ZZZKHOLRVSVFRP 5

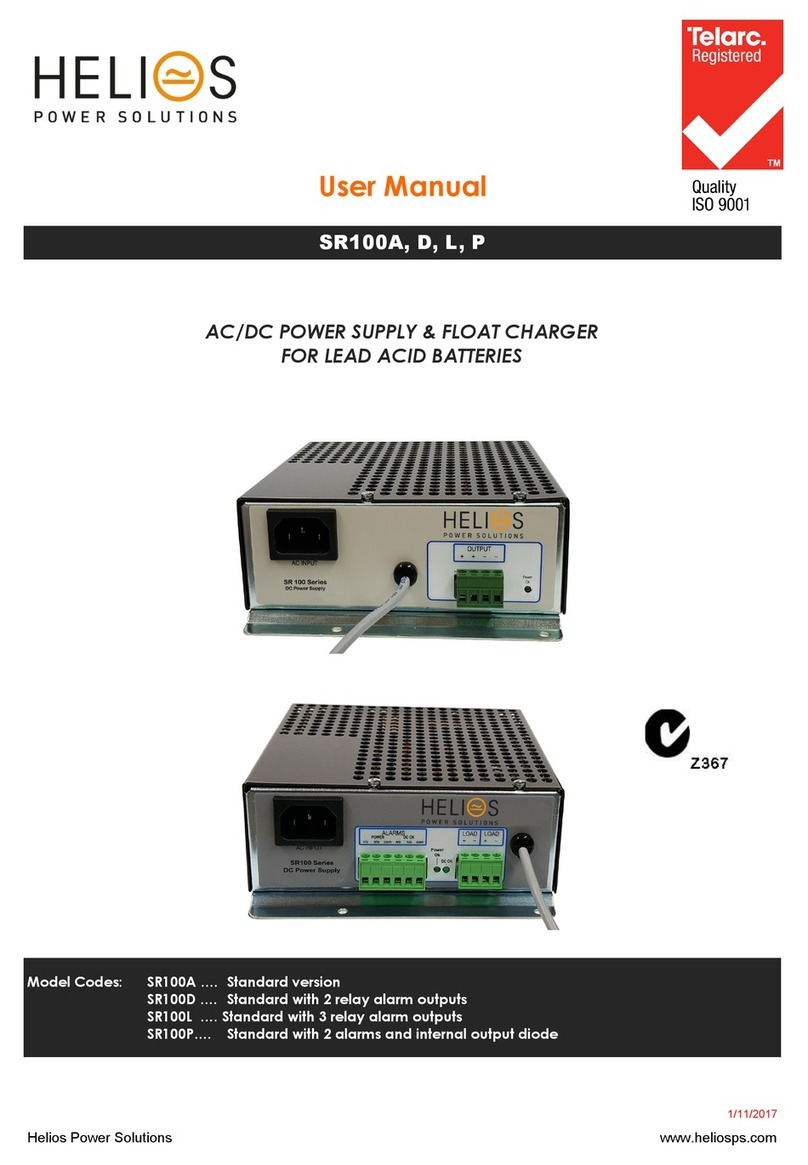

1. PRODUCT DESCRIPTION

ICT Platinum Series DC power supplies provide high efficiency in a

space-saving 1U rack mount design with power factor corrected AC

input and extremely low noise output for powering wireless

communications, broadband, and radio access equipment where high

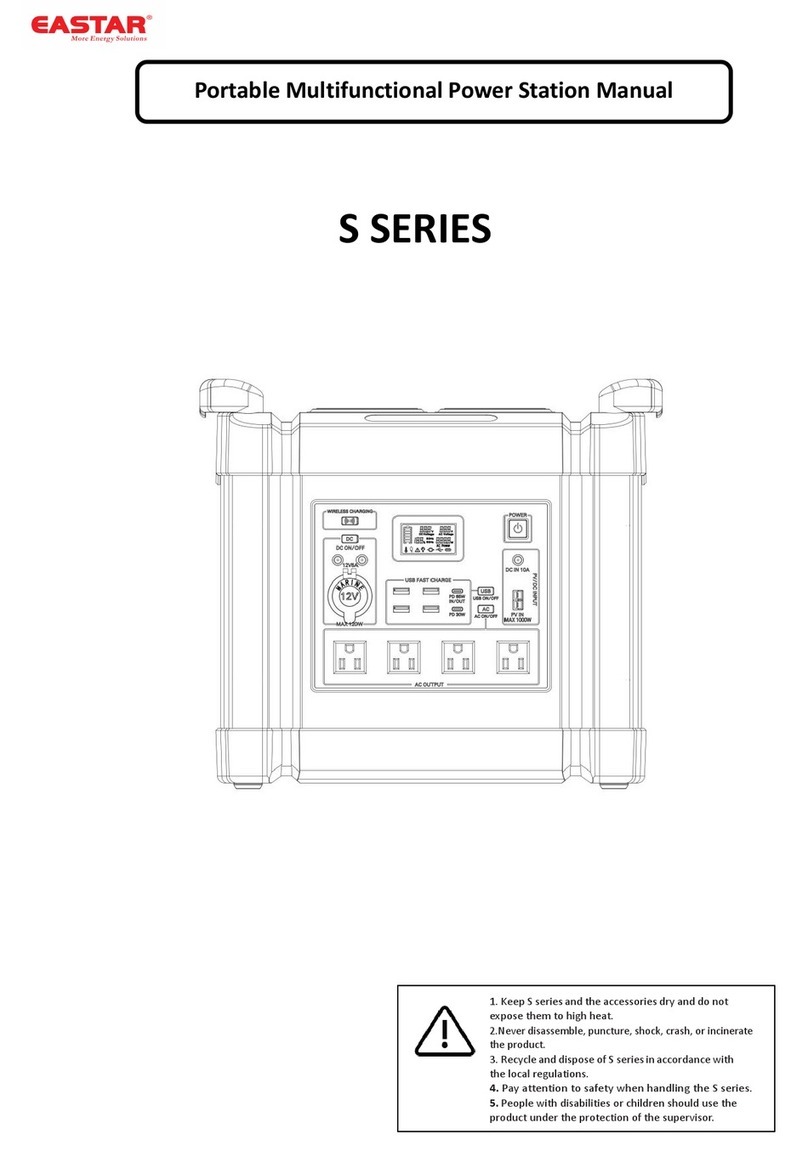

reliability is essential. The Platinum Series has the ability to function

either as a standalone DC power supply or as a complete DC power

system when using the optional Battery Backup feature. Standard

TCP/IP based Ethernet monitoring with Smart Parallel operation for

up to 9.6kW of combined output power and control, with optional

battery backup, programmable charge parameters, and adjustable

LVD provide full featured DC power capability.

Platinum Series Features:

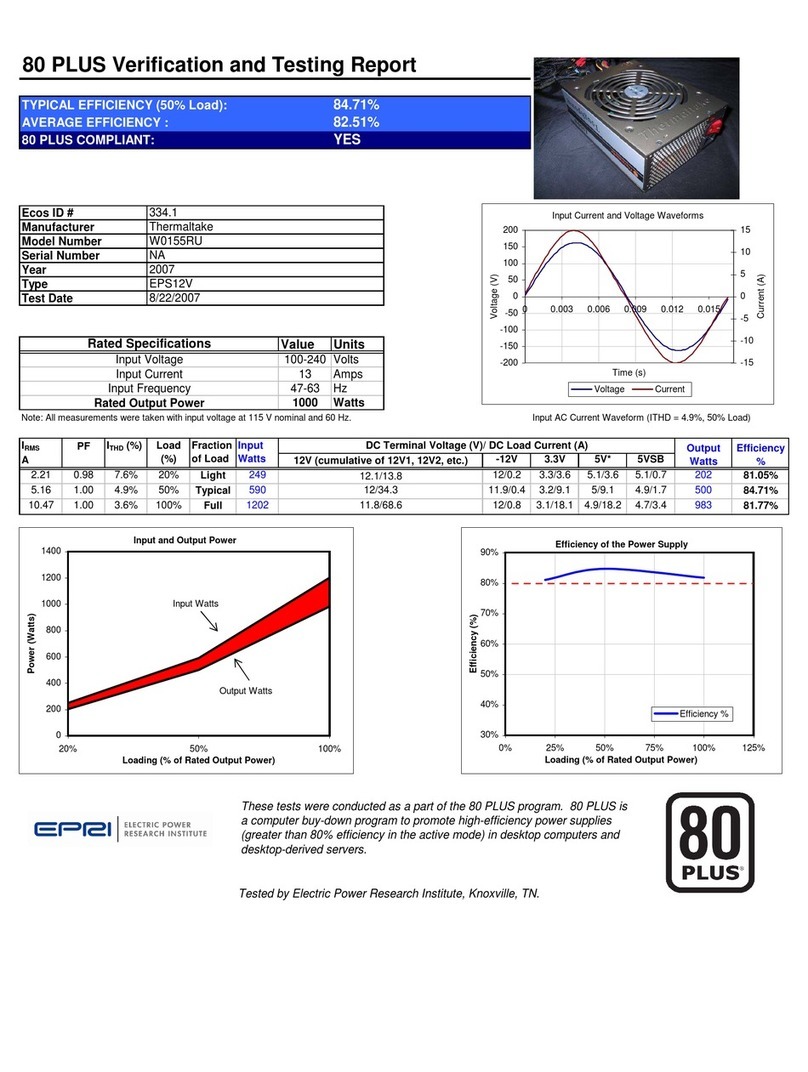

•Up to 1600W in a space saving 1RU rack mount design with 90-

93% typical efficiency over a broad power range

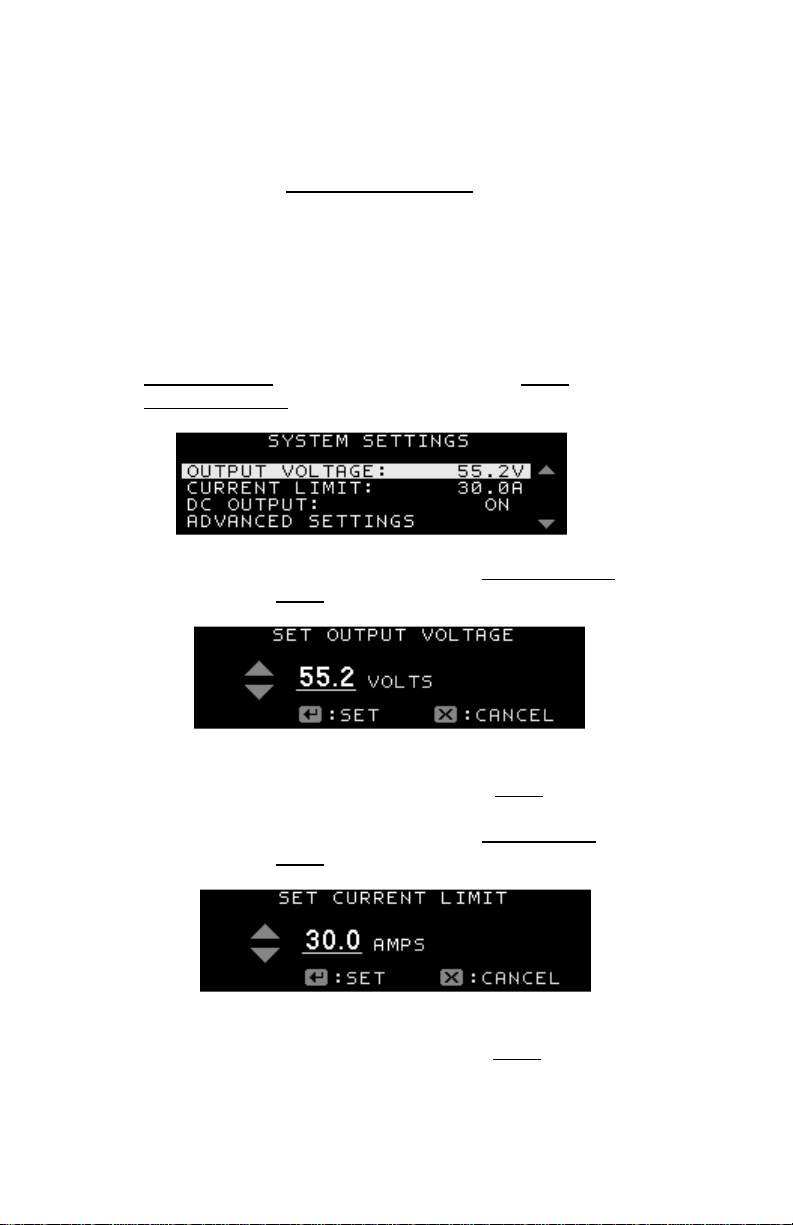

•Output voltage can be easily and accurately adjusted over

standard battery operating voltage ranges using the Intelligent

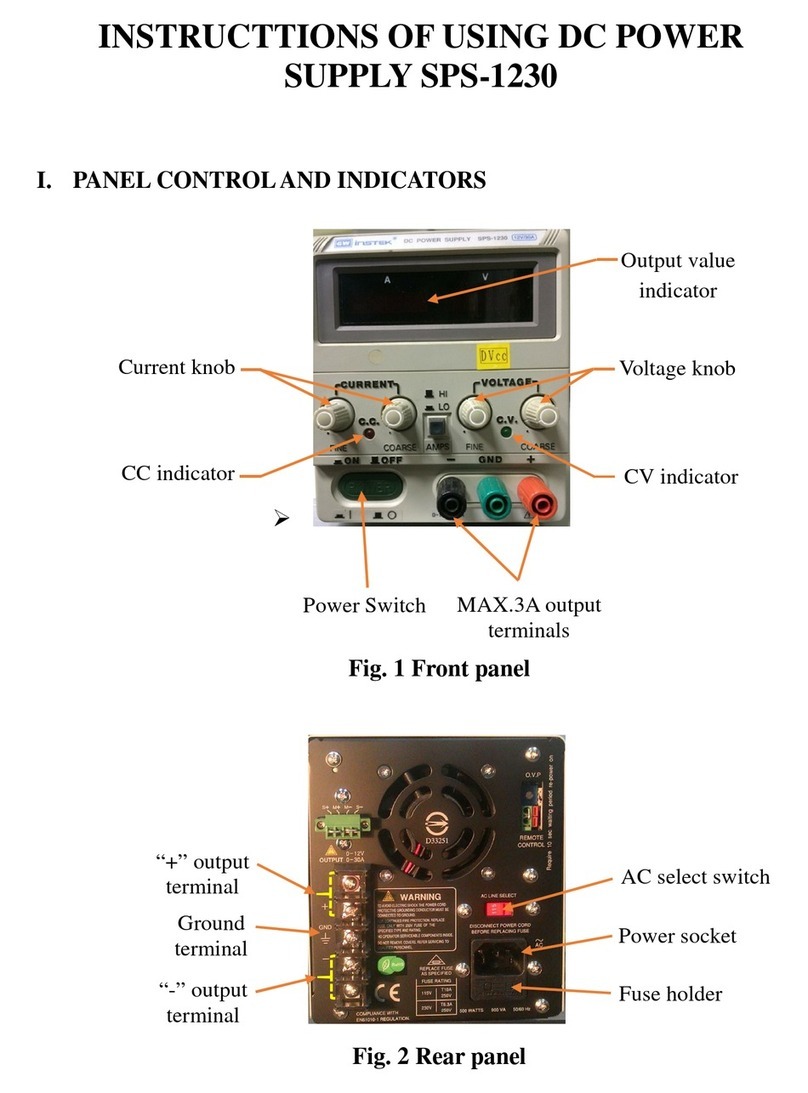

Power Control interface on the front panel

•Standard Ethernet port included for easy-to-use full featured

remote monitoring and control of the power supply using its built-

in web server, or via an SNMP management system

•Smart Parallel operation allows up to six Platinum Series power

supplies to be quickly and easily connected in parallel for up to

9.6kW of nominal power output

•Power Factor Corrected wide range AC input for maximum

flexibility, lowest supply current requirement, and economical

operation

•Isolated design allows operation with positive or negative ground

•-30 to +70C operating temperature range

•Form C contacts for remote alarm signal

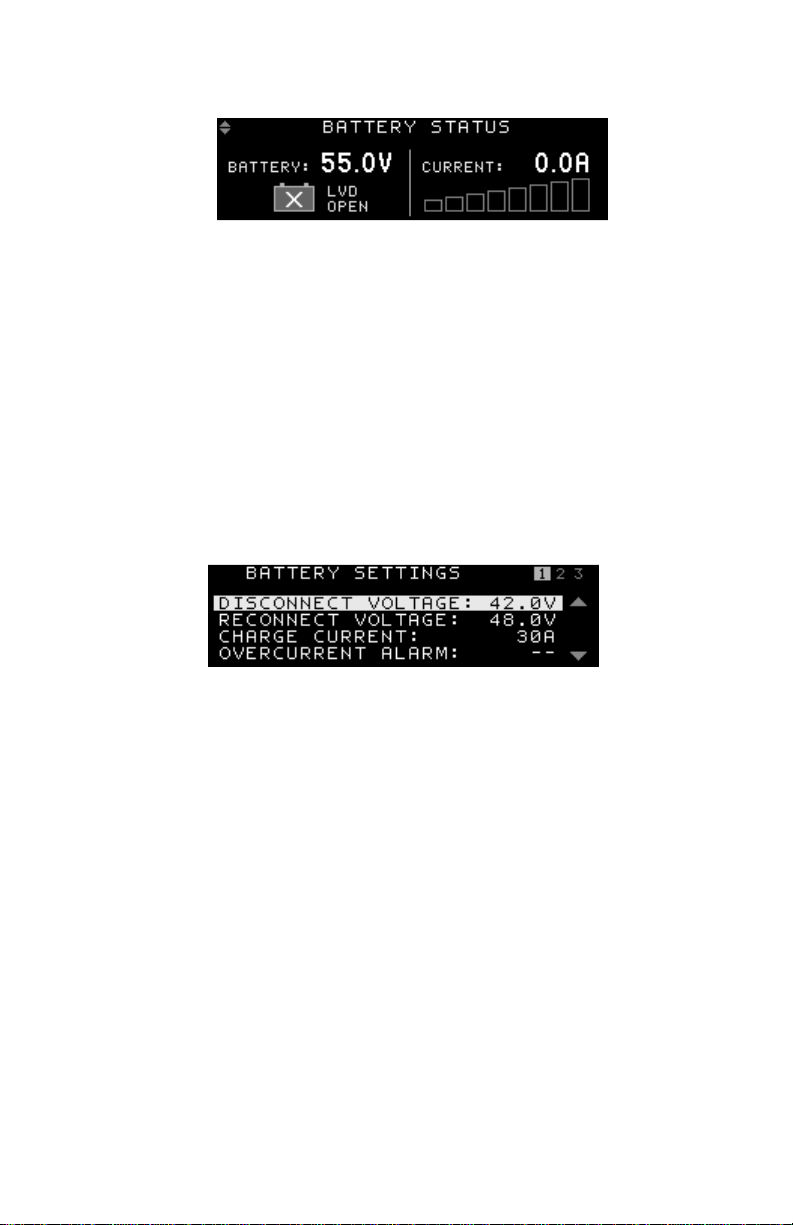

•Optional factory installed battery backup feature with battery

current monitor, LVD contactor (on battery Positive lead) with

adjustable voltage and charge rate set points, auto/manual

equalize charge, and temperature compensated charge voltage

with optional remote battery temperature sensor (ICT-TMP)