Heiniger XTRA VS84-S User manual

swiss made

Ausgabe/Index: XTRA/I 09-11

Betriebsanleitung

Instruction manual

Mode d’emploi

Istruzioni d’uso

Manual de Instrucciones

Bedieningshandleiding

Instruktionsbog

Instruktionsbok

Instruksjonsbok

Käyttöohjekirja

Manual de instruções

δηγίες ρήσης

2Instruction manual XTRA

Contents

1 Proper Use

1.1 Overall View / Controls

1.2 Intended Use

1.3 Technical Data

1.4 Equipment Items

2 Safety Regulations

2.1 Introduction

2.2 Symbols and Warning Signs

2.3 Proper Use

2.4 Safety Principles

2.4.1 Power Connections

2.4.2 Servicing and Checking Requirement

2.4.3 Noise Emission / Personal Protective Equipment

2.4.4 Other Dangers

2.5 Essential Operator Skills

3 Putting into Operation

3.1 Controls and Operating Notes

3.2 Shearing Adjustment using the Tension Nut

3.3 Lubrication

3.4 Switching On / Off

3.5 Malfunctions

4 Servicing

4.1 Cleaning

4.2 Fitting the Shearing Blade

4.3 Resharpening the Shearing Blades

4.4 Cleaning the Air Filter

4.5 Changing the Shearing Head (Option)

4.6 Storing the Shearing Machine

5 Repairs

5.1 Introduction

5.2 Malfunction Lists

6 Environmental Protection and Disposal

6.1 Introduction

6.2 Material Categories

7 Contact Addresses

Illustrations: at the end of the instructions

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 2

POS DESCRIPTION

38 Rotor XTRA 240V incl. Pos. 37 1x

38 Rotor XTRA 120V incl. Pos. 37 1x

39 Spring washer 626 1x

40 Ball bearing 626-2Z 1x

41 Socket head cap screw M3 x 72.5 2x

42 Ribbed washer M3 2x

43 Spacer sleeve XTRA 2x

44 Airflow guide, XTRA 1x

45 Stator XTRA 240V 1x

45 Stator XTRA 120V 1x

46 Motor housing XTRA Heiniger grey 1x

47 Carbon brushes with spring + protection

cap XTRA/HANDY 2x

48 Brush cap XTRA/HANDY 2x

49 Cable XTRA/HANDY with EURO plug 1x

49 Cable XTRA/HANDY with AUS plug 1x

49 Cable XTRA/HANDY with USA plug 1x

50 Anti-kink sleeve XTRA/HANDY EURO/AUS 1x

50 Anti-kink sleeve XTRA/HANDY/12V USA 1x

51 PT-screw KA25 x 6 1x

52 Switch housing, upper XTRA black 1x

53 Retaining screw M3.5 1x

54 Overload security switch XTRA 1A / 240V 1x

54 Overload security switch XTRA 1.8A / 120V 1x

55 Main switch XTRA/HANDY/12V 1x

56 Capacitor 0.15µF XTRA/HANDY 240V 1x

56 Capacitor 0.15µF XTRA/HANDY 120V 1x

57 Cable grip XTRA/HANDY AUS 1x

57 Cable grip XTRA/HANDY/12V EURO/USA 1x

58 Clamp XTRA/HANDY/12V 1x

59 Socket head cap screw M3 x 25 1x

60 Dust cover XTRA/HANDY/12V 1x

61 Switch housing,

lower XTRA/HANDY/12V black 1x

62 Socket head cap screw M3 x 6 4x

63 Filter cover complete

XTRA/HANDY/12V black 1x

Converter EURO/GB plug 1x

POS DESCRIPTION

1 Shear head case XTRA/12V 1x

2 Swivelling fork XTRA/12V 1x

3 Sheep shearing head cover XTRA/12V black 1x

4 Chicken feet 2.5“ XTRA/12V right option

5 Chicken feet 2.5“ XTRA/12V left option

6 Chicken feet 3“ XTRA/12V left 1x

7 Chicken feet 3“ XTRA/12V right 1x

8 Retaining spring XTRA/12V 1x

9 Cogwheel Z30 XTRA/12V black 1x

10 Gauge plate 2.5“ XTRA/12V option

11 Gauge plate 3“ XTRA/12V 1x

12 Crankshaft XTRA/12V 1x

13 Ball XTRA/12V 1x

14 Retaining ring XTRA/12V 1x

15 Tension nut bushing screw XTRA/12V 1x

16 Centre post XTRA/12V 1x

17 Comb screw sheep 2x

18 Tension nut XTRA/12V Heiniger 1x

19 Locknut XTRA/12V 1x

20 Sliding sleeve XTRA/12V 1x

21 Ball bearing 608-2RS 1x

22 Countersunk head screw M4 x 28 2x

23 Countersunk screw M4 x 8 2x

24 Circlip for shaft Ø6 1x

25 PH-screw M4 x 10 2x

26 Ball bearing 608-2Z 1x

27

Sheep shearing head 3" XTRA/12V with blades

1x

28 Socket head cap screw M3.5 x 8 7x

29 Gearbox housing XTRA/12V black 1x

30 Cogwheel Z21/12 XTRA 1x

31 Spindle XTRA/12V 1x

32 Seal XTRA/HANDY/12V 1x

33 Centering flange XTRA/HANDY 1x

34 Spring washer 608 1x

35 Ball bearing 608-2Z 1x

36 Retaining ring for bores Ø22 1x

37 Fan wheel XTRA (1x)

Instruction manual XTRA 3

Illustr. 1

1 Proper Use

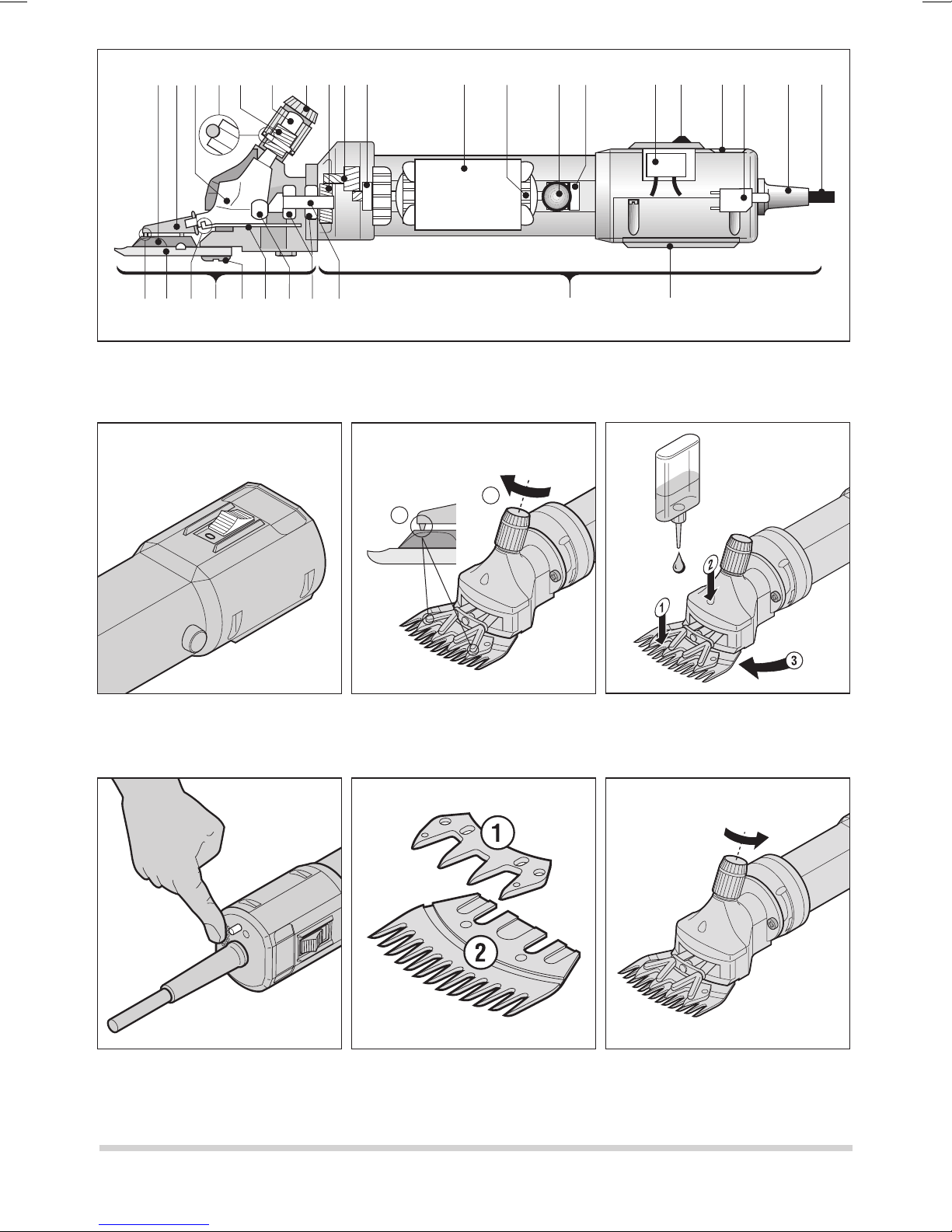

1.1 Overall View / Controls

Component Names

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 3

4Instruction manual XTRA

1.2 Intended Use

The shearing machine is intended exclusively for use on sheep and goats, as well as llamas,

alpacas and other members of the camel family. Its use can also be extended to cattle and

horses by changing the standard shearing head.

Other uses, in particular using the machine on people, are expressly prohibited.

1.3 Technical Data

Model Designation: VS84-S (Shearing)

Mains Voltage:

Motor Output:

RPM:

Fuse Protection Needed:

Dimensions (W/H/L): approx. 80 mm x 95 mm x 350 mm

Weight, excluding cable: 1560 g

Max. Ambient Temperature: 0°C - 40°C

Max. Air Humidity: 10% - 90% (relative)

Noise Emission (LpAm): 93 dB(A) (DIN-45635-1/04.84 + BG-PAS 26)

Acceleration (avhw): 11 m/sec2(EN-28662-1/01.93)

1.4 Equipment Items

1 Shearing Machine with Shearing Head, 1 Pair of Shearing Blades, 1 Special Screwdriver,

1 Bottle of Special Lubricating Oil, 1 Cleaning Brush, 1 Set of Operating Instructions,

1 Transport and Storage Case

Options:

• Alternative exchangeable clipper head (for cattle and horses)

• Various shearing + clipper blades

2 Safety Regulations

2.1 Introduction

This section describes the mandatory safety regulations which must be observed when using

the shearing machine.

All persons undertaking work on or with the machine have an obligation to

read the operating instructions.

The operating instructions must be kept safely in the storage case and acces-

sible at all times.

2.2 Symbols and Warning Signs

Various symbols are used in the operating instructions. They refer to potential dangers or

point to technical information, the non-observance of which will lead to personal injury,

damage to objects or inefficient operation.

see rating plate

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 4

Instruction manual XTRA 5

Danger Symbols

Warning

indicates a potentially dangerous situation. If preventive action is not taken, death or very

serious injury could result.

Caution

indicates a potentially dangerous situation. If preventive action is not taken, the conse-

quences could be slight or minor injuries.

Information Symbols

Note

Note, non-compliance with which can lead to operating malfunctions or damage.

Pictorial Note

This symbol, together with its number, refers to the relevant illustration at the end of the

instructions.

2.3 Proper Use

The use to which the machine is intended for is described in Section 1.2.

The following applies to safe operation: The details at Section 1.3, “Technical Data”, count

as mandatory operating limits and ratings.

Shearing other animals, in particular dangerous animals such as beasts of prey and the like,

counts as mis-use. This could lead to circumstances dangerous to life and limb.

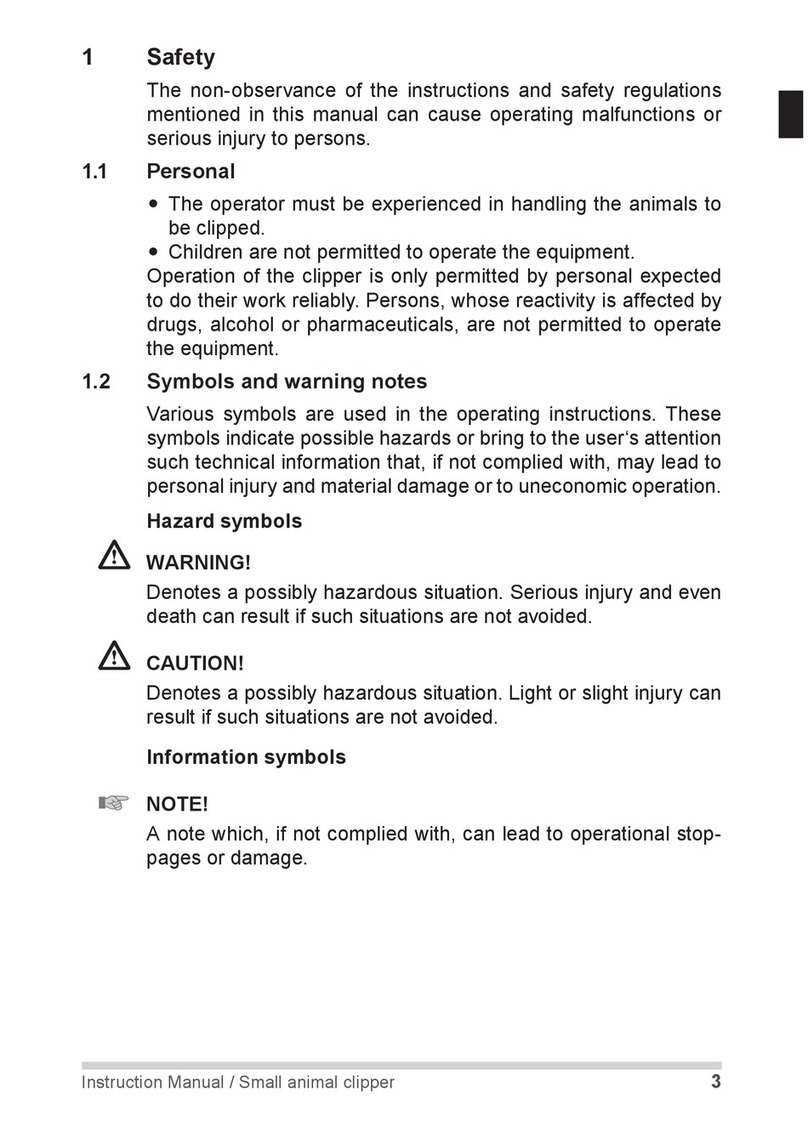

The appliance is not intended for use by young children or infirm persons. If used with a

cord extension device or portable outlet device, ensure such devices are positioned so as

not to be subjected to splashing or ingress of moisture.

2.4 Safety Principles

2.4.1 Power Connections

Only insert the plug into undamaged sockets. Defective installations can cause an electrical

shock or a short circuit. Outside sockets must be equipped with a fault current breaker (Fl).

Observe the relevant national regulations.

Cleaning and servicing should only be done with the mains plug pulled out.

Never let a machine with its cable plugged in, lie around unsupervised. Keep children away

from the working area and store the machine out of their reach.

2.4.2 Servicing and Checking Requirement

Only operate the shearing machine if it is undamaged and in a proper condition. Any

defects to the housing or the electrical cable should be rectified by a repair or service agent.

2.4.3 Noise Emission / Personal Protective Equipment

Wear Ear Protectors!

Typical sound emissions when working are 93 dB(A). We recommend that ear protectors

should always be worn when working.

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 5

6Instruction manual XTRA

Wear Protective Goggles and Gloves!

For your personal protection we recommend that you wear protective goggles and gloves.

Personal protective equipment is to be provided by the operator.

2.4.4 Other Dangers

Should evidence of dangers or potential dangers, not directly related to the shearing of

animals, occur during operation, we would ask you to inform us. This also applies to

dangerous technical deficiencies.

2.5 Essential Operator Skills

Operating the machine safely makes only small demands of the operator. However, it is

essential that they are observed and carried out.

• The operator must be experienced in handling the animals to be shorn.

• The operator must have read and understood the instructions or have been instructed by

an expert in the machine’s use and have had the potential dangers explained.

Children are not permitted to operate the equipment.

3 Putting into operation

3.1 Controls and Operating Notes

There are dangers inherent in the improper use of electrical equipment, especially stockbree-

ding equipment! Before taking the machine into use, you should observe the following

accident-prevention measures:

• The mains voltage must be the same as that shown on the nameplate. The machine may

only be connected to an AC supply.

• Avoid all contact with the moving shearing blades.

• Even when the machine is switched off, do not handle the area of the shearing blades as

long as the machine is connected to a power source. Always disconnect the power supply

before working on the shearing blades/shearing head.

• Avoid touching any machine which is in contact with any liquids. Never shear wet

animals. Any liquid which has got into the machine will lower the electrical insulation.

There is then the danger of an electric shock or short circuit. Only clean the machine

when dry using a brush or the cleaning brush provided.

• An electric cable lying loose on the ground for any distance can snag and become a

source of danger. Before starting to shear, lay the cable out carefully and safely. Avoid

any kinks in the power cable and prevent it becoming entangled. Animals must not stand

on or walk across the power cable or get caught in it. Never wrap the power cable

around the machine and keep it away from hot surfaces and objects. This may result in

breaks and damage to the insulation. The cable should be regularly checked for damage.

• Switch the machine to OFF (Position 0: Illustration 2) before pulling out the plug.

Illustr. 2

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 6

•Only use original shearing blades. Do not use damaged shearing blades with blunt,

missing or broken off teeth. Only work using sharp shearing blades, ground in a specialist

workshop.

• We recommend you use a comb for no longer than an hour and a cutter for no longer

than 15 minutes before you change them for a sharp comb and cutter.

•Look out for foreign bodies (wire, wood, etc.) in the fleece and remove them before

beginning to shear.

• Wear suitable work clothes. Do not wear any loose fitting clothing or items of jewellery

which could get caught up in moving machine parts. We would recommend in the

strongest terms that protective goggles and ear protectors are worn.

• Never insert any object into any of the machine’s apertures.

• Noise from the machine can worry animals. Considerable injury can be caused as a

result of being kicked by an animal or being crushed by its body weight. Tether the animal

securely, approach it from in front and switch the machine on within the animals’ range of

vision.

• Animals should only be shorn if unauthorised persons have been excluded from the

shearing area.

• Only shear in well-ventilated spaces (dust) and never near objects or gases likely to

explode.

• Generally, never plunge the clipper and clipperhead into liquids such as water, soapy

water, diesel, petrol, etc. This may cause serious injury to mechanics and motor.

These safety notes must be complied with in all cases. It is recommended that a fault current

safety plug always be used when working with electrical equipment.

3.2 Shearing Adjustment using the Tension Nut

Before putting into operation, make adjustments as follows:

Before shearing:

With the machine switched off: ensure that the pressure yoke’s carrier cone pins mesh

precisely into the positioning holes in the cutter (Illustration 3, Item 2). Tighten the tension nut

until resistance is first noticeable (Illustration 3, Item 1). Then tighten the tension nut a further

1/4 turn.

Start operating the shearing machine. Slacken off the tension nut (Illustration 7) until the

shearing blades exert almost no more contact pressure (noise level rises).

Caution! If the tension nut is slackened off too much, the cutter can fly off causing injury.

Now tighten the tension nut slowly until the noise level becomes muffled and some resistance

is detectable as you tighten the tension nut. The pressure should now be correctly set. Begin

shearing. If it still does not cut properly you will have to add a little more tension.

During shearing:

The shearing system works with much less pressure having to be applied than with tradi-

tional sheep shearing machines. Care should be taken, therefore, to ensure that the blade

tension is not set too high. Slightly adjust the blade tension from time to time during shearing

(max. 1/4 turn).

Instruction manual XTRA 7

Illustr. 3/7

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 7

8Instruction manual XTRA

Hair may collect between the shear blades, if the tension nut is insufficiently tightened at the

start of shearing. This will have an adverse effect on further shearing progress or make it

quite impossible. If this happens, the shear blades must be disassembled, cleaned, oiled and

re-fitted as described at 4.2.

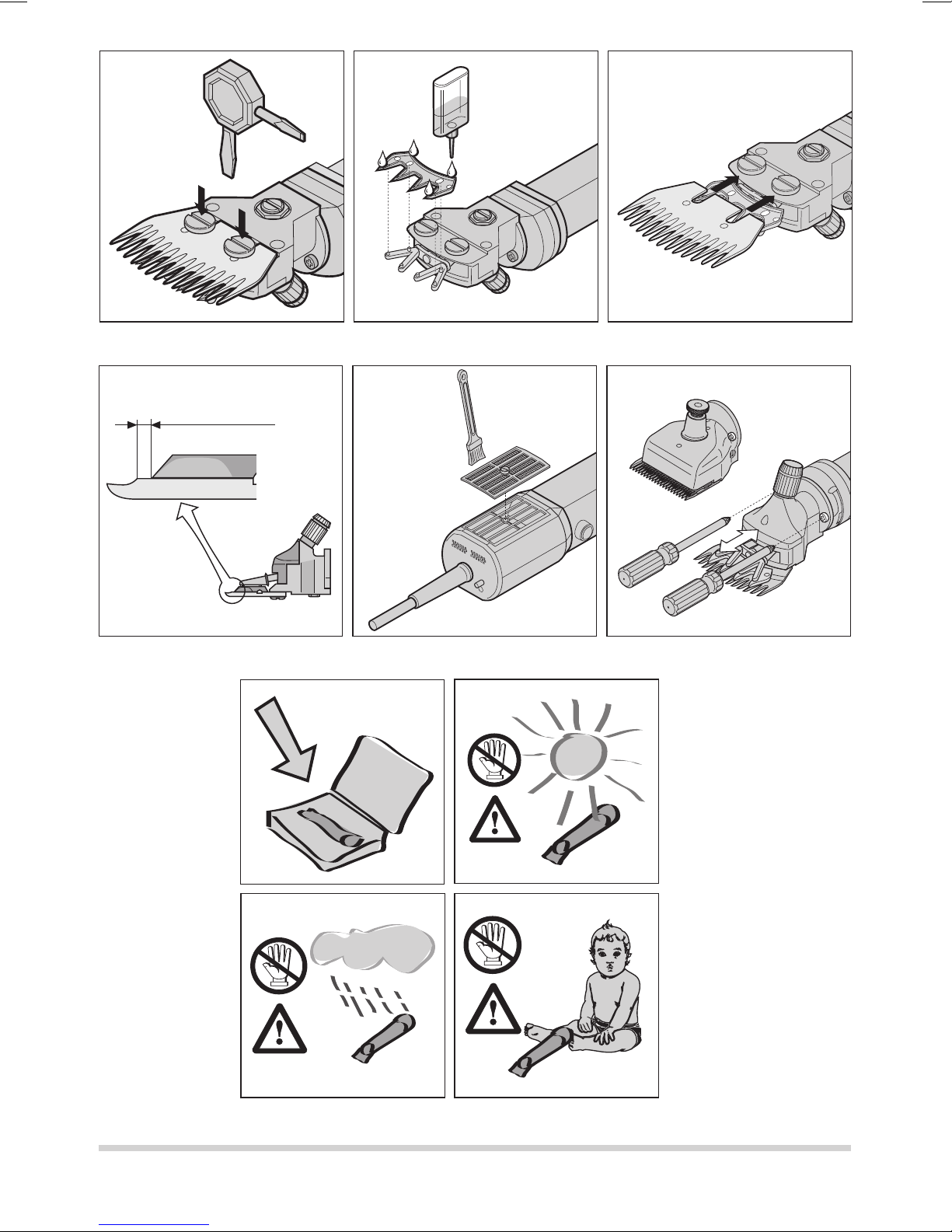

3.3 Lubrication

Before and During Shearing

A thin layer of oil on the cutter and the comb plate (Illustration 4, Items 1 + 3) is essential for

good shearing results and so as to increase the life of the machine and its shearing blades.

All other moving parts in the shearing head must also be well-oiled. Place a few drops of oil

on the shearing blades and pour some into the lubricating holes provided on the shearing

head (Illustration 4, Items 2).

Only use our special oil or a paraffin oil meeting the ISO VG 15 specification. This oil is

non-toxic and produces no irritation on contact with the skin or the mucous membranes. This

paraffin oil degrades to some 20% after 21 days (CEC-L-33-T-82).

Poor lubrication is the most frequent cause of unsatisfactory shearing results. Inadequately

oiled shearing blades will overheat, leading to reduced blade life.

The shearing blades and shearing head must be adequately lubricated during shearing (at

least every 15 minutes) so that they do not run dry.

3.4 Switching On / Off

There are two positions on the slide switch (Illustration 2 shows the 0 Position).

Position I: Machine switched on

Position 0: Machine switched off

Always use the slide switch (Illustration 2) when switching the machine on and off. Check the

switch position before plugging in the cable.

3.5 Malfunctions

Overload Protection Switch

The overload protection switch protects the machine from non-permissible mechanical and

thermal loads. If the overload protection switch button trips (the machine will stop), immedia-

tely switch the machine off with the slide switch as well (Illustration 2) (Position = 0). Reasons

for the overload protection switch tripping are: faulty motor, blade tension too high, jammed

shearing head, blocked air filter, etc.

Rectify the fault with the mains plug pulled out. The machine may be started up again after a

few minutes by pressing in the overload protection button.

For other malfunctions, see also the malfunction list in Section 5, “Repairs”.

Illustr. 4+9

Illustr. 2

Illustr. 5

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 8

4 Servicing

Before starting any servicing work, disconnect the power supply; pull the plug out.

Even with the machine switched off, do not handle the area round the shearing blades as

long as the machine is still connected to a power source. Whenever working on the shearing

blades/shearing head, always first disconnect the power supply.

4.1 Cleaning

Cleaning the Shearing Head and Shearing Blades

After shearing, remove all oil from the machine by rubbing it down with a dry cloth and

carefully clean the shearing head and shearing blades with a dry brush. Then oil the parts to

prevent rusting. Even the smallest rust spots on the blades can adversely affect shearing or

make it completely impossible.

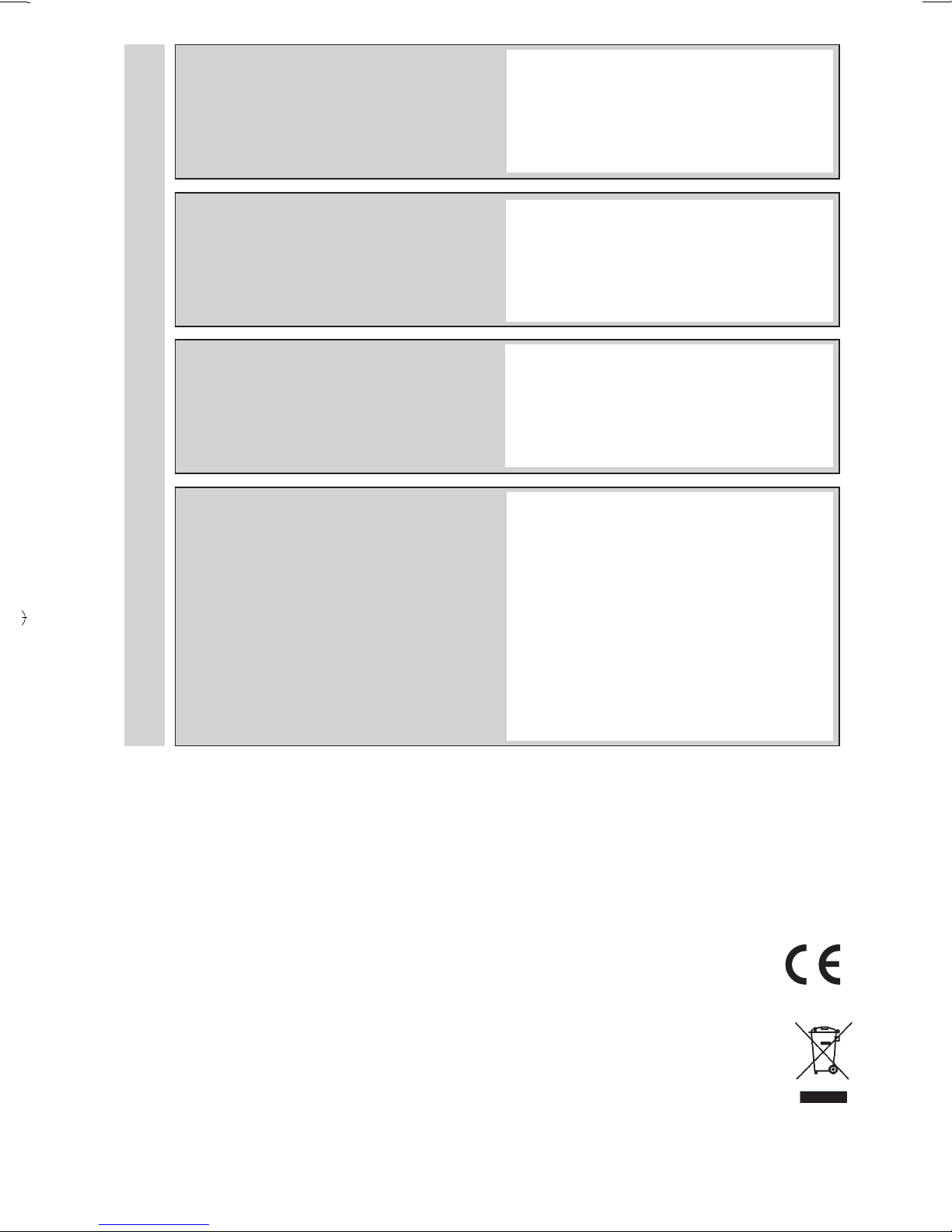

4.2 Fitting the Shearing Blade

A pair of shearing blades consists of a comb plate (Illustration 6, Item 2) and an cutter

(Illustration 6, Item 1). When fitting the blades care should be taken to ensure that the correct

surfaces come to rest against each other. The blades are fitted as follows:

Loosen the tension nut (Illustration 7) and place the machine on a hard surface so that the

blade fixing screws lie uppermost. Slacken off the screws and remove both the old shearing

blades.

Ensure that the new shearing blades are clean. Particular care should be taken to ensure that

the ground surfaces are free of dirt; if not, even newly ground shearing blades will not shear

satisfactorily.

Place the new cutter in the pressure yoke’s carrier cones (Illustrations 9 + 3, Item 2) and push

the new comb plate between the loosened screws (Illustration 10). Now tighten the blade

fixing screws until you can just move the new comb plate sideways by hand.

Now turn the machine over so that the tension nut is again uppermost.

What is now important is that you rest the blades against each other in such a way that the

ground surface of the comb plate projects approx. 1.5 - 2.0 mm beyond the tips of the

upper blade (Illustration 11).

Once you have adjusted the shearing blades, set the position of the comb plate and tighten

up the blade fixing screws.

Check that the shearing blades have been correctly fitted and that the pressure yoke’s carrier

cones (Illustration 3, Item 2) are situated in the holes provided in the cutter. Now tighten up

the tension nut until the cutter is pressed against the comb plate and you can feel a slight

resistance.

Instruction manual XTRA 9

Illustr. 6

Illustr. 7+8

Illustr.

9, 10, 11

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 9

10 Instruction manual XTRA

4.3 Resharpening the Shearing Blades

Only work with sharp shearing blades. Replace blunt blades or those with missing teeth.

Proper resharpening can only be done with a special machine and by a trained technician

contactable through your service centre.

4.4 Cleaning the Air Filter

The air filter element is found on the underside of the motor section of the machine. The air

filter element can be removed from the machine for cleaning. Regularly cleaning the element

with a dry brush is essential. When cleaning the air filter, take care that no foreign bodies

get into the machine.

The machine must never be operated without the air filter element!

4.5 Changing the Shearing Head (Option)

To change the shearing head from “Sheep” to “Cattle” or vice-versa, loosen both head

screws. Remove one head and fit the other (Grease cog wheel, Illustration 1, Item 8, if

necessary). Re-tighten both screws.

4.6 Storing the Shearing Machine

Only store the shearing machine in a dry place and in the case supplied. Do not switch on

the machine if you suspect any liquid has got into it. There is then a risk of an electric shock

or short circuit. Hand the shearing machine into a service centre.

Make it a habit to store the machine between use, stor it well-cleaned, oiled and with tension

slackened off, in its storage case, in a clean, dry place, out of the reach of children.

5 Repairs

This product has been developed and assembled using the best individual components

available. It is designed to give longevity and high performance. If spare parts are used

during the life of this product, please ensure that they are genuine Heiniger parts. Failure to

use genuine Heiniger spares may reduce the performance of this precision engineered

product and will void any warranty claim.

5.1 Introduction

Actions to be taken to rectify malfunctions are indicated in the “Rectification” column of the

malfunction lists. Those rectification notes printed on a dark background may only be carried

out by an authorised service centre.

Details of authorised service centres are to be found at the end in the “Contact Addresses”

section.

5.2 Malfunction Lists

Contact an authorised service centre in the event of malfunctions not contained in these

instructions.

Illustr. 13

Illustr. 12

Illustr. 14

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 10

Sufficient pressure cannot be

applied to the cutter

Pressure yokes fall out

Poor cutting

Tension link broken

Crank spindle and/or crank

roller and/or swiveling fork

worn out

Bearings badly worn

Faulty cogwheel, Z30 black

(Illustration 1, Item 8)

Faulty reduction gear in the

motor section

Crank spindle broken or bent

Crank roller missing

Tension lock spring missing

(Illustration 1, Item 4)

Loose lid bush

Tension link is broken

Sliding sleeve missing

(Illustration 1, Item 6)

Sliding sleeve is worn down

(Illustration 1, Item 6)

Swiveling fork is worn down

on top

Pressure yokes are worn down

(Illustration 1, Item 2)

Securing lugs on tension link

spring

Comb and cutter blades are

blunt

Shearing blade tension too

low

Blades were not properly

sharpened

Have tension link replaced

Have crank spindle and/or

crank roller and/or swiveling

fork replaced

Have bearings replaced

Replace cogwheel

Have reduction gear replaced

Have crank spindle replaced

Have crank roller replaced

Replace tension lock spring

and fit it so that the tension nut

turns easily to tighten but drag

in off direction

Use ‘Loctite’ or similar

adhesive product to glue lid

bush

Have tension spring replaced

Replace sliding sleeve

Replace sliding sleeve

Have swiveling fork replaced

Have pressure yokes replaced

Have tension link spring

replaced

Have resharpened with

approx. 20 µm negative

crown

Increase pressure by tightening

the tension nut

(Illustration 3, Item 1)

Have resharpened with

approx. 20 µm negative

crown

Sheep Shearing Head

Cutter does not move across its

whole running surface

Cutter does not move

Tension nut slackens off by

itself

Instruction manual XTRA 11

MALFUNCTION RECTIFICATIONCAUSE

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 11

Comb plate wrongly fitted

Crank roller missing

(Illustration 1, Item 25)

Cogwheel and/or reducing

gear faulty

(Illustration 1, Item 8)

Shearing head worn out (Illust-

ration 1, Item 23)

Shearing tension too high

No lubricant film on crank

roller (Illustration 1, Item 25)

No grease on sliding sleeve

(Illustration 1, Item 6)

Bearings are worn out

Readjust the upper blade 1.5

mm backwards in relation to

the comb plate (Illustration 11)

Have crank roller replaced

Replace cogwheel

Have reducing gear replaced

see Section 1-4

Reduce shearing tension and

have blades resharpened if

necessary

Oil crank roller

Grease sliding sleeve

Have bearings replaced

12 Instruction manual XTRA

Does not cut

Shearing head gets very hot

Sheep Shearing Head

MALFUNCTION RECTIFICATIONCAUSE

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 12

Instruction manual XTRA 13

No power

Faulty cable

Faulty switch or motor

Overload protection switch

tripped out

Blades jammed (Illustration 6)

Air filter blocked (Illustration 12)

Faulty rotor or stator

Faulty over-current protection

switch

Carbon brushes worn down

Rotor or stator are defective

Air filter is blocked; air can no

longer circulate

(Illustration 1, Item 28)

Shearing tension too high

Faulty bearings (cleaning fluid

has damaged bearings)

Reducing gear and shafts have

no lubricant

Rotor runs untrue (caused by

sharp knock)

Bearings are worn out

Check lead and fuse

Have it checked and changed by

service centre

Have it repaired by service centre

Push in (Illustration 5)

Remove jam

Clean or replace air filter

Have rotor/stator replaced

Have overload protection switch

replaced

Have carbon brushes replaced by

service centre

Have rotor and/or stator

replaced

Remove air filter and clean with

brush or replace filter

Do not tighten pressure

the

shearing pressure adjustment

head

so much (Illustration 7). If

the blades still do not cut, they

should be resharpened or

replaced

Have bearings replaced

Have reducing gear and shaft

lubricated

Have rotor replaced

Have bearings replaced

Motor does not run

Overload protection switch

constantly trips out (Illustration 5)

Motor runs very slowly

Motor section gets warm

Motor section whistles loudly

Motor vibrates

Motor Section

MALFUNCTION RECTIFICATIONCAUSE

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 13

14 Instruction manual XTRA

Material contained in items from Illustration 1a

Rubber 18 / 19

Polyamide 8 / 27 / 28

Iron/Steel 1 / 2 / 3 / 4 / 5 / 6 / 7 / 8 / 9 / 10 / 11 / 12 / 21 / 22 /

24 / 25 / 26 / 28 / 29 / 30

Copper 11 / 12 / 17 / 19

Brass 13 / 15 / 17 / 27

Aluminium 23

Other materials 9 / 10 / 13 / 14 / 15 / 17 / 30

6 Environmental Protection and Disposal

6.1 Introduction

The owner has a duty to dispose of the shearing blades as well as of the shearing machine

properly at the end of its service life. Please observe your relevant national regulations.

6.2 Material Categories

Please hand the machine to a service centre or to a specialist electrical dealer in your vicinity

for disassembly.

7 Contact Addresses

Your purchasing point or the company shown on your guarantee certificate are authorised

service centres or refer to the nearest service centre in your area.

BA XTRA englisch_BA XTRA englisch 06.09.11 11:10 Seite 14

XTRA A1

1

Februar 2011/B copyright© Heiniger AG, CH-Herzogenbuchsee / Spare parts list

Februar 2011/B copyright© Heiniger AG, CH-Herzogenbuchsee / Spare parts list

A2 XTRA

5711

36

27

12 13 14 15 16 17 18

28

4

2

23

10

8

19

20 21 24 25 26

10 19

22 3029

1a

1

2

2 3

5 6

4

7

XTRA A3

1,5–2,0 mm

11

14

12 13

108 9

We reserve the right to make technical changes and improvements without notice.

warranty garantie garantía

Item

Artículo

Article

Artikel

Articolo

Artico

Artikel

Artikel

Artikel

Artikkel

Tuote

Προϊόν

Serial no.

No. de serie

No. de série

Seriennummer

No. di serie

No. de série

Serie nr.

Serie Nr.

Serienr.

Serie nummer

Sarjanro

Αρ. σειράς

Date of purchase

Fecha de compra

Date d’achat

Kaufdatum

Data di vendita

Data de compra

Datum van aankoop

Købsdato

Köpdatum

Kjøpsdato

Ostopäivä

Ηµεροµηνία αγοράς

Stamp and signature

Sello y firma

Cachet et signature

Stempel und Unterschrift

Timbro e firma

Carimbo e assinatura

Stempel en handtekening

Stempel og underskrift

Stämpel och namnteckning

Stempel og underskrift fra forretningen

Myyjän leima ja allekirjoitus

Σφραγίδα και υπογραφή

In case of claim, please return your machine with the instruction manual and the warranty card directly

to your local distributor. Please do not cut off the warranty card from the instruction manual.

En caso de garantía, devuelve su máquina con el manual de instrucciones y la carta de garantía

directamente a su distribuidor local. Por favor no recorte la carta de garantía del manual.

En cas de garantie, retournez votre machine avec le mode d'emploi et la carte de garantie directement

à votre distributeur local. Nous vous prions de ne pas couper la carte de garantie du mode d'emploi.

Im Garantiefall retournieren Sie Ihre Maschine mit der Bedienungsanleitung und Garantiekarte direkt

Ihrem lokalen Händler.Trennen Sie die Garantiekarte bitte nicht aus der Bedienungsanleitung.

Garantie letzte Seite alle sprachen.indd 1 13.09.2010 10:42:55

Table of contents

Other Heiniger Pet Care Product manuals

Heiniger

Heiniger Opal User manual

Heiniger

Heiniger saphir User manual

Heiniger

Heiniger Xperience User manual

Heiniger

Heiniger C12 User manual

Heiniger

Heiniger Cordless User manual

Heiniger

Heiniger PROGRESS User manual

Heiniger

Heiniger Xpert User manual

Heiniger

Heiniger EVO User manual

Heiniger

Heiniger SaphirCord User manual

Heiniger

Heiniger Handy User manual