5.

9. Verify that the following valves are in their respective po-

sitions prior to continuing:

Manual Emergency Release - open

Main Drain Valve - open

Alarm Line Valve - open

Alarm Test Valve - closed

Condensate Drain valve - closed

Air/Nitrogen Supply Valves - closed

10. Open pushrod chamber supply valve and allow water

to fill the pushrod chamber. Close the Manual Emer-

gency Release valve after any trapped air has had a

chance to escape from the deluge valve’s pushrod

chamber.

11. Upon seeing this solid flow of water coming out of the

Model LP Dry Pilot Actuator, open the Rapid-Air Fill

Valve thereby rapidly applying compressed air or ni-

trogen into the Model LP Dry Pilot Actuator and the

sprinkler system until the pressure conforms to Table

A levels, as indicated by the system air pressure

gauge. The Model LP Dry Pilot Actuator will eventually

close during this pressurizing process and water will

stop flowing through the drain tube. At this point, the

pressure gauge on the pushrod chamber pressure will

equalize to the available water supply pressure. Once

the actuator is set up correctly, close the Rapid-Air Fill

Valve and open the Regulated Air Shutoff Valve.

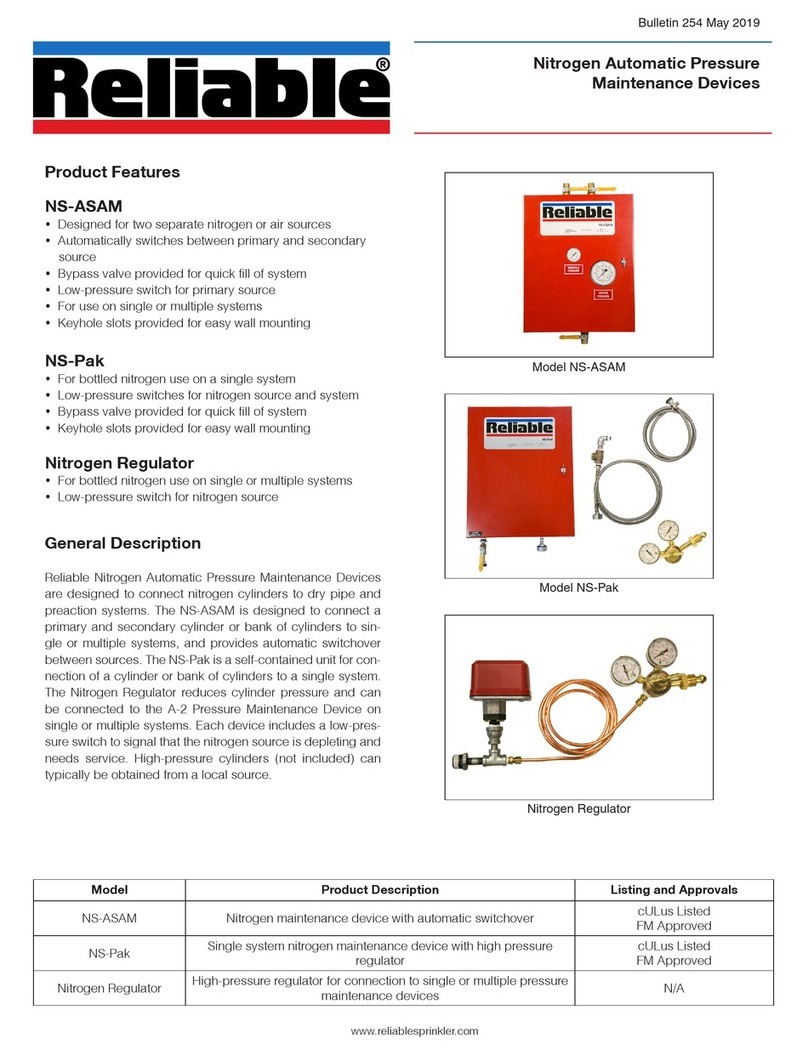

Note: For systems using nitrogen as the primary

source, the system may be set up using the nitrogen

source following the steps above. The air compres-

sor, if present, may then be placed into operation as

the backup pneumatic source.

12. Open the alarm line valve.

13. If the Model B1 Accelerator Kit is installed, open valve

P. Prior to opening valve P, be sure that the Model B1

Accelerator has been successfully reset per Reliable

Technical Bulletin 323.

Note: The B1 Accelerator requires a minimum of 15

psi (1,0 bar) supervisory air or nitrogen pressure for

proper operation.

14. Slightly open the main valve controlling water supply

to the Model DDX-LP Deluge Valve. This will begin

to fill the deluge valve beneath the clapper with wa-

ter. Once any trapped air has been vented, close the

main drain valve. Observe if water leaks through the

ball drip valve into the 1” drain manifold through the

clear tubing. If no leakage occurs, the deluge valve

clapper is sealed. Fully open the main valve control-

ling the water supply to the Model DDX-LP Deluge

Valve and that it is properly monitored

15. Verify that the pushrod chamber supply valve is open.

16. Secure the handle of the Model B Manual Emergency

Station in the OFF position with a nylon tie (supplied

with the assembly).

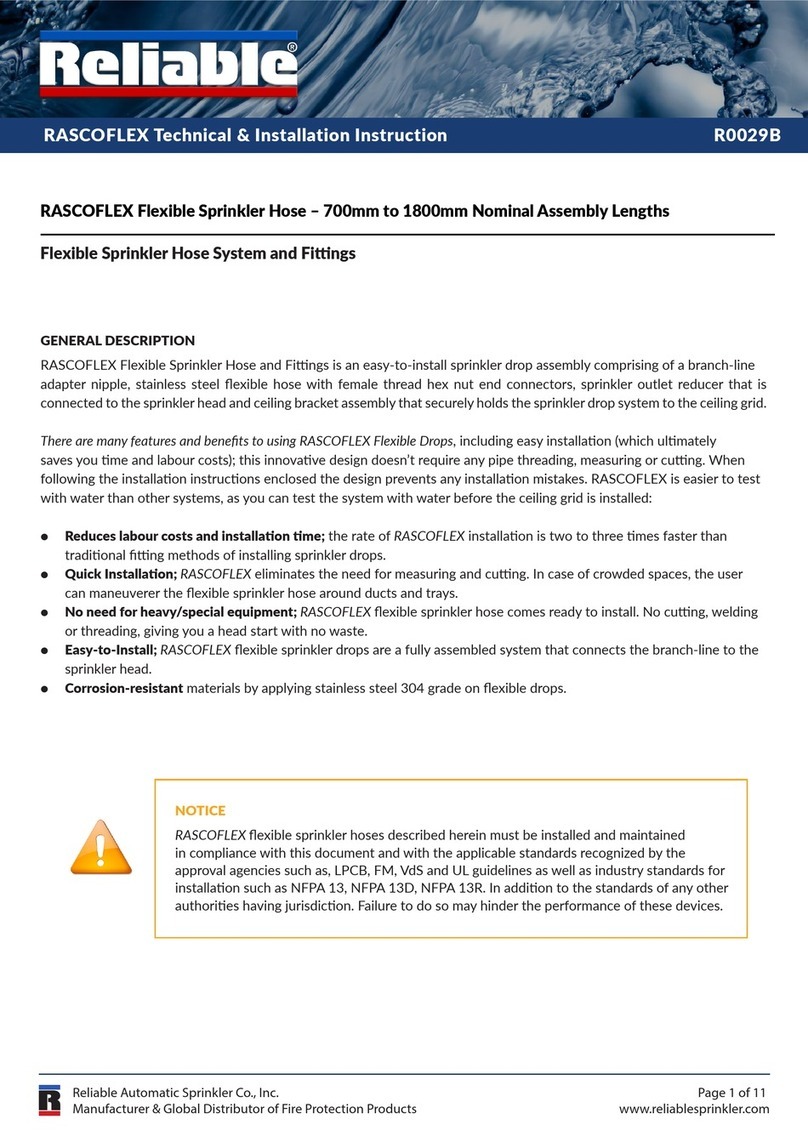

Inspection And Testing Of The DDX-LP PrePak

Systems (Refer to Figure 2)

1. Water supply — Verify that the valve controlling water

supply to the deluge valve is opened fully and properly

monitored.

2. Pushrod Chamber supply — Verify that the valve sup-

plying water to the pushrod chamber is open.

3. Other trimming valves — Verify that the alarm line valve

is open as well as all of the pressure gauge valves. The

main drain valve, alarm test valve, and condensate

drain valve should be closed.

4. Ball drip valve — Push in on the plunger to be sure the

ball check is off its seat. If no water appears, the deluge

valve’s water seat is tight. Inspect the small bleed hole

located on the underside of the Model DDX-LP Deluge

Valve pushrod chamber for leakage.

5. System air pressure — Verify that system air pressure

is in conformance with the values posted in Table A for

the supply water pressure.

6. Releasing device — Check the outlet of the (Model LP

Dry Pilot Actuator and Model B Manual Emergency Sta-

tion) for leakage. Also verify that tubing drain lines from

releasing devices are not pinched or crushed which

could prevent proper releasing of the deluge valve.

7. Testing alarms — Open the alarm test valve permit-

ting water from the supply to flow to the alarm pressure

switch and to the mechanical sprinkler alarm (if pres-

ent). After testing, close this valve completely. Push

in on the plunger of ball drip until all of the water has

drained from the alarm line.

8. Operational test — Open the Model B Manual Emer-

gency Station or, alternatively, reduce air/nitrogen pres-

sure on the system. Note: An operational test will cause

the Deluge Valve to open and flow water into the sprin-

kler system.

9. Secure the Model B Manual Emergency Station in

the OFF position with a nylon tie (included with the as-

sembly) after the deluge valve is reset.

Testing the Model DDX-LP Deluge Valve

Without Flowing Water (Refer to Figure 2)

1. Close the valve controlling water supply to deluge valve

and open the main drain.

2. Verify that the pushrod chamber supply valve is open,

allowing water to enter the pushrod chamber.

3. Close the air/nitrogen supply to the sprinkler system.

4. Decrease pneumatic pressure in the system by opening

the condensate drain valve, until the Model LP Dry Pilot

Actuator operates. Doing so will result in a sudden drop

of water pressure in the deluge valve pushrod chamber.

5. Reset the system per the directions listed in “System

Setup” section of this bulletin.

(cont. bottom of page 8)