4

Performa™Winch 46.2 PTP

Installation and Maintenance Manual

Installation

The winch must be installed on a flat area of the deck, reinforced if necessary to bear a load equal

to at least twice the maximum working load of the winch.

It is the installer's responsibility to carry out all structural tests needed to ensure that the deck can

bear the load.

Harken®does not supply the screws needed to install the winch since these may vary depending on

the deck on which it is to be installed. It is the installer's responsibility to choose the correct screws

taking account of the loads they will have to bear. Harken®assumes no responsibility for incorrect

installation of its winches or for an incorrect choice of mounting screws.

DANGER!

Incorrect installation of the winch may cause severe injury or

death. Consult the yard that built the boat in the case of doubt

over the correct positioning of the winch.

WARNING!

Failure to use the correct number and type of mounting fasteners

or failure to ensure the correct deck strength can result in the

winch pulling off the deck suddenly and unexpectedly during

high loads causing severe injury or death.

WARNING!

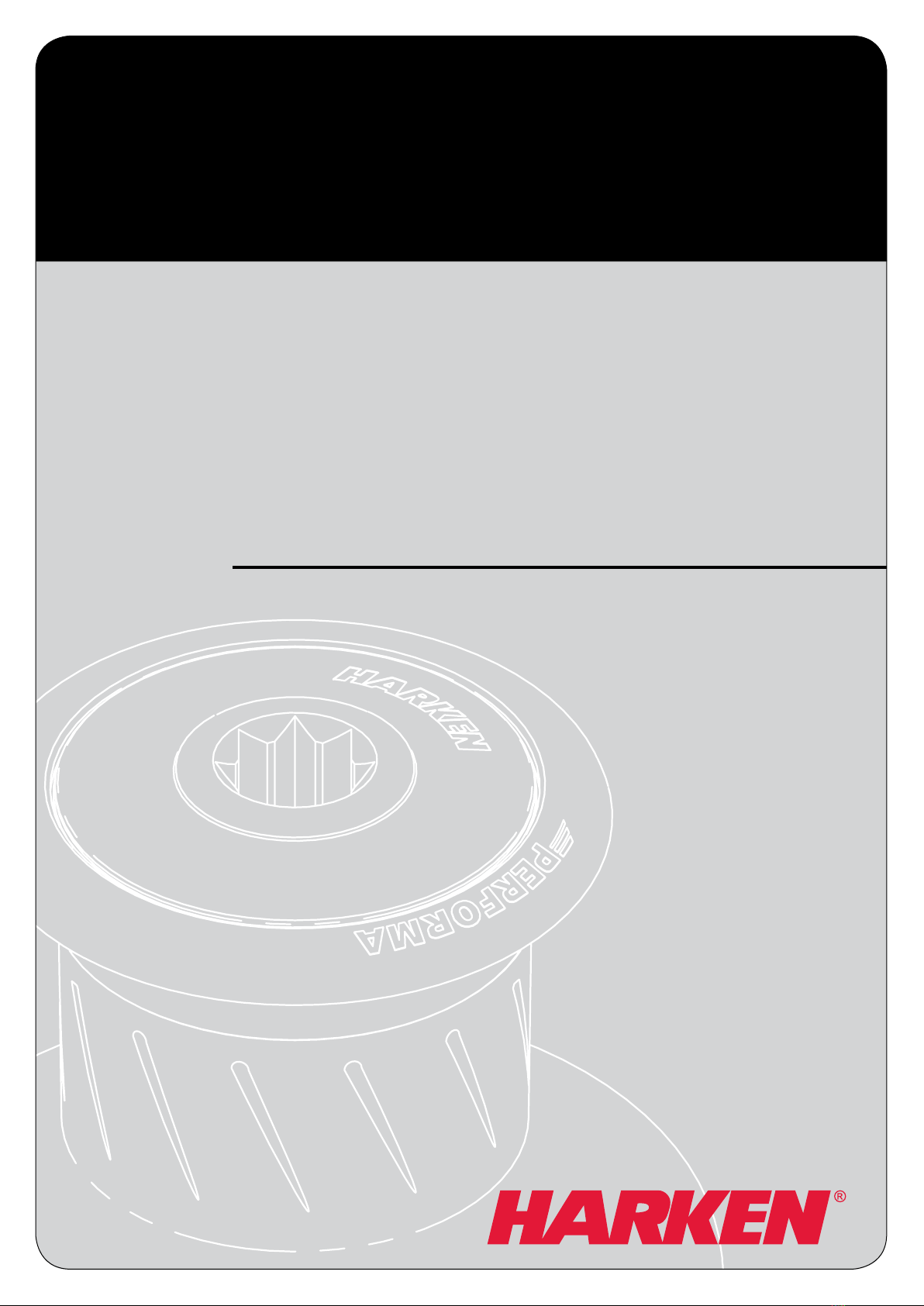

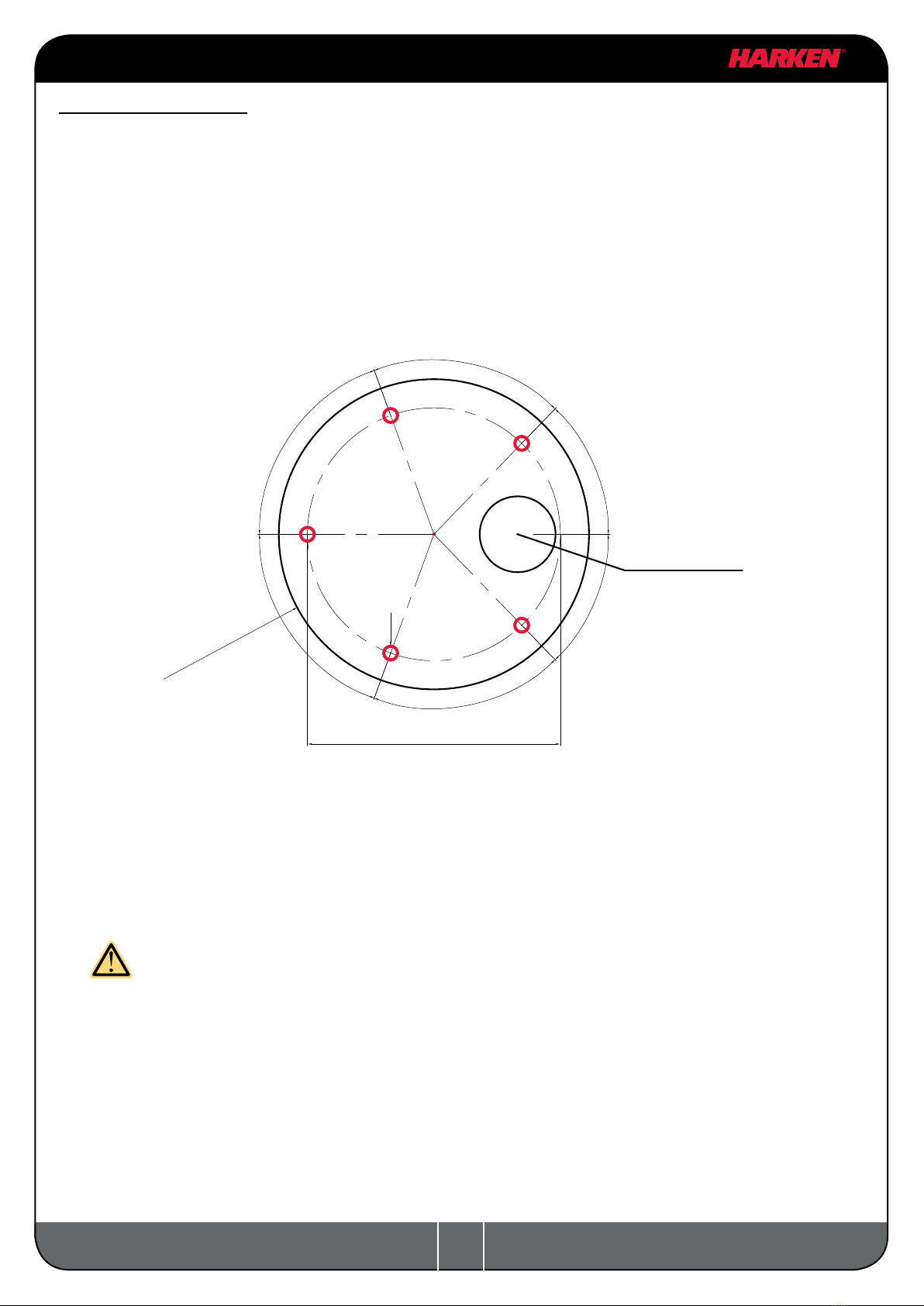

Verify the entry angle of the sheet. This must be 8° with tolerance

of ±2°, to avoid sheet overrides and damaging the winch or

making the winch inoperable leading to loss of control of the boat

which can lead to severe injury or death.

WARNING!

Mount the winch on the deck so that the drive gear is positioned

where the sheet enters the winch drum.

Incorrect position of drive gear can weaken winch leading to failure

which can cause an accident leading to severe injury or death.

Once you have chosen the correct mounting position for the winch on the deck proceed with

installation.

Installation

drive gear

SHEET

8°