R06.0 16/05/2019 Page 3

Table of contents:

1Safety instructions ................................................................................................. 4

1.1 Notes on symbols and instructions ........................................................................................................ 4

1.2 Basic safety information ........................................................................................................................ 5

1.3 Appropriate use ..................................................................................................................................... 5

1.4 Notes for Pacemakers and Defibrillators ............................................................................................... 6

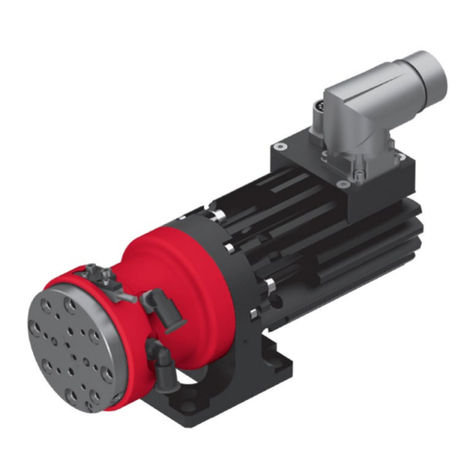

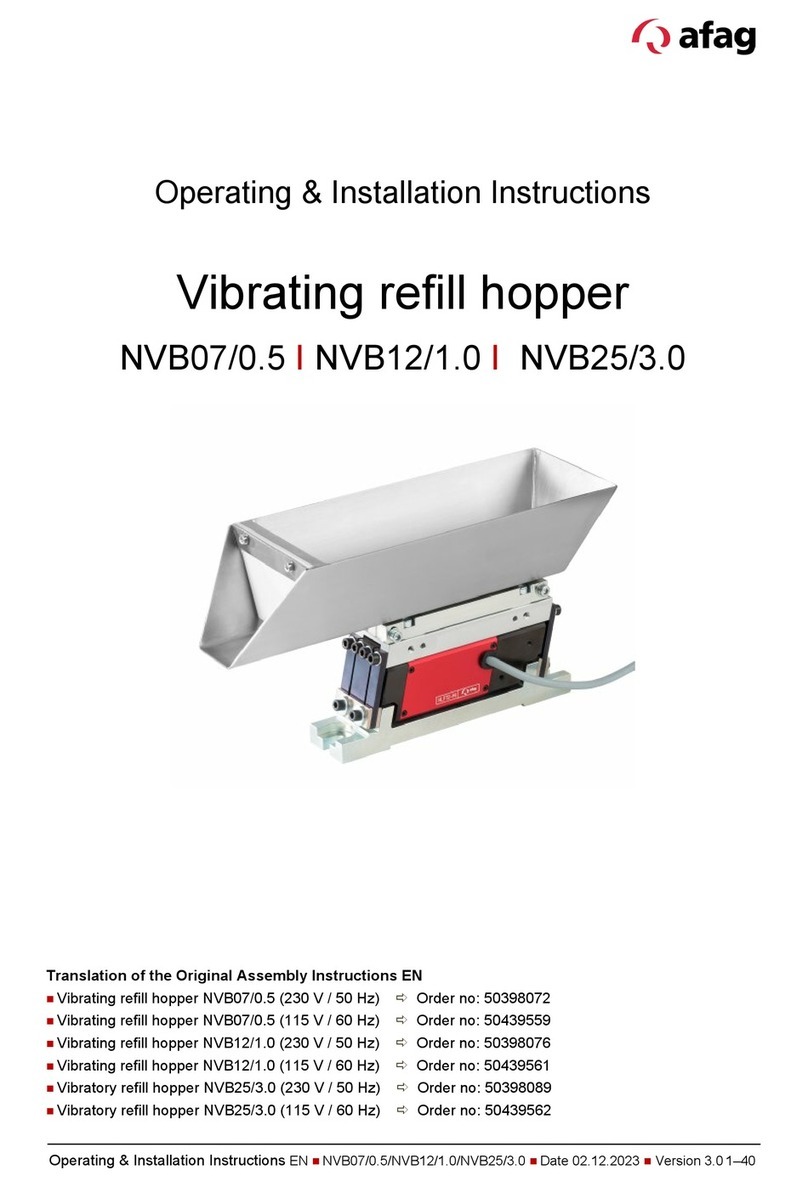

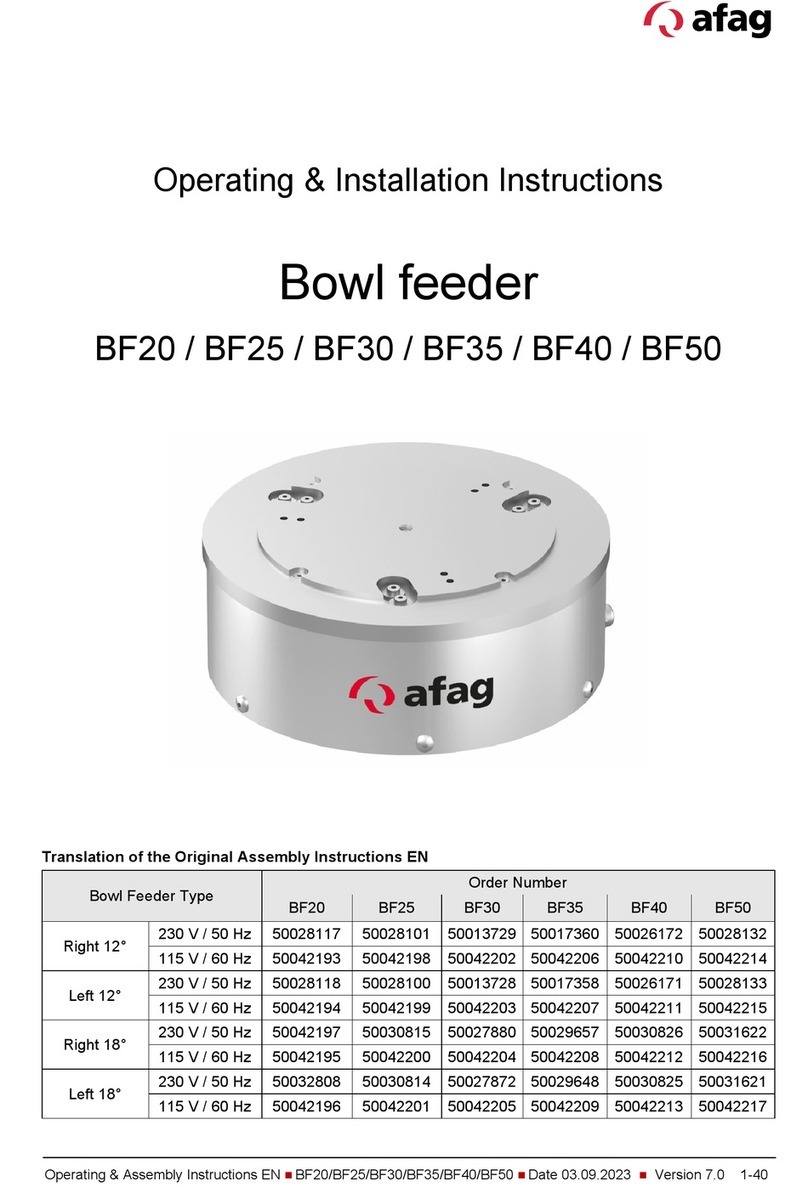

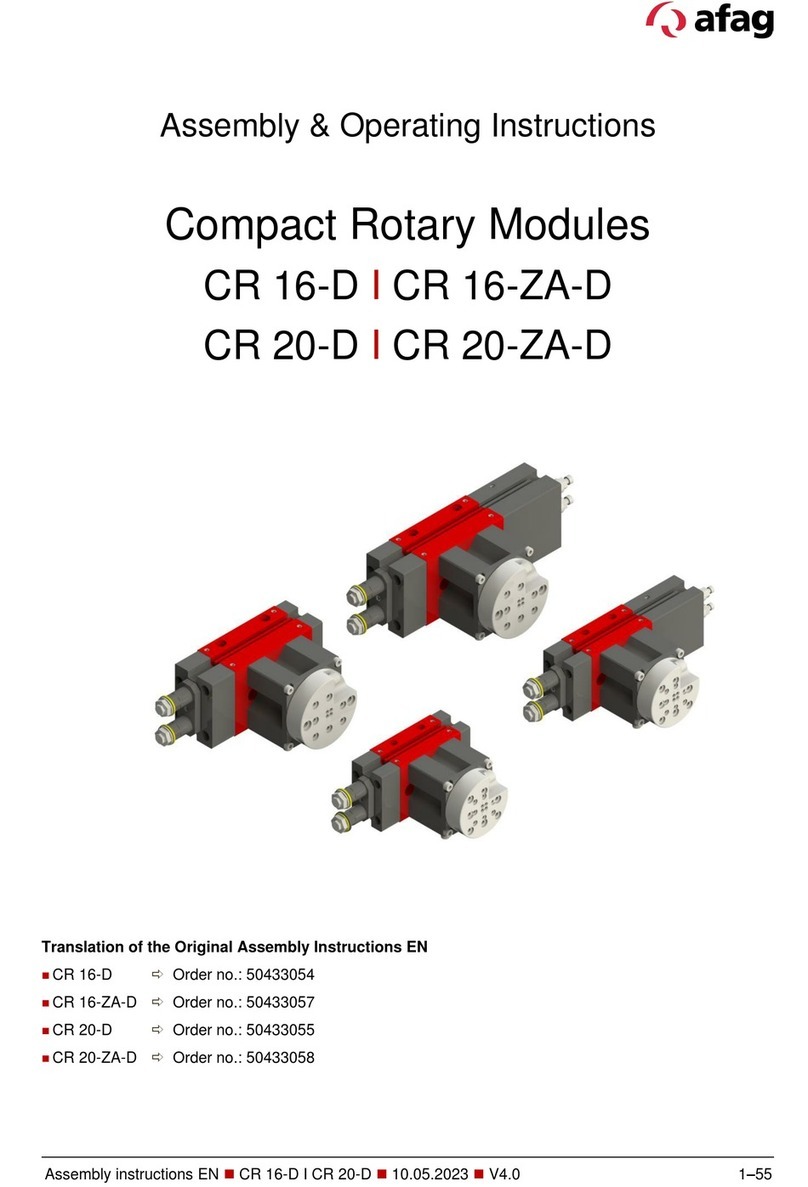

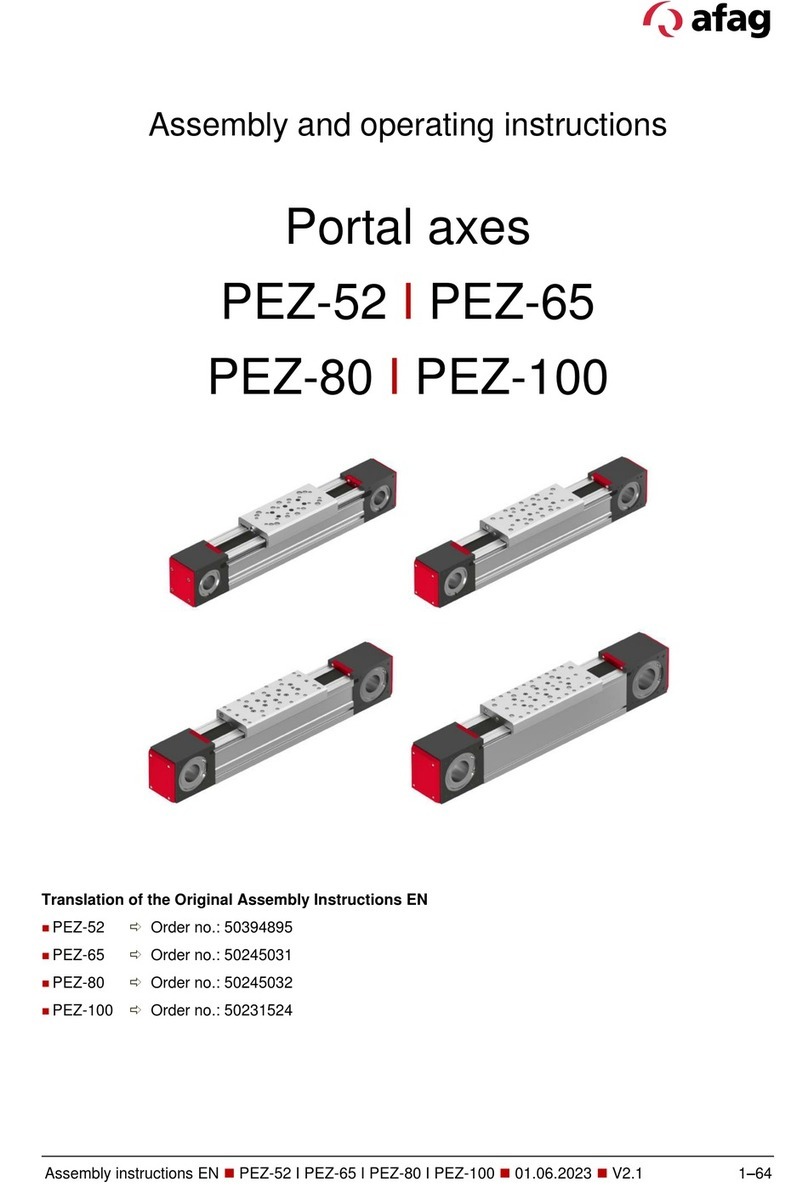

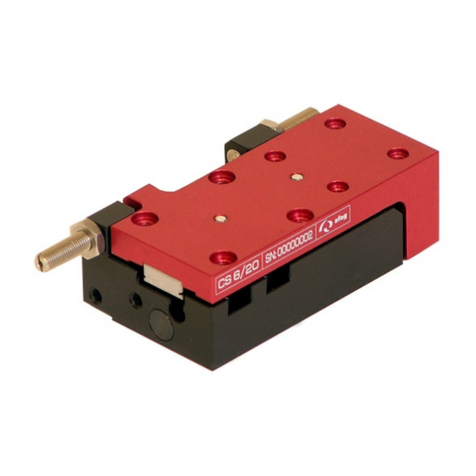

2Description of the device....................................................................................... 6

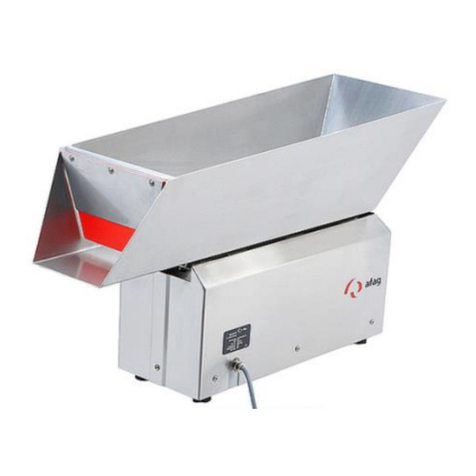

2.1 General .................................................................................................................................................. 6

2.2 Function description .............................................................................................................................. 7

2.3 Definition of the feed direction .............................................................................................................. 7

2.4 Technical data ....................................................................................................................................... 8

3Assembly instructions......................................................................................... 10

3.1 Transport ............................................................................................................................................. 10

3.2 Installing the unit................................................................................................................................. 10

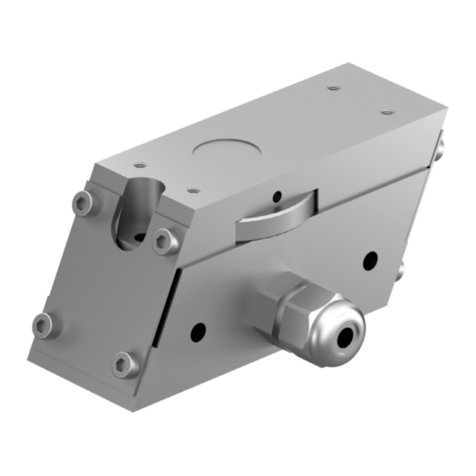

3.3 Fixing the bowl..................................................................................................................................... 11

3.3.1 Central Fixing .............................................................................................................................. 11

3.3.2 Radial Fixing ................................................................................................................................ 12

3.4 Power supply ....................................................................................................................................... 13

4Operating instructions......................................................................................... 14

4.1 Standard operation.............................................................................................................................. 14

4.2 Settings for the specific device............................................................................................................. 14

4.3 Torques ................................................................................................................................................ 16

5Maintenance instructions .................................................................................... 17

5.1 Replacing the leaf springs.................................................................................................................... 17

5.2 Adjusting the magnet gap ................................................................................................................... 18

5.3 Wear parts and Spare parts................................................................................................................. 19

6Accessories .......................................................................................................... 21

6.1 Adjusting tools ..................................................................................................................................... 21

6.2 Controller ............................................................................................................................................. 21

6.3 Address for orders................................................................................................................................ 22

7Disposal ................................................................................................................ 22