HAWS®P/N 0510000456 Rev.5 10/19 Model 8760 Page 3 of 29

TABLE OF CONTENTS

Tempering Skid with Shower and Eyewash.............................................................................................1

General Area Classification & Class I Division 2.....................................................................................1

DISCLAIMER................................................................................................................................................2

TABLE OF CONTENTS ...............................................................................................................................3

PERFORMANCE SERIES 8760 MODEL CONFIGURATIONS...................................................................4

SHIPPING, HANDLING AND STORAGE ....................................................................................................5

INSTALLATION PROCEDURE....................................................................................................................6

Checklist for start-up ..............................................................................................................................9

Tank Control ..........................................................................................................................................11

Alarm Modes – US & [CANADA] ..........................................................................................................11

Messages................................................................................................................................................12

Real Time Clock (RTC)..........................................................................................................................12

Flow Alarms ...........................................................................................................................................13

Fault Condition Notification .................................................................................................................13

Maintenance Required Notification .....................................................................................................13

Tank Monitor..........................................................................................................................................14

Tank History...........................................................................................................................................14

Setting Current Time and Date on the Controller ..............................................................................14

PREVENTATIVE MAINTENANCE.............................................................................................................15

Weekly ....................................................................................................................................................15

Monthly...................................................................................................................................................15

Quarterly.................................................................................................................................................15

Annually..................................................................................................................................................16

SYSTEM DRAIN AND CHECK PROCEDURE:.........................................................................................17

MAINTENANCE, TESTING, REPAIR ........................................................................................................20

Blending Valve System .....................................................................................................................20

Combination Shower/Eyewash ........................................................................................................20

Freeze and Scald Valve.....................................................................................................................20

Y-Strainers..........................................................................................................................................21

TROUBLESHOOTING................................................................................................................................22

SPARE PARTS...........................................................................................................................................23

DRAWINGS ................................................................................................................................................26

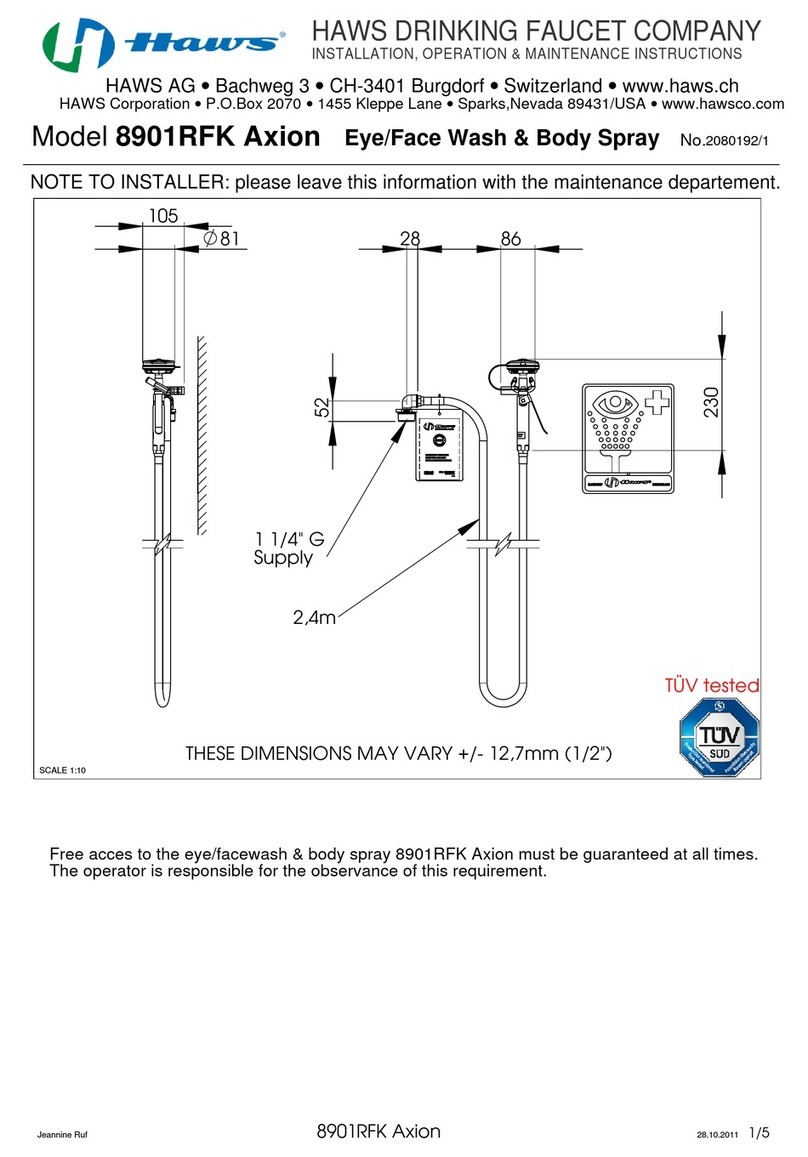

Generalized Installation Drawing (8760.21.31-GA).........................................................................26

Generalized Electrical Schematic (8760.2X.31-E)...........................................................................27

Generalized Piping and Instrumentation Diagram (8710.21.31 & 8760.21.31 P&ID)...................28

LIMITED WARRANTY................................................................................................................................29