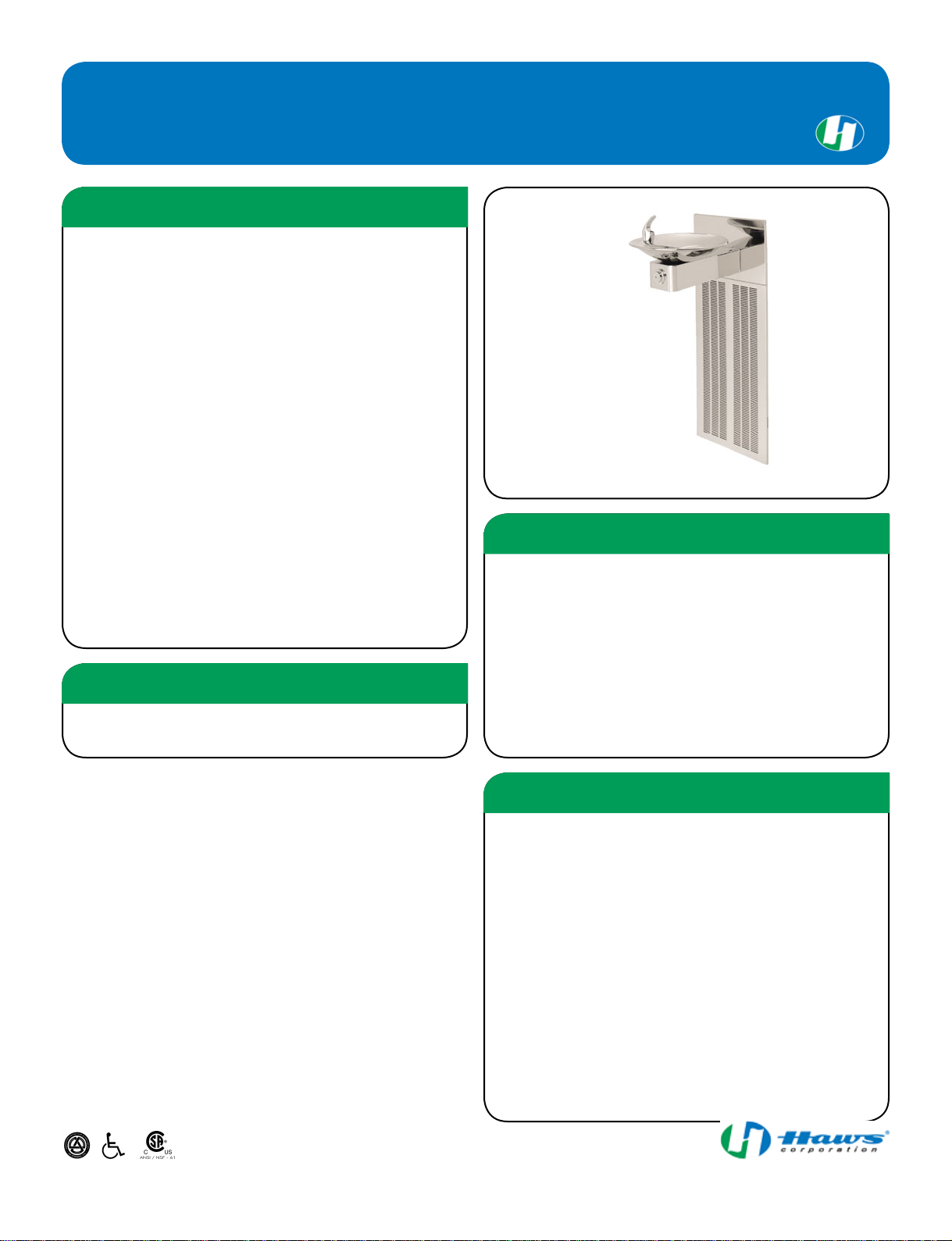

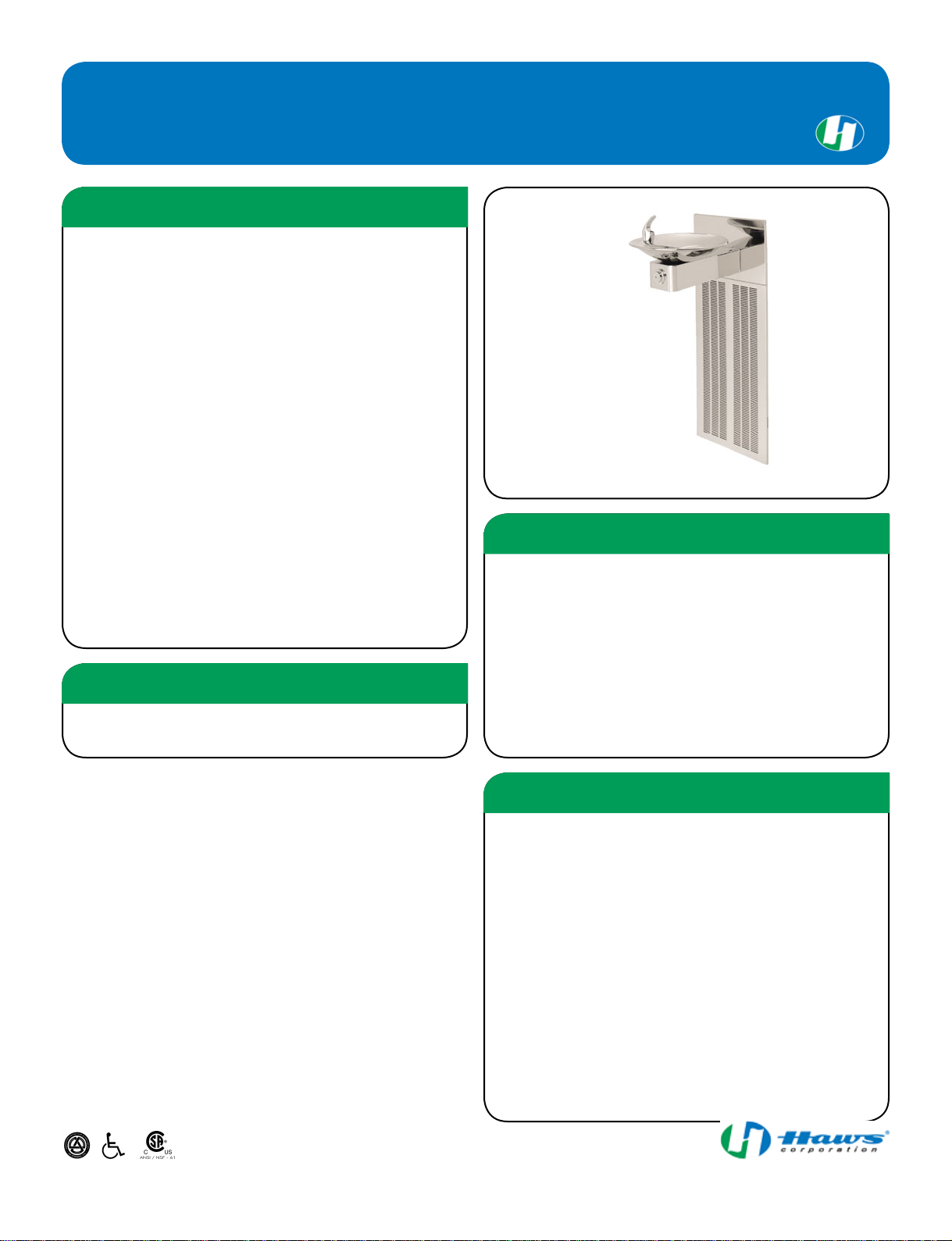

H1001.8HPS

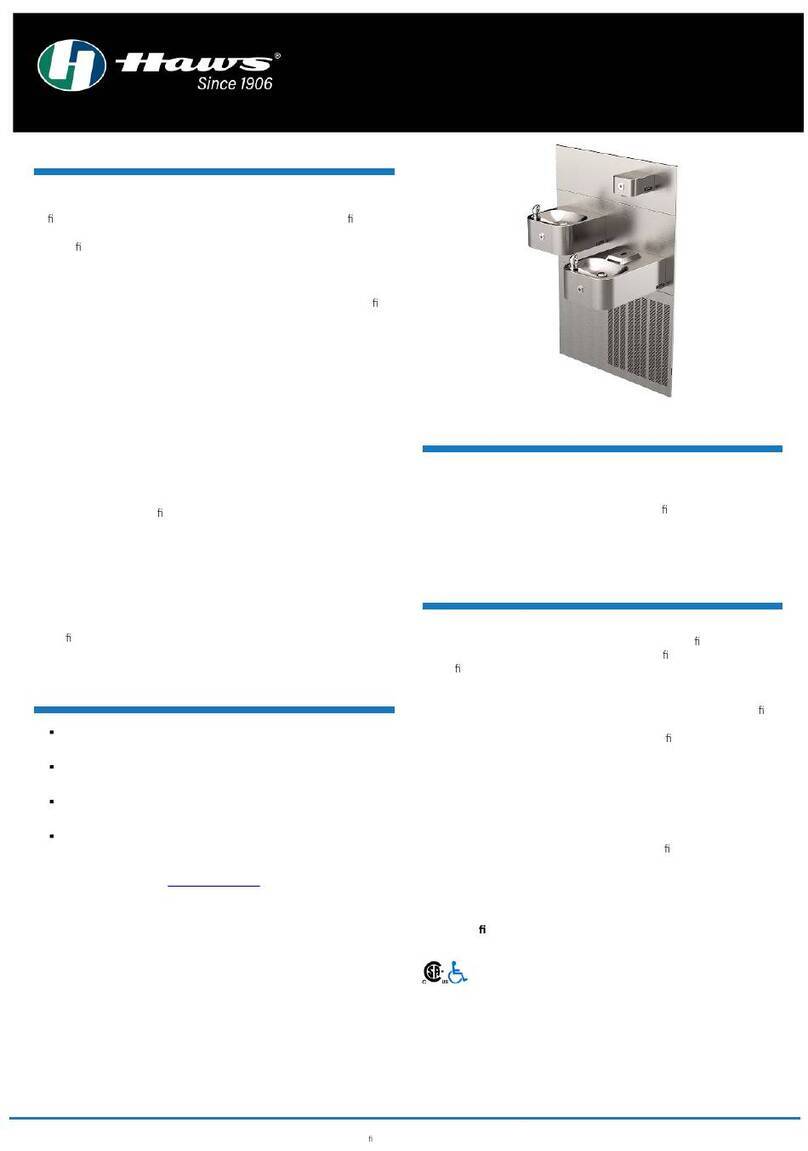

Barrier-Free Wall Mounted Electric Drinking Fountain

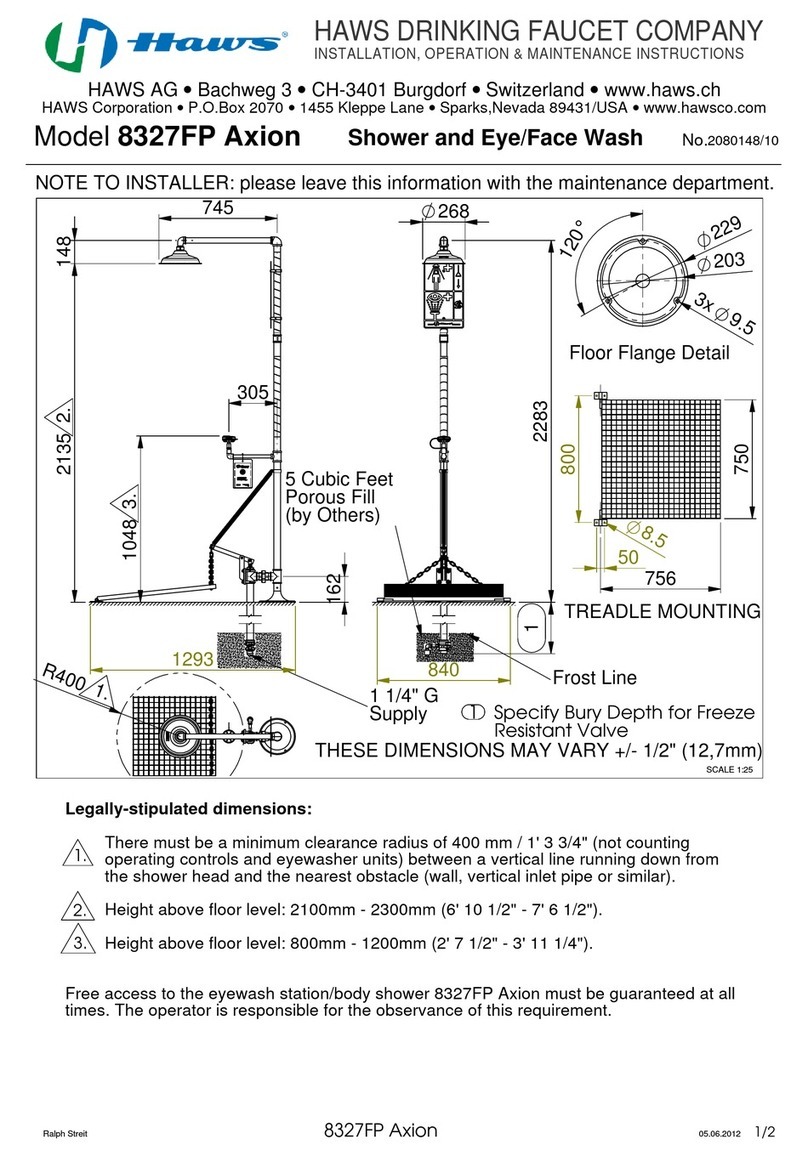

Back Panel

Stainless steel back panel helps to protect the wall from

inadvertent splashing, and its decorative satin finish increases

location visibility and completes the fountains attractive

appearance.

Quality Control

Fountain is pre-built and fully water and pressure tested to

ensure no leaks and proper function for reduced installation time

and added peace of mind.

Construction

18 gauge Type 304 Stainless Steel fountain with attractive and

functional swirl bowl design, along with a vandal-resistant

bottom plate provides a long lasting unit with added peace of

mind.

Bubbler Head

Polished chrome-plated brass bubbler head with integral laminar

flow prevents splashing and provides a superior flow pattern.

The integral basin shank and inserted roll pin adds vandal

resistance strength to the design, and the shielded angled

stream orifice produces a steady sanitary source of water.

Push Button

With its patented (Pat.# 6,981,692) push-button valve assembly

which allows for front access stream adjustment as well as

cartridge and strainer access, this fountain offers the ultimate in

ease of maintenance.

FEATURES & BENEFITS

oFilter: Model 6426, 12" x 2", in-line lead removal element that

reduces lead from incoming water supply.

OPTIONS

Model H1001.8HPS electric wall mounted barrier-free drinking

fountain shall include an 18 gauge Type 304 polished stainless

steel finish basin with integral swirl design, push-button operated

valve with front-accessible cartridge and flow adjustment, polished

chrome-plated brass vandal-resistant bubbler head with integral

laminar anti-squirt flow, chrome-plated brass vandal-resistant

waste strainer, vandal-resistant bottom plate, polished stainless

steel finish back panel and louvered intrusion-proof grill, and 1-1/4"

O.D. waste pipe. The R-134a refrigeration system is hermetically

sealed and delivers a minimum of 8 gph (30.3 lph) of water at 50°F

(10°C) cooled from 80°F (26.7°C) inlet water at 90°F (32.2°C)

ambient. 115 Volts, 60Hz, rated watts: 370, full load amps: 5.

SPECIFICATIONS

Perfect for either public or private settings, our stainless steel

electric drinking fountains are a great fit in indoor environments.

This series is precisely mounted, making it a nice addition to any

surrounding. Specifically, this type fountain may be placed in

settings such as: schools, office buildings, shopping malls, and

other indoor environments where there is a demand for a chilled

water source and/or wheel chair access.

Model meets all current Federal Regulations for the disabled

including those in the Americans with Disabilities Act. Electric

water coolers are not recommended or designed for outdoor

applications or enclosed pool areas (chlorine). These conditions

may void warranty. Haws manufactures drinking fountains, electric

water coolers and electric drinking fountains to be lead-free by all

known definitions including ANSI/NSF Standard 61, Section 9,

California Proposition 65, and the Federal Safe Drinking Water Act.

Haws electric water coolers comply with ARI Standard 1010 and

ANSI A117.1, and be listed by Underwriter Laboratories to U.S.

and Canadian standards.

APPLICATIONS

1455

Kleppe

Lane

|

Sparks,

NV

89431

|

[p]

775.359.4712

|

[f]

775.359.7424

|

[e]

[email protected] |

www.hawsco.com

|

2

March,

2009

DISCLAIMER: Continued product improvements make specifications subject to change without notice. Check www.hawsco.com for the latest product information and updates.