5

Germany: HAUPA, Königstr. 165-169, 42853 Remscheid

Phone:

+49

(0)2

19

1

84

18-0,

F

ax:

+49

(0)2

19

1

84

18-840,

[email protected] •

Errors

and

technical

changes

reserved.

…convincing solutions

english

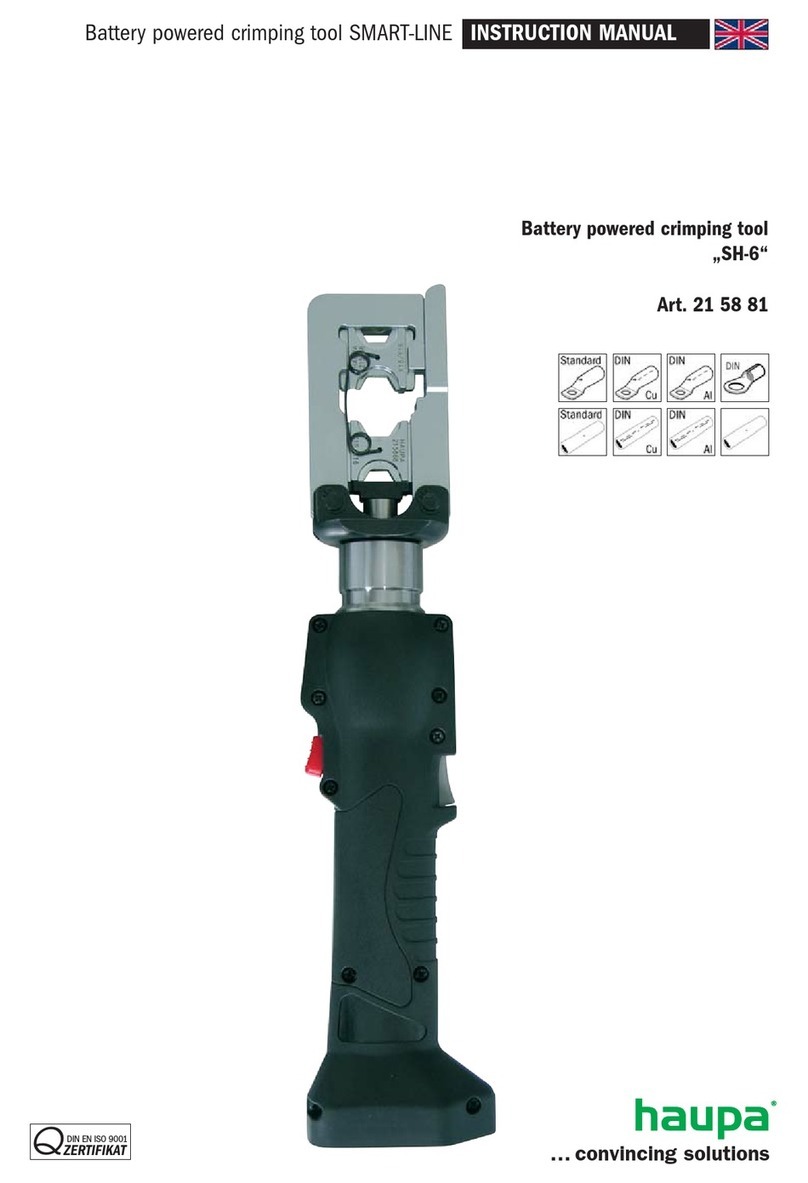

4. CARE AND MAINTENANCE

The tool maintenance must be performed by technical personnel qualified in hydraulic

systems.

4.1. CLEANING

• If the tool is adequately cleaned after use, particularly the mobile parts, this

will help to lengthen its useful life. Remember that dust, sand, environmental

conditions – particularly with a high salt index – and dirt in general are all

extremely harmful for hydraulic tooling.

• Particular care needs to be taken when cleaning both the pump drive piston

and the compression piston since any impurities could scratch the cylinder

walls and damage the leaktight seals. To clean the pistons correctly, in this

case, we would recommend advancing the piston and then cleaning it with

a high quality non-corrosive solvent.

4.2. STORAGE

• In order to prevent damage to the tools, caused by impact, dust etc, we would

recommend storing the tools in their transport and storage cases.

4.3. OIL LEVEL

• Periodically and particularly after extended use, it is advisable to check the oil

reservoir level and add oil when required.

4.3.1. Refilling the oil reservoir

• Unscrew the reservoir plug located at the end of the fixed handle

• With the machine in an upright position, refill with thoroughly clean, filtered

hydraulic oil until it is 2 or 3 cm from the top.

• Important: the hydraulic oil must be filtered, have an ISO grade viscosity of 15,

a viscosity index of 100 and conform to the AFNOR NFE 48603-HM and

ISO 6743/4 L-HM standards.

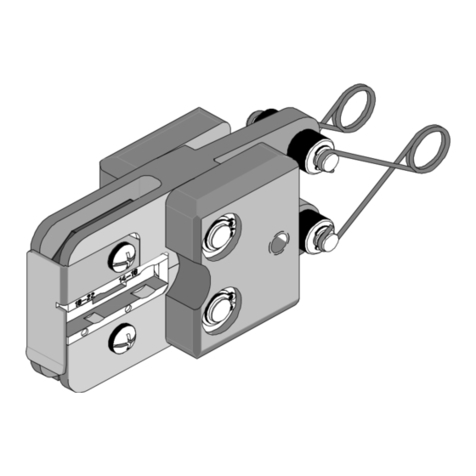

4.3.2. Punch, Die and Stud lubrication

• For extended punch and die duration and to use less force, it is advisable to

lubricate the punch and die cutting edges with a little oil. This will also

facilitate the detachment of the knockout.

4.4. WARNING!

• Particular care should be paid to ensure that the punch is screwed right into

the stud, in order to prevent the stud or thread from breaking, and also to

prevent the tool from reaching the end of its travel limit without having cut right

through the sheet.