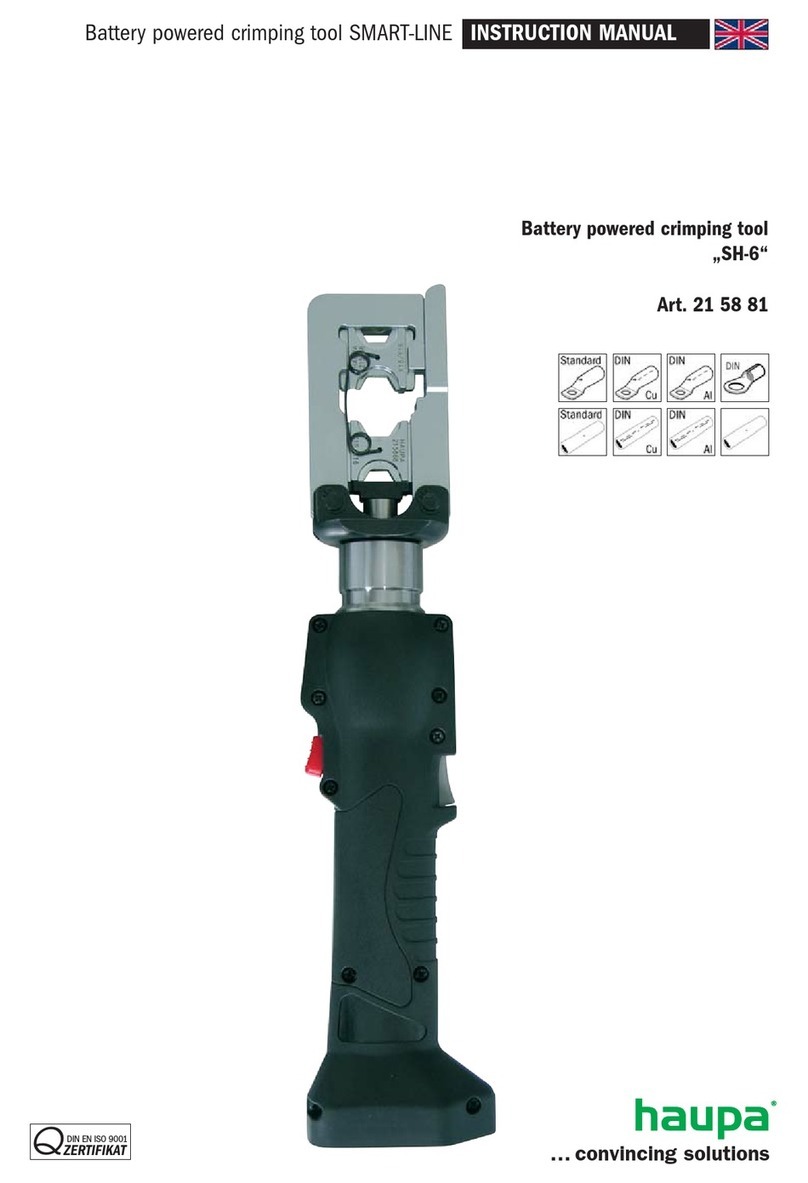

haupa US-6M User manual

Battery powered crimping tool

„US-6M“

Art. 216760-1

Battery powered crimping tool SMART-LINE INSTRUCTION MANUAL

1

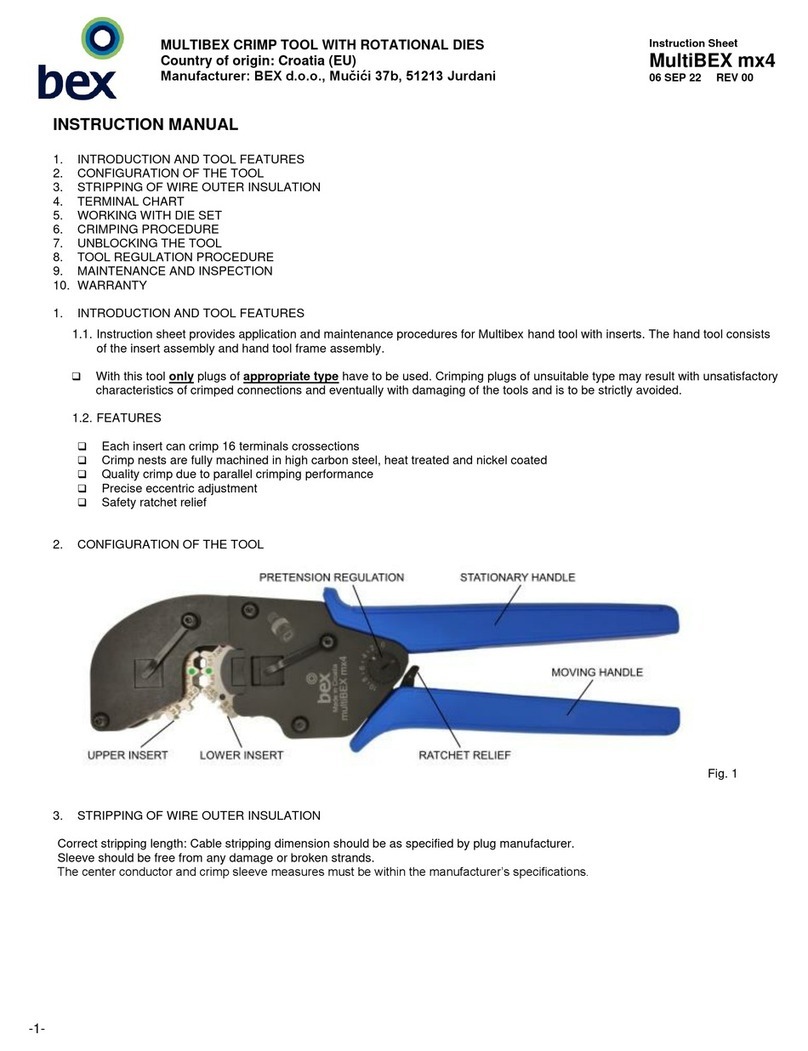

KOPF TYPE & APPLICATION

HEAD

DRAWING

MODEL NO.

216764

216762

216761

216763

216665-U

216666-U

LENGTH(mm)

180

233

140

130

170

225

WIDTH(mm)

134

148

90

93

136

136

HEIGHT(mm)

70

93

60

34

60

60

WEIGHT(kg)

2.7

2.8

1.7

1.2

3

3

APPLICATION

+Punching +

galvannealed

steel plate Max.

thickness

3.2mm or

stainless-steel

plate Max.

thickness

1.6mm

+ Cutting +

Blade opening:

Dia. 50mm

+ Crimping +

Connector

crimping

+ Crimping +

Connector

crimping

Type: Dieless

+ Crimping +

Quad-Mandrel

+ Crimping +

Quad-Mandrel

RANGE

Punch-dies size

1/2”-2”

Thickness range

1.6-3.2mm

Copper Cable

500sqmm

Aluminum Cable

750sqmm

DIN 10-300 mm²

AWG8-600MCM

Copper

Connector

16-240 mm²

Aluminium

Connector

50-240 mm²

DIN 16-300 mm²

AWG6-600MCM

DIN 25-400 mm²

AWG3-750MCM

SPECIFICATION

MODEL NO.

216760-1

OUTPUT

6 TON

VOLTAGE

DC 18V

PRESSURE

700 KG/CM2

WEIGHT

2.4 KGS (WITHOUT BATTERY)

DIMENSION

116mm(L)x75mm(W)x334mm(H)

CHARGING TIME

60-70 MINUTES(215525)/30 MINUTES(215523)

ACCESSORY

CHARGER/BATTERY SET & SYSCON

FEATURES

⚫Quick-exchange design for head

⚫LED working light design

⚫Multi-function/one body with different application heads

3

REMARKS BEFORE OPERATION OR WHILE OPERATING

uPlease wear protective equipment while operating to make sure your safety.

Warning: This tool & heads are not insulated.

uPlease kindly check the crimping/cutting/punching range and suitable

crimping/cutting/punching materials before any action. (You could find the

range at this manual page 1) Do not crimp/cut/punch without any material

in working area, otherwise the tool will be damaged.

uAfter operation of tool, please press the oil-release button to set the tool

hydraulic ram back to original position. And separate the battery from tool.

Please store the tool without connecting with battery. This will affect the life

time of tool and battery.

uPlease do not put your hands/fingers in the working area while operating,

cleaning and testing. This action is very dangerous.

uPlease do not aim at anyone while operating. This action is very dangerous.

uBefore crimping, the dies must be fixed tightly to the dies holder. Make sure

you use correct size crimping dies before crimping.

Before cutting, if there are any broken blade pieces or any foreign object,

please do not operate. Please change new spare blade.

Before punching, if there are any broken plate pieces or any foreign object

causing bad-running, please do not operate. Please check if there is

anything got stuck inside/between the punch head & dies. Make sure you

use correct size punch dies before punching.

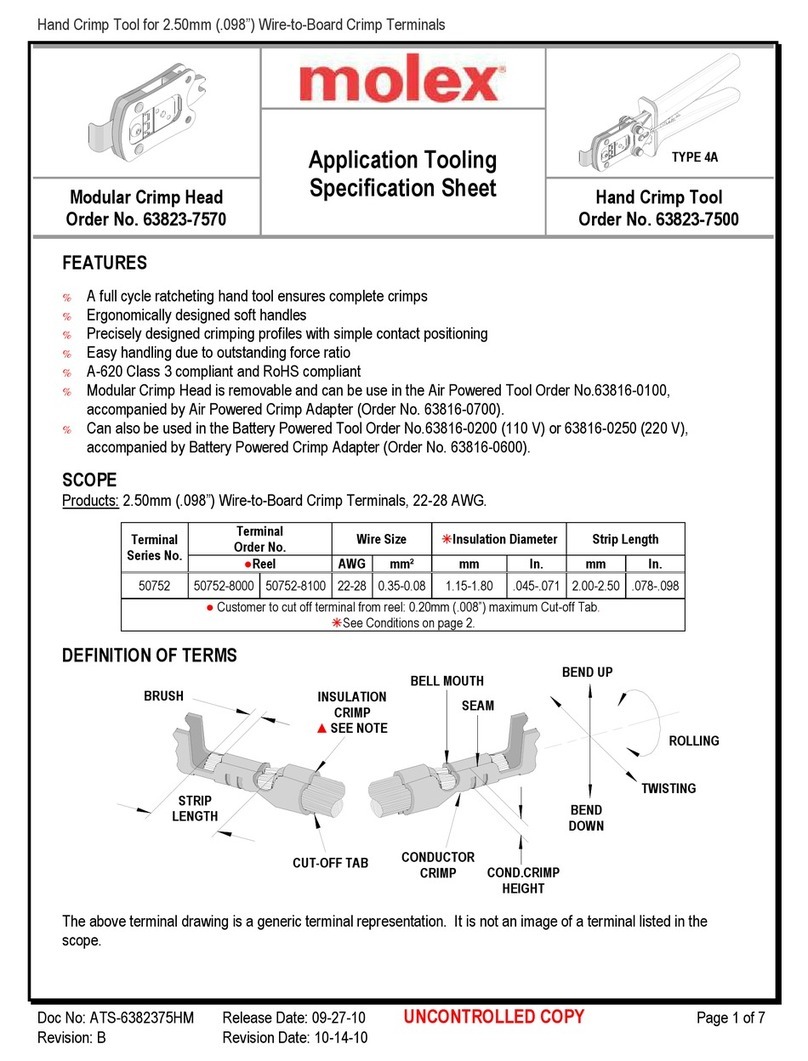

HOW TO OPERATE/USE 18V BATTERY CHARGER 215527

THIS CHARGER COULD WORK WITH 18V LI-ION BATTERY: 215523 & 215525

SPECIFICATION

MODEL NO.

215527

INPUT VOLTAGE

100 – 240 V AC

FREQUENCY

50 / 60 Hz

OUTPUT VOLTAGE

21 V DC

OUTPUT CURRENT

1,5 A

WEIGHT

0.126 KG

DIMENSION

92 mm(L) x 47 mm (W) x 45 mm (H)

Charger: Connecting battery to charger:

5

ABOUT THE 18V LI-ION BATTERY: 215523 & 215525

215523 (2 Ah)

215525 (4 Ah)

LED indicator state of charge (press the button):

*Please follow the manual of battery with correct instruction.

*Our company does not guarantee anything due to the purpose damage or wrong use.

Please pull the battery out of tool if the tool will not to be used for a long

period time!

SPECIFICATION

MODEL NO.

215523

VOLTAGE

18 V DC

WEIGHT

0.35 KG

DIMENSION

114 mm(L) x 73,5 mm (W) x 67 mm

(H)

CHARGING TIME

~ 30 MINUTES

CAPACITY

2 Ah

SPECIFICATION

MODEL NO.

215525

VOLTAGE

18 V DC

WEIGHT

0.58 KG

DIMENSION

114 mm(L) x 73,5 mm (W) x 67 mm (H)

CHARGING TIME

~ 60 MINUTES

CAPACITY

4 Ah

MANUAL/INSTRUCTION OF BATTERY

BEFORE OPERATION PLEASE NOTE

u Do not put the battery together with any metal. Otherwise the battery may have a short circuit.

u Do not store the battery at a wet/hot space. Put battery in a dry clean space.

u Do not give the battery to children. Keep the battery away from the children.

u The electric capacity of battery may be lost and the battery may be damaged if the battery is put in

the tool or charger for a long time.

u Do not heat the battery or put the battery in the fire.

u Keep the battery away from water, no matter sea water or faucet water. Please keep the battery dry

& clean.

u Do not press/take apart/throw down the battery. Do not let the battery near the water or fire. Also do

not put the battery in your pocket.

u Do not destroy the housing/package/body of battery.

u Do not use old transformed battery with strange/abnormal appearance.

u The battery after use will be a little warm.

u The battery in low temperature (10 Degree or below), the battery will be deteriorated and its use

time will be shorter. This is normal.

u Please follow the instruction of battery manual to charge the battery.

u Do not charge the battery directly under the sun or in a space with high temperature.

u Please use charger to charge the same brand battery.

u Do not use battery with other brand.

u Please charge the battery before storage if you will not use the battery for a long time. Please charge

the battery at least once a month to ensure its life.

HOW TO CLEAN THE BATTERY

u If the connecting points (+/-) or the cap of battery is dirty. It may cause the electric current can not

go through. Therefore you will find the digital monitor will still show “Without Power” under full

charged.

u Please keep the connecting points (+/-) or the cap of battery clean. Please use dry soft cloth to wipe

the battery housing/cap and even the connecting points (+/-).

u Do not use cleaner or chemical cleaner to clean the battery or charger, otherwise they will be

damaged.

RECYCLE & THROW AWAY

u Make sure there is without any power inside the battery before throwing the battery away.

u Please charge the battery full at the first time use. If the battery’s use time is shorter after long

time use, it means you need to amend an extra new battery.

u Please stick gummed tapes on the connecting points (+/-) for fire/explosion preventing. Please

follow the local rule of recycling.

SAFETY INSTRUCTION

l This product is not to be used by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction.

l Children should be supervised to ensure that they do not play with the

appliance.

l Never recharging non-rechargeable batteries.

l Please follow the manual of battery with correct instruction. Our company

does not guarantee anything due to the purpose damage or wrong use.

7

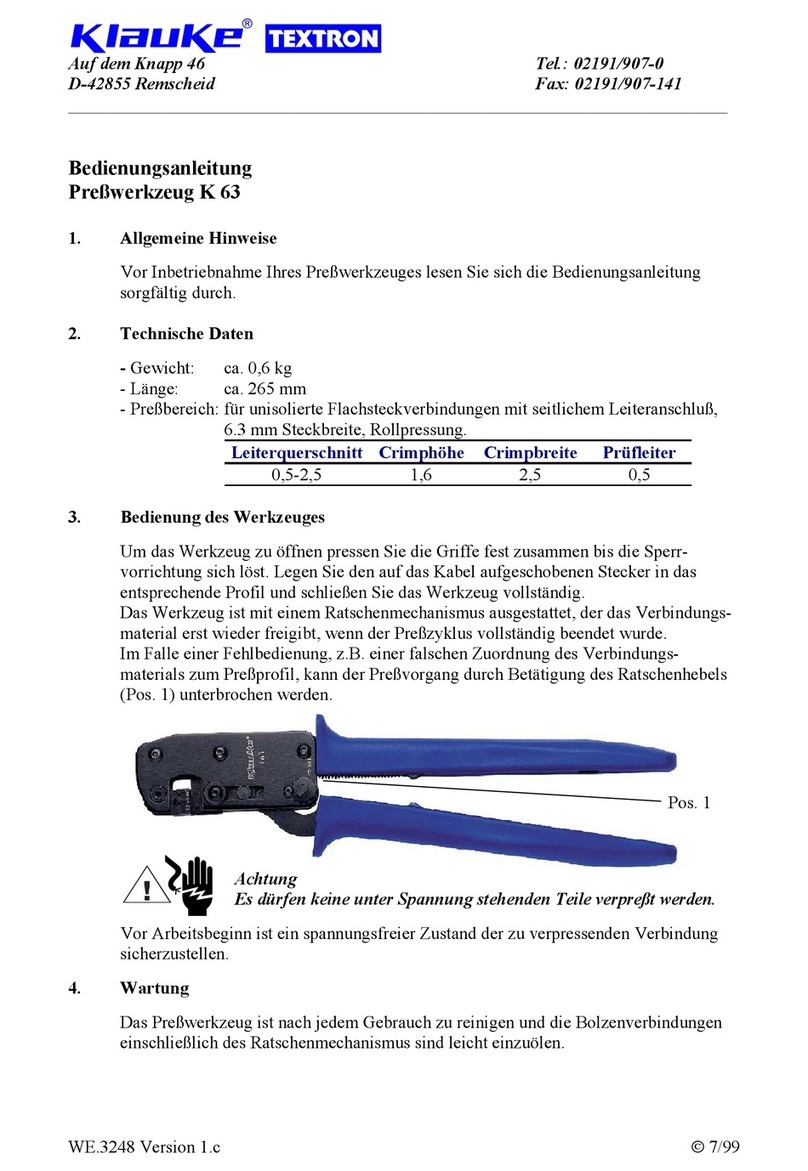

HOW TO OPERATE/USE THE BATTERY TOOLS SET

*Operation Steps

u Insert the battery to art. 216760 as below picture 1:

*While the battery is inserted, the battery lock will lock the battery.

*While the tool connects the battery successfully and press the ON start

button, the “LED working light” will turned on about 15-20 seconds.

If the acoustic signal sounds 3 times, the battery is empty.

Picture 1: Set/Take battery

u Push the switch to change the function. Red means cutting and punching

and green stands for pressing.

u Please kindly note that the T-Bar only could rotate 180 degrees as below

picture 2:

Picture 2: T-Bar Rotation Degree

HOW TO EXCHANGE DIFFERENT APPLICATION HEADS

u Set 216763 dieless crimping head like below steps:

Ø Pull both fixed pins on T-Bar and insert art. 216763 dieless crimping

head like below picture 3:

*After inserting head, please press oil-release button to ensure the ram back to the original position, i.e.

Max. Opening, then you could put crimping material inside.

Picture 3: Insert art. 216763 dieless crimping head

Ø Put the crimping material inside the opening and close the jaws, make

sure both fixed pins are well fixed with head, like below picture4:

Picture 4: How to set crimping material

Ø Press the start button to crimp the terminal and oil-release button to

take the crimped terminal out of working area, like below picture5:

Picture 5: Crimping connector

u Set art. 216761 crimping head like below steps:

9

Ø Pull both fixed pins on T-Bar and insert art. 216761 crimping head like

below picture 6:

*After inserting head, please press oil-release button to ensure the ram back to the original position, i.e.

Max. Opening, then you could put crimping material inside.

Picture 6: Insert art. 216761 crimping head

Ø Choose the correct size crimping dies and set it inside dies holder. Put

the correct terminal meet the dies size inside, make sure both fixed

pins are well fixed with head, like below picture7:

Picture 7: How to set dies & crimping material

Ø Press the start button to crimp the terminal and oil-release button to

take the crimped terminal out of working area, like below picture8:

Picture 8: Crimping connector

u Set 216762 cutter head like below steps:

Ø Pull both fixed pins on T-Bar and insert art. 216762 cutter head like

below picture 9:

*After inserting head, please press oil-release button to ensure the ram back to the original position, i.e.

Max. Opening, then you could put cutting material inside.

Picture 9: Insert art. 216762 cutter head

Ø Rotate the T-Bar to meet the direction of cable/cutting material. Put

the cable/suitable cutting material inside the opening. Make sure both

fixed pins are well fixed with cutter head, like below picture10:

Picture 10: How to set cable/cutting material

Ø Press the start button to cut the cable and oil-release button to take

the cut cable/cutting material out of working area, like below picture11:

(Make sure the cable is with correct & suitable material before cutting.)

Picture 11: Cutting cable

u Set 216764 punch head like below steps:

11

ØPull both fixed pins on T-Bar and insert art. 216764 punch head like

below picture 12:

*After inserting head, please press oil-release button to ensure the ram back to the original position, i.e.

Max. Opening, then you could put punching material inside.

Picture 12: Insert art. 216764 punch head

ØRotate the punch head and if action is ok. Set the correct punch dies

in correct method. Make sure both fixed pins are well fixed with punch

head, like below picture13:

Picture 13: How to set punch dies/punching material

ØPress the start button to punch the suitable plate and oil-release button

to take the punched plate/punched material out of working area, like

below picture14:

*Make sure the plate is with correct thickness & suitable material kinds before punching.

*Before punching, please make a suitable pre-hole on plate.

Picture 14: Punch plate

Punch Dies Accessories

uSet crimping head (art. nr. 216666-U) like below steps:

ØPull both fixed pins on T-Bar and insert crimping head like below

picture 15:

ØPress fixed pin down.

ØRotate fixed pin as above pictures and pin will be out automatically.

ØPull head cap open as picture.

ØClose head cap as picture.

ØPress fixed pin down and rotate same as above picture.

uSet crimping head (art. nr. 216665-U) like below steps:

ØPull both fixed pins on T-Bar and insert crimping head like below

picture:

ØPut proper crimping material into working area.

Picture 15: Opening & closing of crimping head

Picture 16: Operation of crimping head

Picture 17: Operation of crimping head

13

STORAGE

uThe hydraulic oil for the body:

Add/use hydraulic oil Shell Tellus T15/HV 15. Do not use other

brand. Otherwise the tool will be damaged.

uStorage

Put the tool, charger and battery in a dry clean place. Please charge the

battery full once a month to make sure the life time. Clean the tool and add

some antirust oil on the metal parts, i.e. dies, dies holders before storage.

BREAKDOWN SOLVING

BREAKDOWN

SITUATION

PROBLEM

METHOD TO SOLVE

NORMAL MOTOR

BUT DIES

NOT MOVING

OIL IS NOT ENOUGH

SEND BACK TO REPAIR

AIR IN OIL RESERVOIR

SEND BACK TO REPAIR

OIL RETURN IS DEFECT

SEND BACK TO REPAIR

NORMAL MOTOR

BUT WITHOUT

PRESSURE

O-RING IS BREAKDOWN

SEND BACK TO REPAIR

OIL IS NOT ENOUGH

SEND BACK TO REPAIR

OPERATION

VERY SLOW

DUST IN OIL RESERVOIR

SEND BACK TO REPAIR

INNER SCREWS ARE LOOSEND

SEND BACK TO REPAIR

WRONG STEEL BALL

POSITION

SEND BACK TO REPAIR

MOTOR

DEFECT

BATTERY DEFECT

CHANGE BATTERY

CONNECTION OF BATTERY

AND TOOL DEFECT

CHECK ALL

CONNECTION POINTS

SWITCH BREAKDOWN

CHECK SWITCH

SEND BACK TO REPAIR

OIL RETURN

DEFECT

CAN NOT OPERATE

COMPLETE

THE CIRCLE

DIES BLOCKED

CLEAN THE BLOCK

OIL RETURN BREAKDOWN

SEND BACK TO REPAIR

ØIF YOU MEET ANY BREAKDOWN THAT YOU CAN NOT

HANDLE, PLEASE CONTACT US WITHOUT ANY

HESITATION.

ØDO NOT TRY TO SLOVE THE BREAKDOWN WITHOUT

ANY PROTECT EQUIPMENT.

HAUPA GmbH & Co.KG, Königstr. 164-169, 42853 Remscheid, Germany

Declaration of Conformity

HAUPA Factory Certificate

Remscheid, 24.02.2021

Product: Battery Hydraulic Crimping Tool„US-6M“

Product Range: Around the cable

Art.-Nr.: 216760-1

Application: universal

Force: 60 kN

Pressure: 700 Bar

Battery: 18 V, 2 Ah Li-Ion

Weight (Set): 6,7 kg

Optional accessories: Crimping head „U-KO-6“ Art. 216761

Crimping head „U-KDE240-6“ Art. 216763

Cutting head „U-KS6-S50“ Art. 216762

Punching head „U-S-6“ Art. 216764

Crimping head „U-D300-6“ Art. 216665-U

Crimping head „U-D400-6“ Art. 216666-U

Additional remarks: Includes a sensor (to display that a crimp has been completed according

to standards), Universal hydraulic tool with exchangeable heads for

multiple applications (Crimping-Cutting)

We, HAUPA GmbH & Co KG, Headquatered in 42853 Remscheid/Germany, Koenigstrasse 165-169,

declare under our sole responsibility that the products mentioned in the data sheet comply with the

European Standards or Standard Documentations according to the regulations of the following

mentioned directives:

EN 62841-1, EN 12100 Teil 1 + 2, EN ISO 13857 , EN 349, EN 60204-

1, EN 20643, EN 61000-6-3, EN 61000-6-2, EN 60529, EN 4413, EN

1037

According to 2006/42/EG

And the EMV-Guideline 2014/30/EU

HAUPA GmbH & Co.KG

Product Management

This manual suits for next models

1

Table of contents

Other haupa Crimping Tools manuals

haupa

haupa SMART-LINE SH-6 User manual

haupa

haupa 21 66 01 User manual

haupa

haupa 21 67 50 User manual

haupa

haupa SD300-6M User manual

haupa

haupa SMART-LINE SH-6 User manual

haupa

haupa MO-6 User manual

haupa

haupa SMART-LINE SHs-6 User manual

haupa

haupa SMART-LINE SO-6M User manual

haupa

haupa AC25-12 User manual

haupa

haupa SMART-LINE 216801-1 User manual

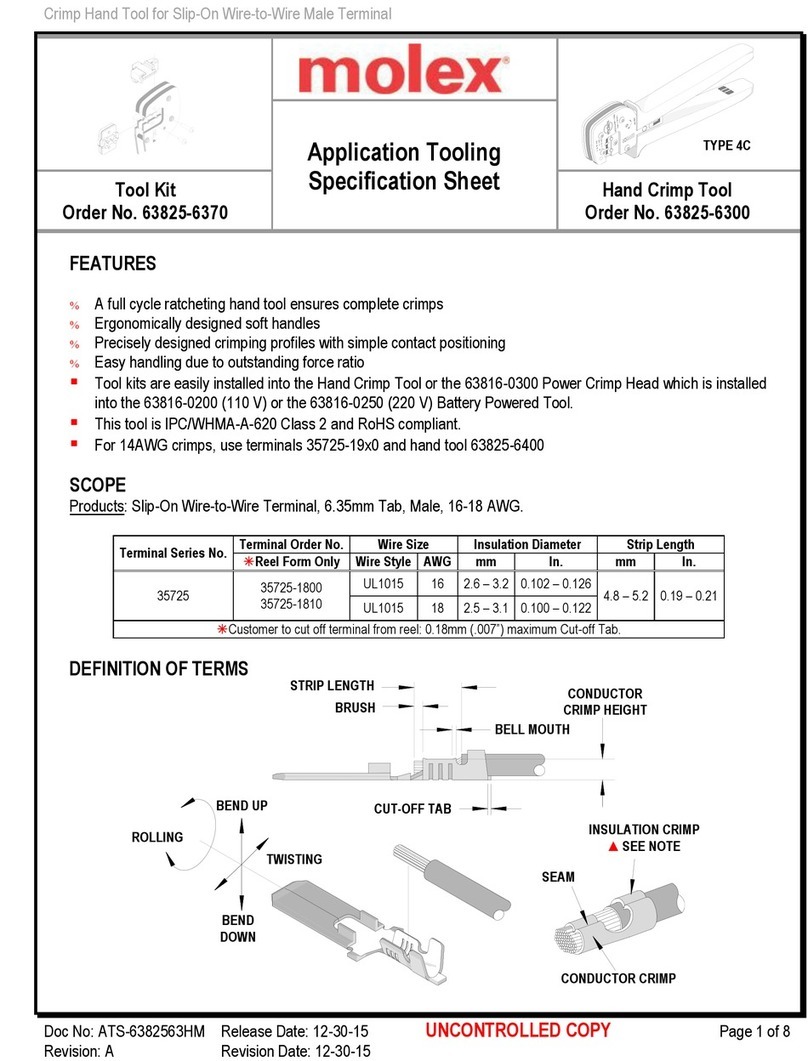

Popular Crimping Tools manuals by other brands

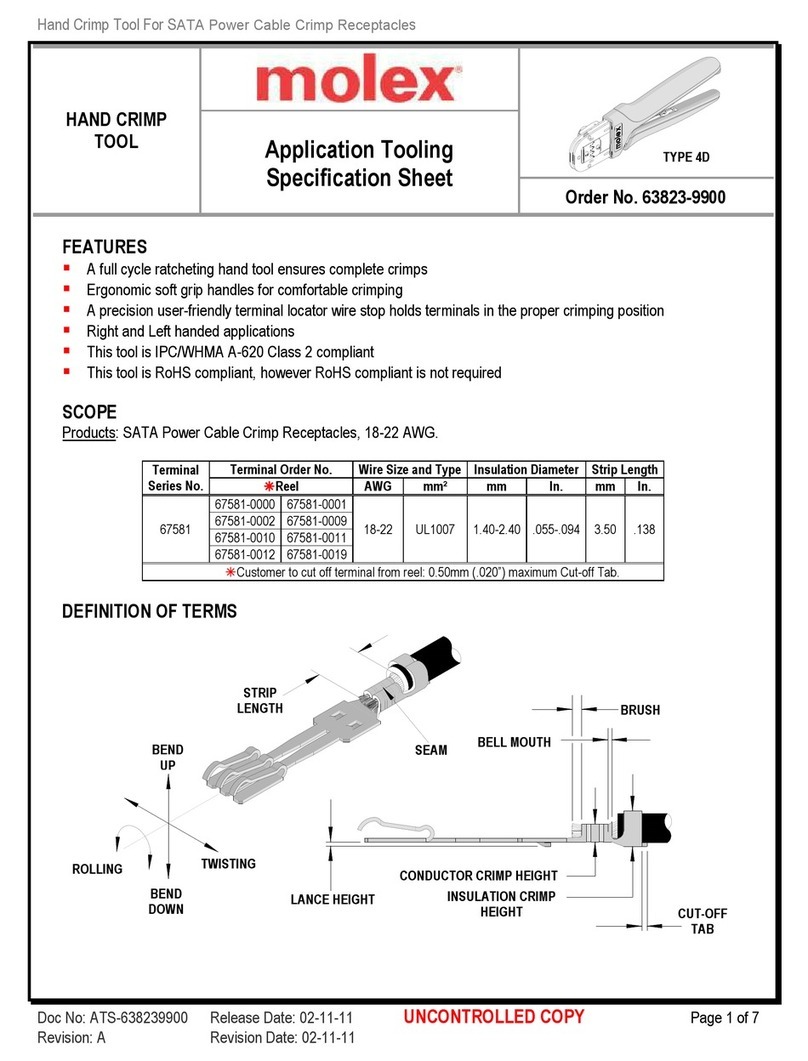

molex

molex 207129 Series manual

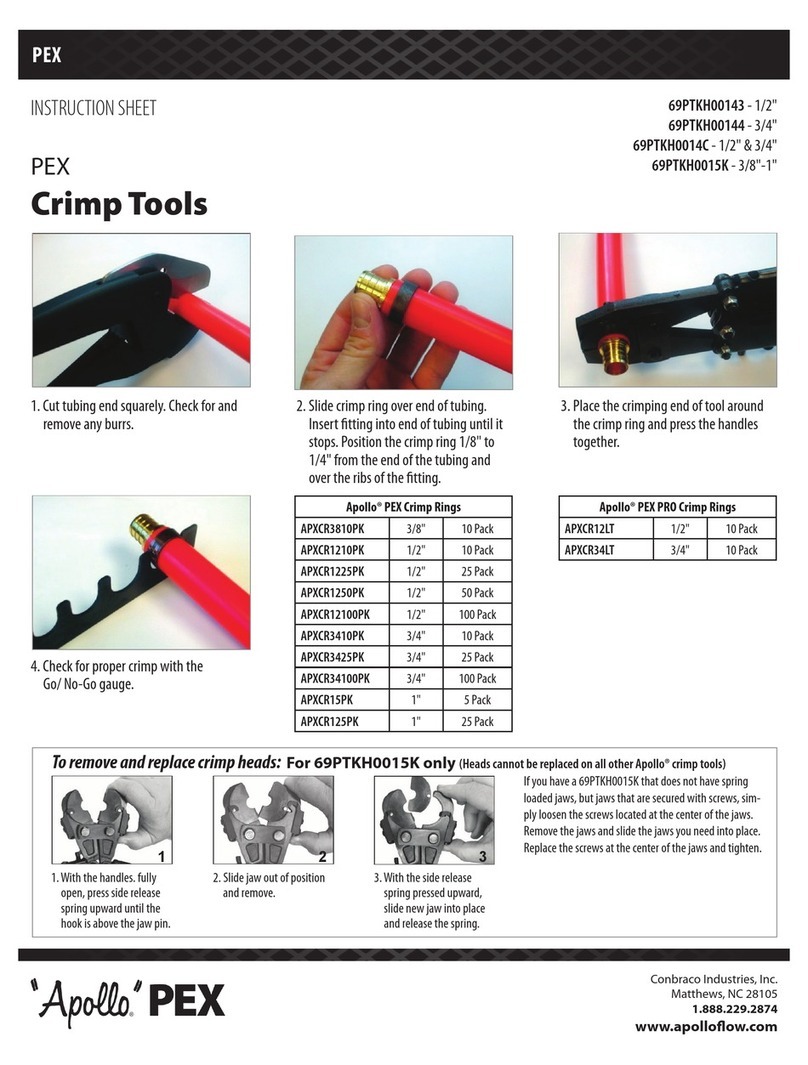

Aalberts industries

Aalberts industries Apollo PEX 69PTKH00143 instruction sheet

Cembre

Cembre B540ND-BVA Operation and maintenance manual

molex

molex 207129 Series Specification sheet

Lapp Group

Lapp Group EPIC CIRCON LS1/M23 instruction manual

Emerson

Emerson Klauke UAP432CFB manual