Henny Penny OE 301 User manual

Other Henny Penny Fryer manuals

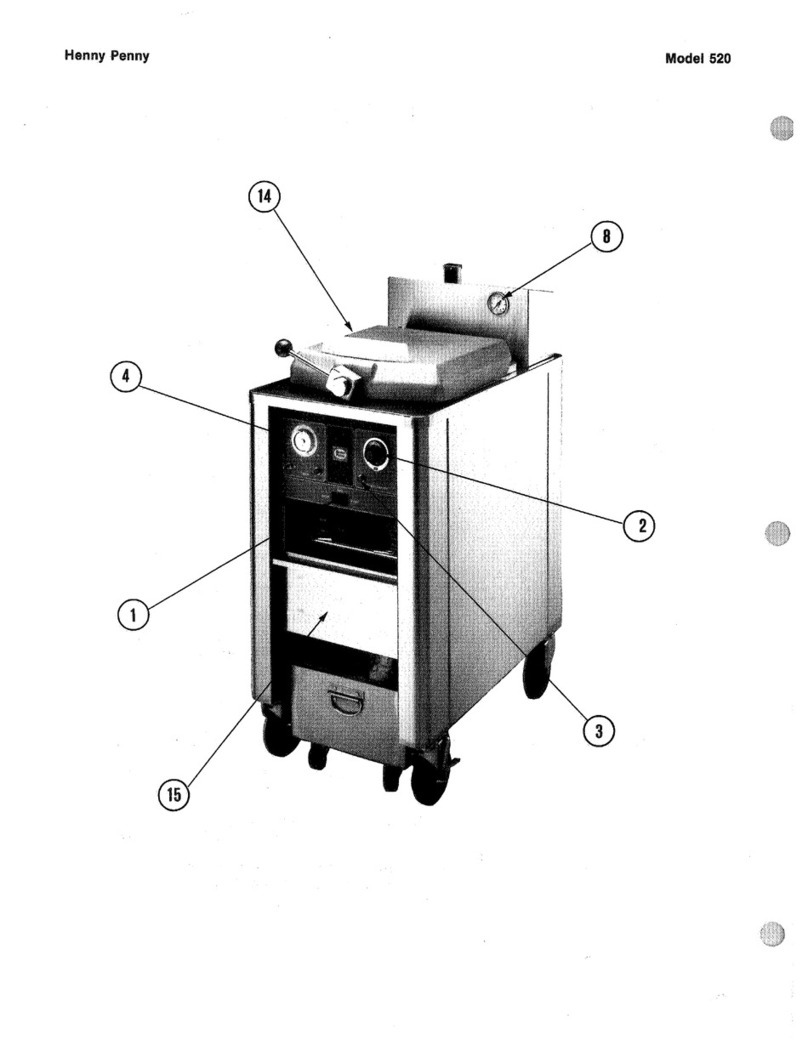

Henny Penny

Henny Penny 520 User manual

Henny Penny

Henny Penny PFG-600 User manual

Henny Penny

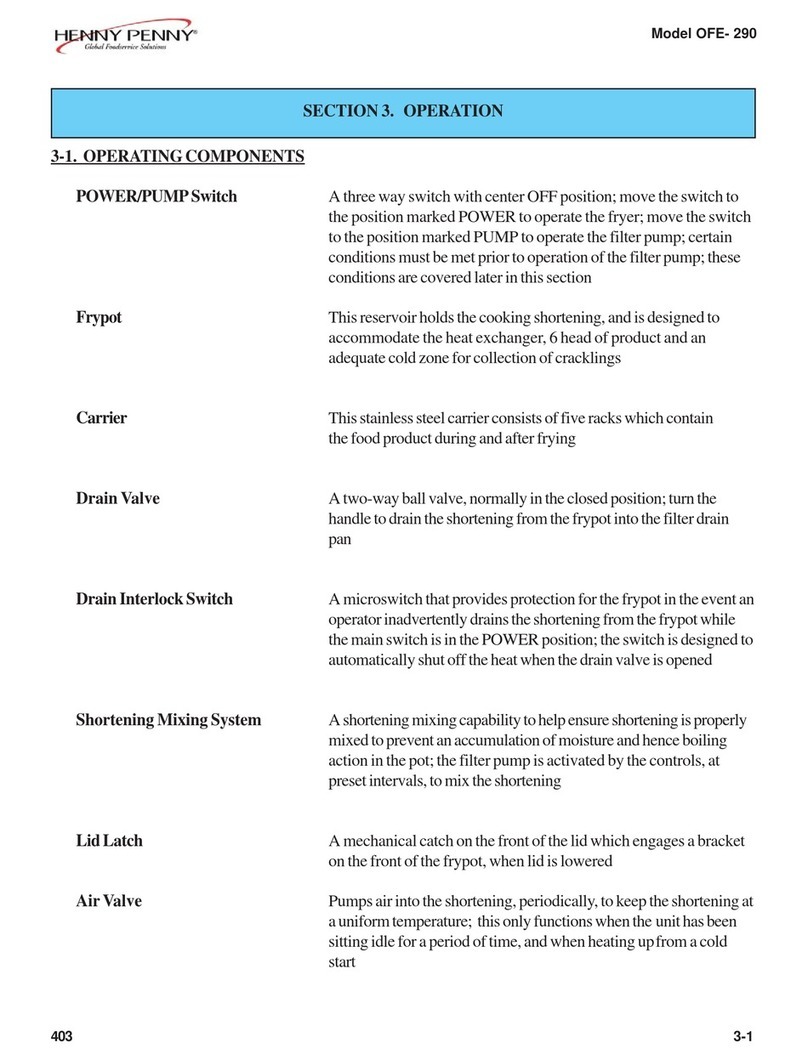

Henny Penny OFE- 290 Instruction Manual

Henny Penny

Henny Penny OFE-391 User manual

Henny Penny

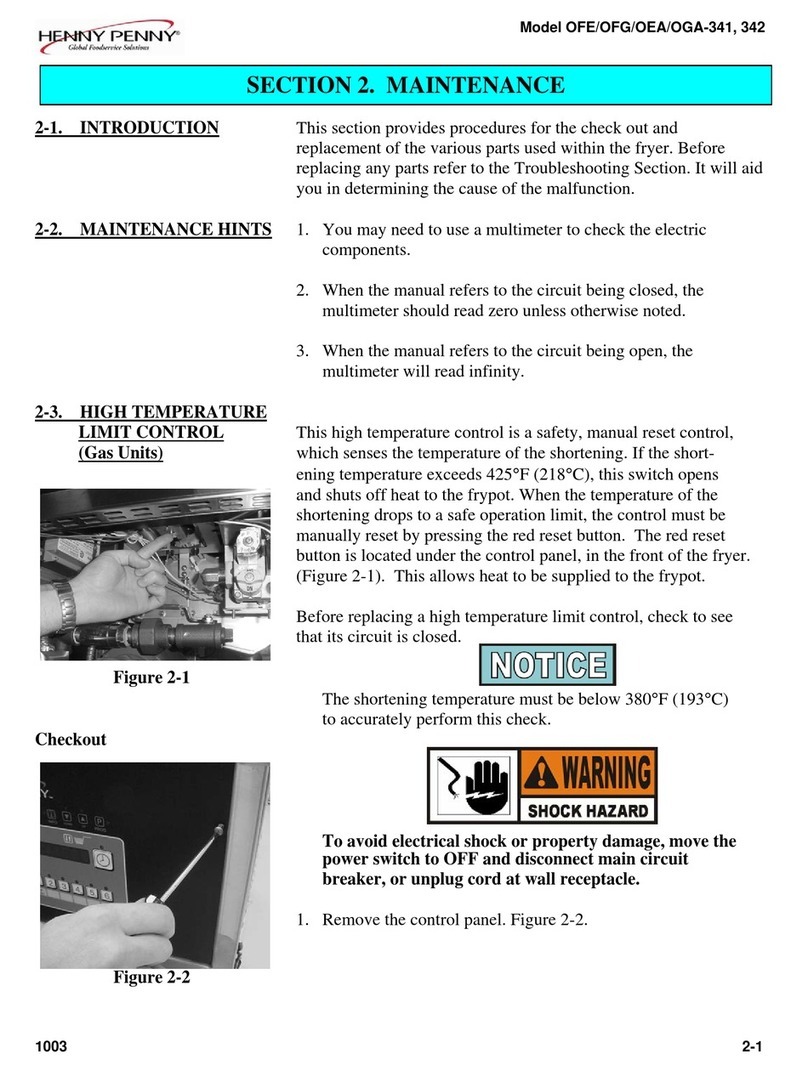

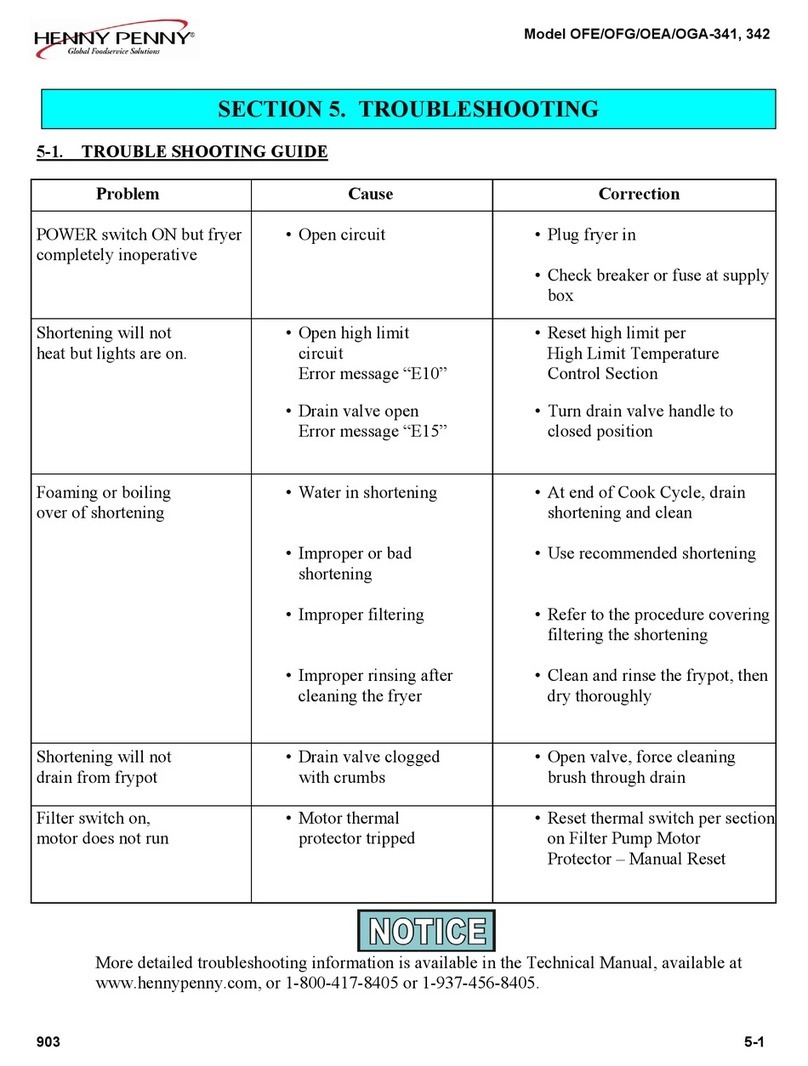

Henny Penny 342 Guide

Henny Penny

Henny Penny CFE-415 User manual

Henny Penny

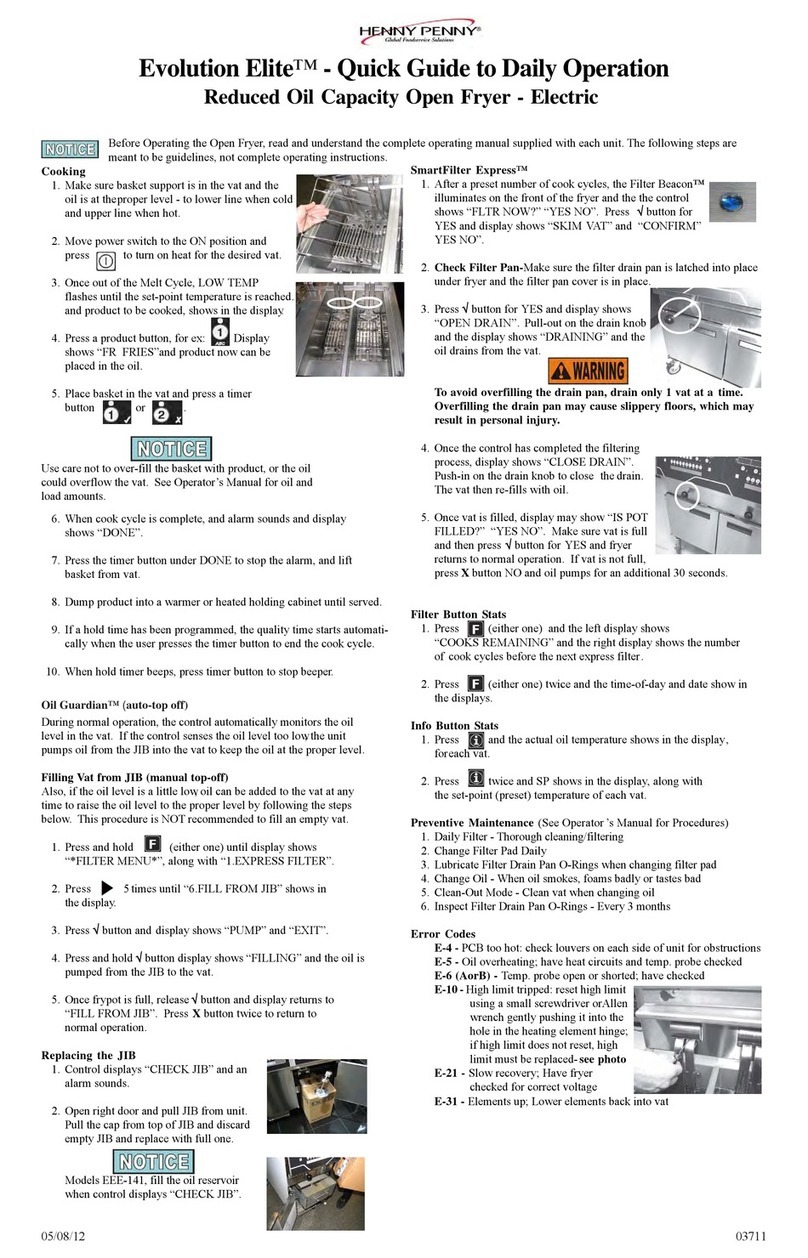

Henny Penny Evolution Elite User manual

Henny Penny

Henny Penny OFE-341 Operating instructions

Henny Penny

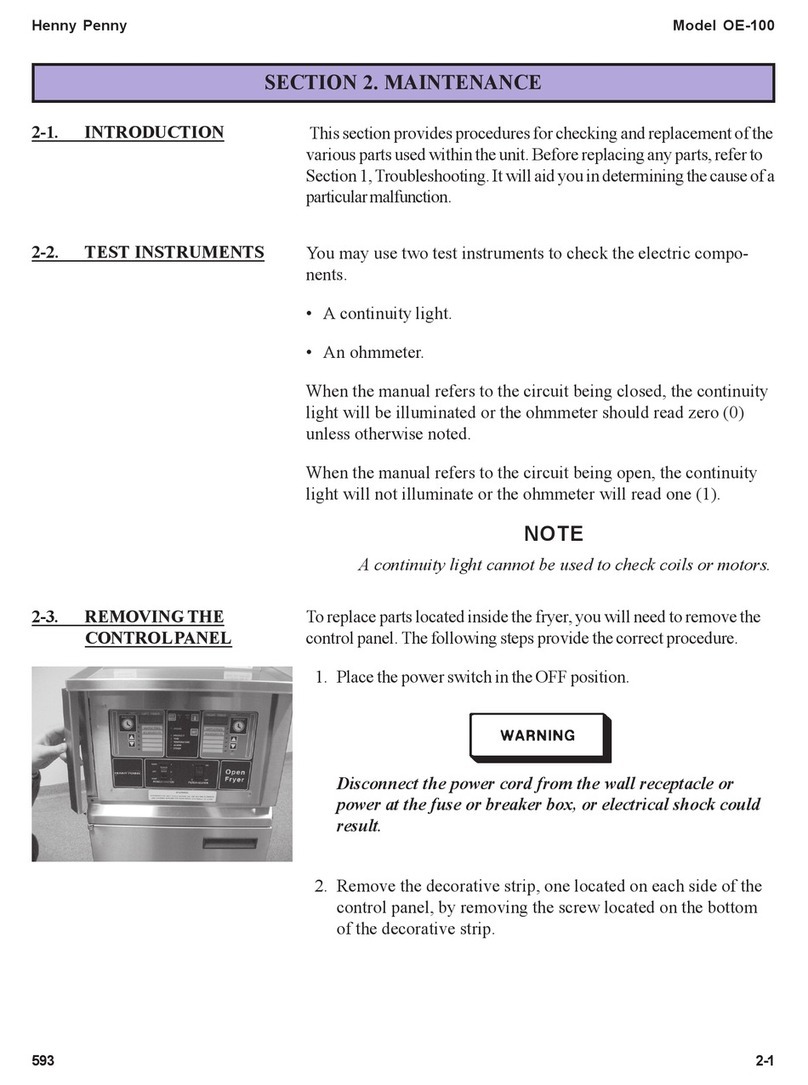

Henny Penny OE-100 Guide

Henny Penny

Henny Penny Evolution Elite EEE-154 User manual

Henny Penny

Henny Penny OFE-321 User manual

Henny Penny

Henny Penny EVOLUTION ELITE Series User manual

Henny Penny

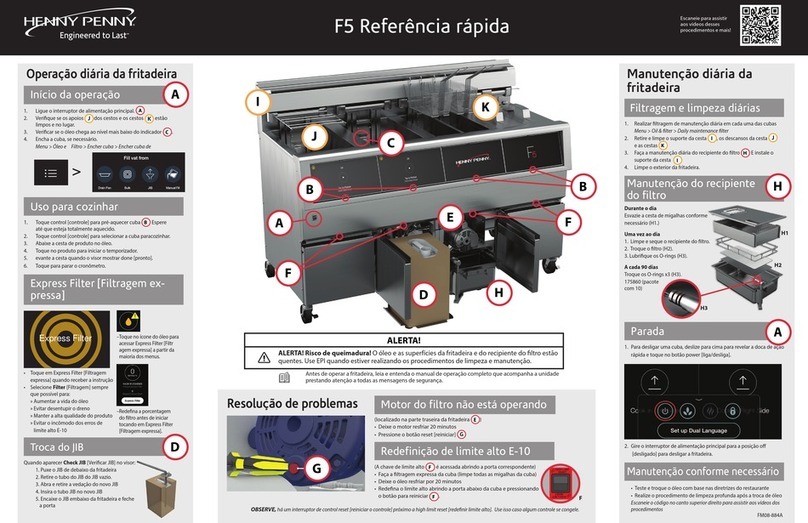

Henny Penny F5 User manual

Henny Penny

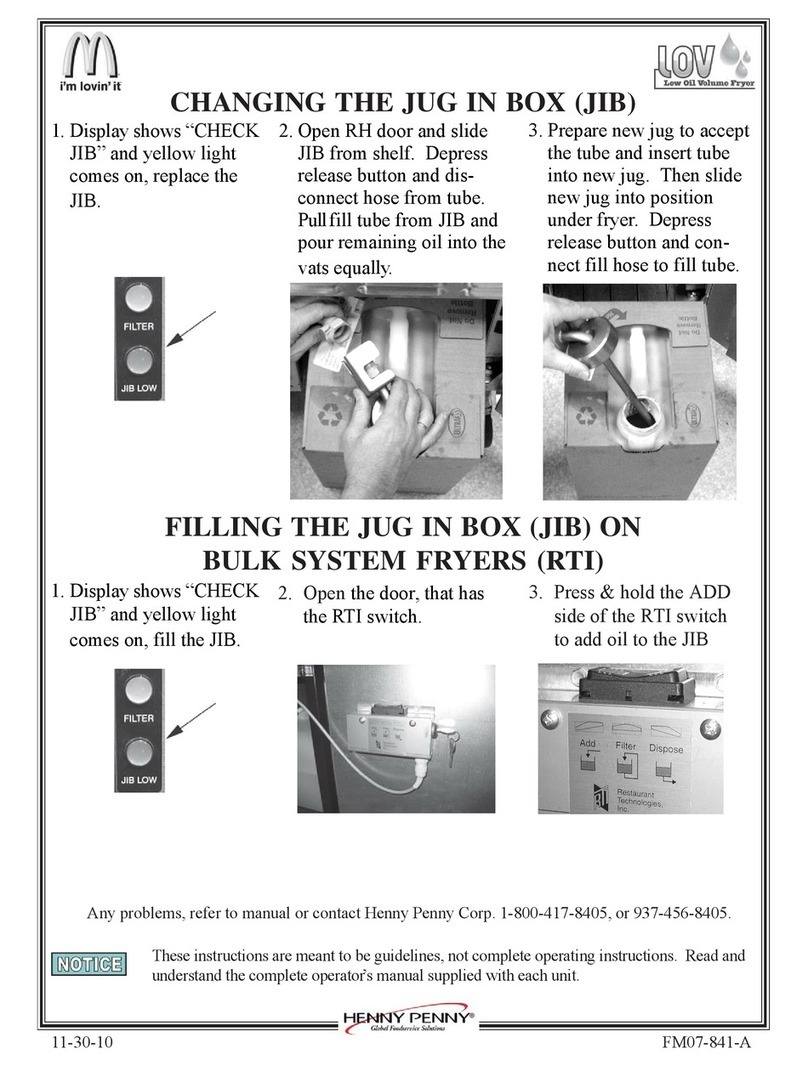

Henny Penny LOV LVG-100 Series User manual

Henny Penny

Henny Penny OFE-341 User manual

Henny Penny

Henny Penny EVOLUTION ELITE EEE-182 User manual

Henny Penny

Henny Penny FM07-020-F User manual

Henny Penny

Henny Penny KFC Velocity PXE-100 User manual

Henny Penny

Henny Penny Evolution Elite EEE-141 User manual

Henny Penny

Henny Penny Evolution Elite EEE-153 User manual