Page 6

SKU 92509 For technical questions, please call 1-800-444-3353

15. Maintain a safe working environment. Keep the work area well lit. Make sure there

is adequate surrounding workspace. Always keep the work area free of obstructions,

grease, oil, trash, and other debris. Do not use a power tool in areas near flammable

chemicals, dusts, and vapors. Do not use this product in a damp or wet location.

16. Avoid unintentional starting. Make sure you are prepared to begin work before

turning on the Router.

17. Do not force the Router. This tool will do the work better and safer at the speed and

capacity for which it was designed.

18. Always unplug the Router from its electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

19. Never leave the Router unattended while running.Turn power off if you have to

leave the Router.

20. Before each use, check all nuts, bolts, and screws for tightness.Vibration during

mixing may cause these to loosen.

21. Keep extension cord off the ground and away from water.

22. Always connect the Line Cord (or extension cord) to a Ground Fault Circuit

Interrupter (GFCI) protected electrical outlet.

WARNING! People with pacemakers should consult their physician(s) before us-

ing this product. Electromagnetic fields in close proximity to a heart pacemaker could

cause interference or failure of the pacemaker.

WARNING! Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities, contain chemicals known (to the State of California) to

cause cancer,birth defects or other reproductive harm. Some examples of these chemi-

cals are:lead from lead-based paints,crystalline silica from bricks and cement or other

masonry products, arsenic and chromium from chemically treated lumber. Your risk

from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

(California Health & Safety Code 25249.5, et seq.)

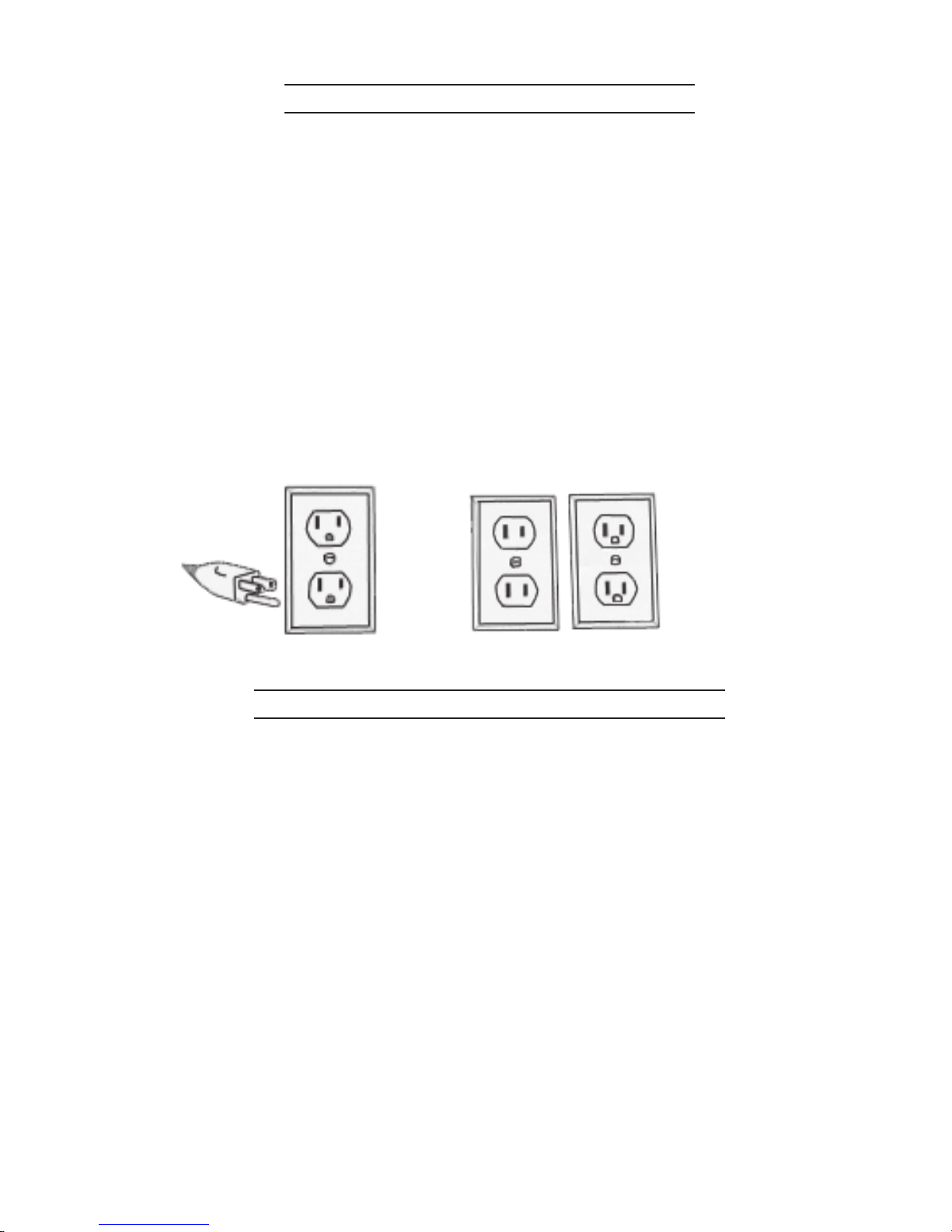

GROUNDING

WARNING!

Improperlyconnectingthe groundingwirecan resultin theriskofelectricshock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded.Do not modify the power cord plug provided with the tool or

product.Never remove the grounding prong from the plug.Do not use the tool if

the power cord or plug is damaged. If damaged, have it repaired by a service

facility before use.If the plug will not fit the outlet,have a proper outlet installed

by a qualified electrician.