HBX ECO-1000 HVAC Control

Version 1.35

Page 2

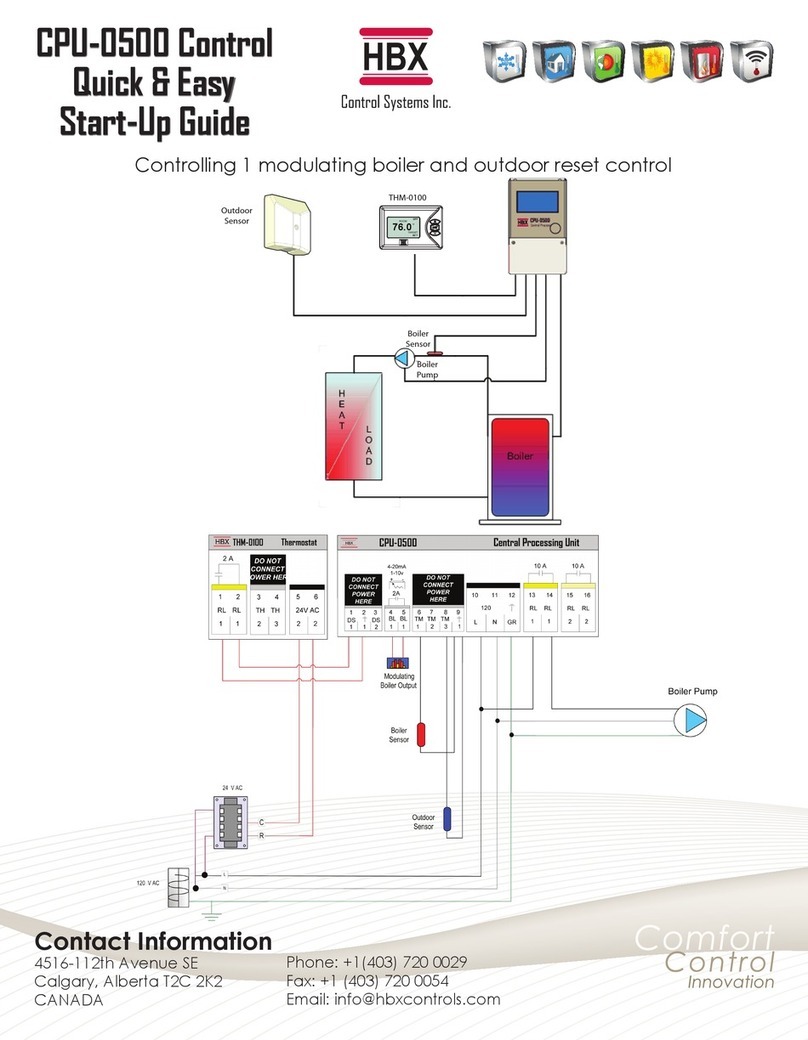

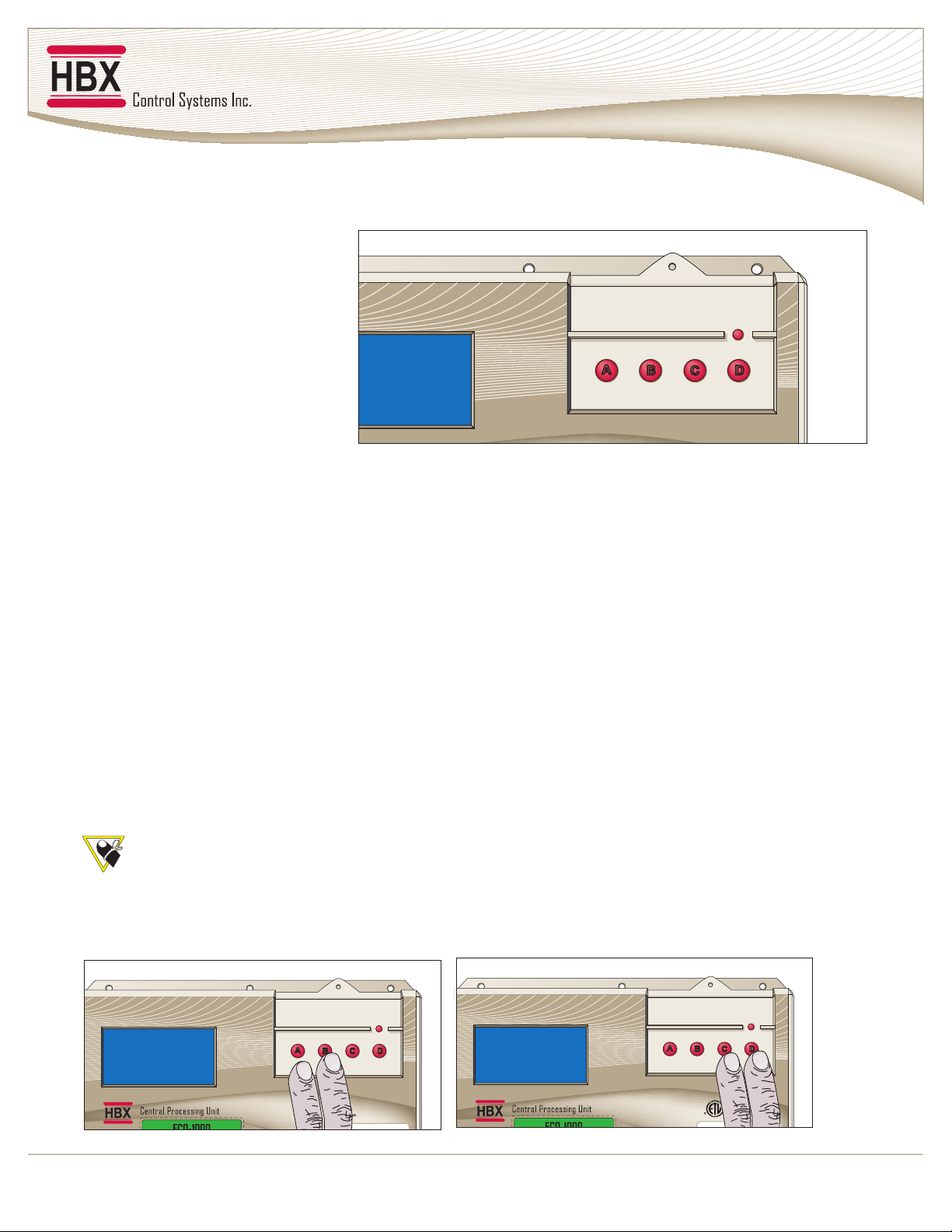

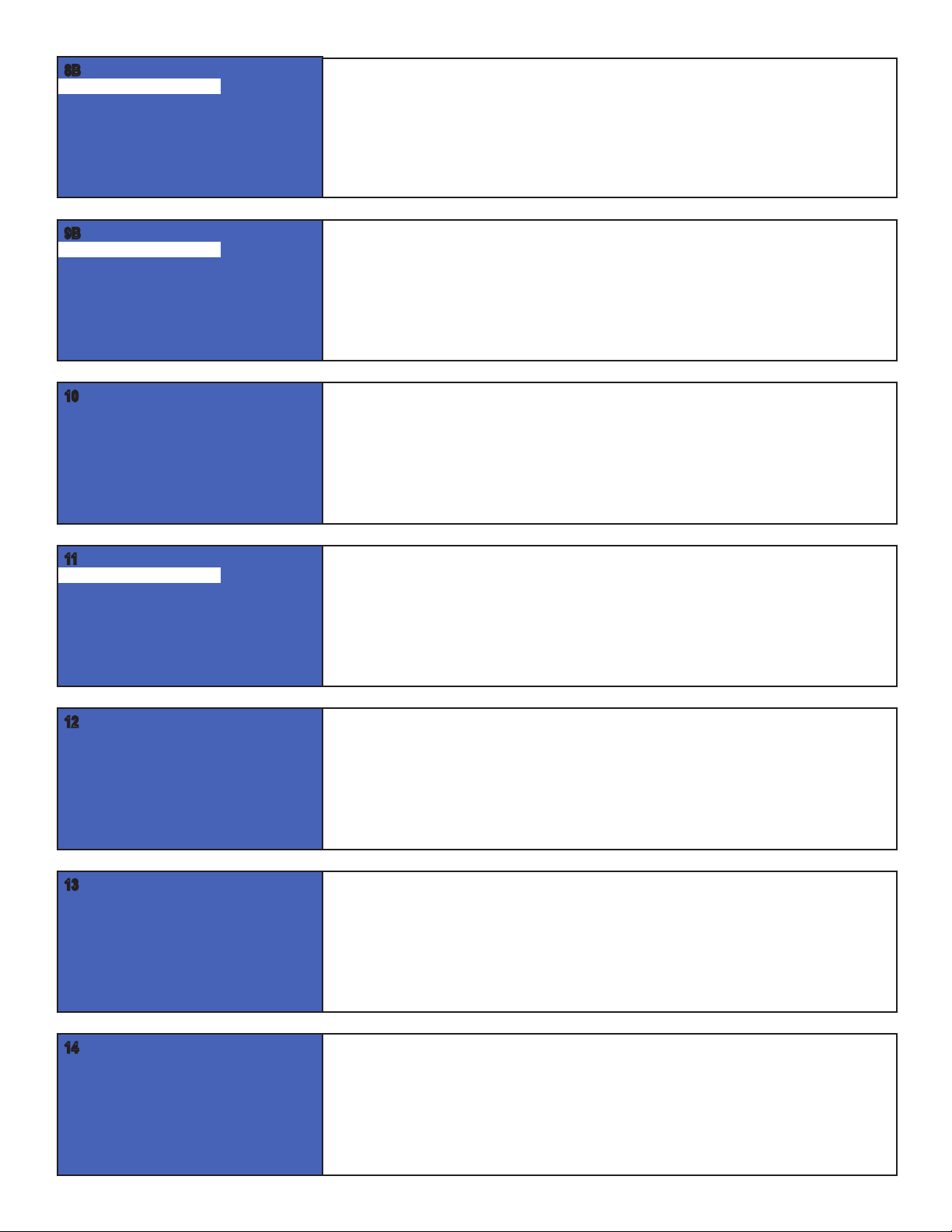

NAVIGATING THE CONTROL

The four large red buttons labeled “A”, “B”, “C”, and “D” are used to make your way through the programming

options within the Control.

Pressing the “A” or “B” button while

viewing the initial “System Status” and

“System Function” main screens will

swap from screen to screen. Pressing

the “D” button will take you to the

“Programming Options” screen.

Pressing the “D” button again will

revert to the main system screens.

Once in the “Programming Options”

menu you may move the selection

indicator up and down by pressing the A and B buttons, pressing the “C” button will enter the selected option.

Pressing the “C” button on options with limited choices (ie. on/off, yes/no) will toggle the selection.

Pressing the “A” and “B” buttons on options with variable numerical choices (ie. temperature values, time settings)

will increase and decrease the selected amount. Pressing the “C” button upon completion will forward you to the next

step.

The “D” button can be used to revert to the previous menu.

AAB

BC

CD

D

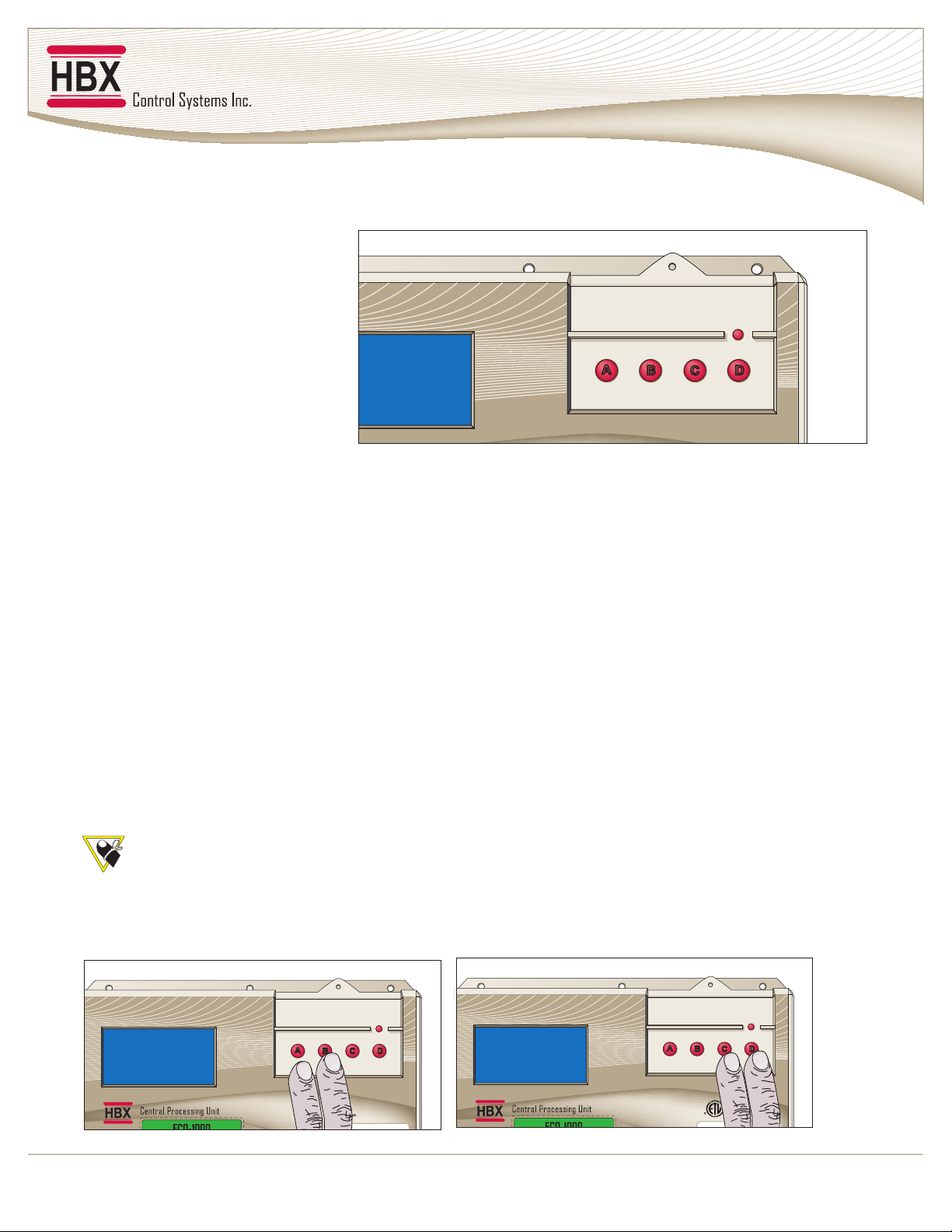

Input: 120VAC 60Hz 5A

Relays: 240VAC 10A

Demand Signal: 20 - 240V

Model: CPU - 1000

CAUTION,

RISK OF ELECTRICAL SHOCK - DISCONNECT POWER PRIOR TO SERVICING

Certified to CSA C22.2 No 24

Conforms to UL Standard 873

Central Processing Unit

ECO-1000

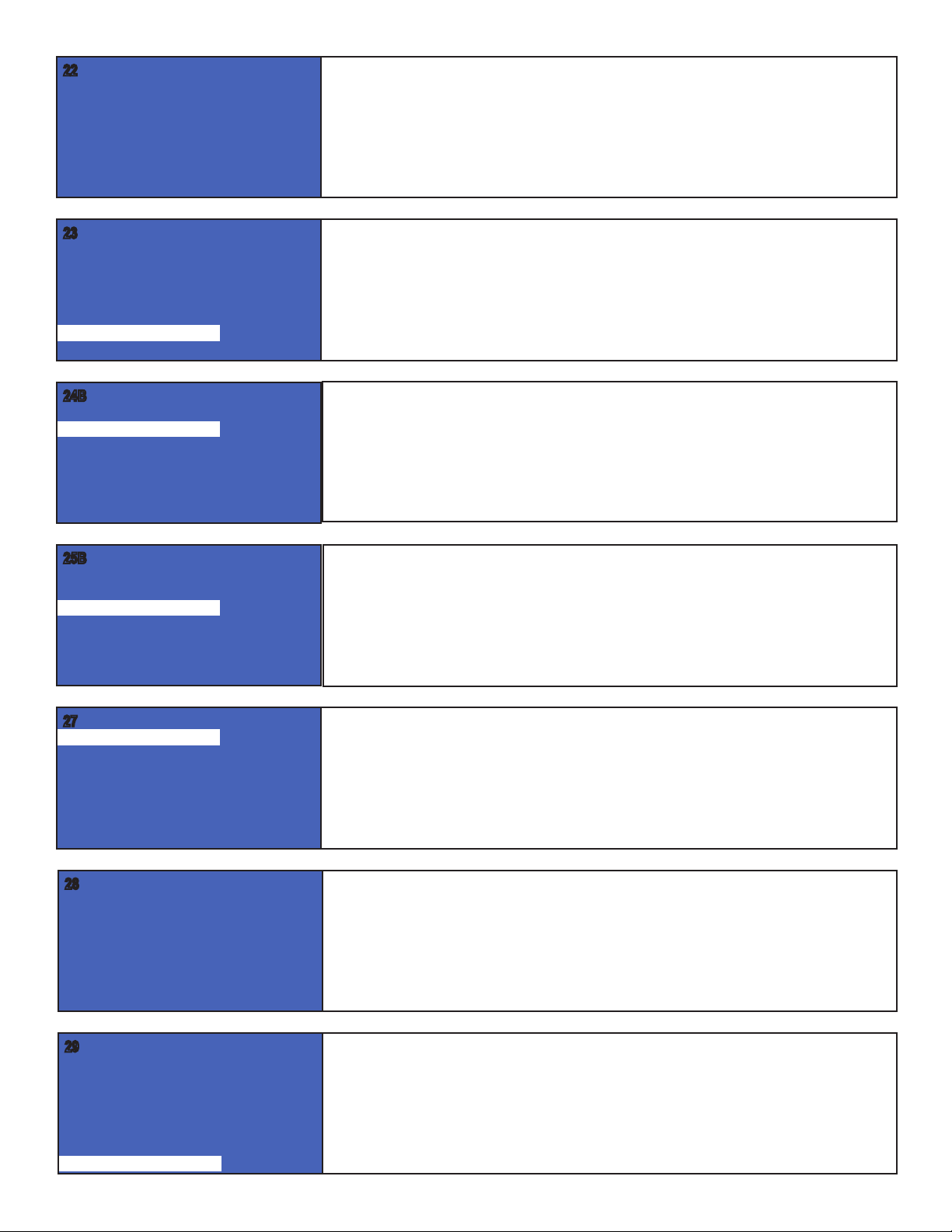

Program Lock Feature

To minimize the potential for unauthorized tampering of your control after commissioning, you have the ability to

limit/lock the programming menus.

To lock the control, use two ngers to press and hold down the A and B buttons simultaneously for approximately 10

secs.

To unlock the control, use two ngers to press and hold down the C and D buttons simultaneously for approximately

10 secs.

at the same time.

AAB

BC

CD

D

Input: 120VAC 60Hz 5A

Relays: 240VAC 10A

Demand Signal: 20 - 240V

Model: CPU - 1000

CAUTION,

RISK OF ELECTRICAL SHOCK - DISCONNECT POWER PRIOR TO SERVICING

Certified to CSA C22.2 No 24

Conforms to UL Standard 873

AAB

BC

CD

D

Input: 120VAC 60Hz 5A

Relays: 240VAC 10A

Demand Signal: 20 - 240V

Model: CPU - 1000

CAUTION,

RISK OF ELECTRICAL SHOCK - DISCONNECT POWER PRIOR TO SERVICING

Certified to CSA C22.2 No 24

Conforms to UL Standard 873