Packing Guide

Table of Contents

Chapter 1 Head Unit ··············································································· 1-1

1-1 Securing the Head Unit Fixing Parts ··························································· 1-1

1-1-1 Securing the LNC Z-Axis Fixing Parts ················································· 1-1

1-1-2 Securing the ZA-Axis ······································································ 1-2

1-2 Attaching the Packing Materials ································································· 1-3

1-3 Securing the Head Unit Fixing Parts (Head Rev. A and Later)··························· 1-4

1-3-1 Securing the LNC Z-Axis Fixing Parts ················································· 1-4

1-3-2 Securing the ZA-Axis ······································································ 1-5

1-4 Attaching the Packing Material (Head Rev. A and Later) ·································· 1-5

Chapter 2 X-Y Unit·················································································· 2-1

2-1 Securing the X-Axis Frame······································································· 2-1

2-2 Securing the Head·················································································· 2-2

Chapter 3 Board Transport Unit ······························································· 3-1

3-1 Packing the Accessory Units ····································································· 3-1

3-2 Packing Procedure ················································································· 3-2

3-2-1 Center Part··················································································· 3-2

3-2-2 Left and Right End Parts·································································· 3-2

Chapter 4 Base Bridge Section································································ 4-1

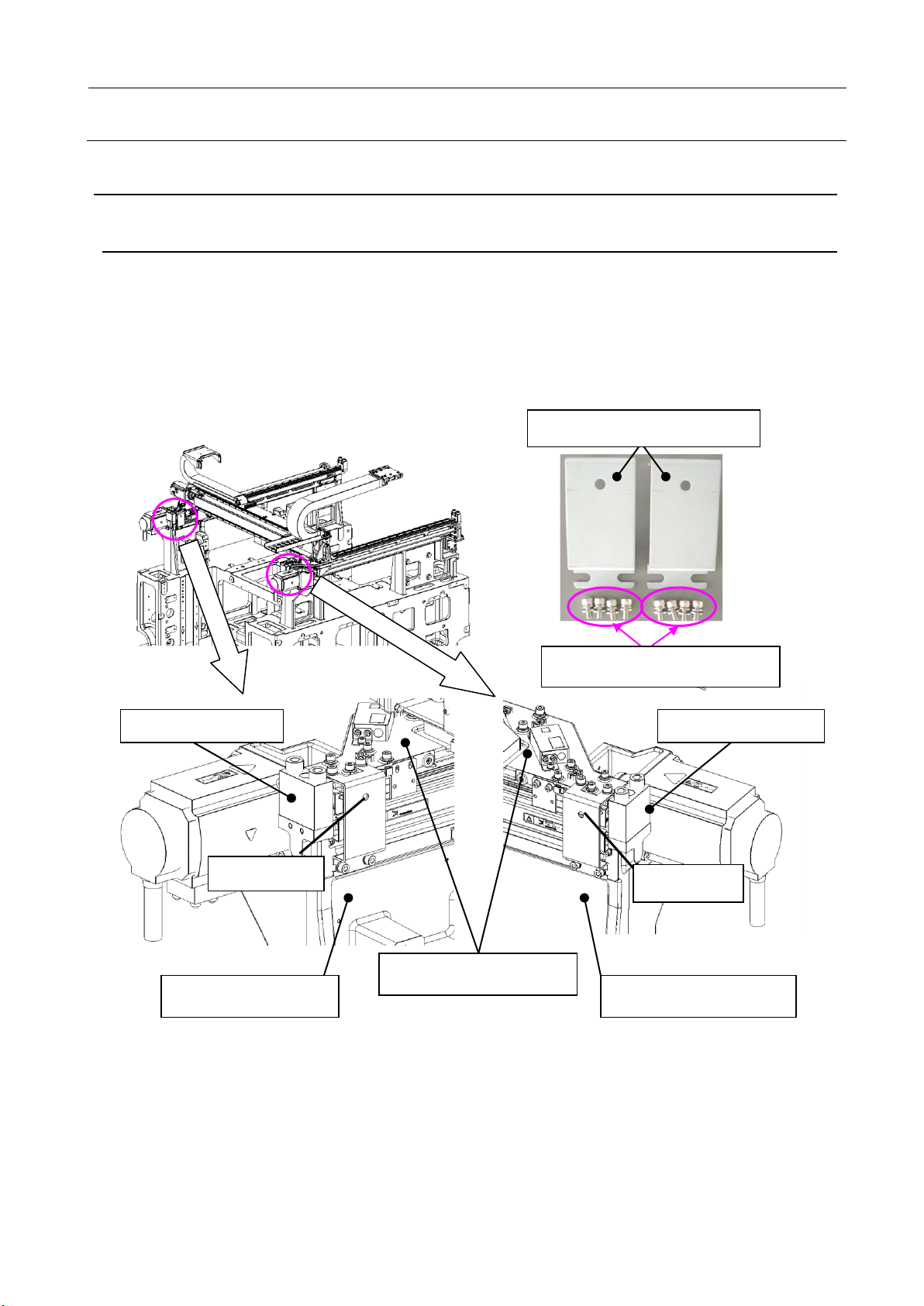

4-1 ATC Unit······························································································· 4-1

4-2 General View of Base Bridge (ATC and VCS Light Units) ································ 4-2

Chapter 5 Signal Light ············································································ 5-1

Chapter 6 Safety Cover ··········································································· 6-1

Chapter 7 Pneumatic Units······································································ 7-1

Chapter 8 Electric Fixed Bank ································································· 8-1

8-1 Detaching the Packing Parts ····································································· 8-1

8-2 Packing Procedures················································································ 8-1

Chapter 9 LCD Monitor ··········································································· 9-1

Chapter 10 Overall Machine Cover ························································· 10-1

Chapter 11 Packing the Accessory Units ················································ 11-1

11-1 Outer Carton Case ··············································································· 11-1

11-2 Check List for Units and Components to Be Put in the Carton Box ·················· 11-2

Chapter 12 Transport Extension (Option)················································ 12-1

Chapter 13 Other Optional Units ···························································· 13-1

Chapter 14 Feeder Exchange Trolley······················································ 14-1

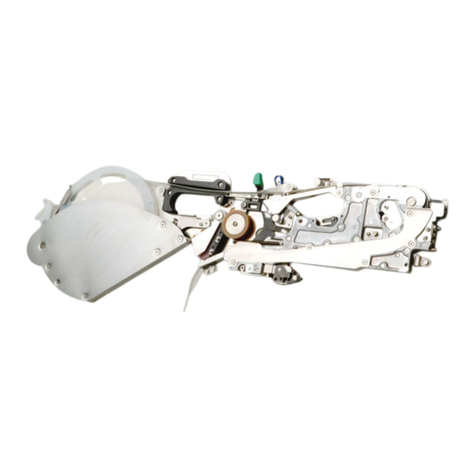

Chapter 15 Tape Set Unit (Machine Rev. D and Later) ······························ 15-1

Chapter 16 Touch Pen (RS-1R Only)······················································· 16-1