haupa 21 66 01 User manual

Q

ZERTIFIKAT

DIN EN ISO 9001

… convincing solutions

Electro hydraulic crimping tool

Art. 21 66 01

INSTRUCTION MANUALHydraulic pliers

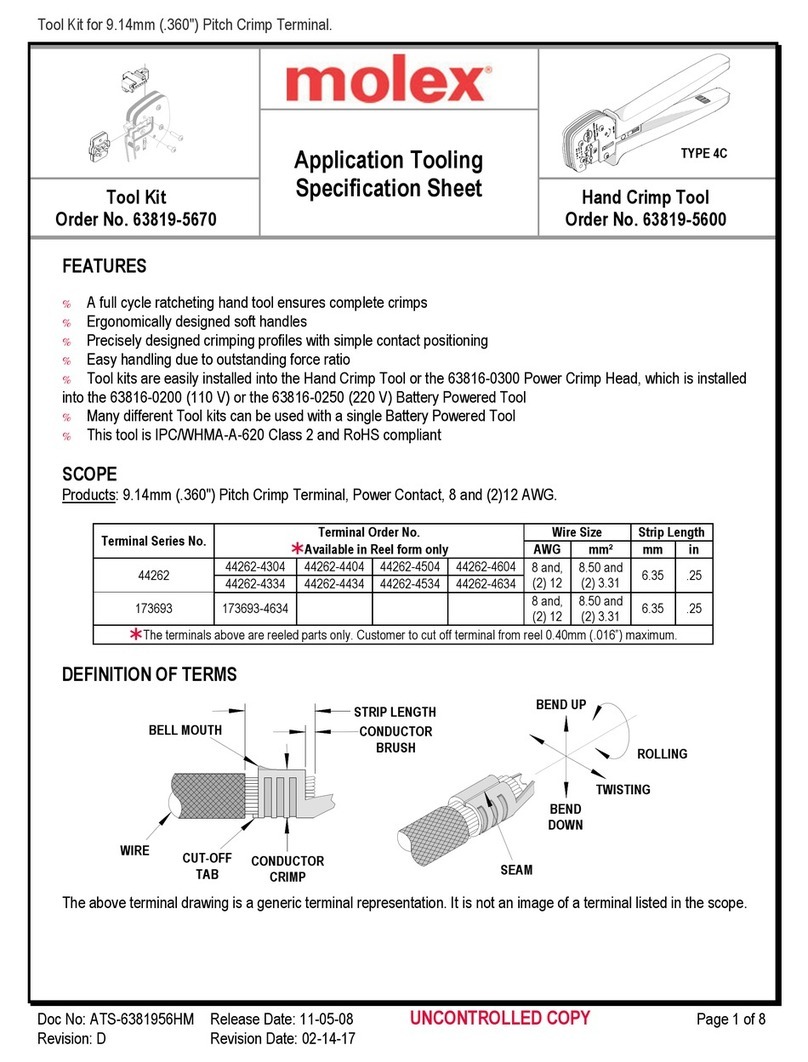

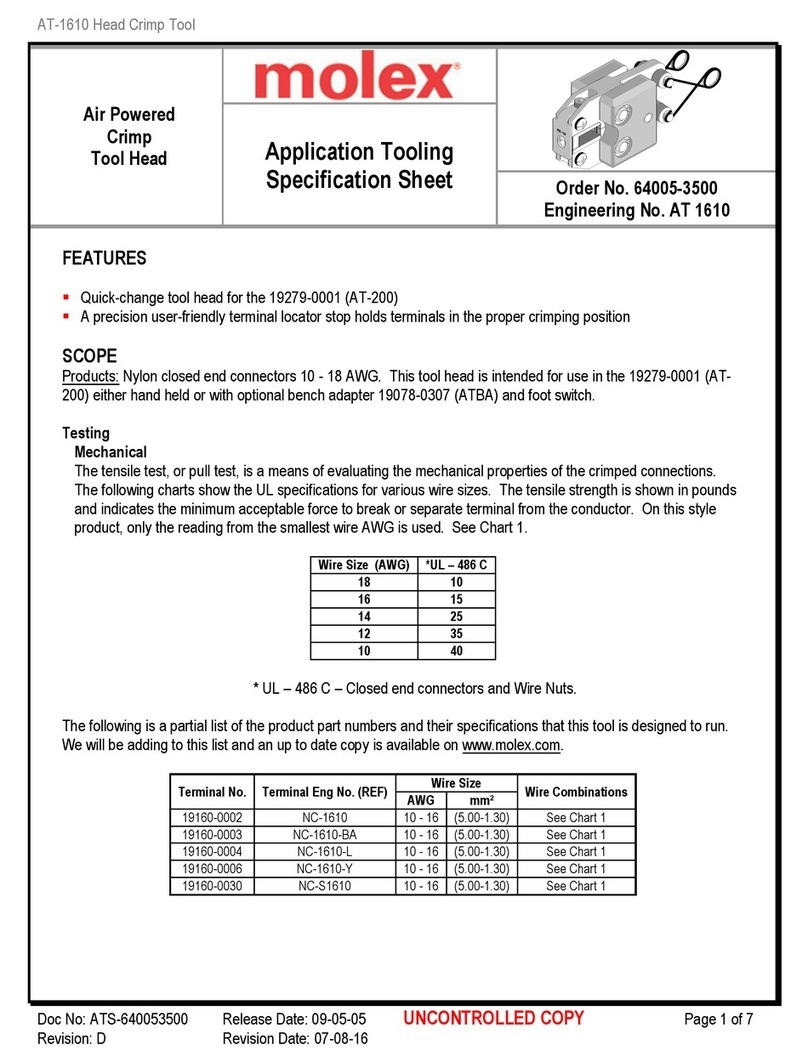

1. Technical characteristics

Application field: A compression tool for crimping electrical connectors,

suitable for copper conductors up to 400 mm2and aluminium

conductors up to 300 mm2.

Force developed: 120 kN

Press opening: 25 mm

Rated operating pressure: 700 bar

Oil type: ISO class viscosity 15

Voltage 14.4V

Battery: 3.0 Ah

Speed of advance: The tool moves at two speeds. A speed to move the dies

together and a slower speed for the crimping action.

The changeover from one speed to the other is automatic.

Safety: The tool is equipped with a factory-set safety valve.

Sicherheitsventil ausgestattet.

Construction: 216601 model features a built-in drive pump.

It is equipped with an 180º rotating head for easy access in

confined areas. The model 216601 is not designed to protect the

operator in hot line work.

2. Working range

Pressure: 120 kN

Crimping range: DIN cable lugs 300 mm2

standard copper 400 mm2

aluminium 240 mm2

Crimping time: 6 - 12 sec.

Charging time for batteries: 20 min

Battery voltage: 14.4 V

Battery capacity: 3.0 Ah

Working pressure: 700 bar

Dimension: 335 x 310 x 75 mm

Weight: 7 kg

Weight Set: 12 kg

Germany: HAUPA GmbH & Co. KG, Königstraße 165-169, D -42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected]om • Errors and technical changes reserved.

… convincing solutions

english

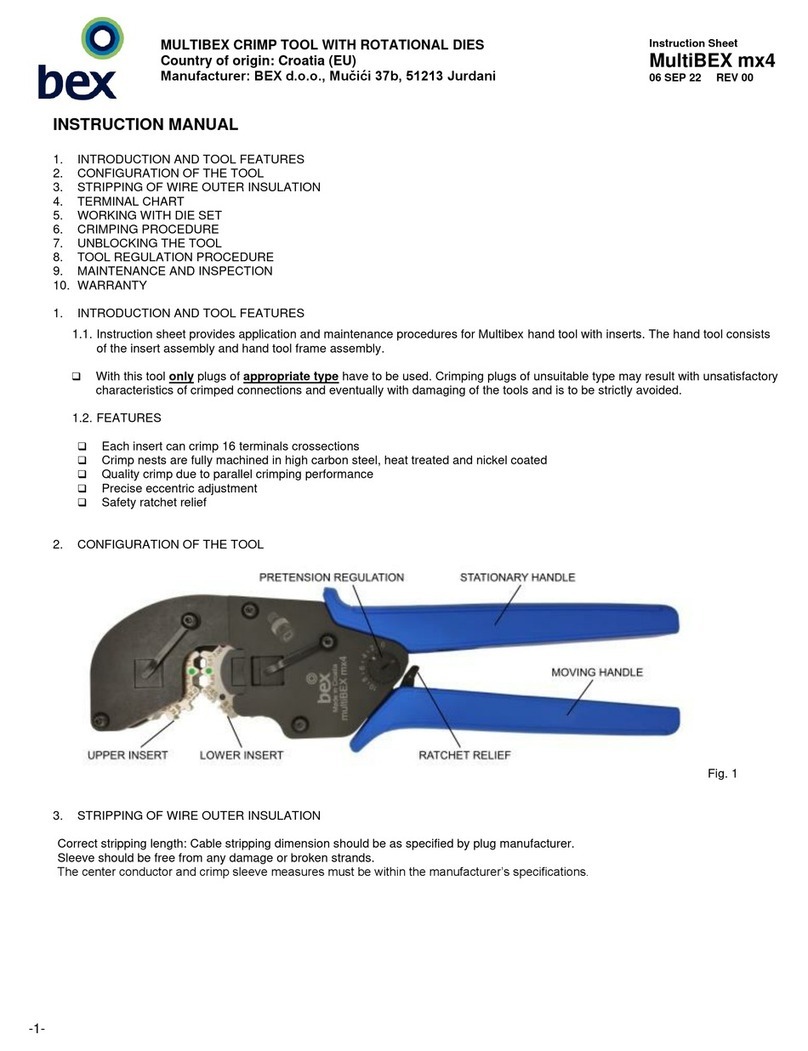

3. Instrucctions for use

WARNING! NEVER USE THE TOOL WITHOUT FIRST INSERTING THE DIE SET.

Ensure that the dies correspond exactly to the area to be crimped and that the dies are perfectly

positioned in their corresponding holders.

FAILURE TO DO SO COULD RESULT IN SERIOUS DAMAGE OR BREAKAGES AND WOULD VOID

THE GUARANTEE.

Preparation:

• Select the correct die for the connection to be made.

• Insert the die set in the tool head. All the dies used in these models are semicircular,

regardless of the type of compression or crimping to be performed. Both die parts have

identical outside dimensions and can therefore be mounted indistinctly on either the piston

or the head. The same procedure is used for mounting the dies on both the piston and the

head.

• Insert the die along the guides, until it comes to a stop against the locking pin.

• Then, remove the locking pin by pressing the release button and continue to insert the die

until it is retained in position by the pin.

• For the piston side: To carry out the above-mentioned operations, it is first necessary to

move the piston forward to allow access to the release button.

• Die removal: The procedure is also the same for both parts of the die set. Release by pres

sing the locking buttons and slide the die outwards. When removing the die from the

piston, reverse the procedure described in the previous point.

Die holder

Pushbutton

to advance

Pushbutton for

return movement

Start:

- Place the tool in the operating position

- Select the appropriate die for the connection to be made

- Insert the die set in the tool head

- Insert the conductor in the connector

- Place the connector between the two dies.

- Grip the tool and actuate the pushbutton to advance, the piston will rapidly advance

until the dies are in contact with the connector to be crimped.

- When the dies start to press the connector, the tool automatically changes from rapid

speed to crimping speed.

- Crimp until the audible sound of the pressure limiter release is heard, or until the two

dies touch.

- Rotate the release valve handle a quarter of a turn to the left and the piston will auto-

matically retract to its initial position or to the desired position.

4. Battery removal and installation

Hold the grip firmly and press the battery release button to remove it.

CAUTION

Never short circuit the battery

Battery installation

Insert the battery ensuring that the poles are correct.

Battery charging

Before using the tools, charge the battery as follows:

When you insert a battery into the charger, the battery will start to charge and the red pilot light

will be on continuously. Once the battery is completely charged, the red pilot light will flash (at

one second intervals).

Plug the charger cable into an AC socket.

Once the charger plug has been connected to the mains, the red pilot light will

light.

Germany: HAUPA GmbH & Co. KG, Königstraße 165-169, D -42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected]om • Errors and technical changes reserved.

… convincing solutions

english

Insert the battery in the charger

Firmly insert the battery, in the direction indicated in the following figures, until it

comes into contact with the charger compartment bottom.

CAUTION

If the battery is inserted the wrong way round, apart from not charging this could also damage

the charger, such as the deformation of the charging terminal.

5. Care and maintenance

Cleaning

• Adequate cleaning of the tool after use, particularly the mobile parts, will help to

lengthen its useful life. Remember that dust, sand, environmental conditions –

particularly with a high salt index – and dirt in general are all extremely harmful to

hydraulic tooling.

• Particular care should be taken when cleaning both the pump drive piston and the

compression piston since any impurities could scratch the cylinder walls and damage

the leaktight seals. To clean the pistons correctly, in this case, we would recommend

advancing the piston and then cleaning it with a high quality non-corrosive solvent.

Power switch

Check that the machine switch is automatically released when you stop pressing it.

Should you detect any anomaly, replace it immediately.

Reservoir oil level

Ensure that the oil level is always above the black line on the viewer.

Do not fill the reservoir with noncompatible oil or brake fluid.

Oil type: VESTA HLP-15 manufactured by VERKOL or similar. Remove the reservoir cap and add oil to

the level marked. The oil must be filtered first. If necessary, any quantities you may

require could be supplied from our factory.

Storage

In order to prevent damage to the tools, caused by impact, dust etc, we would recommend

storing the tools in their carrying cases in a storage area.

Oil level

It is advisable to check the oil level in the tank at regular intervals, and particularly after

prolong use, and top up if necessary.

Oil top-up or filling procedure

This operation should only be performed by authorised technicians.

Important: the hydraulic oil must be filtered, have an ISO grade viscosity of 15,a viscosity index of

100 and conform to the AFNOR NFE 48603-HM and ISO 6743/4 L-HM standards.

CAUTION

To operate the tool correctly, the WORKING POSITION must be the natural one, that is with the hand-

le pointing downwards.

Turn off the cap and fill in

the oil on demand

Germany: HAUPA GmbH & Co. KG, Königstraße 165-169, D -42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected]om • Errors and technical changes reserved.

… convincing solutions

english

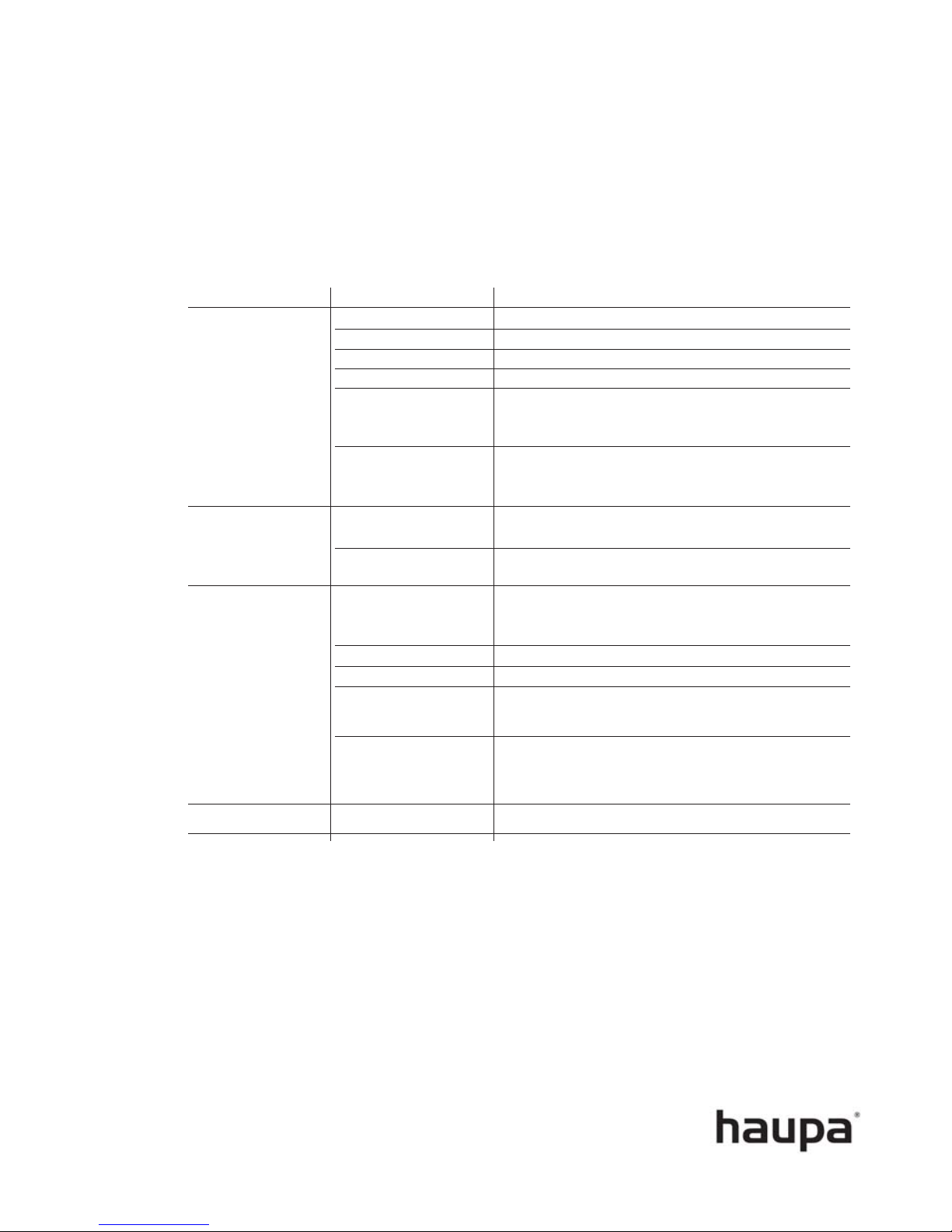

6. Fault diagnostics

Before performing any work on the tool, ensure that it is disconnected from the mains.

ATTENTION:

If you should require any service other than those detailed below, please consult the nearest

Technical Service Centre.

PROBLEM

The tool does not advance,

advances slowly or

intermittently

The tool advances but

does not retain the

pressure

The tool does not retract,

partially retracts or does

so slower than normal

Loss of oil at the piston

POSSIBLE CAUSE

Oil level low

Release valve open

Loose quick connection

Load too big

Air in the system

Cylinder plunger jammed

Leak at the connections

Internal pump leak

Valve closed. Pump reservoir

excessively full

Loose connection

Air in the system

Interior hose Ø too narrow

Damaged cylinder spring or

the cylinder is damaged in

some other way

Broken o-rings

SOLUTION

Add oil in accordance with the instructions given above

Close the release valve

Check that all the connections are tight

Do not try to go above the rated load

Purge the air, keeping the pump higher than the

tool and operate it several times without increasing

the pressure

Check the cylinder for damage. Ask a mechanic

specialising in hydraulic systems to repair it

Check that all connections are tight and that there

are no leaks

Ask a mechanic specialising in hydraulic systems

to repair the pump

Open the release valve Remove all until it reaches the max line

shown on the viewer

Check that all connections are tight

Purge as indicated above

Use a hose with a larger diameter that supports an

operating pressure of 700 bar

Ask a mechanic specialising in hydraulic systems

to repair the pump

Have specialised personnel replace the o-rings.

Always use original spares. Any other part type could seriously damage the tool and void the guarantee.

If despite the above, the tool still does not work correctly, return it to the nearest Technical

Service for repair and fine tuning by specialised personnel or send an e-mail to:

WHEN ORDERING SPARES, ALWAYS PROVIDE THE FOLLOWING INFORMATION.

1. Item code number

2. Item description

3. Instruction manual reference and/or date

4. Tool type

5. Tool serial number

The guarantee will become void if spares other than the HAUPA original spares are used.

Spare parts list

No. Decription PU

1 PLASTIC BOX (L) 1

2 PLASTIC BOX (R) 1

3 UP PLASTIC CAP 1

4 BATTERY 14.4V 1

5 PUMP BODY 1

6 SCREW 2

7 SPRING 2

8 BALL CAP 2

9 BALL7.0 mm 2

10 SPRING 2

11 BALL 4.75 mm 4

12 SPRING 1

13 O RING 1

14 BACK-UP RING (P4) 1

15 SCREW 1

16 WASHER 1

17 VALVE BODY 1

18 SPRING 1

19 SPRING 2

20 BALL 4.0MM 3

21 SCREW 4

22 O RING 2

23 VALVE BASE 1

24 O RING 1

25 VALVE BODY 1

26 VALVE ROD 1

27 O RING 1

28 SPRING 1

29 PIN 1

30 BACK-UP RING (P8) 1

31 SPRING 1

32 O RING 1

33 PISTON 1

34 O RING 1

35 ROTATION ROD 1

36 O RING 1

37 RELEASE VALVE STEM 1

No. Decription PU

38 O RING 1

39 OIL RERSERVOIR 1

40 OIL RESERVOIR PLUG 1

41 SNAP RING 1

42 SPRING FIEXED PIECE 1

43 SPRING 1

44 AXEL 1

45 O RING 1

46 BACK-UP RING 1

47 PISTON 1

48 PIN 1

49 PISTON BUTTON 1

50 PLATE 1

51 PIN 1

52 SPRING 1

53 FIXED BUTTON 1

54 C-TYPE HEAD 1

55 SCREW 1

56 BALL 2

57 SPRING 2

58 SPRING BASE 2

59 NUT 2

60 -

61 -

62 -

63 -

64 SNAP RING 1

65 SCREW 1

66 ALUM-HEAD 1

67 RELEASE 1

68 NUT 1

69 SCREW 1

70 MONITOR 1

71 SCREW 1

72 SCREW 4

73 BEARING 2

74 ROTATION ROD 1

No. Decription PU

75 BEARING 1

76 BEARING BASE 1

77 FIRST GEAR BASE 1

78 FIRST GEAR PART 4

79 RING GEAR 2

80 RUBBER WASHER 1

81 SECOND GEAR BASE 1

82 SECOND GEAR PART 4

83 WASHER 1

84 GEAR BOX CAP 1

85 SCREW 2

86 MOTOR FIXED PIECE 1

87 SCREW 4

88 GEAR 1

89 MOTOR 1

90 LOCK RING 1

91 PROTECT CAP 1

92 MONITOR 1

93 SCREW 2

94 RELAY 1

95 OVER LOAD BREAKER 1

96 SPRING 2

97 PLASTIC FIXED PIECE 1

98 SCREW 4

99 FLYING RING 2

100 PROTECT CAP 1

101 SWEACH 1

102 SWEACH PIN 1

103 SPRING 1

104 SWEACH 1

105 SCREW 2

106 INSULATE PLATE 1

107 LOCK PLATE 2

108 CONDUCTION PLATE 2

109 SCREW 1

110 SCREW 1

111 SCREW 5

112 SCREW 2

Germany: HAUPA GmbH & Co. KG, Königstraße 165-169, D -42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected]om • Errors and technical changes reserved.

… convincing solutions

english

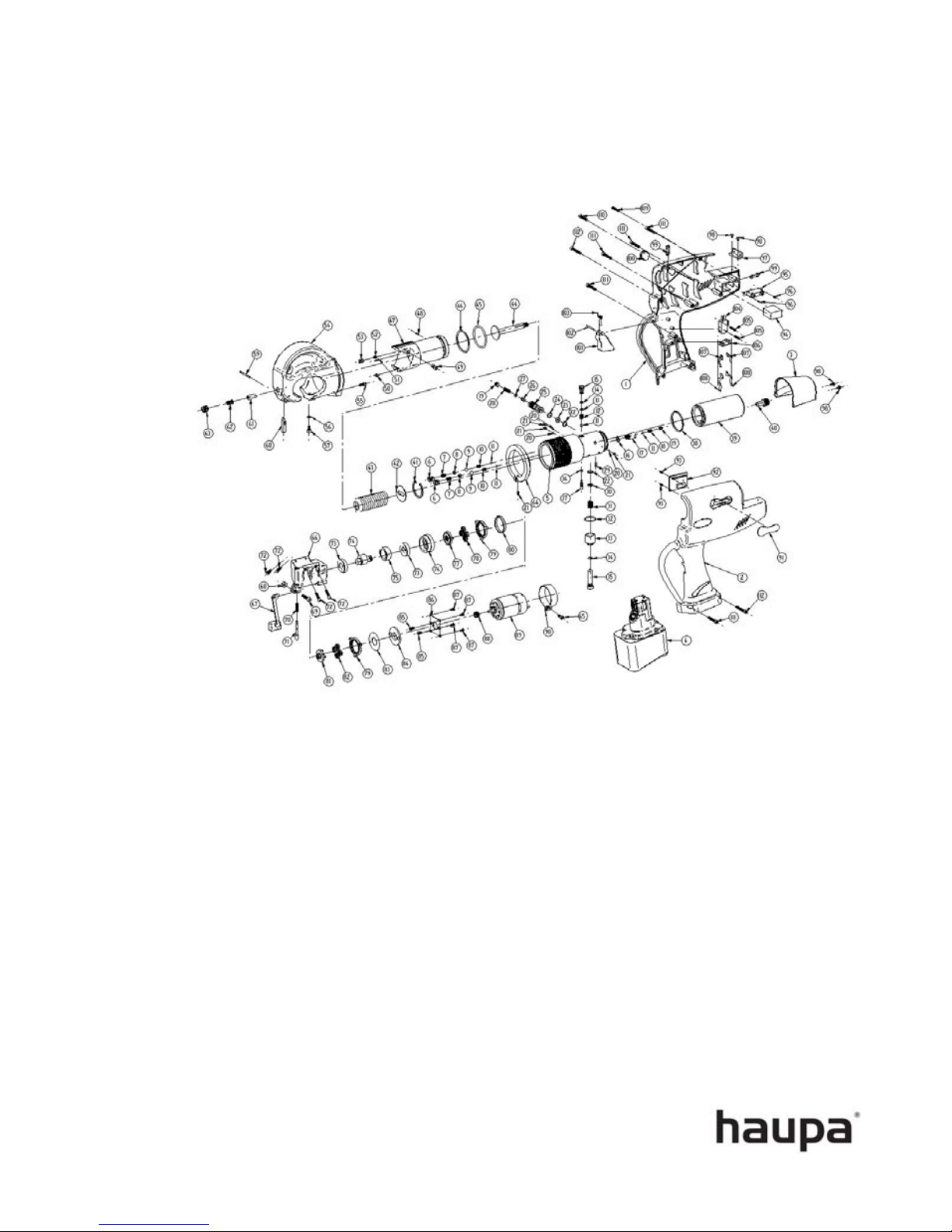

Exploded assembly drawing Art. 21 66 01

Table of contents

Other haupa Crimping Tools manuals

haupa

haupa AO-6 User manual

haupa

haupa KH-12 User manual

haupa

haupa MO-6 User manual

haupa

haupa SMART-LINE 216801-1 User manual

haupa

haupa SD300-6M User manual

haupa

haupa AC25-12 User manual

haupa

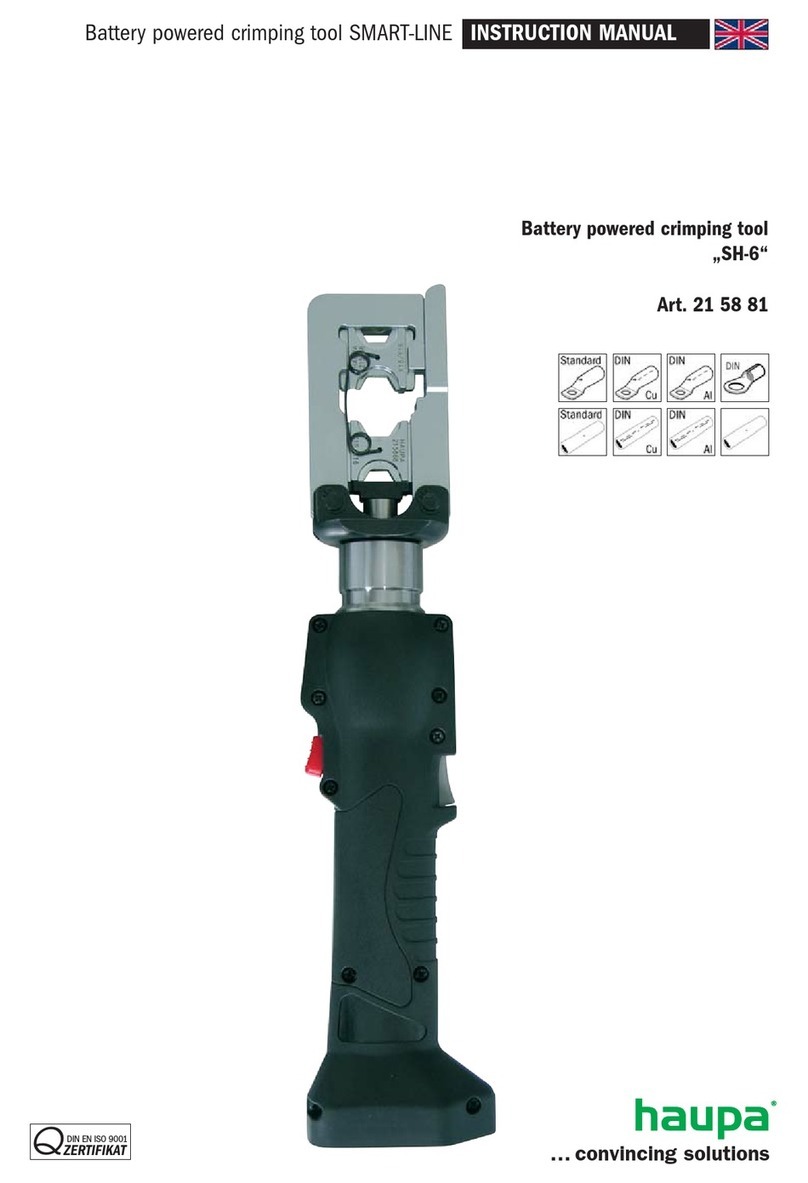

haupa SMART-LINE SH-6 User manual

haupa

haupa SMART-LINE SO-6M User manual

haupa

haupa SMART-LINE SH-6 User manual

haupa

haupa SDE240-6M User manual

Popular Crimping Tools manuals by other brands

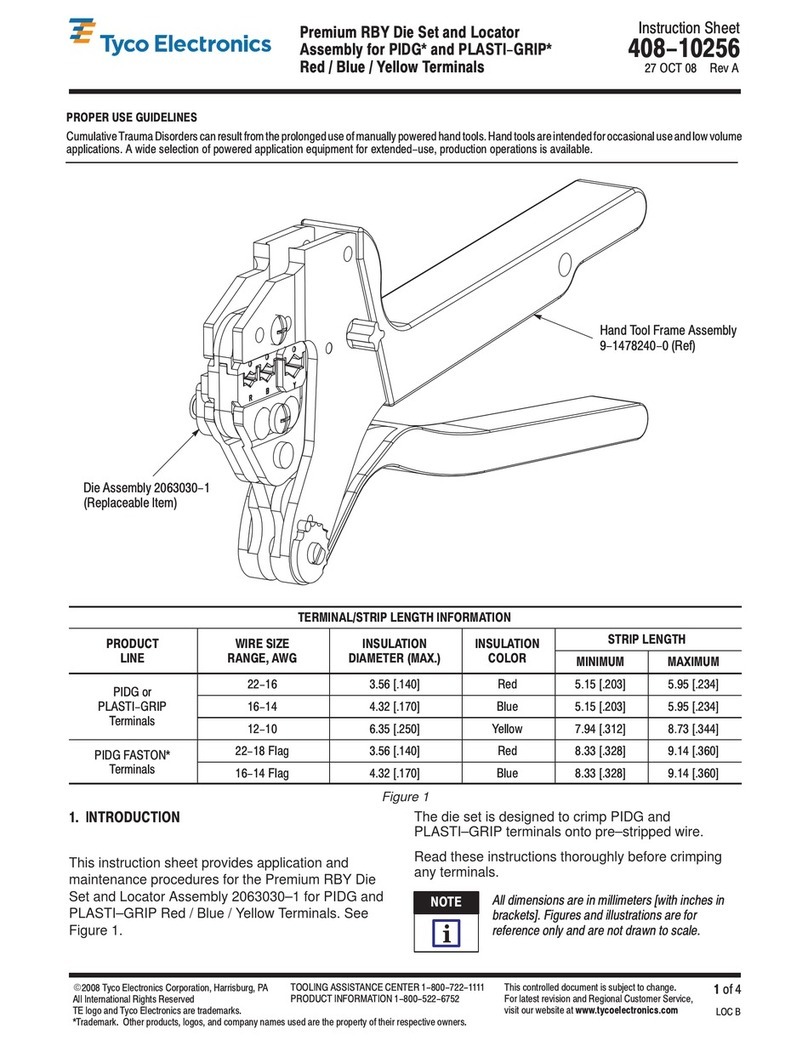

Tyco Electronics

Tyco Electronics PIDG Series instruction sheet

ZURN

ZURN Medium QickClamp Operation instructions

Tyco Electronics

Tyco Electronics AMP CERTI-CRIMP II instruction sheet

Staubli

Staubli PV-CZM-61100 operating instructions

molex

molex CR5905 Operating Instruction and Specifications Sheet

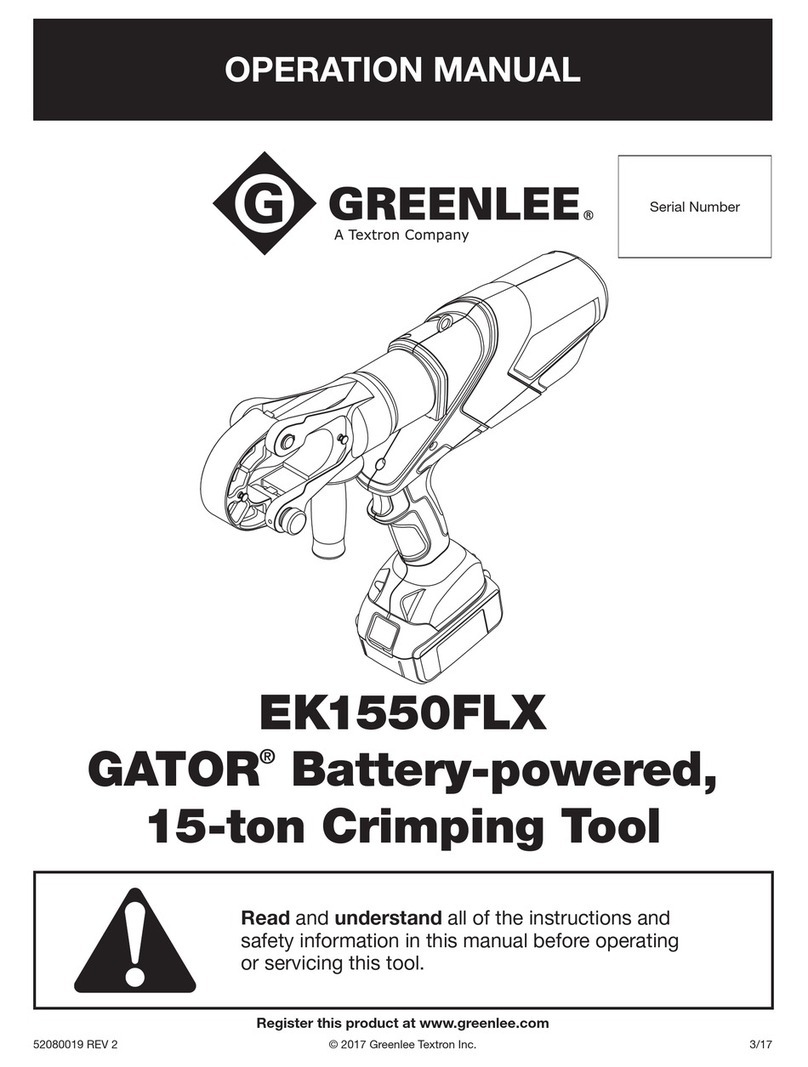

Textron

Textron Greenlee GATOR EK1550FLX Operation manual