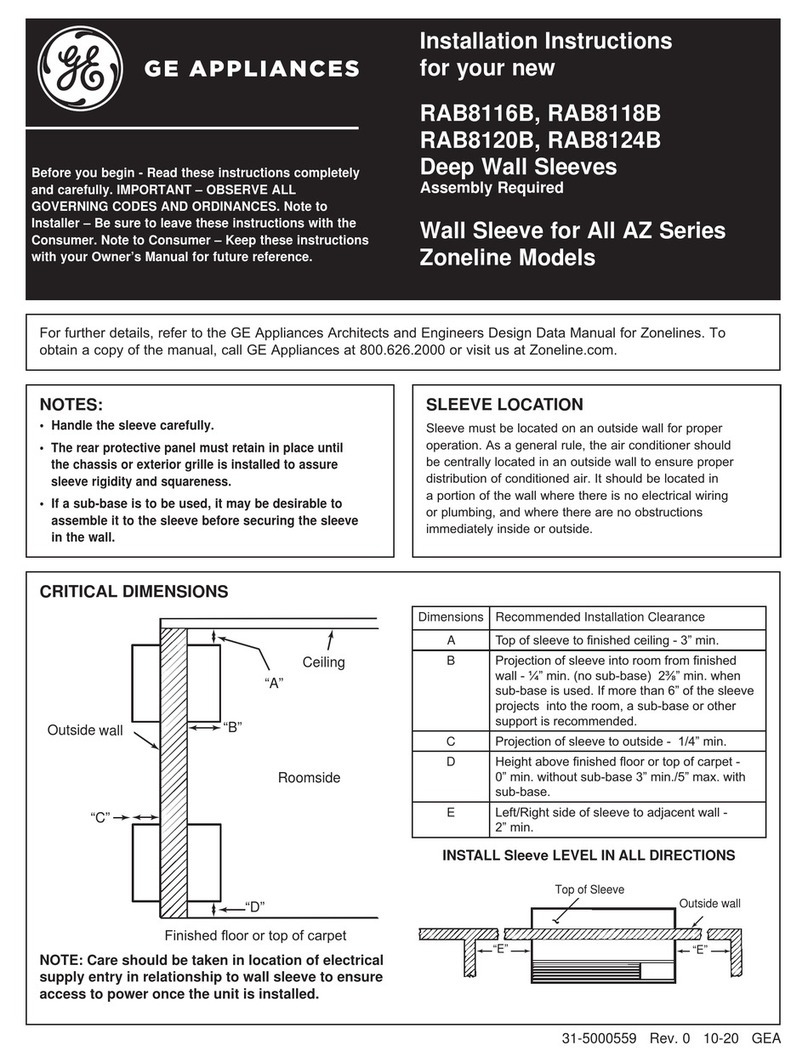

Foundation Requirements...................................................................21

Foundation Preparation........................................................................22

Indoor Equipment...............................................................................22

Assembly and Installation of Switchgear ....................................25

General.....................................................................................................25

Detailed Assembly and Installation Instructions ...............25

Switchgear Anchoring .....................................................................29

External Control Wire Connections...........................................30

Power Cable Connections..............................................................31

Relay and Control Devices.............................................................31

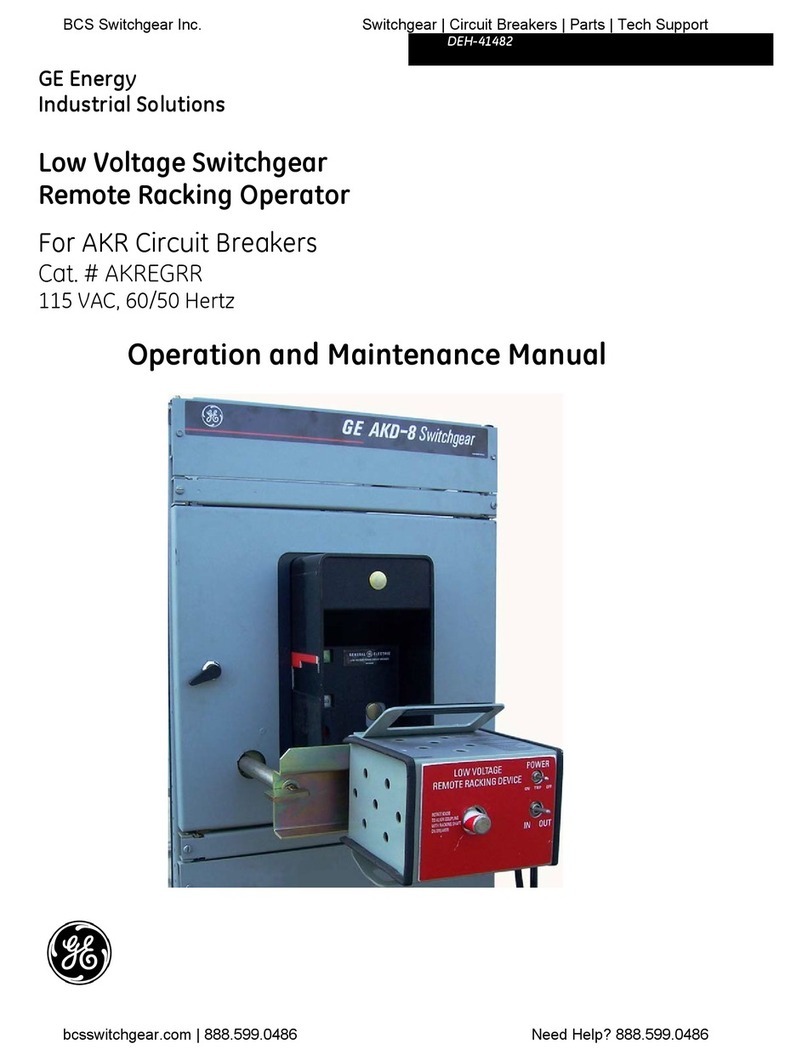

Breaker Lifting Device ............................................................................32

Indoor Equipment...............................................................................32

Rear Door Ventilation .............................................................................35

Wall Mounted HMI (Entellisys AR Only)..........................................36

General.....................................................................................................36

Installation..............................................................................................36

Wiring........................................................................................................36

Section 5. Exhaust Plenum Installation..................................37

General...........................................................................................................37

Installation....................................................................................................38

Exhaust Plenum above Switchgear..........................................38

Exhaust Plenum End Cap ...............................................................40

Exhaust Plenum End Portal...........................................................40

Plenum System between Equipment and End Portal .....41

Section 6. Installing and Removing Circuit Breakers ..........42

General...........................................................................................................42

Circuit Breaker Identification..............................................................42

Rejection Feature......................................................................................42

Installing a Circuit Breaker...................................................................43

General.....................................................................................................43

Installation Procedure......................................................................43

Removing a Circuit Breaker ................................................................45

Section 7. Testing and Inspecting ...........................................46

General...........................................................................................................46

Key Interlocks .............................................................................................46

Breaker Operation Test .........................................................................46

EntelliGuard Trip Units (AKD-20 AR Only) ...............................46

Entellisys System Test Kit (Entellisys AR Only)......................47

Final Steps to be taken Before Energizing Equipment..........47

Section 8. Operating the Switchgear......................................48

General...........................................................................................................48

Manually Operated Circuit Breakers ..............................................48

Closing Operation...............................................................................48

Opening Operation ............................................................................48

Electrically Operated Circuit Breakers...........................................48

Closing Operation...............................................................................48

Opening Operation ............................................................................48

Circuit Breaker Draw-out Operation ..............................................49

Courtesy of NationalSwitchgear.com