i

CONTENTS

Form No. HBGM-0608

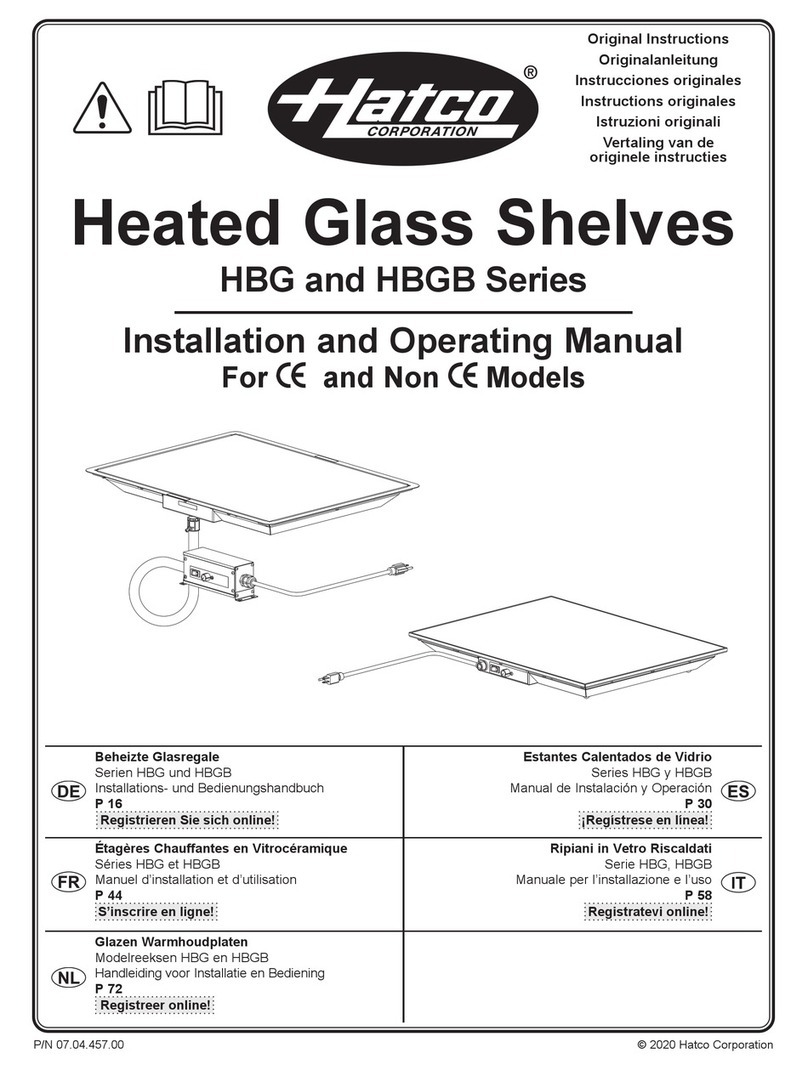

INTRODUCTION

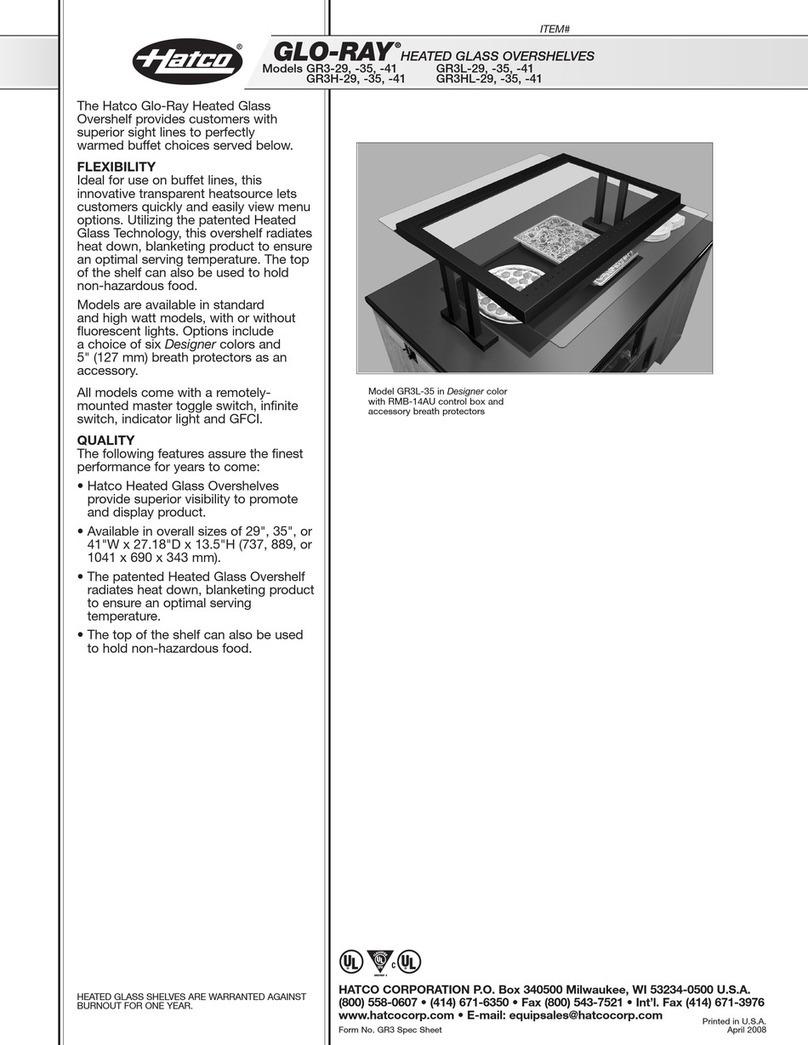

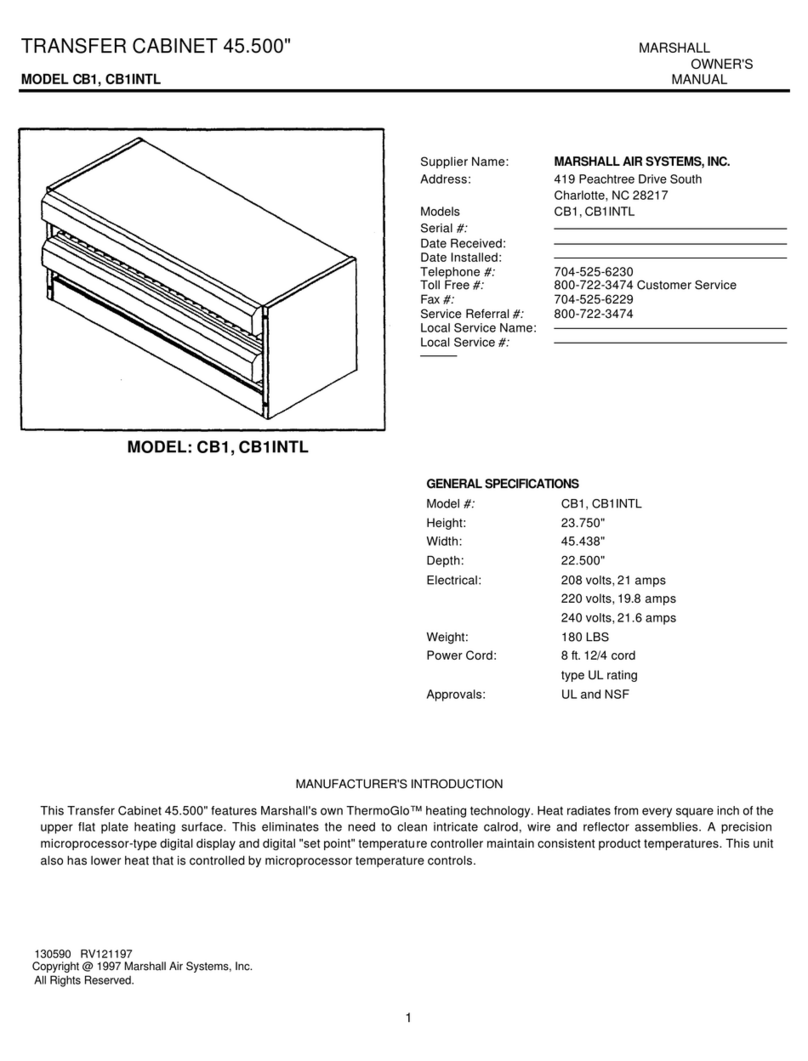

The Hatco Heated Black Glass shelf is designed to

safely hold food hot while blending into your décor.

t will keep all food at proper serving temperatures

without affecting quality. This unit features a

thermostatically-controlled heated glass base that

extends the food holding times.

Heated Black Glass shelves are a product of

extensive research and field testing. The materials

used were selected for maximum durability,

attractive appearance, and optimum performance.

Every unit is inspected and tested thoroughly prior

to shipment.

This manual provides the installation, safety, and

operating instructions for the Heated Black Glass

shelf. Hatco recommends all installation, operating,

and safety instructions appearing in this manual be

read prior to installation or operation of the Heated

Black Glass shelf.

Safety information that appears in this manual is

identified by the following signal word panels:

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury.

NOTICE is used to address practices not related

to personal injury.

Important Owner Information...............................i

Introduction...........................................................i

Important Safety Information..............................1

Model Designation...............................................2

Model Descriptions..............................................2

All Models........................................................2

HBG Models....................................................2

HBGB Models..................................................2

Specifications.......................................................3

Dimensions — HBG Models............................3

Dimensions — HBGB Models.........................3

Plug Configurations.........................................4

Electrical Rating Chart — HBG Models ..........4

Electrical Rating Chart — HBGB Models........5

Installation ............................................................6

HBG Models....................................................6

HBGB Models..................................................6

Operation..............................................................9

General............................................................9

Maintenance .......................................................10

General..........................................................10

Daily Cleaning ...............................................10

Cleaning Burned-On Residue........................10

Cleaning Sugary Spills ..................................10

Cleaning Metal Marks and Scratches............10

Troubleshooting Guide......................................11

Options................................................................12

Accessories........................................................13

Hatco imited Warranty.....................................13

Authorized Parts Distributors...........Back Cover

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage,

and purchase date of your Heated Black Glass shelf

in the spaces below. Please have this information

available when contacting Hatco for service

assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.S.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.S.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts and Service)

(414) 671-3976 ( nternational)

24 Hour 7 Day Parts and Service

Assistance available in the

United States and Canada

by calling (800) 558-0607.

Additional information can be found by visiting our

web site at www.hatcocorp.com.